Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1857results about "Grains drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

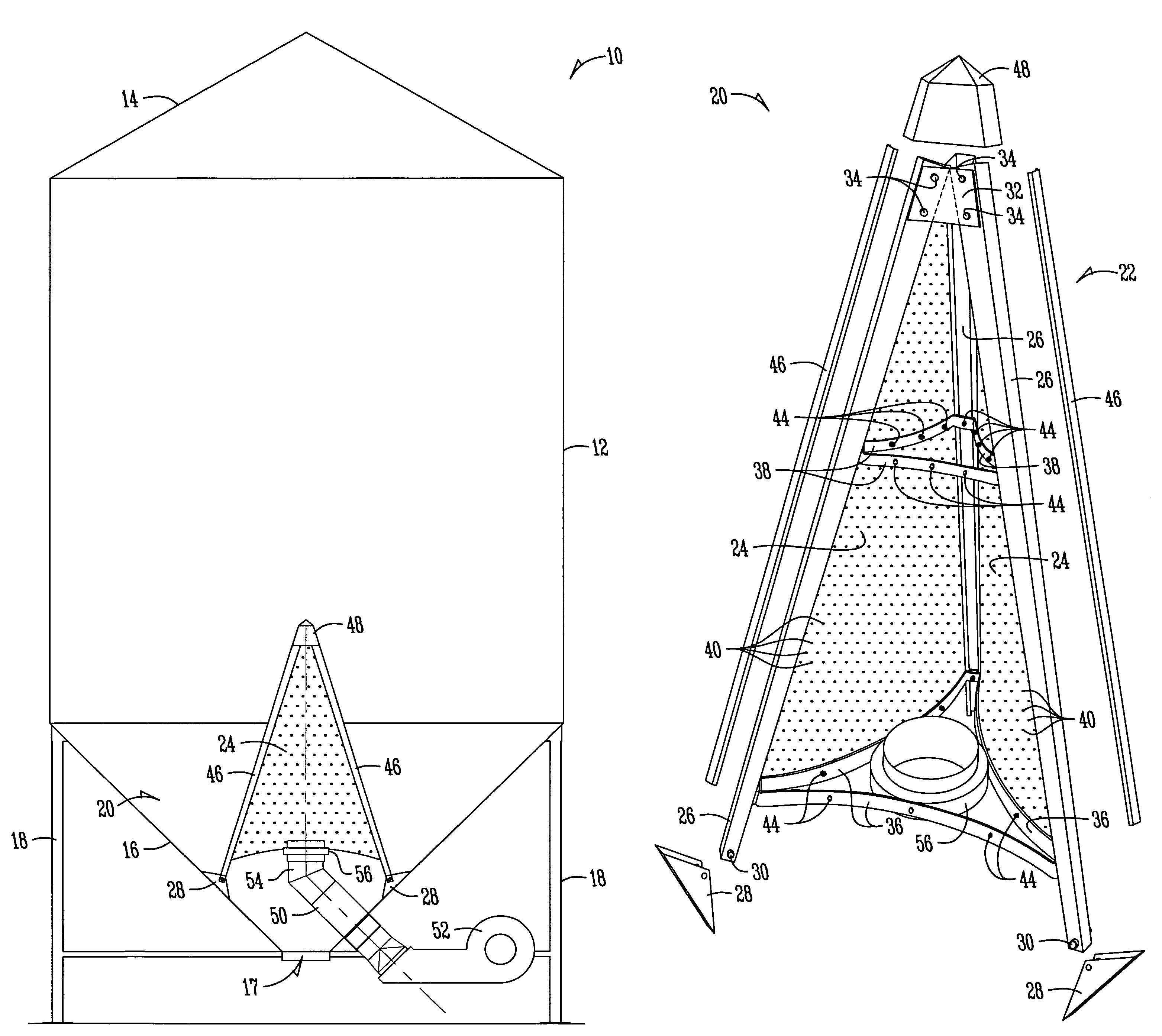

