Beating type oilseed rape thresher

A thresher and rapeseed technology, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low work efficiency, rapeseed shedding, waste, etc., and achieve the effect of high work efficiency, not easy to damage, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

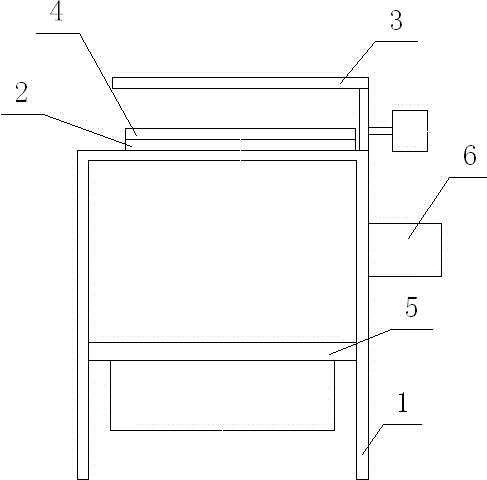

[0010] Example: such as figure 1 As shown, a beating type rape thresher comprises a frame 1, a platform 2 is provided on the top of the frame 1, a beating plate 3 is arranged above the platform 2, and the bottom of one end of the beating plate 3 is connected with the frame 1 , one side of the platform 2 is also provided with a push plate 4, a mesh screen 5 is provided below the platform 2, a toolbox 6 is provided on the outer wall of the middle part of the frame 1, and the flapping plate 3 is connected with a sieve to make it up and down. The driving device of the movement, the mesh screen 5 is connected with the driving device to make it swing left and right; the bottom surface of the flapping plate 3 is provided with regularly arranged protrusions.

[0011] The invention has a simple structure, can thoroughly thresh rapeseeds, avoids the waste of rapeseeds, adopts the way of beating, and since the beating plate 3 is connected with a driving device, the beating strength can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com