A harvester grain tank monitoring system and a harvester with the system installed

A monitoring system and technology for harvesters, which are used in harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of high power consumption, complex structure, high cost, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

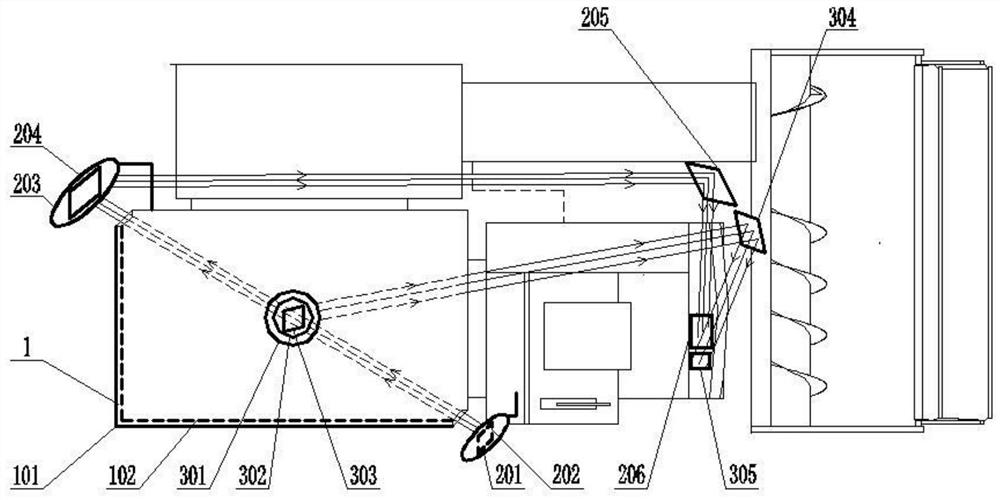

[0040] In this embodiment, a crawler combine harvester is taken as an example to describe the present invention in detail. figure 1 and figure 2 Shown is an embodiment of the grain tank monitoring system of the present invention. The grain tank monitoring system includes a grain tank heating device 1 , a grain height monitoring device 2 and a grain tank grain damage state monitoring device 3 .

[0041] Such as image 3 and 4 As shown, the grain tank heating device 1 includes an outer wall shell 101 and an inner wall shell 102; a light-gathering layer is arranged between the outer wall shell 101 and the inner wall shell 102, and the light-gathering layer will The light converges to the inner shell 102 .

[0042] In this embodiment, the light concentrating layer may include multi-layer convex lenses. Preferably, the light concentrating layer includes several first convex lenses 103 and second convex lenses 104; the second convex lenses 104 are installed on the inner wall sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com