Movable type automobile maintenance station

A mobile and automobile technology, applied in the direction of motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of low lifting height and unfavorable car maintenance work, and achieve the goal of reducing the occupied space and facilitating maintenance operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 provides a mobile vehicle maintenance station.

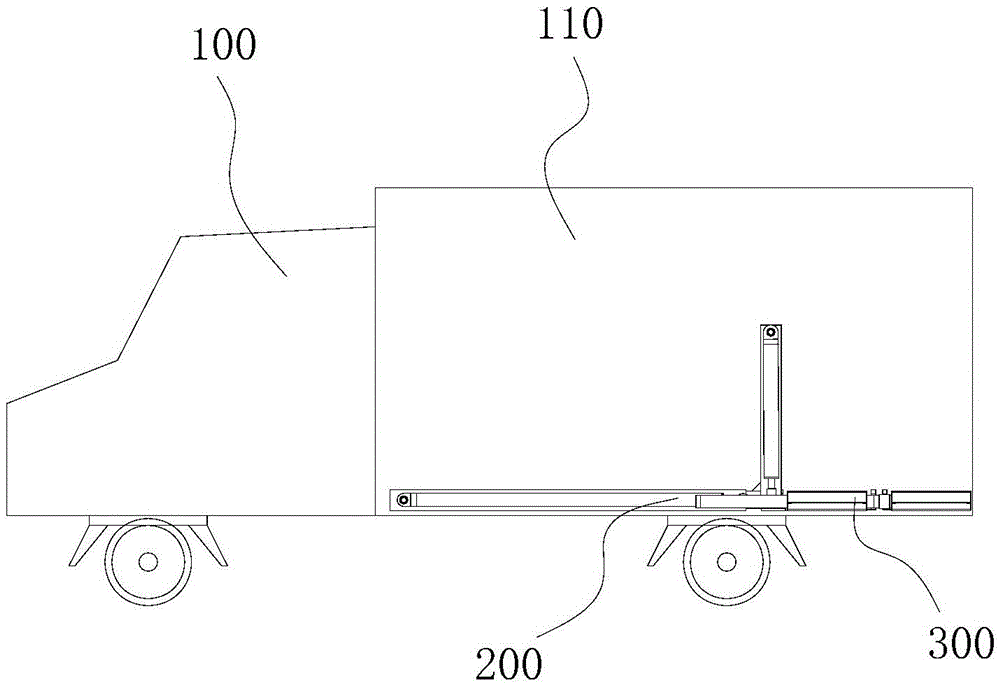

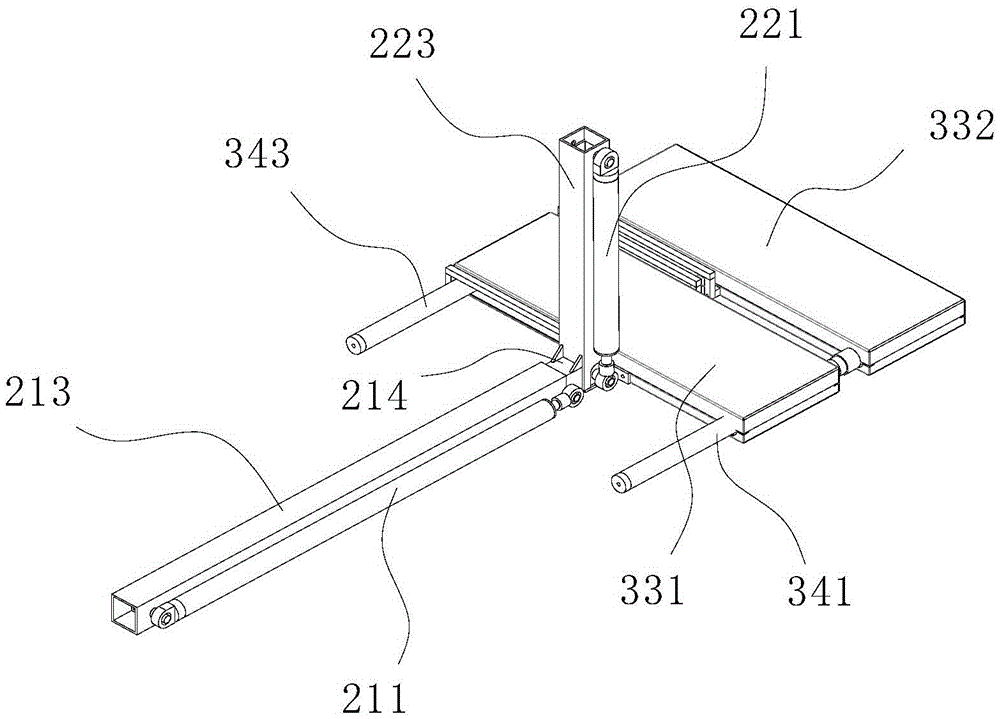

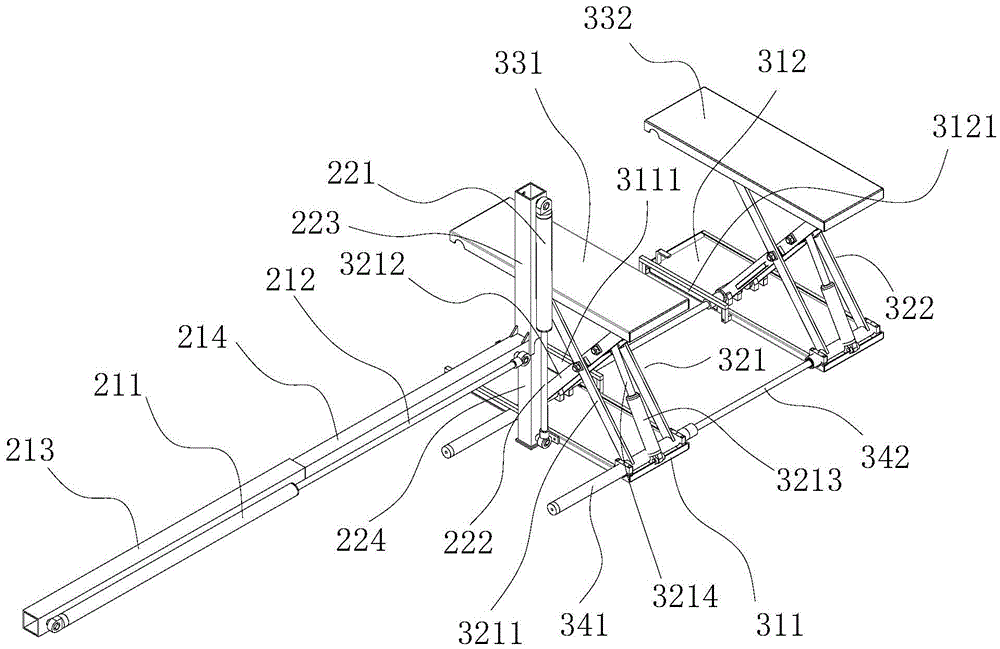

[0033] Please refer to figure 1 , the mobile car maintenance station includes:

[0034] a motor vehicle 100 having a rear compartment 110;

[0035] a moving mechanism 200, the moving mechanism 200 is installed on the motor vehicle 100;

[0036] And the lifting mechanism 300, the lifting mechanism 300 includes a base, a support for supporting the bottom of the car and a drive assembly for driving the support to rise and fall vertically, the support and the drive assembly are installed on the base, the The base is connected to the moving mechanism 200 , which drives the lifting mechanism 300 to move from the vehicle 100 to the ground and to retract from the ground to the vehicle 100 .

[0037] The motor vehicle 100 ensures the mobility of the vehicle maintenance station. The moving mechanism 200 enables the lifting mechanism 300 to be opened when in use, and retracted to the motor vehicle 100 when not in use...

Embodiment 2

[0059] The second embodiment provides a mobile vehicle maintenance station.

[0060] Please refer to Figure 5 and 6 The difference between the mobile vehicle maintenance station provided by the second embodiment and the first embodiment lies in the difference of the moving mechanism 200, wherein the first embodiment adopts the cooperation of horizontal reciprocating movement and vertical reciprocating movement to realize the opening and closing of the lifting mechanism 300. retracted, and the moving mechanism of the present embodiment 2 is an overturning mechanism 400, which is arranged at the bottom, and the output end of the overturning mechanism 400 is connected with the lifting mechanism 300, and the lifting mechanism 300 is driven to turn over and open to the motor vehicle 100. The motor vehicle 100 is turned over and retracted.

[0061] This overturning mechanism is similar to the structure of the existing automobile tailgate. When the lifting mechanism 300 is retract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com