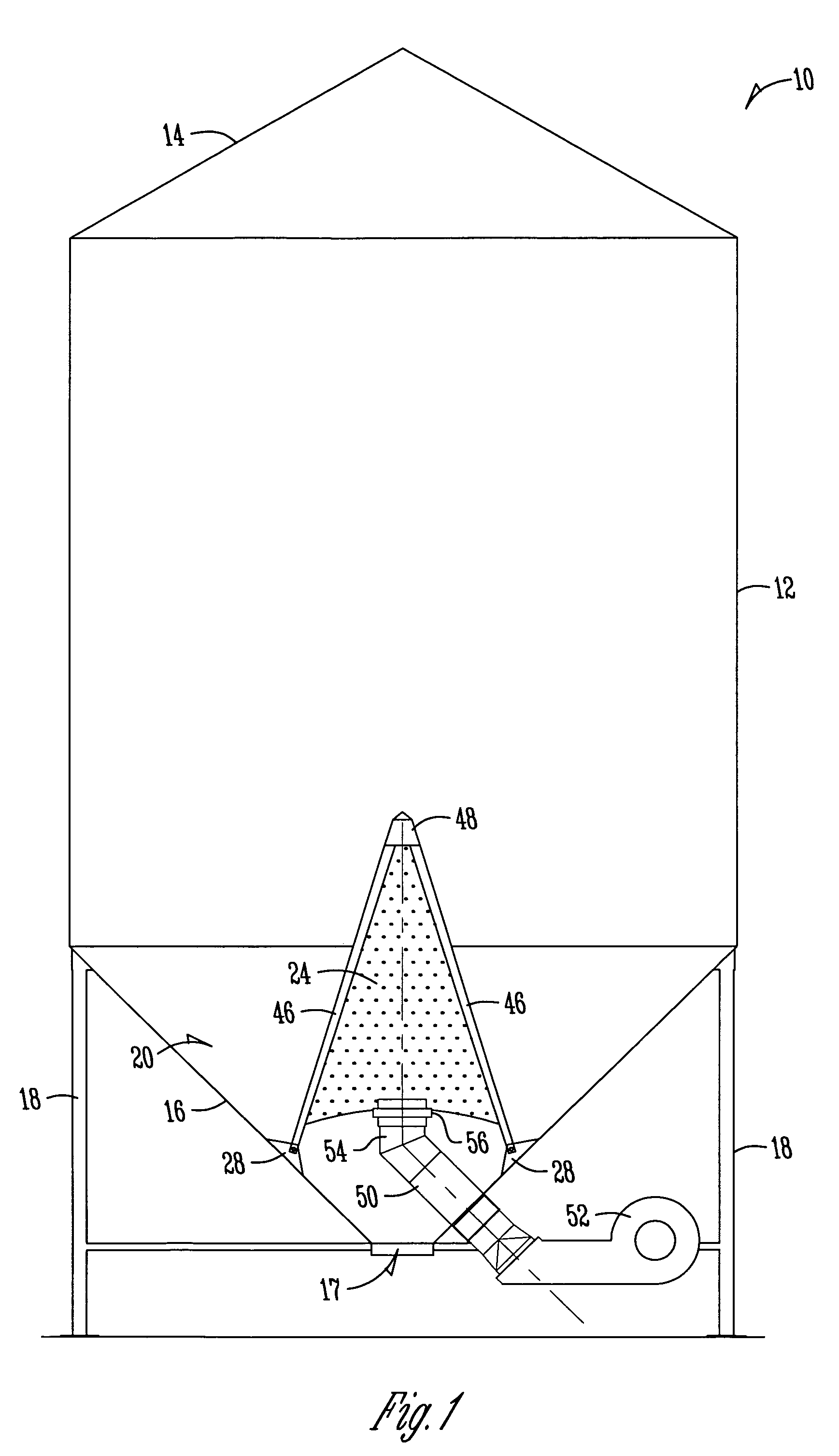

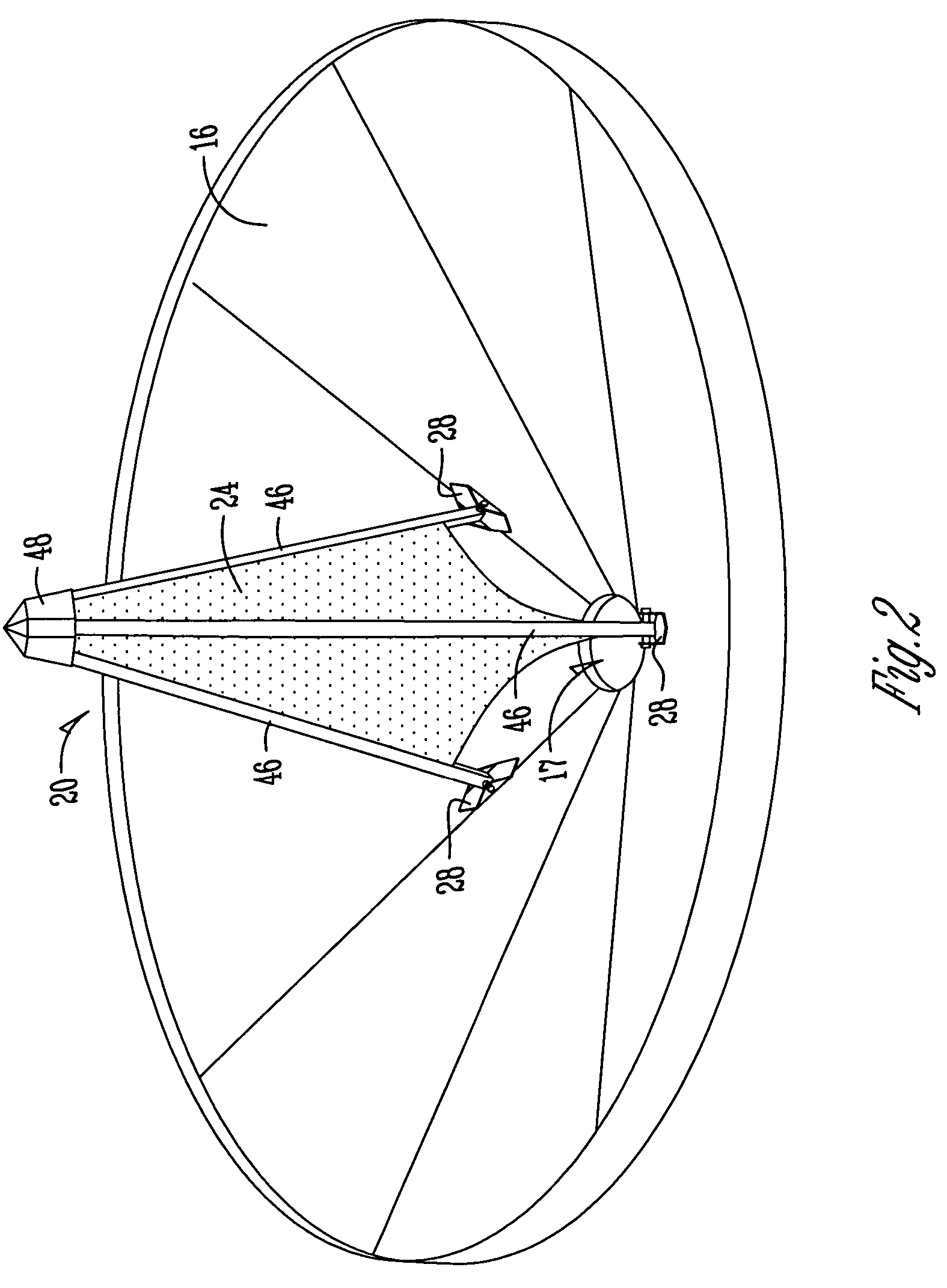

