Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Grain damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain damage is any degradation in the quality of grain. In the current grain trade, this damage can affect price, feed quality, food product quality, and susceptibility to pest contamination. Between the field and the end use, grain may go through any number of handling operations which can each contribute to grain damage. For example, grain might encounter free fall, conveyors, spouts, grain throwers, elevators, hoppers, dryers, and many more. Overall, these handling methods can be evaluated as to what effect they have on the grain. Damaged grain can often be characterized by the extent to which it reduces storage time. For example, cracked or broken kernels are more susceptible to insect or bacteria as well as chemical degradation. The damage to the actual grain is only one example of losses incurred after harvest. In order to quantify grain damage, one must also understand grain quality. Grain quality is a very broad term and can relate to many topics such as foreign material, chemical compositions, mechanical damage, insect infestations, and many more. These references to quality are highly dependent on the end use of the grain. Certain types of damage may be acceptable to specific industries, whereas others cannot use grain with these issues.

Five-cereal instant rice gruel and method for producing the same

InactiveCN101473914AHas an auxiliary therapeutic effectAttractive colorFood preparationSmall fragmentAir separation

The invention discloses a corn quick cooking rice gruel and a production method thereof, aiming at solving the problem of single nutrition of the existing fast food. The production method is characterized in that: a. rice, sorghum rice and unpolished rice do not need processing; b. cowpea, mung beans, small red beans, black kerneled rice, small fragments, myotonin and sticky rice are cleaned and edulcorated; the methods of screening, air separation and the like are adopted to remove impurities and imperfect grains and grains damaged by disease and pests; the provisions are dipped in water to moisten the provisions, dried by a microwave and naturally cooled by radiation and burned grains are removed; e. the provisions are mixed evenly by the following weight proportion: 60% of the rice, 10% of the cowpea, 10% of mung beans or the small red beans, 10% of the black kerneled rice and 10% of one of the sorghum rice, the small fragments, the myotonin, the unpolished rice and the sticky rice; and d. the mixture is vacuumized. The corn quick cooking rice gruel is rich in nutrition, convenient in eating and can be produced continuously.

Owner:张丽萍

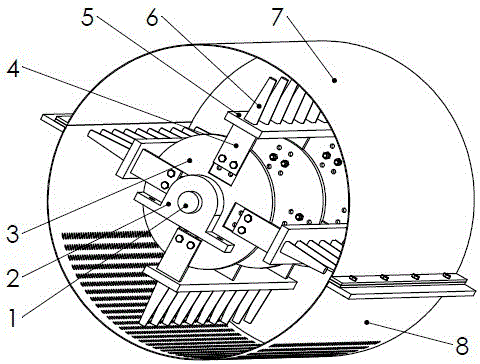

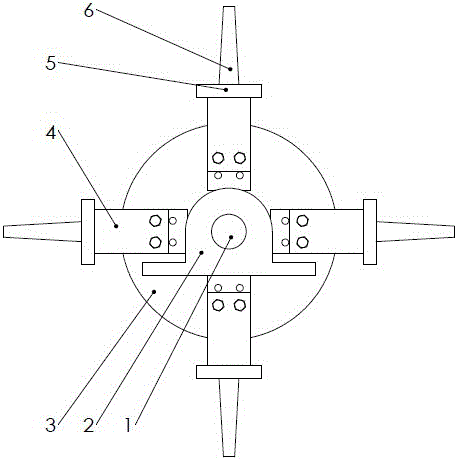

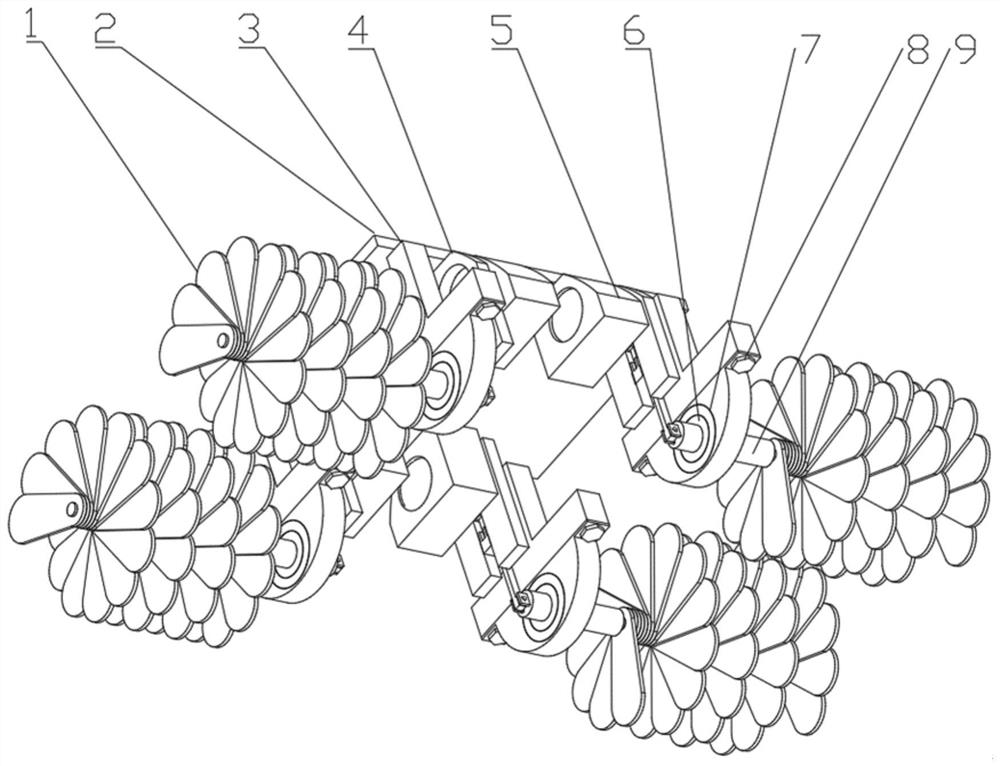

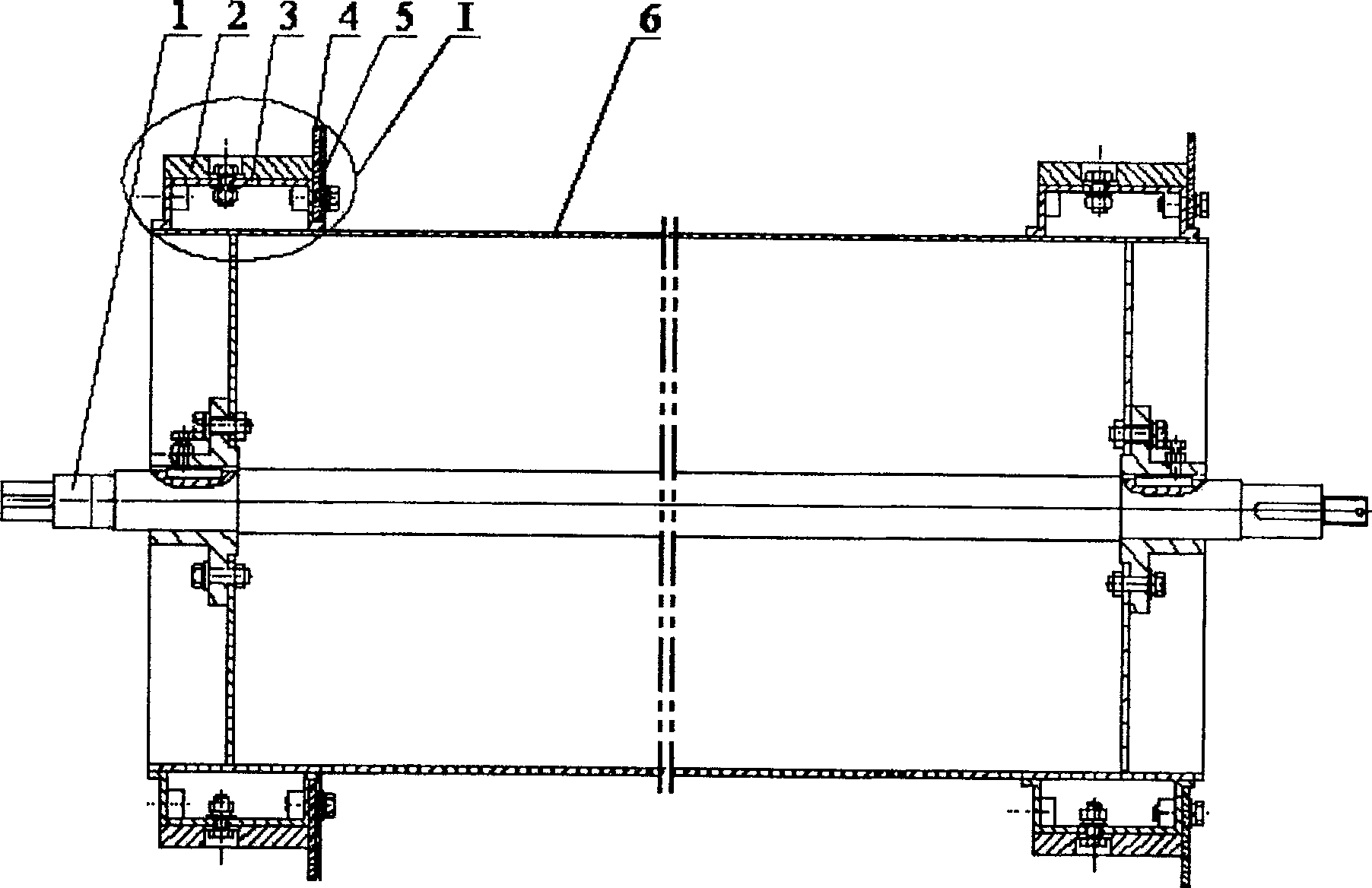

Diameter-adjustable corn threshing and flow cutting roller

The invention provides a diameter-adjustable corn threshing and flow cutting roller. The roller comprises a rotary shaft, a bearing seat, a spoke disk, a connecting seat, a supporting rod, threshing rod teeth, an upper cover plate and a lower concave plate. The roller is characterized in that the rotary shaft is matched with the bearing seat, the spoke disk is connected with the rotary shaft in a key connection mode, the connecting seat is connected with the spoke disk through bolts, the supporting rod is connected with the connecting seat in a welded mode, the threshing rod teeth are connected with the supporting rod in a welded mode, and the upper cover plate and the lower concave plate are connected through bolts after being aligned. The roller has the advantages that the structure is simple, blockage in the threshing process can be effectively prevented by adjusting the threshing gap, so that the grain damage rate and machine fault rate are reduced, efficient corn threshing can be realized, and the roller can be widely applied to agricultural production.

