Sufficiently-threshed whole-feed combine harvester

A combined harvester and full-feeding technology, which is applied to harvesters, threshing equipment, cutters, etc., can solve the problems of high cost, uncleanness, unreasonable design, etc., and achieve low cost, clean grain and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

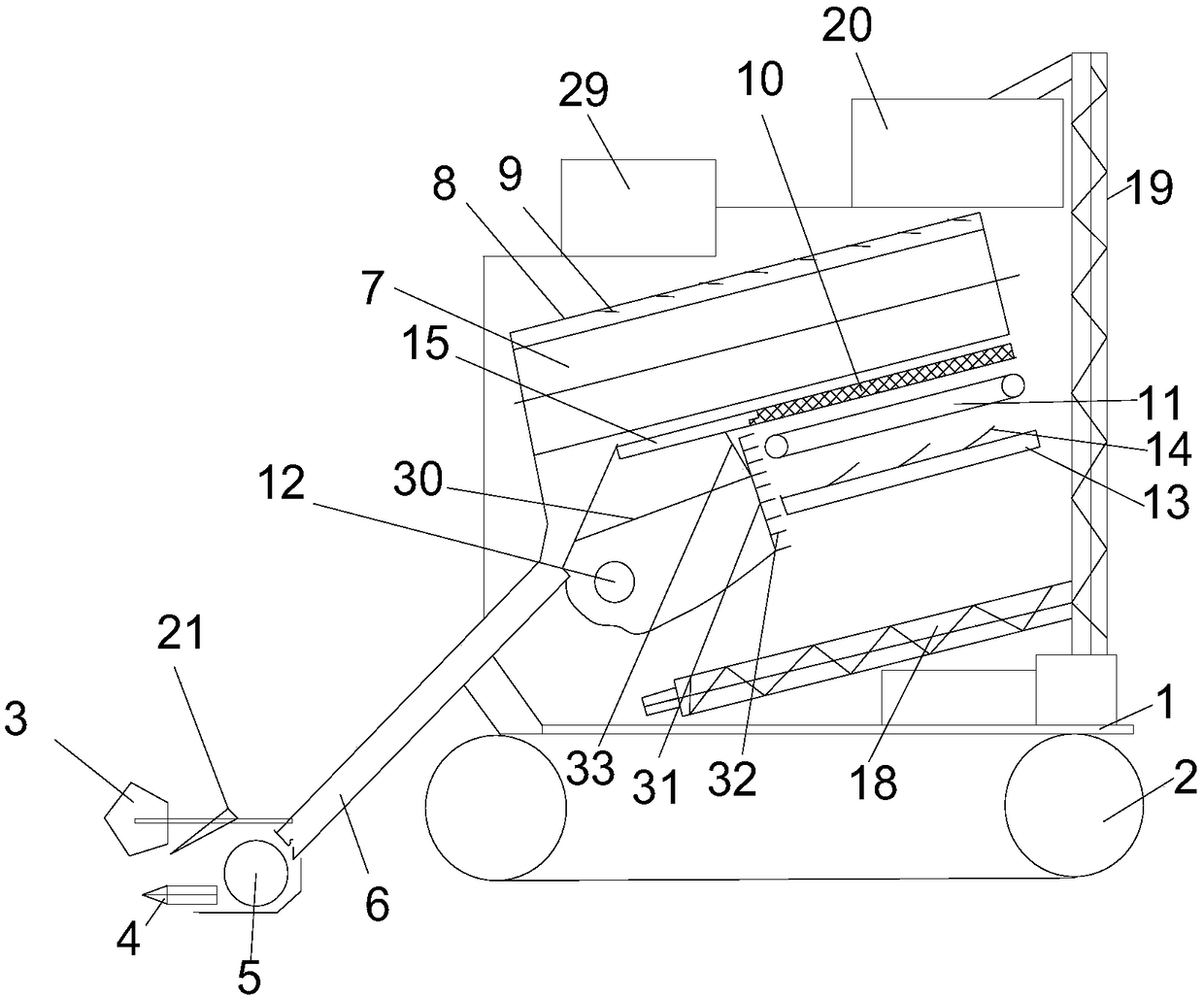

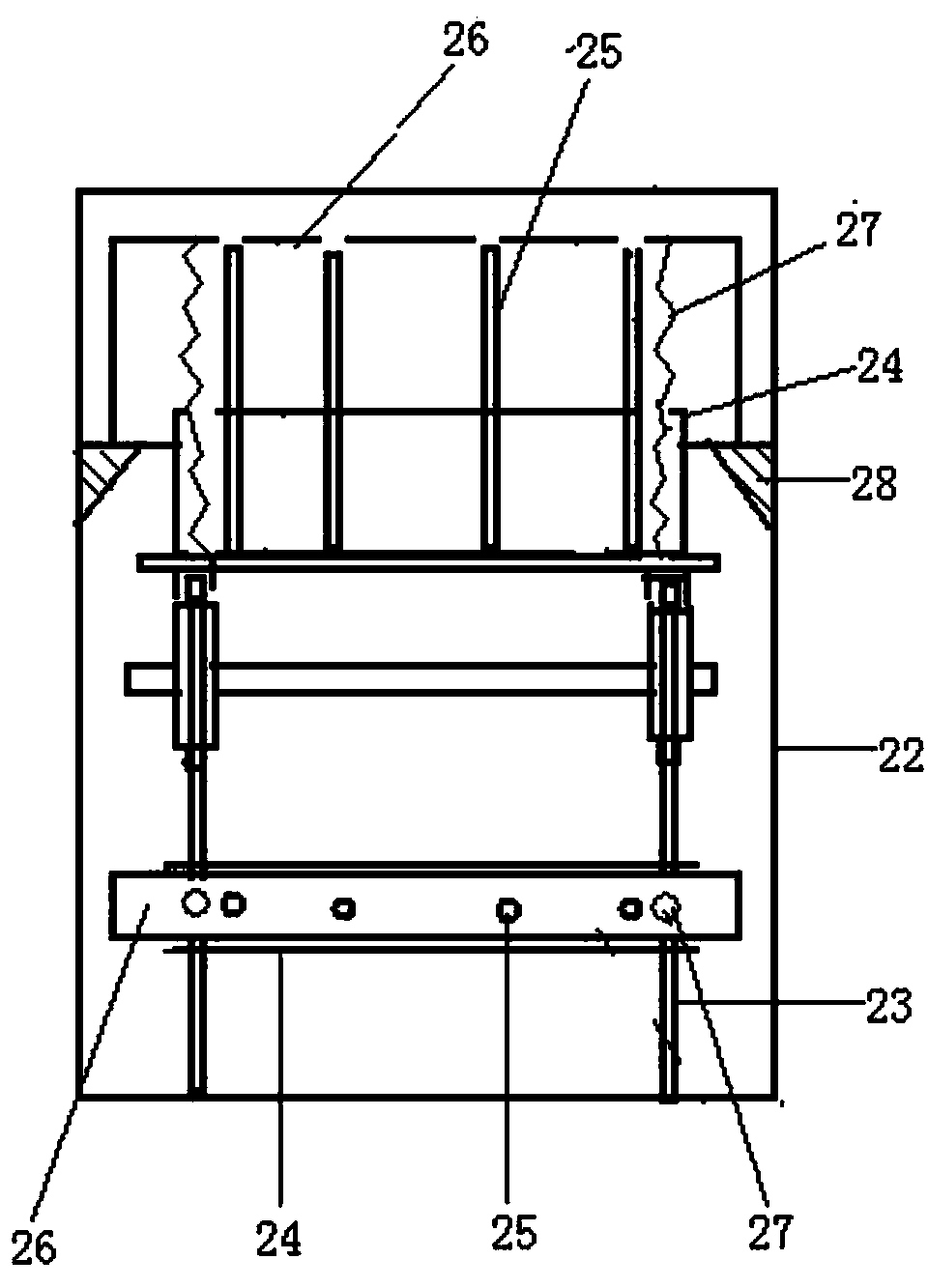

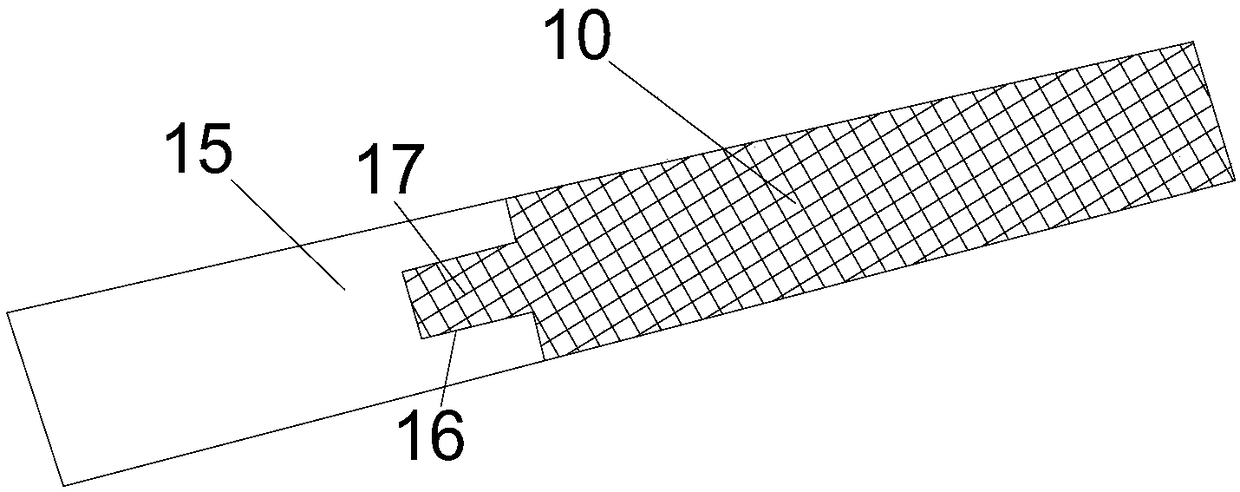

[0015] refer to figure 1 , figure 2 and image 3 , the present embodiment adopts the following technical solutions:

[0016] This fully threshing and full-feeding combine harvester includes a power part, a transmission part, a hydraulic part and a body 1. The lower part of the body 1 is a crawler walking mechanism 2, and a pentagonal reel 3 is installed on the front end of the body. There are 2 horizontally installed grass-cutting blades 4 that cooperate with each other in the lower part. There is a reeling drum 5 behind the grass-cutting blades 4. There is a grass conveying chain 6 that is installed inclined upwards behind the reeling roller 5. The grass conveying chain 6 upper end is a threshing machine. The roller 7 and the threshing roller 7 are installed inclined upwards. The central axis of the threshing roller 7 forms an angle of 20° with the horizontal plane. There is a screen 10 at the lower part of the roller 7, the screen 10 is semicircular and surrounds the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com