Tab cutting device of lithium battery core and tab cutting equipment using tab cutting device

A technology of lithium batteries and tabs, which is applied in the field of lithium-ion power battery manufacturing, can solve the problems of affecting the quality of battery products, low cutting quality, and uneven front ends of tabs, so as to improve utilization rate, automation efficiency, and simple structure , Ease of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

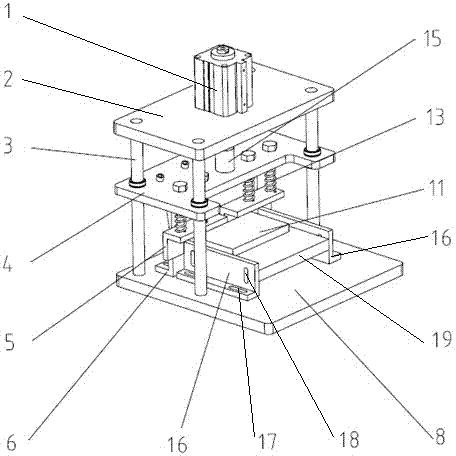

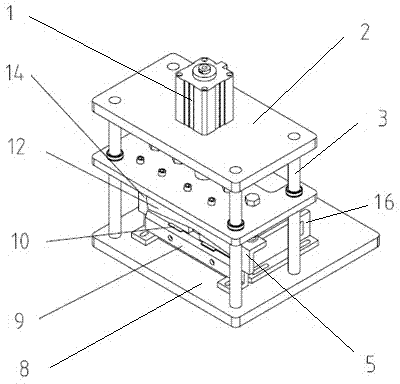

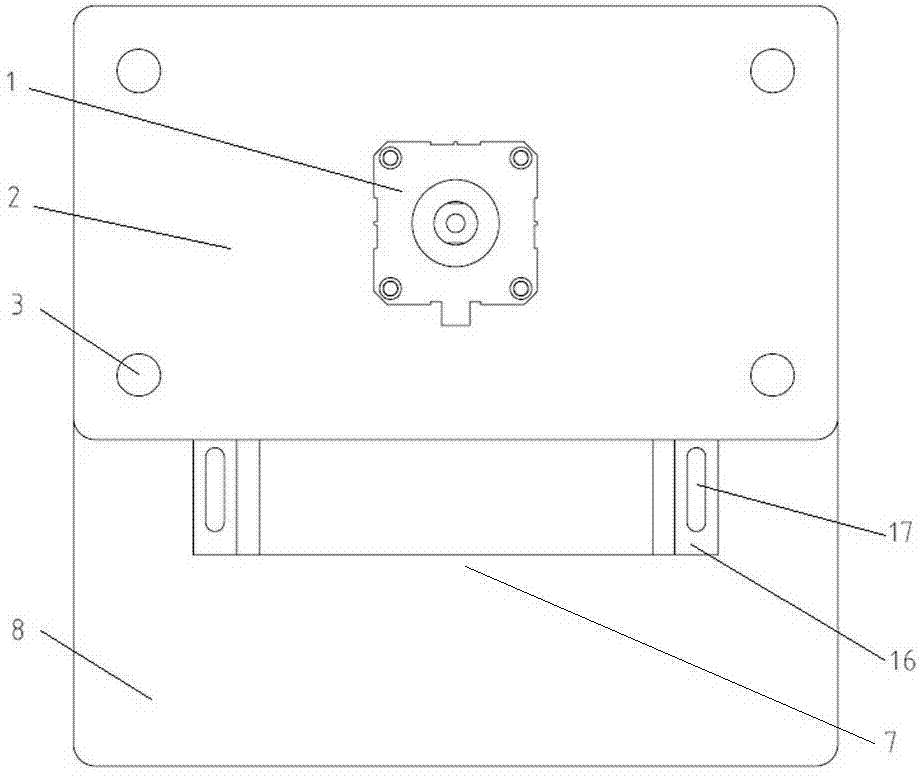

[0026] An embodiment of the lithium battery cell tab cutting device of the present invention is as follows: Figure 1~Figure 5 As shown, including the base 8, the base 8 is provided with four guide columns 3 along the up and down direction, and the guide column 3 is equipped with a driving mechanism 4 through sliding sleeves to guide and move. A cylinder 1 capable of driving the drive mechanism 4 to move downward is provided on the top plate 2 as a cutting drive device. The lithium battery cell tab cutting device also includes two sets of tab pressing assemblies that are independently arranged corresponding to the tabs 10 of the battery cells 11, and each set of tab pressing assemblies includes a lower cushion block 6 capable of supporting the tabs. , the upper pressing block 5 that is arranged up and down with the lower cushion block 6; the driving mechanism 4 is provided with a guide rod extending downward and the guide rod is sleeved with a compression spring 13, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com