Owner:UNIV OF JINAN

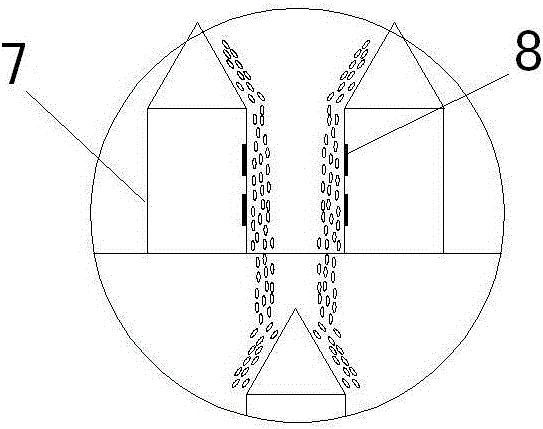

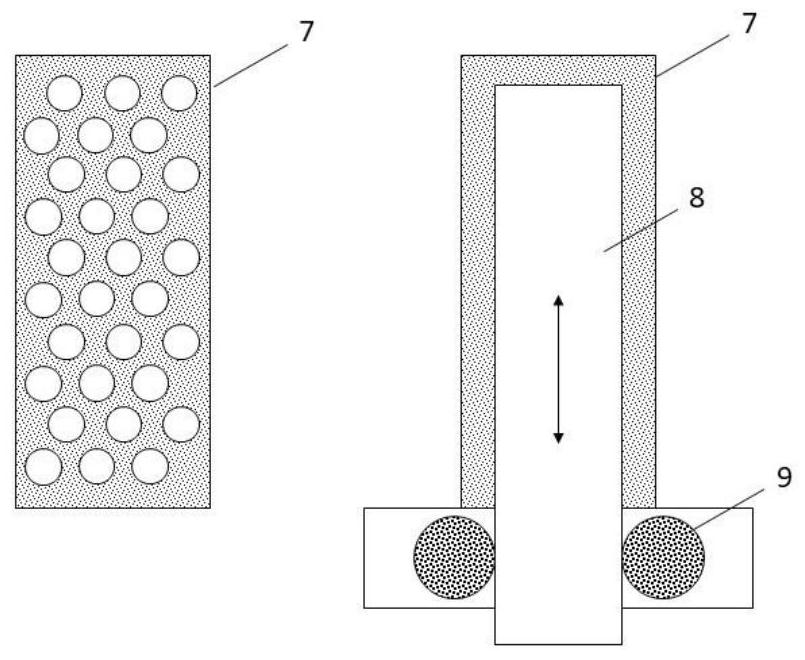

Device and technology for damage-free hulling and color sorting of tea-oil tree fruit

Disclosed are a device and technology for damage-free hulling and color sorting of tea-oil tree fruit. The device comprises a hulling assembly, a vibrating screen (7), a guide groove (8) and a color sorting separating assembly. The hulling assembly, the vibrating screen (7) and the color sorting separating assembly are connected in sequence. The technology includes the four steps including grading, grinding hulling, separating and color sorting. The device and technology can be used for processing a wide range of tea-oil tree fruit and processing green fruit which is just picked as well as tea-oil tree fruit which has been tedded for one or two days; the tea-oil tree fruit in a wide size range can be sorted by adjusting gaps of grating bars of a cylindrical grating grading mechanism, therefore, the size of the tea-oil tree fruit entering a grinding mechanism can be fixed within a certain range, and grinding efficiency and the grinding effect are improved; because a gap between a grinding wheel and a grinding bottom plate can be adjusted through a gap adjusting mechanism, hulling rate is further improved, and fruit grain damage rate is lowered; the picture processing and control technology is applied to tea-oil tree fruit hulling and fruit nut sorting by using the difference between the color of hulls and the color of fruit nuts, and sorting efficiency is greatly improved.

Owner:HUBEI UNIV OF TECH

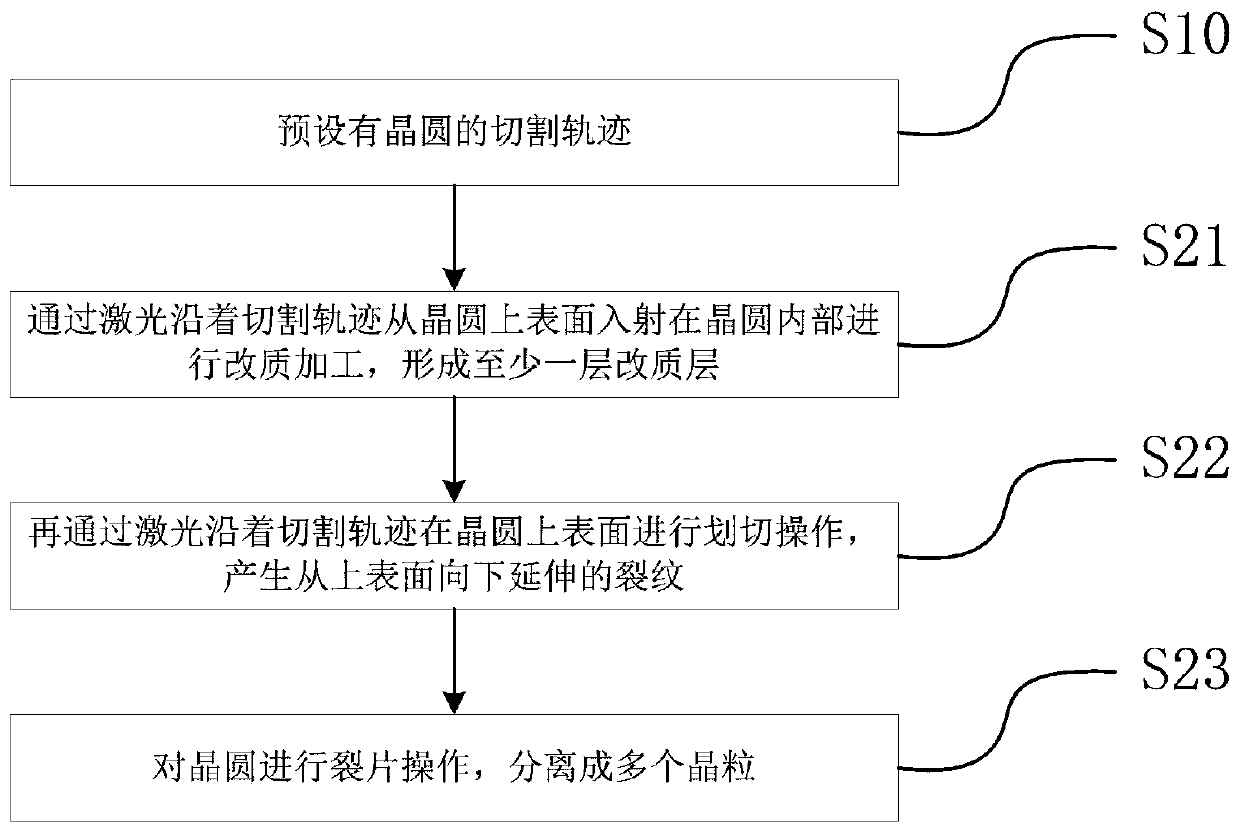

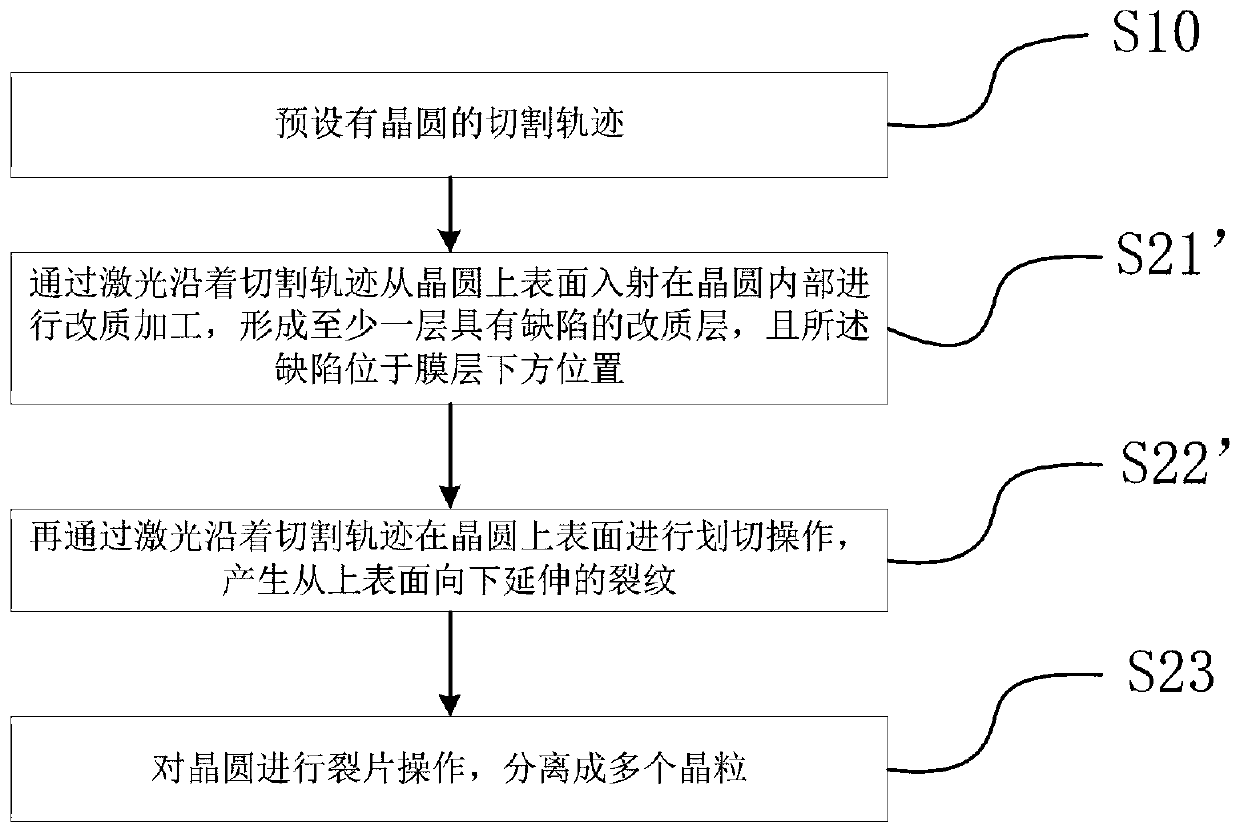

Laser machining method and system for a wafer

InactiveCN110216389AImprove yieldImprove efficiencyLaser beam welding apparatusLaser processingEngineering

The invention relates to the field of wafer machining, in particular to a laser machining method and system for a wafer. A wafer cutting track is preset. The laser machining method includes the stepsthat a laser is incident into the wafer to conduct modification machining from the upper surface of the wafer along the cutting track, and at least one modification layer is formed; then cutting-up operation is conducted on the upper surface of the wafer along the cutting track through the laser, and a crack extending downwards from the upper surface is generated; and piece splitting operation isconducted on the wafer, and the wafer is separated in to multiple grains. The laser machining method and system for the wafer are designed so that the problem of obvious edge breakage or even grain damage can be prevented in the piece separation process, and the piece separation yield and efficiency are improved under the condition that a cutting way is narrower or the function area of the cuttingway is plated with a film layer. Meanwhile, even if in the condition that the cutting way is not narrower or the film layer is not plated on the cutting way function area, the wafer piece separationyield and efficiency can still be improved in the scheme.

Owner:HANS LASER TECH IND GRP CO LTD

Flowering period synchronization regulating method for wheat and corn cross inducing haploid embryo

InactiveCN105532248AProlonged cross-pollination timeStrong plantClimate change adaptationPlant cultivationDiseaseGreenhouse

The invention discloses a flowering period synchronization regulating method for wheat and corn cross inducing haploid embryo. The method comprises the steps that on April 8-18 of every year, 200 materials of a single crossing and multiple crossing F1 generation and a preferable F2 generation of wheat are prepared, seeds are harvested after the wheat is ripe, each material contains 10 ears, threshing and drying are performed, unripened grains, extremely-small grains and grains damaged by diseases and pests are removed, the grains are stored in a seed refrigerating chamber and prepared to be applied to a staging autumn sowing test; from June to October, 4-8 corn species of different types are selected to serve as corn seeds for the test, the seeds are stored in the seed refrigerating chamber and prepared to be applied to the staging test. The wheat flowering period and the corn flowering period are regulated to be synchronized in mid-to-end April, the flowering period is regulated through the methods such as seed sorting, fertilizer and water and disease, pest and weed damage prevention and control management enhancing and staging temperature controlling, therefore, plant health and strongness of the wheat and corn can be promoted, the wheat and corn cross pollination time can be prolonged, the flowering period synchronization regulating successful rate is increased, and light supplementary is performed on a greenhouse by controlling heat increasing in a cold chamber; the equipment is simple, the effect is good, and the operation cost is low.

