Drying machine with purification pretreatment function

A pretreatment and dryer technology, applied in dryers, grain drying, drying of solid materials, etc., can solve the problems of increased costs and increased costs for customers, and achieve the effect of saving manufacturing costs, saving space, and reducing the rate of grain damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

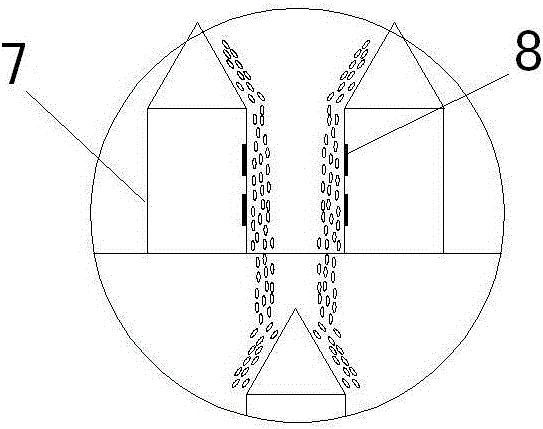

[0009] Such as Figure 1-3 As shown, a drying machine capable of impurity removal and pretreatment in this embodiment includes a drying tower 1, and the drying tower 1 is sequentially composed of a slow sore layer 2, a separation layer 3, a drying layer 4, Circulation layer 5, the circulation layer 5 is connected to the bottom of the hoist 6, the slow layer 2 is connected to the top of the hoist 6, the outlet of the circulation layer 5 is higher than the feed port at the bottom of the hoist 6 and passes through the inclined slideway Connected with it, the discharge port at the top of the elevator 6 is higher than the feed port of the slow layer 2 and is also connected to it through an inclined slideway. The drying layer 4 is divided into multiple layers, and each layer is provided with a plurality of Splitter 7, the splitter 7 of each layer is arranged in the middle of the splitter 7 of the upper and lower adjacent layers, the top of the splitter 7 is in the shape of a figure-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com