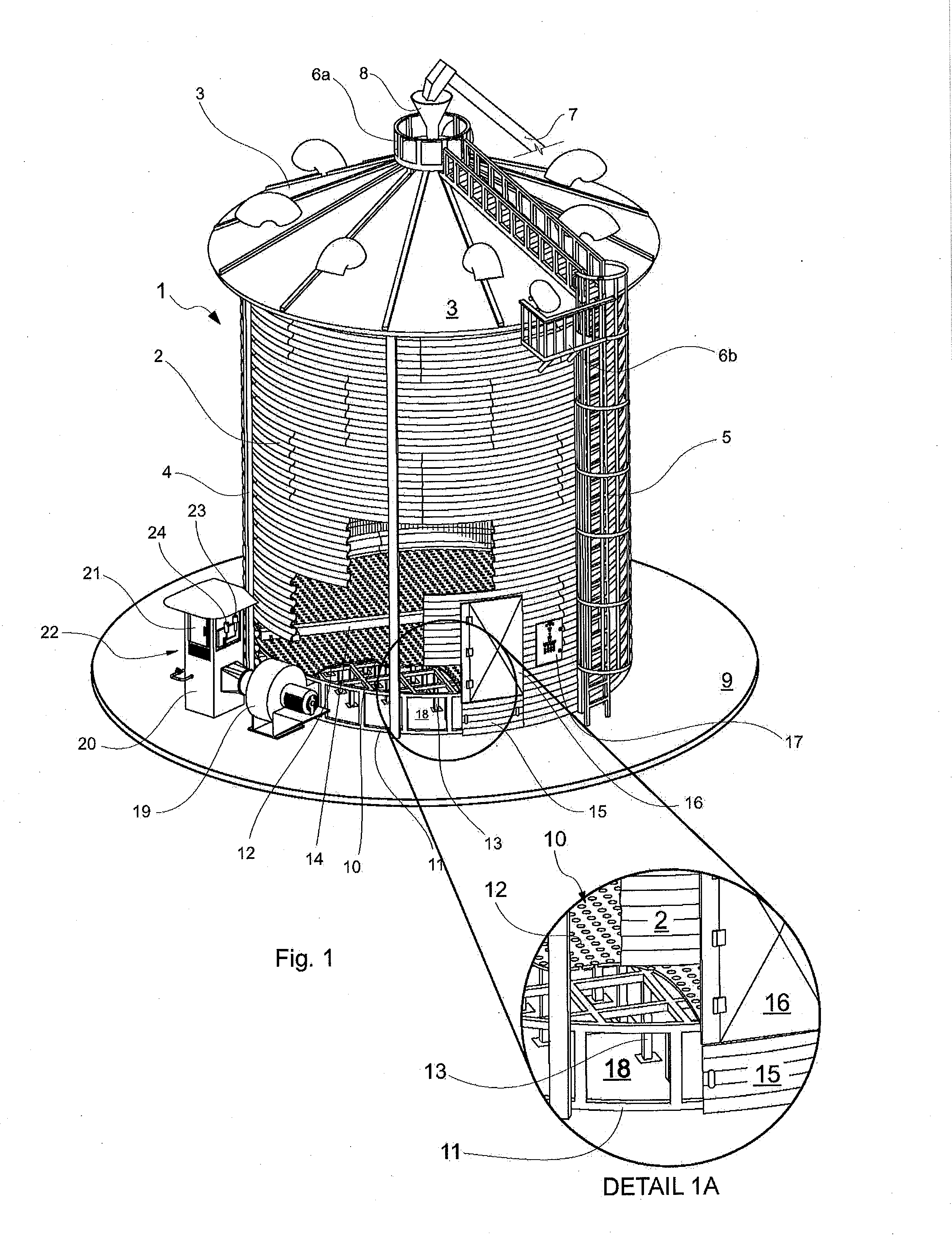

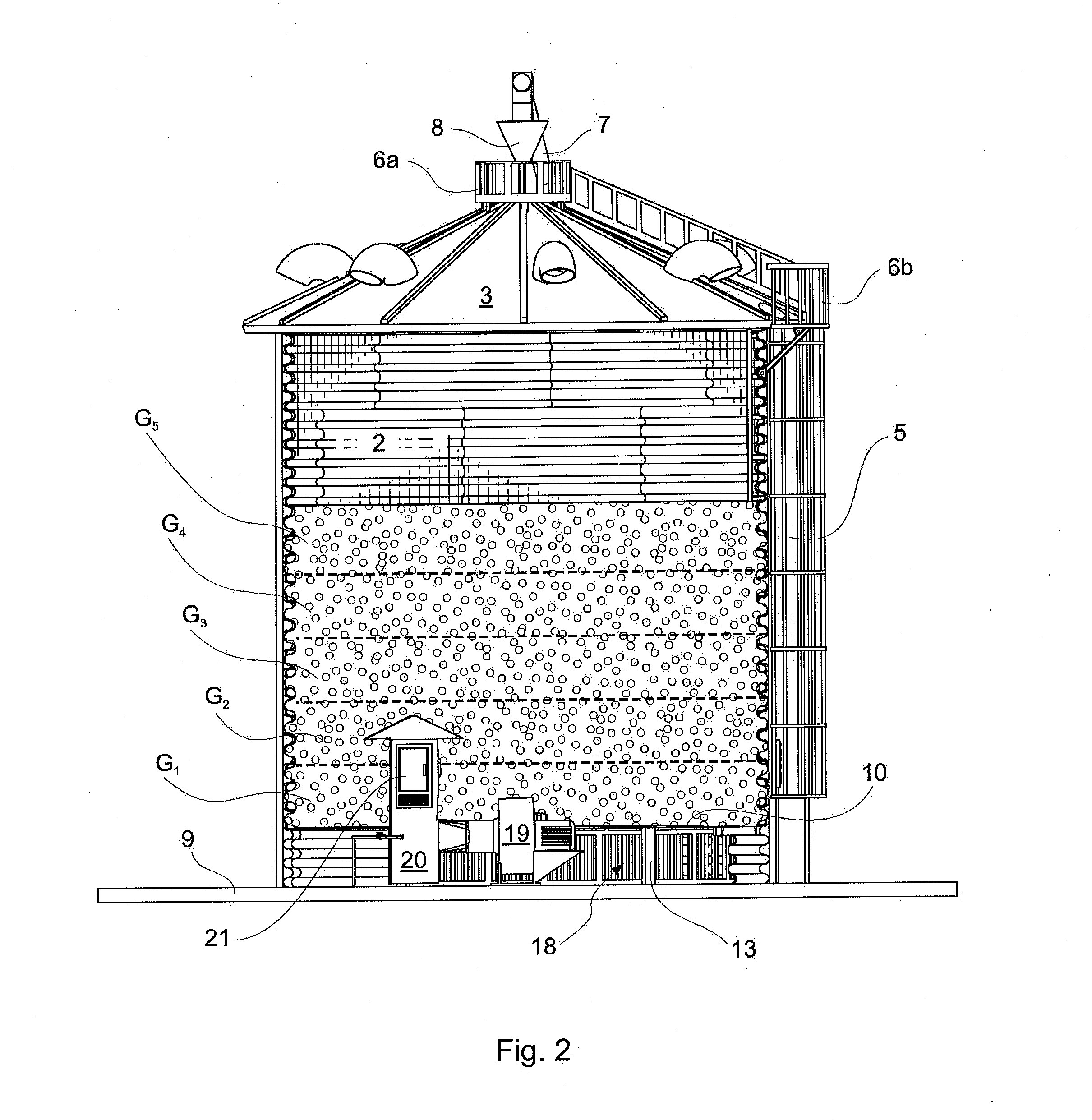