Owner:襄阳市农业科学院

D2PAK rectifier diode producing and soldering technology

ActiveCN103474359AAvoid damageIncrease free spaceWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingRectifier diodesEngineering

The invention relates to the production technology of rectifier diodes, in particular to a D2PAK rectifier diode producing and soldering technology. The D2PAK rectifier diode producing and soldering technology has the advantages that the technology is ingenious and reasonable, heat dissipation is good, a novel structural frame is adopted, materials are saved by one third, the time of process production is reduced, the external soldering of leading wires brings great convenience for follow-up work (crystalline grain damage caused by the soldering technology is reduced, and the releasing space of heat stress in a later using process is improved), and the production efficiency and quality of products are improved greatly. In addition, the D2PAK rectifier diode can completely replace a photovoltaic tube encapsulated by the diode, and is good in heat dissipation performance, encapsulated crystalline grains can be improved to 180mil compared with the size of the diode, the forward current capable of being borne by the encapsulation of the large-size crystalline grains is increased compared with the diode, the application range is wider, and the service life of a solar photovoltaic connecting box is prolonged.

Owner:NANTONG HORNBY ELECTRONICS

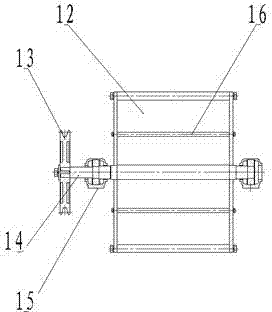

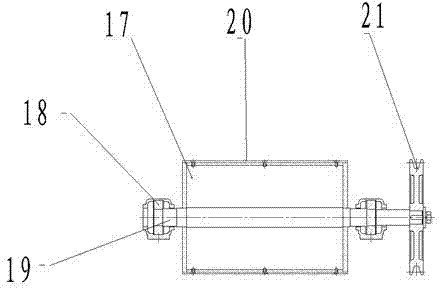

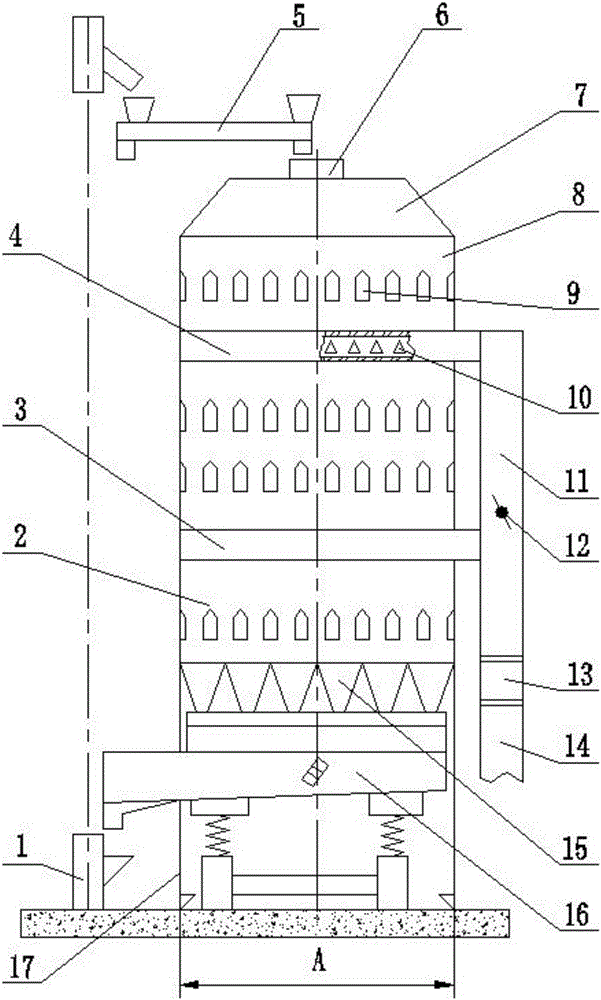

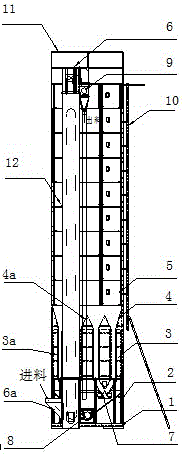

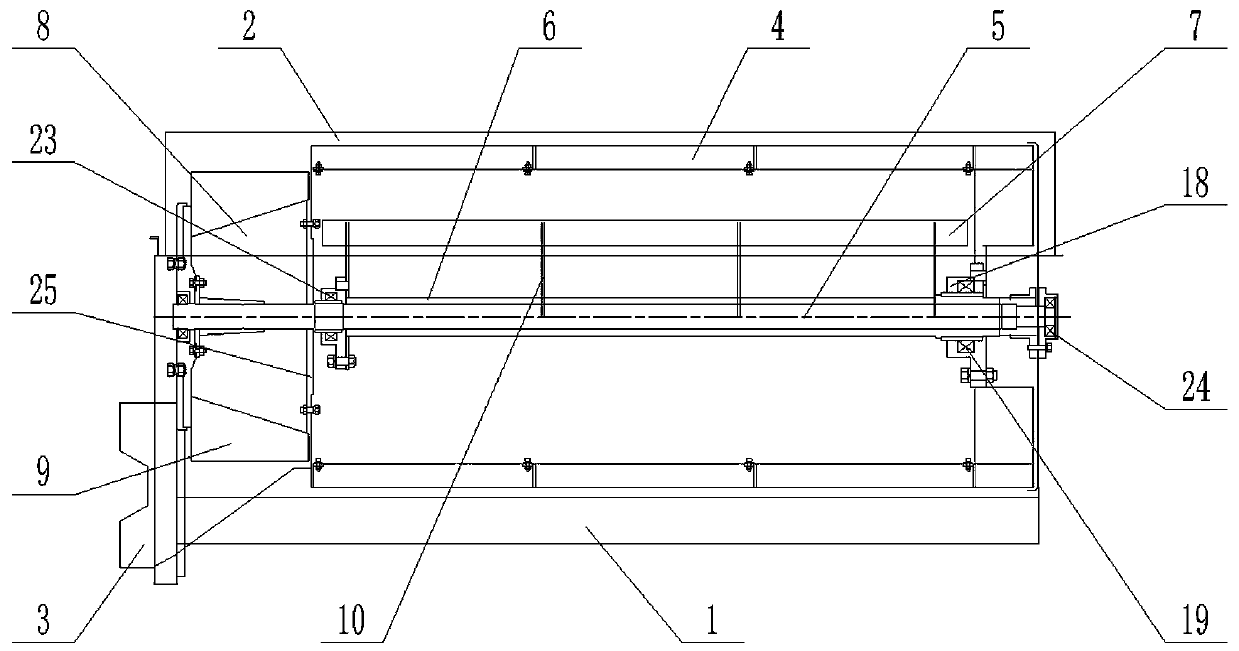

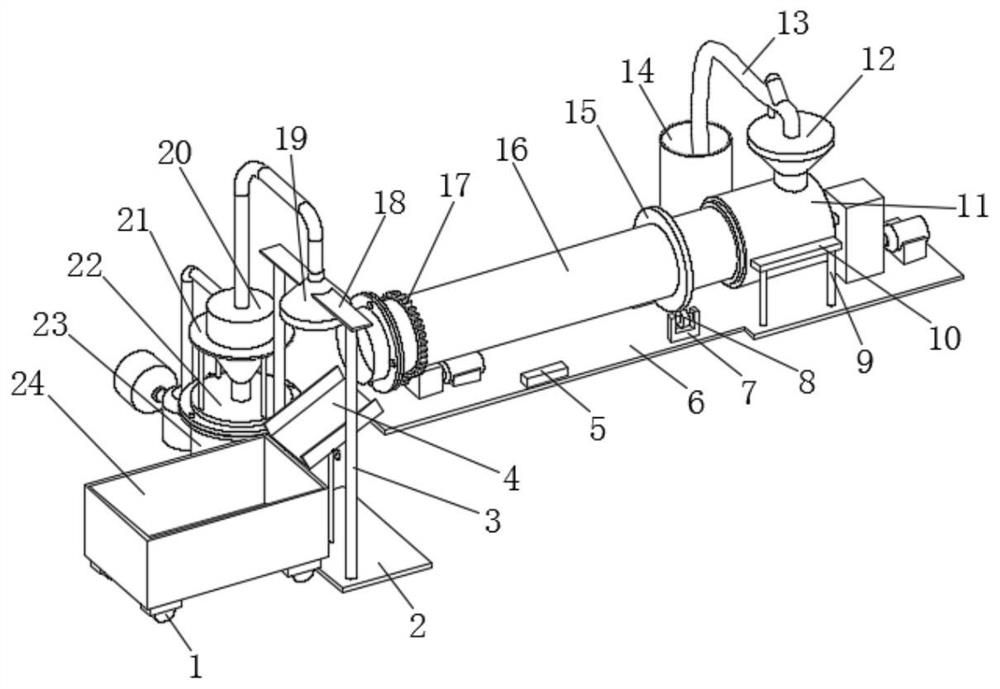

Integral vibration measuring discharge and partial cycle grain drying machine

ActiveCN106172737AEasy to moveAvoid damageSeed preservation by dryingDrying solid materialsCotton materialGrain damage

The invention discloses an integral vibration measuring discharge and partial cycle grain drying machine. The grain drying machine is composed of a feeding system, a drying warehouse, an elevator, an air network system, a vibration motor, a vibration spring and a frame; the drying warehouse (2) is composed of a warehouse body (8), a warehouse top (7), a discharge hopper (15), an integral vibration measuring discharge hopper (16) air network system and the frame (17); and a top device of the warehouse top (7) is a charging system formed by a burden distribution packing auger (5) and a burden distribution rotating disk (6). The drying machine has the beneficial effect that the integral vibration measuring discharge is employed for realizing grain nondestructive metering discharge, the sectional area of a grain discharge port is large, which is in favor of integral flowing of grains in the drying machine. The grain drying machine can realize quasi-state drying and partial cycle drying technology, which is in favor of minimizing grain damage and in favor of saving operation cost.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Batch circular grain dryer

InactiveCN105767159AReduce waist burst rateReduce maintenance costsSeed preservation by dryingAgricultural engineeringGrain distribution

The present invention discloses a batch circular grain dryer. The batch circular grain dryer includes a base. A bottom layer, a drying layer, a shunt layer and a retention layer are successively arranged from the bottom to the top of the base and communicate with each other. A lower auger and a hoister are also connected on the base. A material inlet hopper is arranged at one side of the lower part of the hoister, the upper part of the hoister is connected to an upper auger, and the upper auger and the retention layer is connected. The drying layer is connected to a grain distribution valve, the grain distribution valve is connected to the lower auger, and the lower auger is connected to the material inlet hopper. A grain discharge pipeline is also connected to the hoister. The batch circular grain dryer can reduce the grain damage rate during the drying process, and is high in thermal efficiency, easy in operation, and convenient in maintenance.

Owner:ANHUI XINSHENGLI BIOLOGY TECH

Fracturing equipment for coal bed gas exploiting

The invention discloses fracturing equipment for coal bed gas exploiting. A special pressurizing mixing mechanism is arranged to fully mix and pressurize high pressure water and sand grains fed by a sand grain supply mechanism and the mixture is sprayed through a fracturing pipe. Therefore, the sand grains are not sprayed by a high pressure pump, so that the problem that the sand grains damage blades of the high pressure pump can be solved effectively. Meanwhile, before the sand grains enter into the pressurizing mixing mechanism, the sand grains are mixed by using a lubricant, so that the condition that the cutting action to coal bed fractures is reduced as the sharp edges of the sand grains are damaged is prevented, and the fracturing and crack-increasing effects are achieved. By arranging a filter base, the sand grains can be prevented from entering a piston end, so that the piston end is prevented from being damaged. Meanwhile, increase of the pressure and the mixing action of thesand grains and the high pressure water can be also guaranteed.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

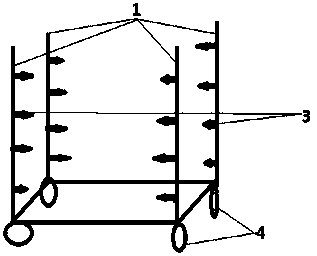

Country grain airing platform

InactiveCN104081952ASolve the problem of soakingIncreased load-bearing capacityAgriculture tools and machinesClimate change adaptationHeat resistanceMaterials science

The invention relates to the field of farm tools, in particular to a country grain airing platform solving the problems that the space for airing the grain in the country is small, the airing progress is slow, carrying is difficult, and the grain damage caused by the fact that rain comes suddenly, and it is too late to collect the grain. The country grain airing platform is composed of supports, an airing platform body, four steel rods, four wheels and a waterproof cover, and is characterized in that the four supports are provided with holes formed at equal intervals and can be made of rolled steel or wood, the steel rods are fixed to the holes of the supports, the airing platform body is placed on the steel rods, the wheels are located at the bottoms of the supports, the airing platform is a net in the form of a silkworm platform, the waterproof cover is arranged at the top ends of the supports in a sleeved mode, the country grain airing platform is preferably made of materials good in waterproof performance, tenacity and heat resistance, and one multi-layer airing platform is formed by five to six airing platform bodies. The country grain airing platform is simple in structure, capable of effectively solving the problems such as the grain damage and difficult carrying caused by the small airing space and the slow progress and suitable for being popularized.

