Integral vibration measuring discharge and partial cycle grain drying machine

A grain dryer and integrated technology, applied in drying solid materials, preserving seeds by drying, drying, etc., can solve the problems of poor measurement accuracy, large volume, inconvenient online operation and adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

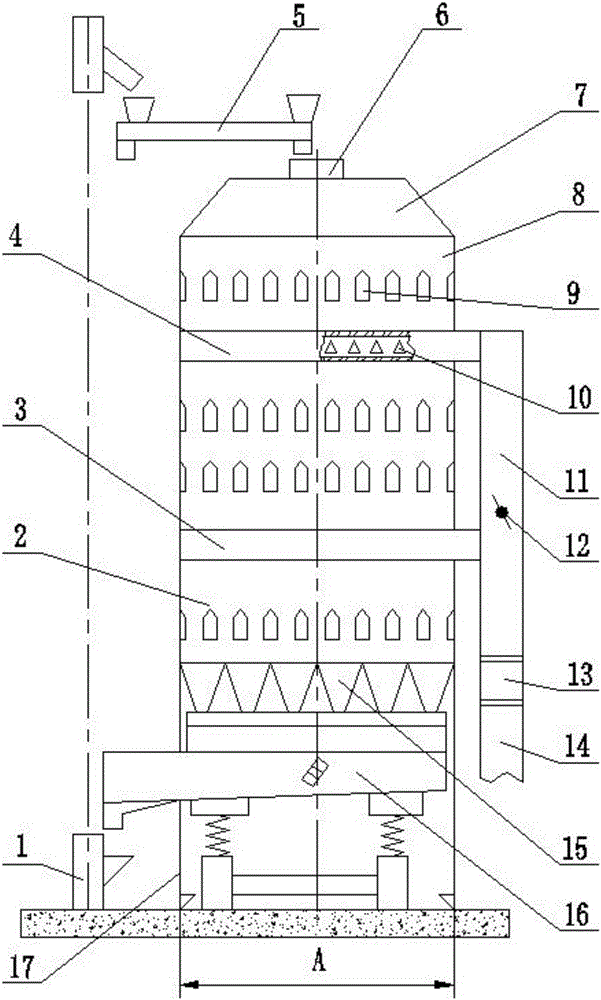

[0054] A grain dryer with overall vibrating metering and partial circulation, such as figure 1 As shown, it is mainly composed of drying warehouse, elevator, integral vibration metering and discharging trough, cloth auger, cloth turntable, air inlet duct, fan, etc.

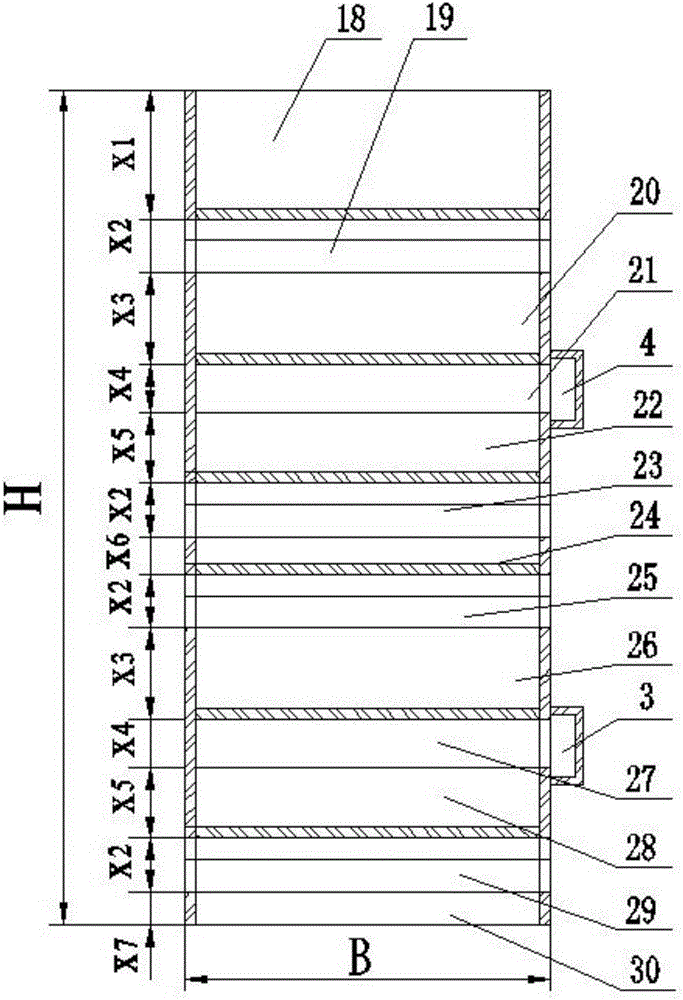

[0055] Drying storehouse (2) is made up of storehouse body (8), storehouse top (7), discharge hopper (15), air net system, frame (17) etc.; storehouse body (8) is a cuboid, storehouse body (8) The height is H, and the value of H is at 9000mm, and the length of warehouse body (8) is A, and the value of A is at 3000mm; The width of warehouse body (8) is B, and the value of B is at 3000mm. Such as figure 2 As shown, the upper part of the bin body (8) is connected to the bin roof (7), and the bin roof (7) is a square platform, and the upper end of the bin body (8) is provided with a grain storage layer 1 (18), and the grain storage layer 1 (18) is a rectangular space, its cross-sectional area is the cross-sectional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com