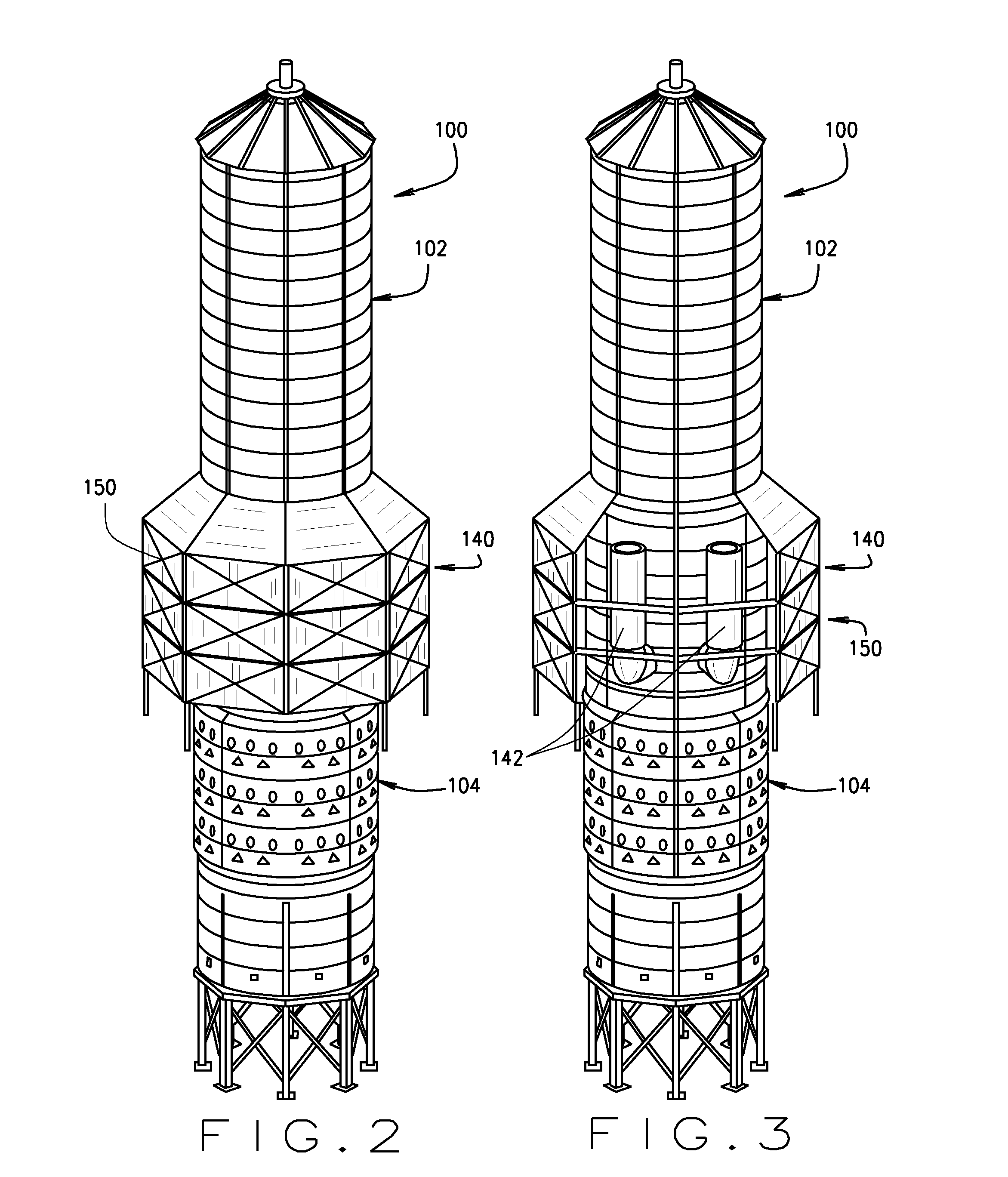