Owner:MIANYANG ANZHI SHENGDA CREATIVE TECH

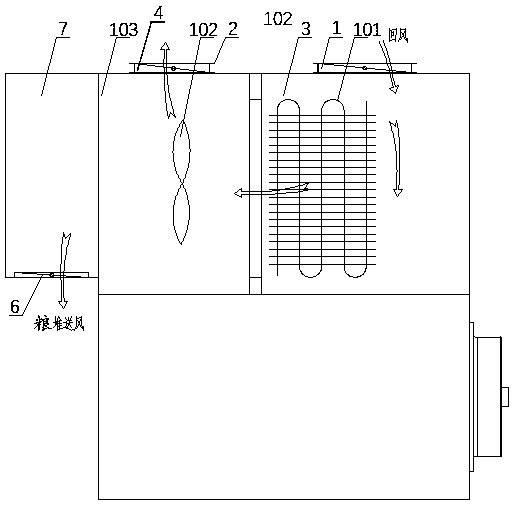

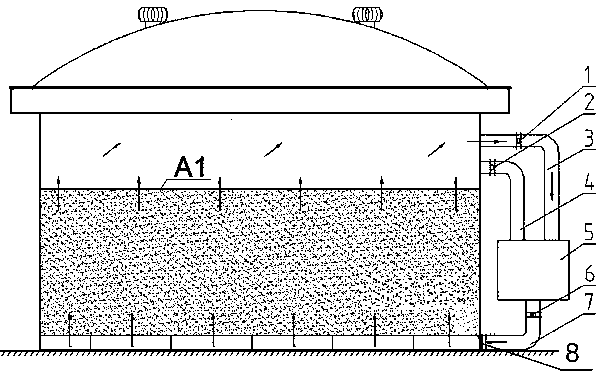

Multifunctional temperature and humidity control device for barn

PendingCN108131767AAvoid inhomogeneityGood storage stabilityMechanical apparatusLighting and heating apparatusTemperature controlGrain storage

The invention discloses a multifunctional temperature and humidity control device for a barn and belongs to the field of grain storage and barn temperature and humidity control. The multifunctional temperature and humidity control device comprises temperature cooling equipment arranged at the outer part of the barn; the barn is connected with cooling equipment by an internal air return pipeline and an internal air supplying pipeline in the upper space of the barn wall in an air-path manner. The multifunctional temperature and humidity control device also comprises a grain-mass air path pipeline, wherein the grain-mass air path pipeline is connected at the bottom part of the barn and connects the barn and the cooling equipment in an air-path manner; an internal air return valve is arrangedin the internal air return pipeline; an internal air supplying valve is arranged in the internal air supplying pipeline; a grain-mass air path valve is arranged in the grain-mass air path pipeline. Compared with the prior art, the multifunctional temperature and humidity control device for the barn disclosed by the invention has the beneficial effects that mobile equipment cooling is improved intofixed installation, so that a foundation is laid for automatic grain storage; simultaneously, the functions of grain-mass internal cooling and grain-mass surface temperature control are achieved, theproblems of easy grain damage and easy fumigating corrosion when the temperature control equipment is installed in the barn are solved, and the function for selectable air supplying modes is achieved.

Owner:CHENGDU LANGBOWANG SCI & TECH DEV

Permanent magnetic ferrite for automobile motor and manufacturing method of permanent magnetic ferrite

The invention discloses a permanent magnetic ferrite for an automobile motor and a manufacturing method of the permanent magnetic ferrite. The permanent magnetic ferrite for the automobile motor comprises the following raw materials in parts by weight: fine iron powder, barium carbonate, strontium carbonate, silicon dioxide, polyvinyl alcohol, aluminum oxide, cobalt oxide, lanthanum oxide, calcium gluconate and boric acid. When the permanent magnetic ferrite is manufactured, the fine iron powder prepared by using an iron sand resource is used as a preparation raw material, so that the production cost is reduced; and the powder is firstly subjected to coarse grinding and fine grinding treatment, so that the prepared powder is uniform in particle size distribution and low in crystal grain damage degree. The manufacturing method is simple in process and convenient to operate; and the manufactured permanent magnetic ferrite is rich in raw material source, low in cost, good in product cost performance, favorable in magnetic property, relatively high in residual magnetic flux density, relatively good in intrinsic coercivity and high in operability and practicability.

Owner:CHONGQING TONGSAI ELECTROMECHANICAL

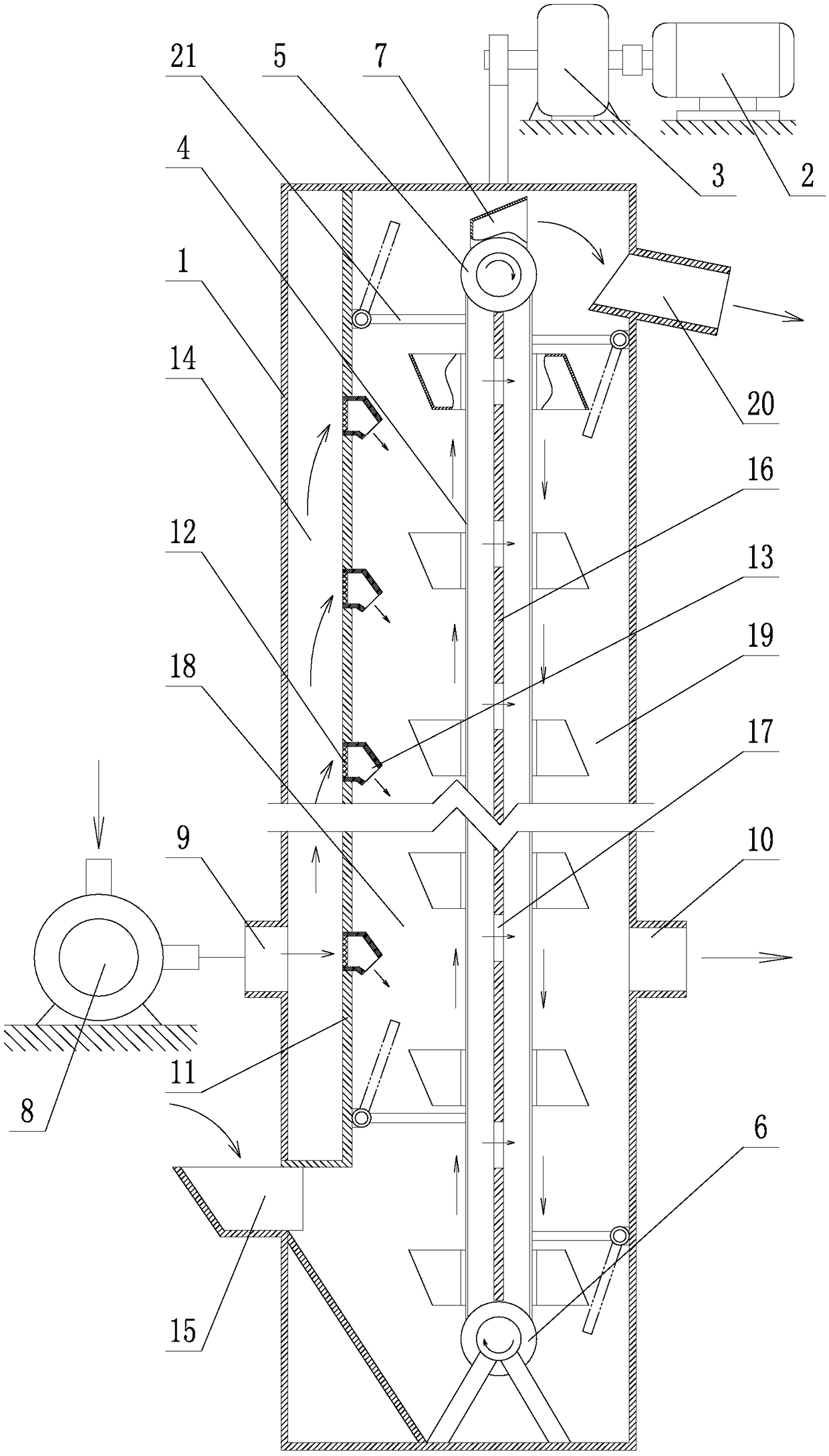

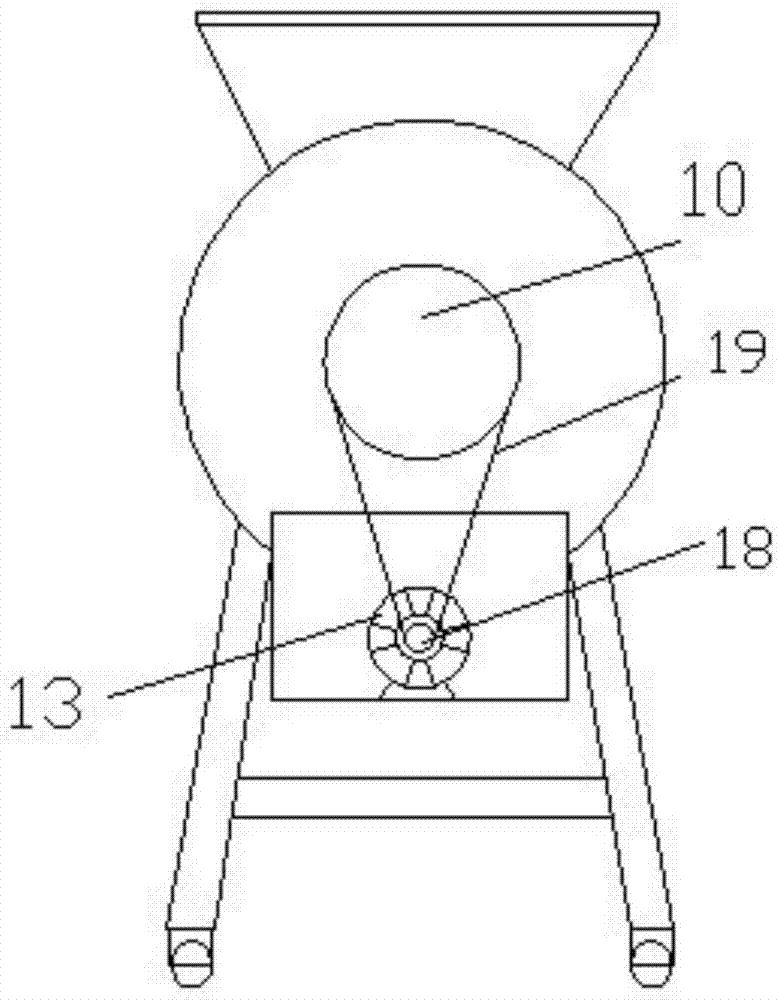

Centrifugal threshing device for coarse cereal crops

The invention particularly relates to a centrifugal threshing device for coarse cereal crops, and solves problems that an existing threshing device is poor in separation effect, high in grain damage rate and easy to block and influences threshing efficiency. The centrifugal threshing device includes a box-type rack, a top cover is arranged at an upper end of the box-type rack, a feeding inlet is arranged at a lower part of a left side wall of the box-type rack, a spiral feeding device and a threshing cylinder are arranged in the box-type rack, a transmission shaft is arranged in the box-type rack, a hollow shaft sleeve is sleeved on the transmission shaft, and a spiral pushing device is arranged on the hollow shaft sleeve; the spiral feeding device comprises a conical feeding cylinder andspiral blades; the spiral pushing device comprises a connecting plate, a strip-shaped supporting plate is fixed on the connecting plate, a semi-arc pushing disc is arranged on the strip-shaped supporting plate, the semi-arc pushing disc is hinged with the strip-shaped supporting plate and an adjusting pull rod, and a scraping plate is arranged on the strip-shaped supporting plate. The centrifugalthreshing device avoids damage to seeds in previous processes of impact, kneading and combing, reduces damage rate, retains integrity of straw, and reduces impurity content.

