Double-helix threshing and conveying system and combine harvester

A conveying system and double helix technology, applied in harvesters, threshing equipment, cutters, etc., can solve the problem that the harvester threshing system cannot meet the overall mobility and threshing effect of the harvester at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

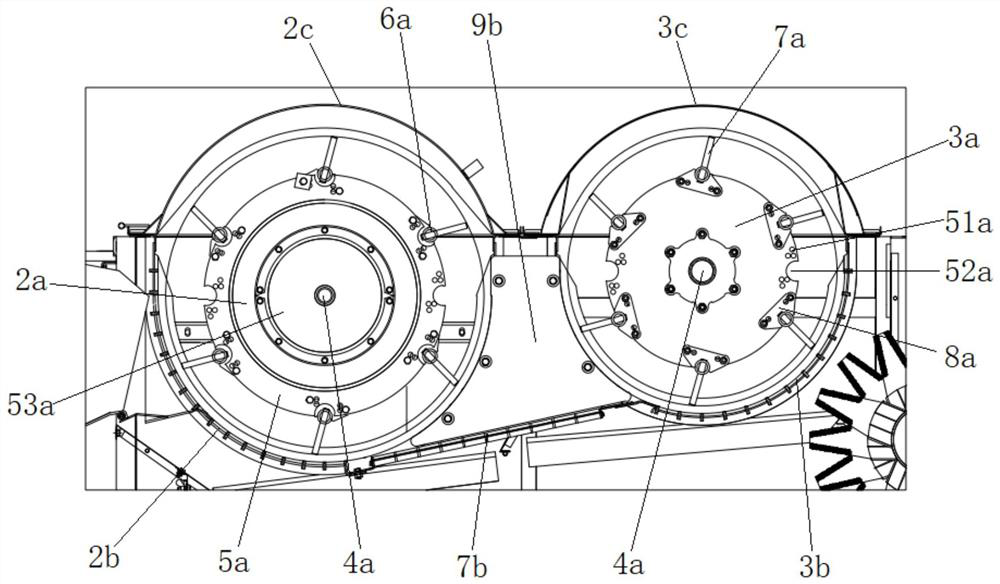

[0060] This embodiment provides a double-screw conveying system, which includes two threshing spaces arranged horizontally and spaced forward and backward in the direction of harvester travel. The threshing space is a hollow cylindrical installation cavity surrounded by a concave screen and a cylinder cover. A roller is installed in the cavity. The inner wall of the cylinder cover is provided with guides at intervals, which are used to guide the crops entering the threshing space to move directional around the axis. When the drum rotates, the crops are driven to move, and are guided by the guides from the first threshing space to the second threshing space. The working area of the threshing space is the same length, therefore, the crop threshing path goes through the length of both drums, enabling sufficient threshing. The two threshing spaces are arranged horizontally at intervals to make the structure on the frame more compact. The length of the two threshing work areas is...

Embodiment 2

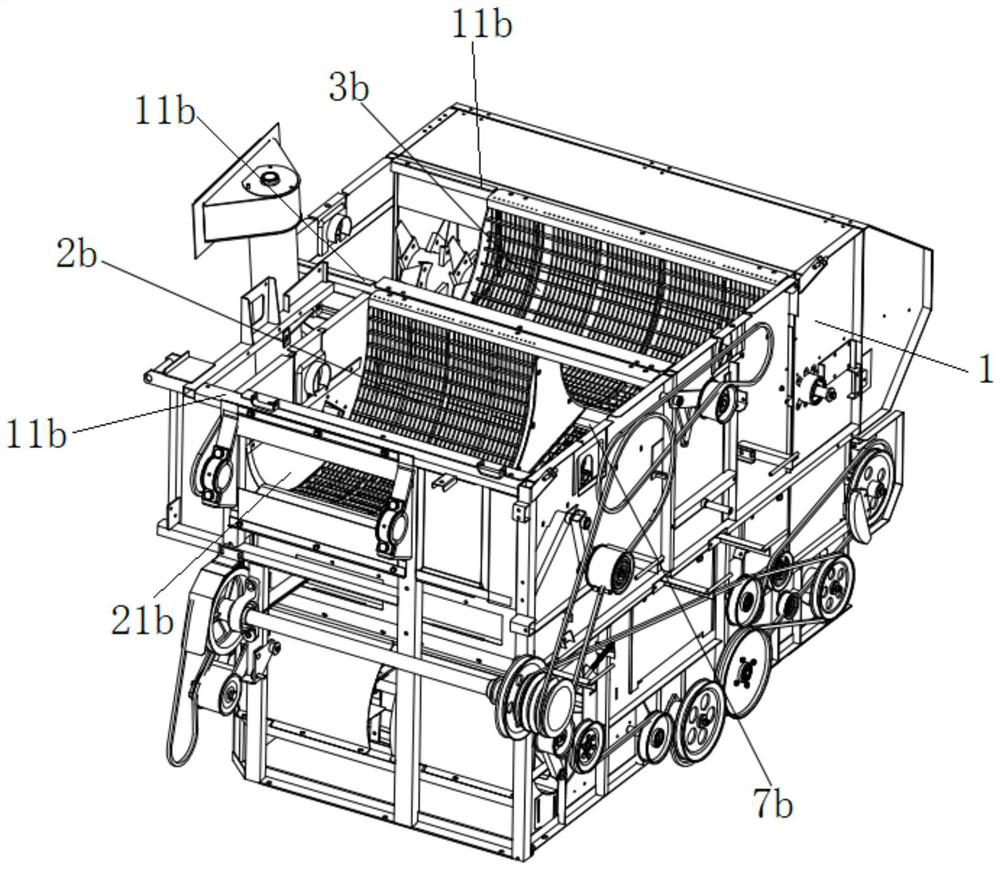

[0086] This embodiment provides a combine harvester, including the double-screw conveying system in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com