Three-speed variable transmission device for threshing cylinder of semi-feeding rice and wheat combine harvester

A combine harvester and threshing drum technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of poor adaptability to cross-regional operations, inability to adjust the threshing speed, and high grain breakage rate. The effect of improving harvest stability, improving service life and enhancing threshing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

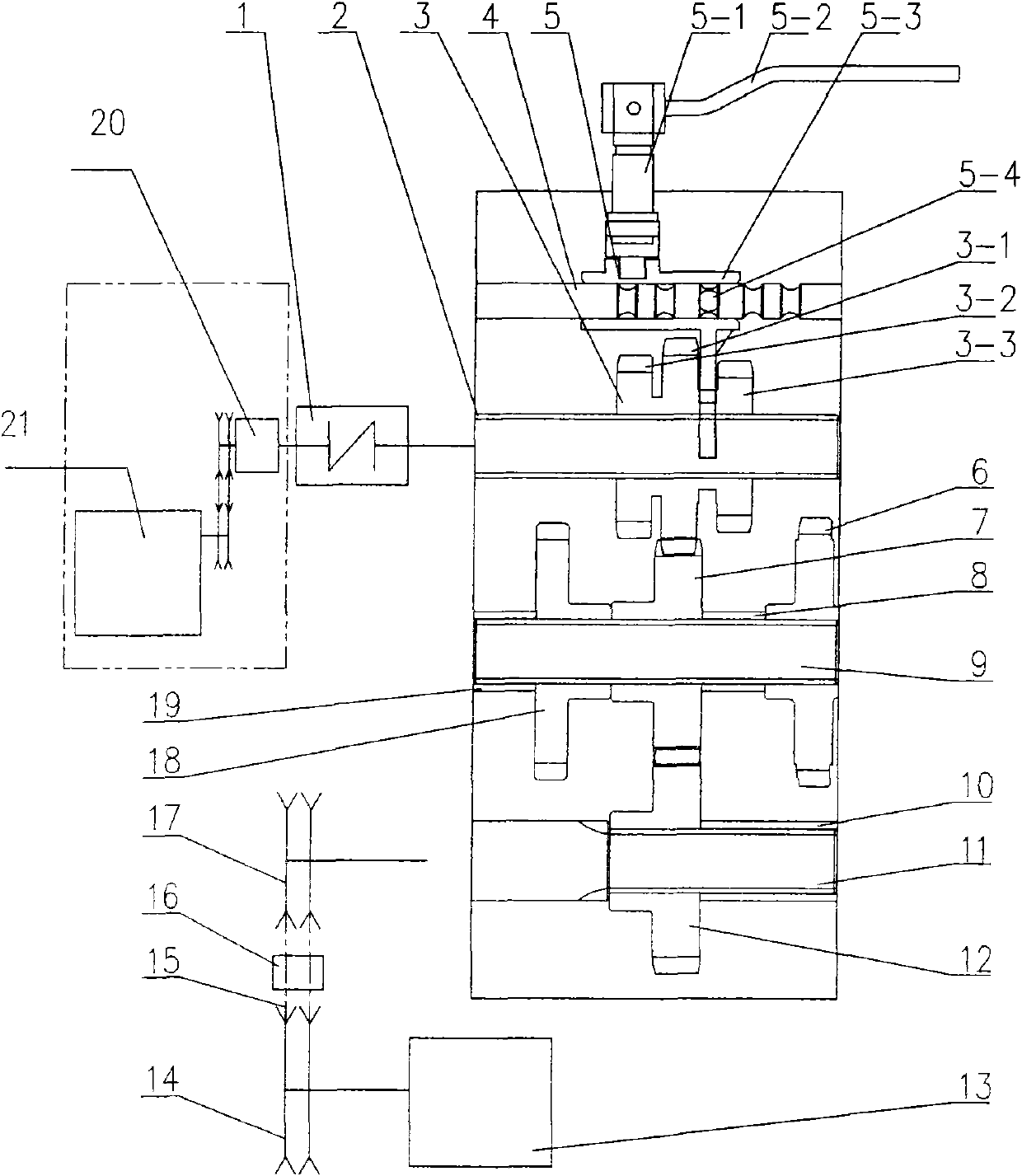

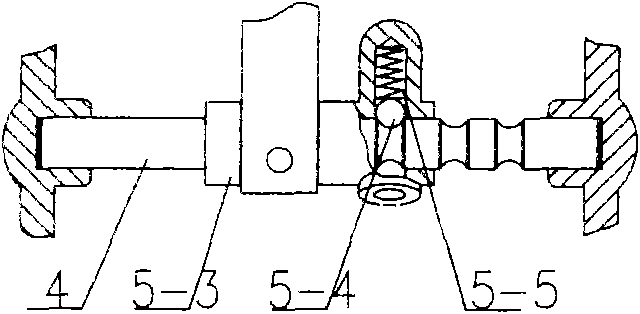

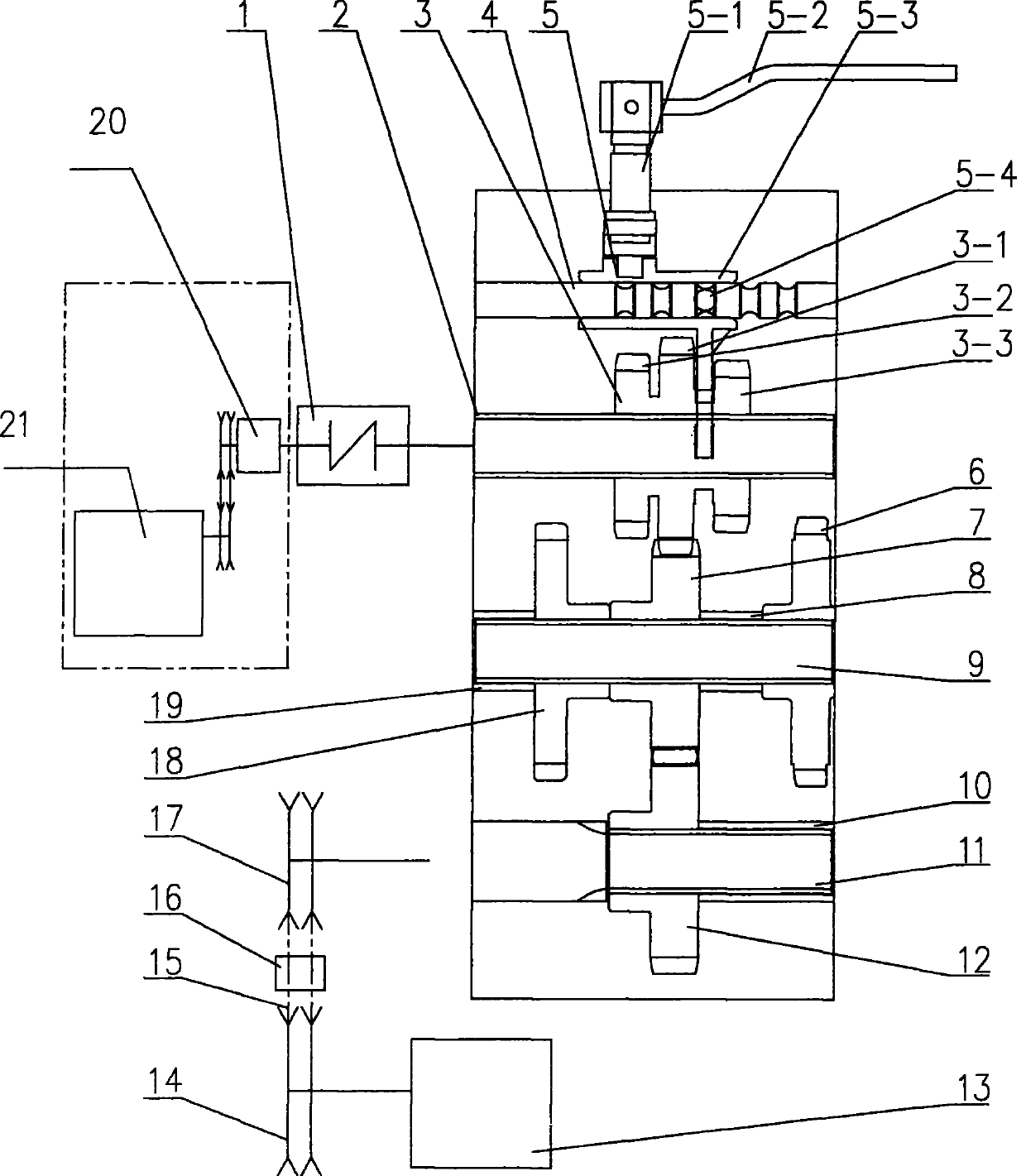

[0025] See attached figure 1 , 2 , in the embodiment of the present invention, the shift fork combination 5 includes a shift fork handle body 5-1, a shift fork handle 5-2, a shift fork 5-3, a steel ball 5-4, a shift fork spring 5- 5. The transmission gear combination 3 includes the transmission gear I3-1, the transmission gear II3-2, and the transmission gear III3-3; the transition gear spline shaft is equipped with the I gear transition gear 7, the II gear transition gear 18, and the III gear transition gear 6 , spacer I8, spacer III19; the output gear 12 on the output shaft is axially positioned by the shaft shoulder and the spacer II; adjust the axial position of the shift fork on the shift fork shaft by turning the handle of the shift fork, and adjust here During the process, the relative position of the steel ball is changed through the expansion and contraction of the shift fork spring, so that the shift fork can slide freely. When moving 32.4mm to the left, the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com