Owner:SHANXI AGRI UNIV +1

Method for Detecting Infestation by Grain-Damaging Insects, and Insect Trapping Device

A method for detecting infestation of grain-damaging insects in grain stored in a storage facility. This method comprises a first step of placing an insect trapping device that traps grain-damaging insects in the storage facility and leaving the device in the storage facility for a predetermined length of time, and a second step of detecting infestation of grain-damaging insects in the grain on the basis of how many grain-damaging insects have been trapped in the insect trapping device after the first step. The insect trapping device has a base that is impermeable to water or oil, a porous substrate that is disposed on one side of the base and is capable of holding water or oil, and water or oil held in the porous substrate.

Owner:SAPPORO BREWERIES

Granary capable of automatically drying grains

InactiveCN104738164AKeep dryKinetic power with automated handlingAgriculture tools and machinesSeed preservation by dryingAgricultural engineeringQuality safety

The invention discloses a granary capable of automatically drying grains. The granary comprises a granary body, wherein exhaust columns are arranged in an inner cavity of the granary body, exhaust holes are formed in the surfaces of column bodies of the exhaust columns, insect repelling lamps are circumferentially arranged on the inner wall of the granary body, an insect discharging hole is formed in the lower part of each insect repelling lamp, a rain canopy is installed on the edge of a granary cover, an exhaust fan is installed on the middle position of the top of the granary cover, the bottom of the exhaust fan is provided with a humidity sensor and a controller, the controller is respectively electrically connected with the humidity sensor and the exhaust fan, and an exhaust port is connected with the upper part of the exhaust fan. The exhaust fan, the controller and the humidity sensor are additionally arranged on the top of the granary cover, so that the granary body has an automatic processing function, and the dryness of the grain can be maintained; the granary is provided with the insect repelling lamps and the insect discharging openings, so that the amount of the grain damaged by the biting of insects can be greatly reduced; the granary cover is additionally provided with the rain canopy, so that the quality safety of the stored grain can be guaranteed.

Owner:李天亮

Bucket-type grain elevator with blast heat exchange function

ActiveCN109132344AReduce damage rateReduce purchasesConveyorsLoading/unloadingGrain elevatorInlet channel

The invention relates to a bucket-type grain elevator with a blast heat exchange function. A main air inlet and a main air outlet are distributed on a shell of the elevator, heat exchange gas is introduced into the shell from the main air inlet by a blower, an air inlet partition plate and an air exhaust partition plate are arranged in the shell, secondary air inlets are formed in the air inlet partition plate, air supply nozzles are installed on secondary air outlets, the secondary air outlets are arranged in the air exhaust partition plate, and an air inlet channel is formed between the airinlet partition plate and the side wall of the shell on the side of the main air inlet. An elevating channel is formed between the air inlet partition plate and the air exhaust partition plate, and adescending channel is formed between the air exhaust partition plate and the side wall of the shell on the side of the main air outlet. The food in a hopper completes heat exchange in the elevating channel, and the gas after heat exchange is directly discharged into the atmosphere. In the process of grain lifting and transporting, preheating warming or cooling is synchronously realized, equipmentpurchasing cost and space occupation are saved, and overall operation time and grain damage rate are reduced.

Owner:NORTHEASTERN UNIV

Slide-type grain dropping device of grain drying machine

InactiveCN109573644AAvoid breakingInnovative designConveyorsDrying solid materialsAgricultural engineeringGrain damage

The invention belongs to the technical field of grain drying machines, in particular to a slide-type grain dropping device of a grain drying machine. The slide-type grain dropping device includes a machine body, a horizontal fixed plate is arranged at the internal upper end of the machine body, the periphery of the fixed plate is fixedly connected with the inner wall of the machine body, a grain receiving device is arranged on the fixed plate, penetrates through the fixed plate, and extends to the lower part of the fixed plate, the two sides of the bottom end of the grain receiving device is constantly shrunk, and the vertical tangent plane of the grain receiving device is in a funnel shape; and a fixing block is fixedly connected to the outer wall of the grain receiving device, the crosssection of the fixing block is of a annular structure, the fixing block is connected with the fixed plate through fixing bolts, a vertical grain distributing pipe is welded to the bottom end of the grain receiving device, and a separating plate is fixedly connected within the grain distributing pipe. The shortcomings of the prior art is overcome, a first slide way is used to guide the grain to enter the drying machine, the grain damage due to the fact that the grain hits the inner wall of the drying machine in the grain dropping process is avoided, and the application scope of the drying machine is improved.

Owner:安徽省久泰农业装备有限公司

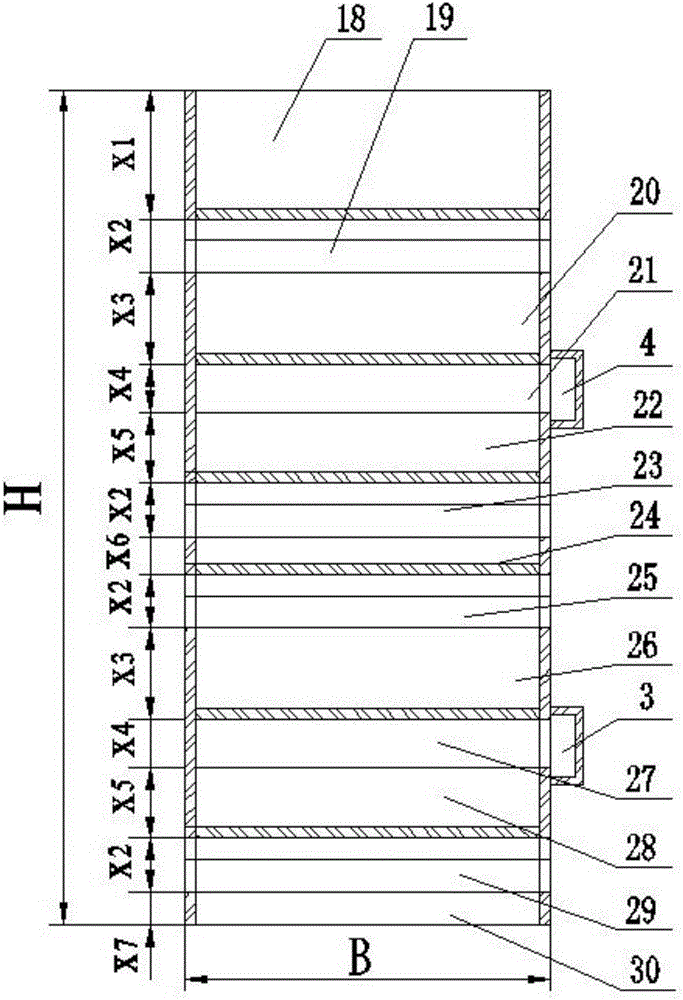

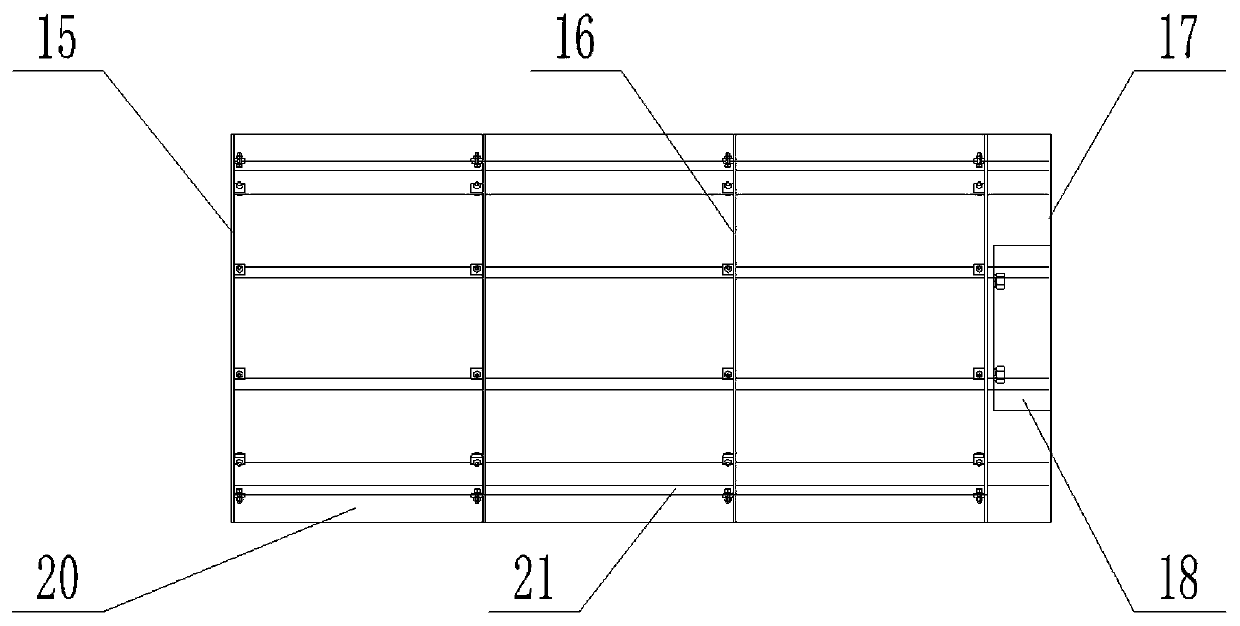

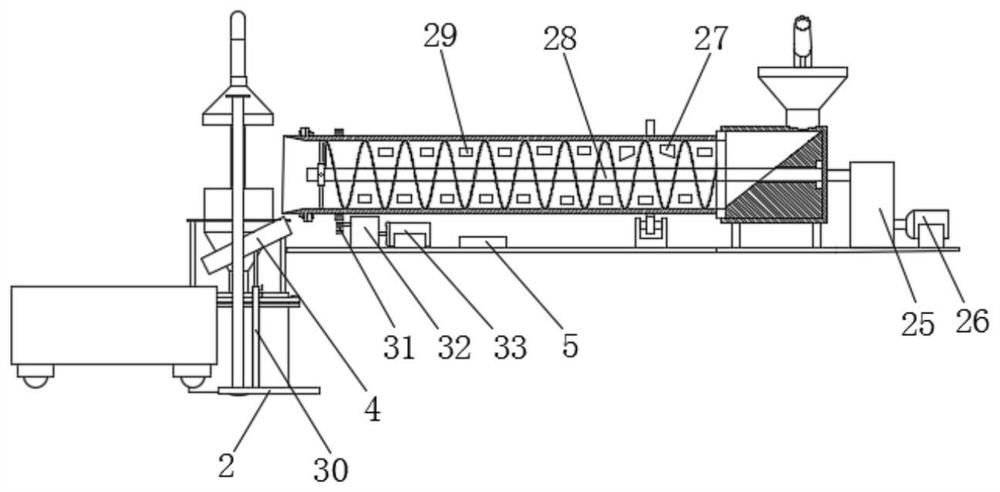

Drying machine with purification pretreatment function

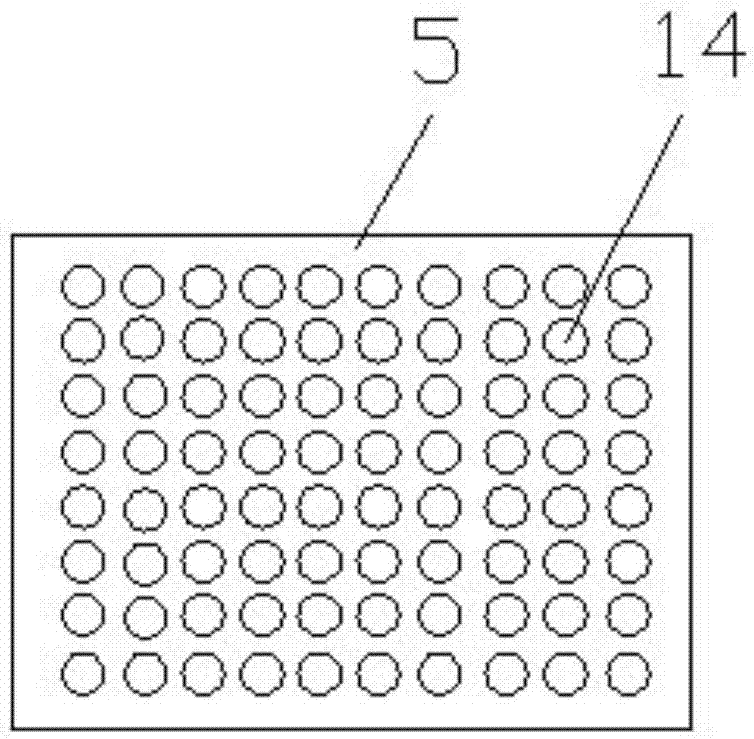

InactiveCN106225428AReduce damage rateSmall sizeSeed preservation by dryingGrains dryingPre treatmentTower

A drying machine with a purification pretreatment function comprises a drying tower. The drying tower includes a tempering layer, a diversion layer, a drying layer and a circulation layer sequentially from top to bottom. A discharging outlet of the circulation layer is higher than a feeding inlet in the bottom of a lift and is connected with the feeding inlet through an inclined slideway. A discharging outlet in the top of the lift is higher than a feeding inlet of the tempering layer and is connected with the feeding inlet through an inclined slideway. The drying layer is divided into multiple sub-layers, each sub-layer is provided with a plurality of diverters, and the diverters on each sub-layer are arranged between the diverters on the upper adjacent sub-layer and the diverters on the lower adjacent sub-layer. The top end of each diverter is shaped like an inverted V, and air outlets are formed in two sides of each diverter. A cyclone separator is arranged above the tempering layer. Downward sliding of grain under the action of self gravity is used, an upper auger, a lower auger and an auger power motor are omitted, the manufacturing cost is greatly reduced, the machining, manufacturing and maintenance processes are simple, and the grain damage rate is greatly lowered. Therefore, drying is more uniform, and the drying effect is better. In addition, an overturning layer does not need to be arranged independently, the size of the drying tower is reduced, and space is saved.

Owner:合肥三伍机械有限公司

Internal and external rotary type grain damage-free dryer

InactiveCN112284073AQuick drying processEasy loadingDispersed particle filtrationDrying solid materialsReduction driveElectric machine

The invention discloses non-damage dryer suitable for grains with different grain diameters. A hollow cylindrical rotary drum is arranged, a first gear and a second speed reducer are arranged at the left end of the outer side face of the hollow cylindrical rotary drum, a second gear meshing with the first gear is arranged on an output shaft of the second speed reducer, a second motor is arranged at the end, close to the second speed reducer, of the upper surface of a second supporting plate, and an input shaft of the second speed reducer is connected with the output end of the second motor. The internal and external rotary type grain damage-free dryer is compact in structure, convenient to operate, small in occupied space in the using process, capable of rapidly conducting drying treatmenton the various types of grains, arrangement of an air suction nozzle facilitates collection of dust, arrangement of a vacuum material suction pump facilitates feeding of the grains, arrangement of locking universal wheels combined with a collecting box facilitates collection and transportation of the dried grains, and the drying time is controlled through the relative rotating speed of a screw rod and a hollow cylindrical rotating cylinder.

Owner:杜海美

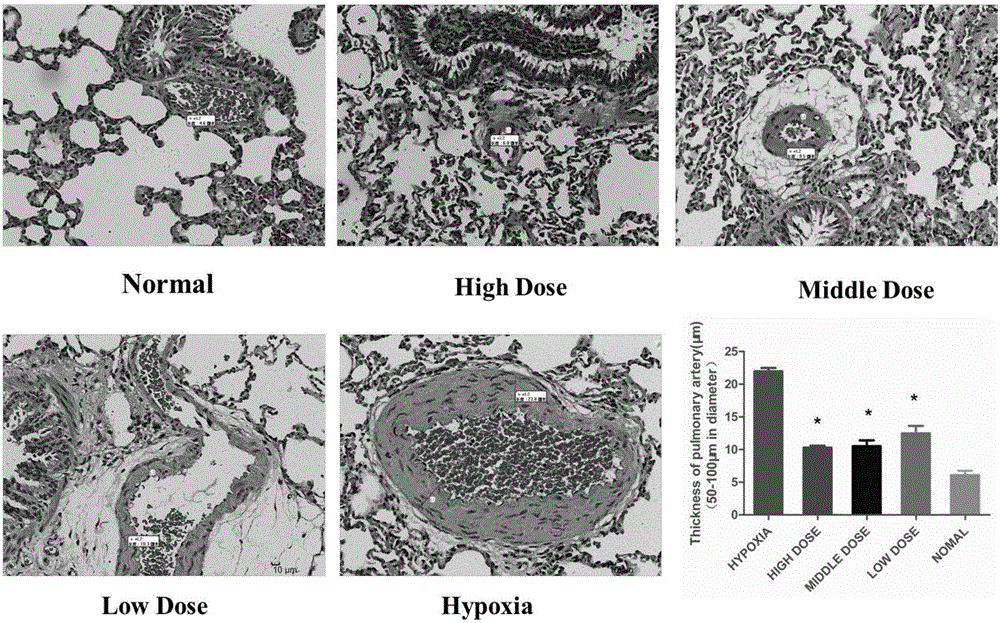

Preparation method and pharmaceutical application of effective part of rhodiola rosea

InactiveCN106511437APromote repairImprove protectionNatural extract food ingredientsFood ingredient functionsFreeze-dryingRHODIOLA ROSEA ROOT

The invention discloses a preparation method and pharmaceutical application of an effective part of rhodiola rosea. The preparation method comprises the following steps that the rhodiola rosea is extracted by ethanol after being smashed; and an extract is subjected to separation through macroporous adsorption resin and gradient elution through water and ethanol systems, an eluent is subjected to decomperssion concentration, and after freeze drying, the effective part of the rhodiola rosea is obtained. According to the application of the effective part of the rhodiola rosea, the effective part is used for preparing medicine for treating and / or preventing pulmonary arterial hypertension, health care products for treating and / or preventing the pulmonary arterial hypertension, medicine for promoting vascular endothelial cell repair and protection, health care products for promoting vascular endothelial cell repair and protection, medicine for treating cell line grain damage, and health care products for treating cell line grain damage. The raw material supply of the effective part is stable, the cost is low, the preparation cost is low, and the medicine effect is reliable.

Owner:QINGHAI UNIVERSITY

A warehouse detection robot

The invention discloses a warehouse detection robot. The invention includes a robot chassis and four wheel-driven steering and lifting mechanisms; the four wheel-driven steering and lifting mechanisms have the same structure; The position of the crank rocker can realize the up and down movement of the spiral tire, and the robot can move freely inside and outside the grain stack of the granary, and accurately realize the temperature and humidity detection at the fixed position inside the granary. The traditional method of measuring the internal temperature of the granary is changed, and the technical problems of low detection efficiency of grain condition in the granary, many grain damages, complex structure control of the detection robot, and high manufacturing difficulty and cost are solved in the existing technology. The robot is simple in structure, convenient in operation, more flexible in movement, and more efficient and accurate in temperature and humidity detection.

Owner:HANGZHOU DIANZI UNIV

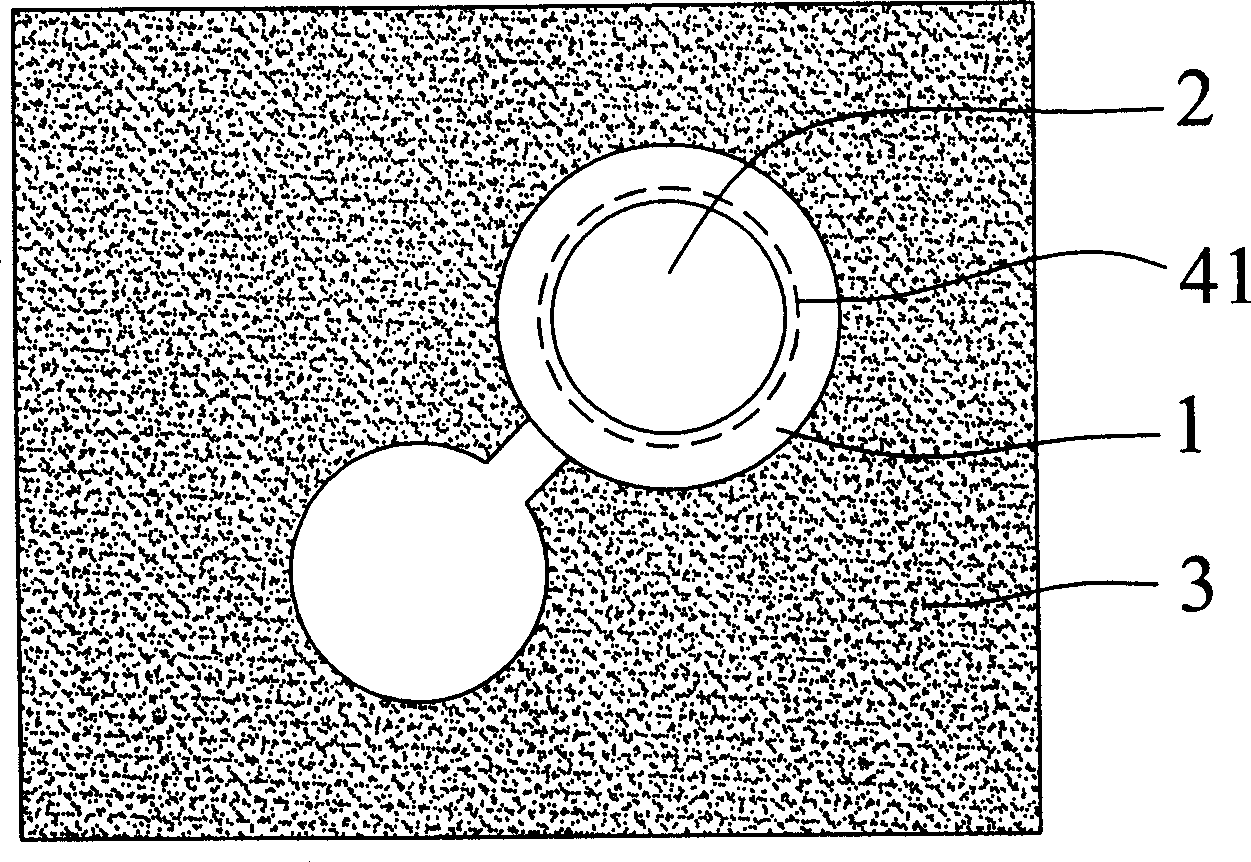

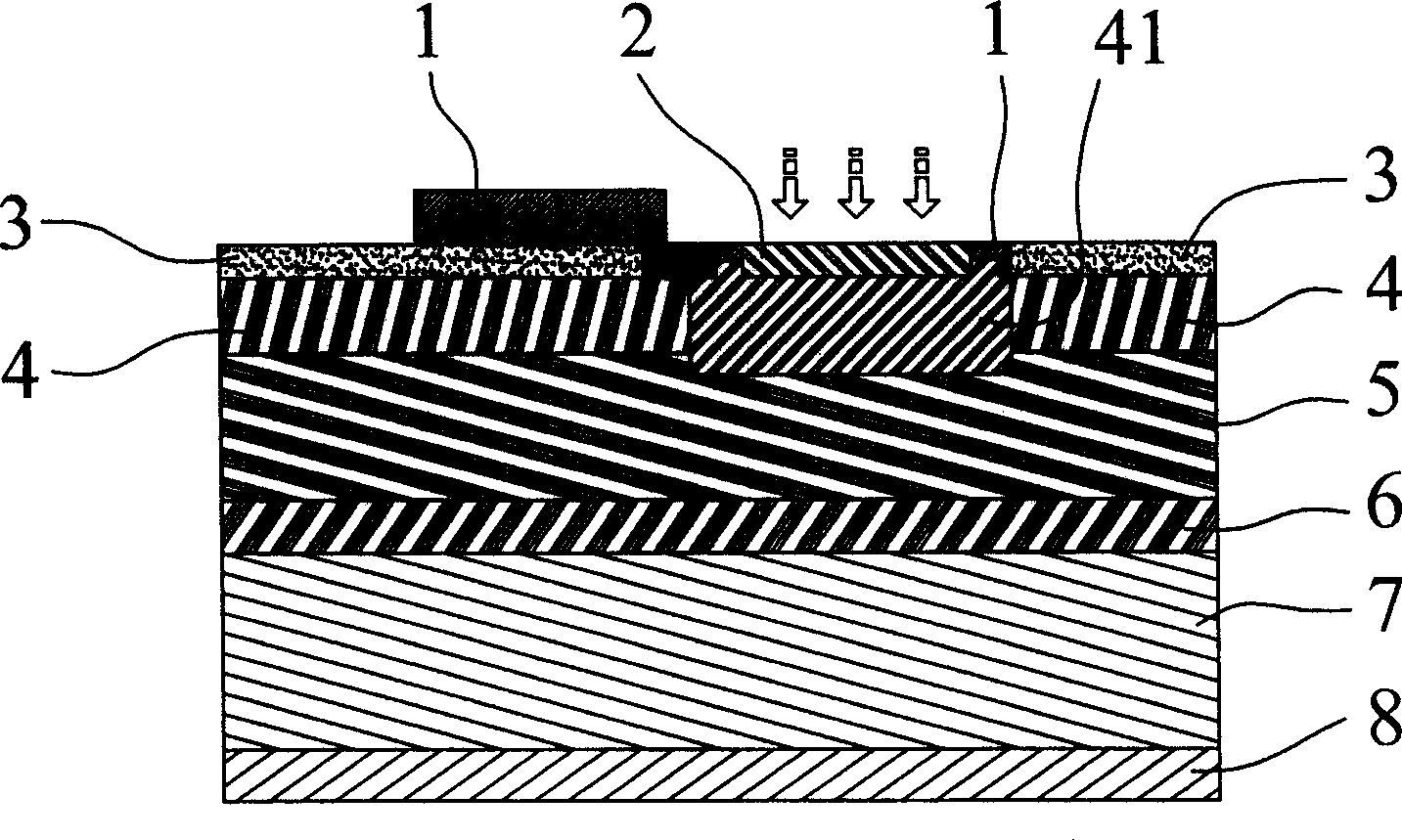

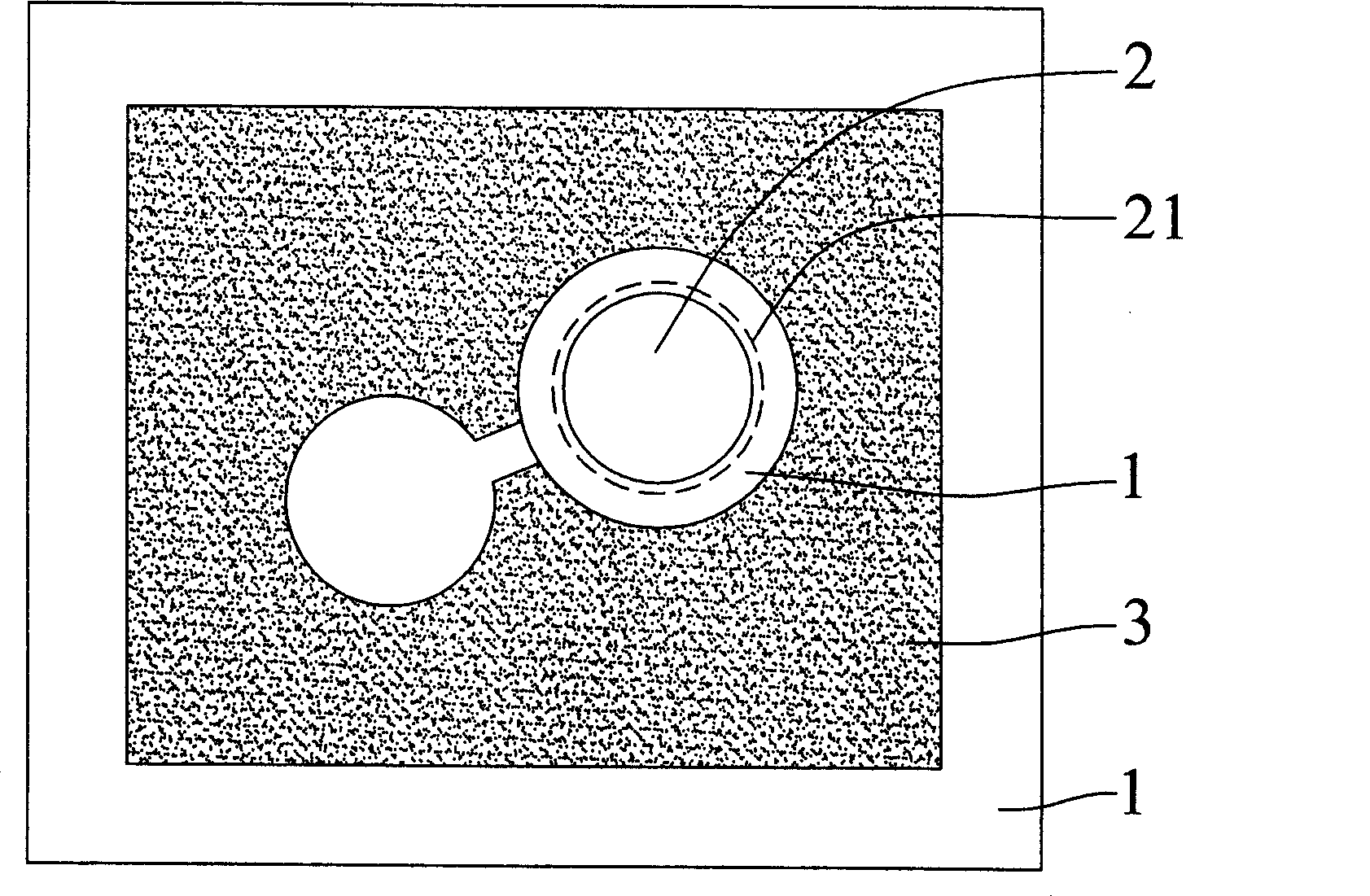

Atoll static release device

ActiveCN100468783CEnhanced ability to resist reverse bias electrostatic damagePrevent penetrationSemiconductor devicesBack biasAgricultural engineering

The invention discloses an atoll type electrostatic discharge device for improving the back bias electrostatic damage resistance capability of light tester grains and increasing the electrostatic charge release patches to improve the grain back bias electrostatic damage resistance capability. The electrostatic release paths increased around the light tester grain are a P type metal layer, a resistance reduction area, a P type semiconductor area, an i type light absorption layer, a N type buffering layer, a N type base plate and a N type metal layer. Leading most of the electrostatic charges to release around the grains can avoid most of the electrostatic charges centered among and through the grains and cause grain damage and improve the grain back bias electrostatic damage resistance capability.

Owner:LAND MARK OPTOELECTRONICS

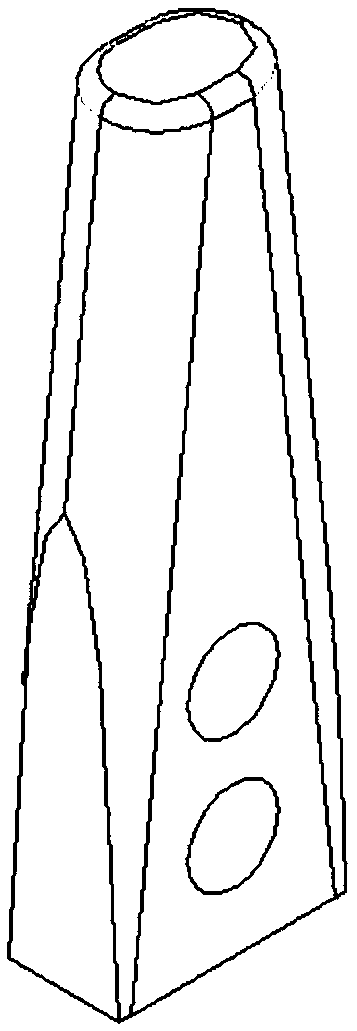

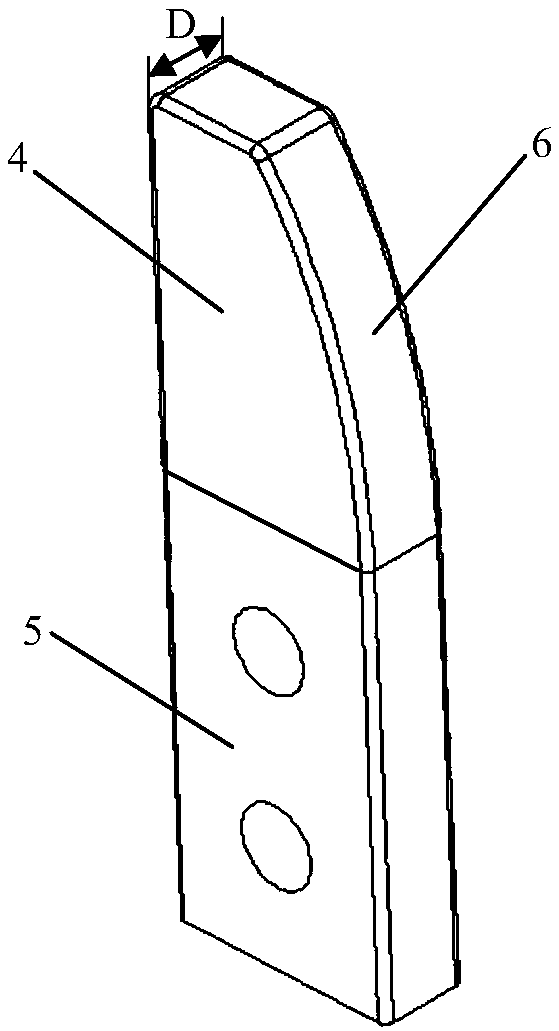

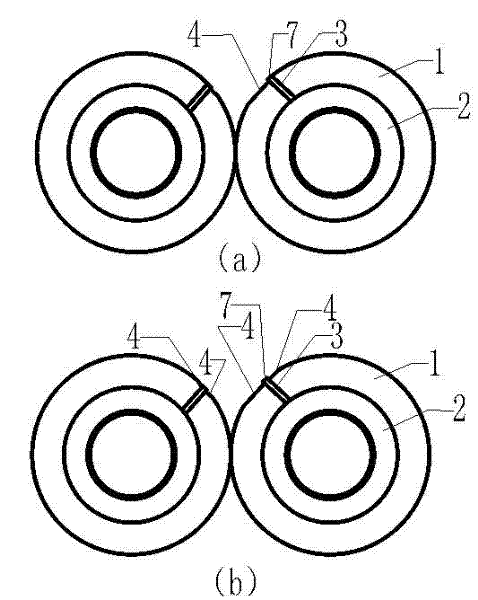

Threshing spike tooth of corn grain harvester

The invention belongs to the technical field of agricultural harvesting machines, and relates to a threshing spike tooth of a corn grain harvester. The threshing spike tooth comprises a spike tooth body (1) and a rubber sleeve (2). The spike tooth body (1) is a platy tooth with a certain thickness, and comprises a working section (4) on the upper side and a fixed section (5) on the lower side. Thefixed section (5) is detachably and fixedly connected to a threshing roller of the corn grain harvester. The thickness end face of the spike tooth body (1) is arranged in the rotating direction of the threshing roller. The thickness end face of one side of the working section (4) of the spike tooth body (1) is a working surface (6), and the working surface (6) is a curved surface. The outer surface of the working section of the spike tooth body (1) is sleeved with the rubber sleeve (2) corresponding to the working section in shape. By means of the threshing spike tooth, corn grain ears can berapidly threshed, the impact of the spike tooth on grains in the threshing process is effectively reduced, and the grain damage rate in the grain harvesting process is reduced.

Owner:CHINA AGRI UNIV

Novel threshing machine

The invention discloses a novel threshing machine, comprising a threshing machine housing, landing legs, a threshing outlet, an air blower, and universal wheels. The upper side of the threshing machine housing is provided with a feeding inlet. The internal of the threshing machine housing is provided with a threshing chamber. The threshing chamber is internally provided with a threshing roll. The threshing roll is provided with a plurality of threshing blades. The lower side of the threshing machine housing is welded with the landing legs. The lower side of the threshing chamber is provided with a sieving chamber. The upper side of the sieving chamber is provided with a filter screen. The lower side of the sieving chamber is provided with the threshing outlet. One side in the sieving chamber is provided with the air blower. One side in the sieving chamber is provided with a clutter outlet. The novel threshing machine is simple in structure, novel and reasonable in design, low in grain damage rate, high in clean ratio, and low in operation resistance, and has little faults. The machine does not need special personnel to operate, and saves power and is light in weight, and improves manual threshing efficiency. Through the universal wheels, the threshing machine is convenient to carry and use. The threshing machine solves problems of labor intensity and manpower waste.

Owner:CHONGQING XIANGGUIYUAN ECOLOGICAL TRAVEL DEV CO LTD

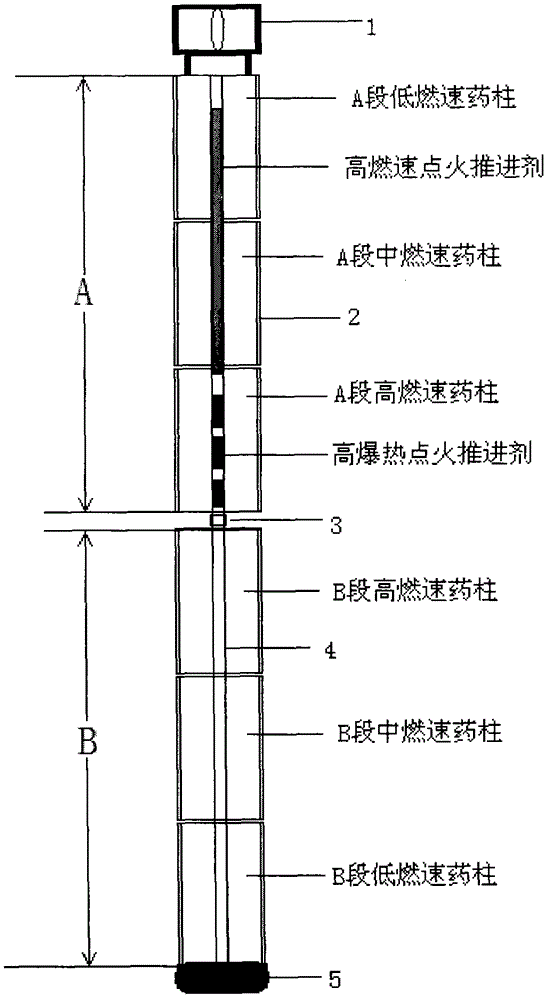

Controllable multi-pulse gas generator

The invention discloses a controllable multi-pulse gas generating device, which is used for improving the recovery rate of crude oil. The device is composed of an igniter, a central tube, a section A propellant grain, a B section propellant grain, a plugging joint and a centralizer. A high burning rate ignition propellant and a high explosive hot spot are respectively placed in the A section of the central tube. Fire propellant, by setting different sequences of high, medium and low burning rate propellant grains in A and B sections and the matching of central tube grains, the control realizes multiple pulses during the construction process; the plugging joint is used to Prevent the high-temperature and high-pressure airflow after the ignition propellant in the center tube of section A from leaking into the center tube of the charge column in section B, and ensure that the high-alumina and high-chlorine propellant charge in section A burns first, and the centralizer ensures that the shell of the charge column in the construction of the device is not protected from the casing wall. Frictional damage. The invention realizes the safe and effective release of the high energy produced by the propellant downhole without causing damage to the well. At the same time, long and difficult to close cracks are formed, which is conducive to the progress of construction.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

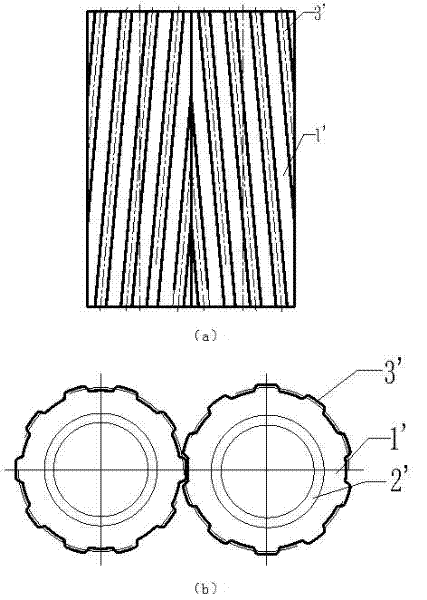

Husking rubber roller mechanism for corn husker

The invention relates to a husking rubber roller mechanism for a corn husker, which comprises a roll shaft and a rubber sleeve, wherein the rubber sleeve is sleeved and fixed on the roll shaft. The husking rubber roller mechanism is characterized in that the rubber sleeve is cylindrical, the rubber sleeve is fixedly provided with transverse, longitudinal or spiral blades or a blade group. The rubber sleeve which is adjacent with the blades or each blade of the blade group is provided with a blade edge opening. The fixed height of the blades or each blade of the blade group is level with or slightly higher than the thickness of the rubber sleeve. The husking rubber roller mechanism has the advantages that the grain-damaging rate of corn grains is greatly reduced during corncob husking, namely, the grain-damaging rate is lower than 5% while the ripening degree is between 65%-75%, and the grain-damaging rate is lower than 2% while the ripening degree is between 75%-85%.

Owner:陆洲

D2PAK rectifier diode producing and soldering technology

ActiveCN103474359BAvoid damageIncrease free spaceWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingRectifier diodesEngineering

Owner:NANTONG HORNBY ELECTRONICS

Grain dryer with gradient dehydration

ActiveCN113280610BAvoid uneven drying problemsAvoid destructionFood processingDrying gas arrangementsThermodynamicsHigh humidity

The invention relates to a gradient dehydration grain dryer. The vibrating stratifier is used to stratify the grain according to the particle size and weight, and the stratified grain enters the drying bucket of the next layer from top to bottom; the drying bucket has vibration, so that the grain inside it It is also layered according to the particle size and weight. The grains that are more thoroughly dried will gradually move up to the edge of the drying hopper due to the decrease in moisture, so that the drier grains can enter the edge of the drying hopper preferentially, while The grain with high humidity is in the center of the drying hopper; the drier grain enters the next layer of the drying hopper and gradually dries; it can avoid the problem of uneven drying caused by a single drying; secondly, when drying, the bottom layer The drying hoppers in the upper layer use hot air directly, while the drying hoppers on the upper layer use the waste heat of the hot air used up in the next layer in turn, so that on the one hand, heat can be saved, and on the other hand, a temperature gradient is formed between the drying hoppers in each layer. Avoid the problem of grain damage and uneven drying caused by direct drying with higher temperature hot air when the grain humidity is high; secondly, although the air used up in the lower layer has a certain humidity, it must be lower than the humidity that can be produced by the upper layer of grain, so It does not affect the drying of the upper grain.

Owner:安徽华谷机械科技有限公司

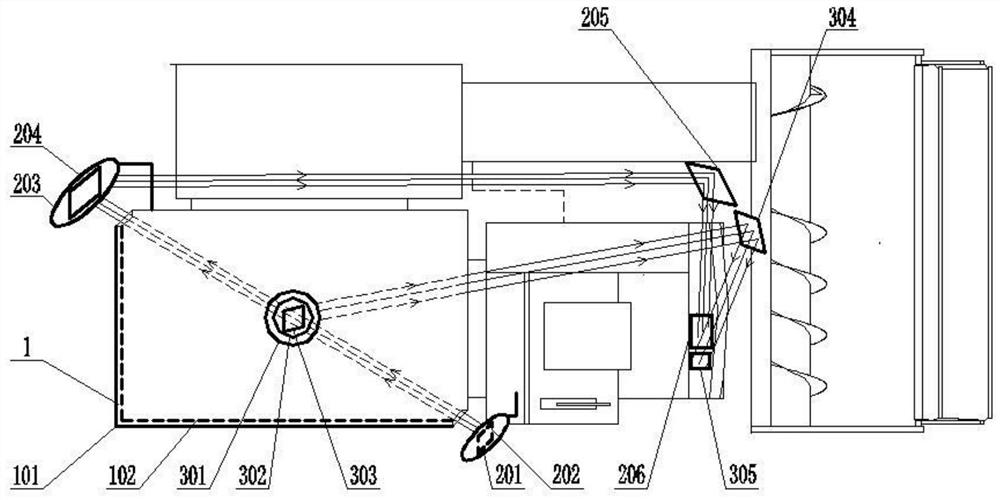

A harvester grain tank monitoring system and a harvester with the system installed

ActiveCN109041757BStatus real-time monitoringIntuitively understand the real-time status of loading capacityMowersThermodynamicsPlane mirror

The invention relates to a harvester grain tank monitoring system and a harvester equipped with the system, including a grain tank heating device, a grain height monitoring device and a grain tank grain damage state monitoring device. The system uses a combination of a convex lens and a plane mirror to assist The operator observes the real-time status of the grain tank and the grain inside it, and heats the grain in the grain tank. The convex lens can gather light, and the flat mirror can reflect light. The combination of two convex lenses with different focal lengths can magnify and heat the grain. Get rid of the power supply, sensor, algorithm, control system, etc. required by the traditional monitoring method of the working condition of the combine harvester, and the operator can intuitively understand the grain tank and its internal grain with a simple structure, low cost, and high reliability. The real-time status of the loading and status of the grain, and heat treatment of the grain.

Owner:JIANGSU UNIV

Axial flow threshing separation facility in tangential feeding type

The invention relates to a tangential feeding axial flow threshing and separating device, which is used for taking off the grains of crops from the ear head. The threshing element adopts the composite structure of short grain rod and plate teeth, the short grain rod is installed on the grain rod seat, the plate teeth are located on one side of the grain rod seat, and the concave plate adopts two combined structures of grid screen and punching screen, which can be realized with the threshing drum. Threshing and separation of crops. The short-grain rod-plate teeth composite elements are arranged on the closed cylinder of the threshing drum in a spiral manner; by changing the short-grain rods and plate teeth of different sizes, changing the position of the plate teeth, and adjusting the motion parameters, the device can adapt to rice and wheat. , rapeseed, soybean and other crops threshing and separation requirements. The invention has high depuration rate, less entrainment, low grain damage rate, light stalk breakage, less short stalks and miscellaneous residues in the shedding, uniform distribution along the axial direction of the threshing drum, and strong adaptability to the environment. After simple adjustment, it can adapt to the threshing requirements of various crops, the structure is simple, and the processing and manufacturing are convenient.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com