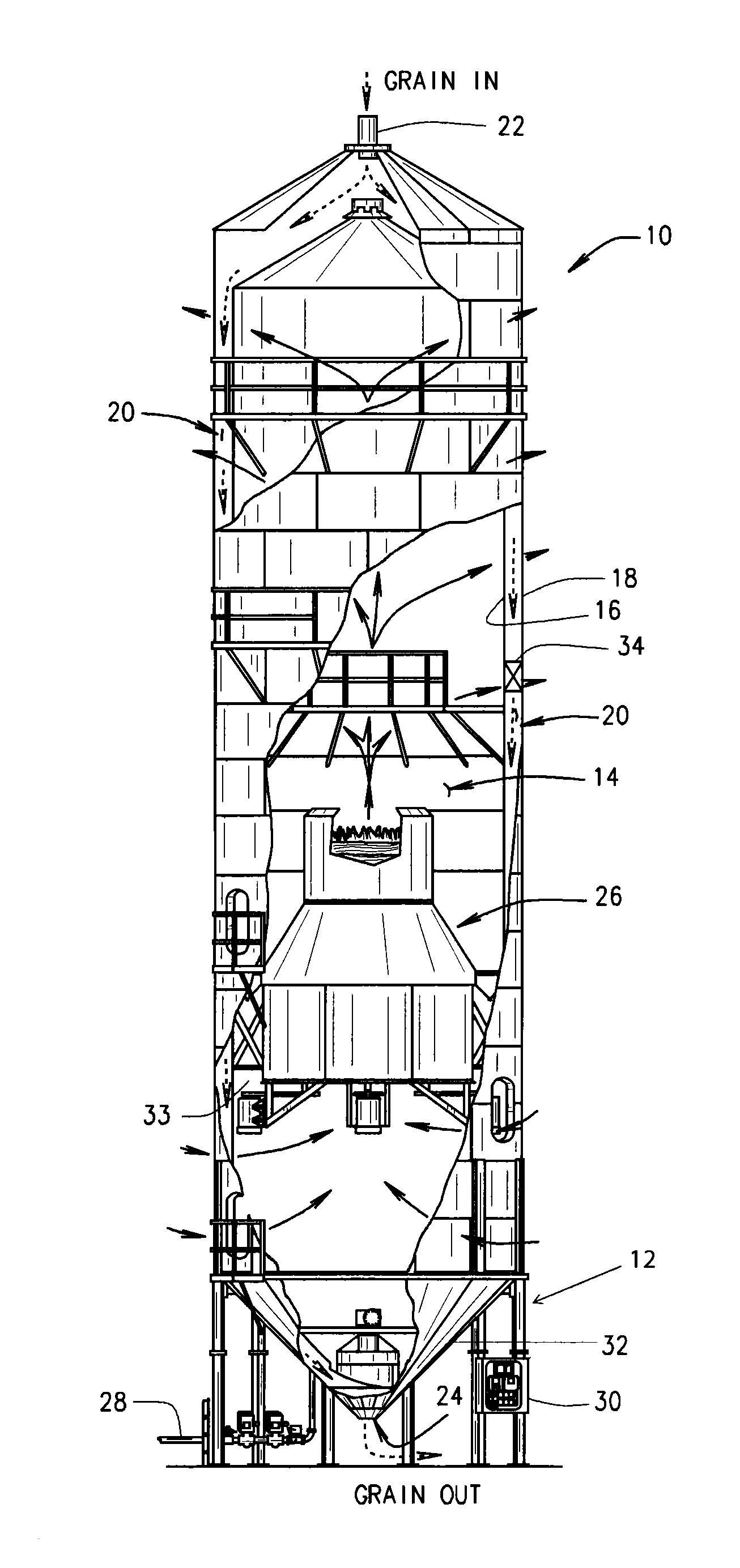

Grain drying aeration system

InactiveUS7568297B2Drying solid materials with heatDrying chambers/containersAeration systemWaste management

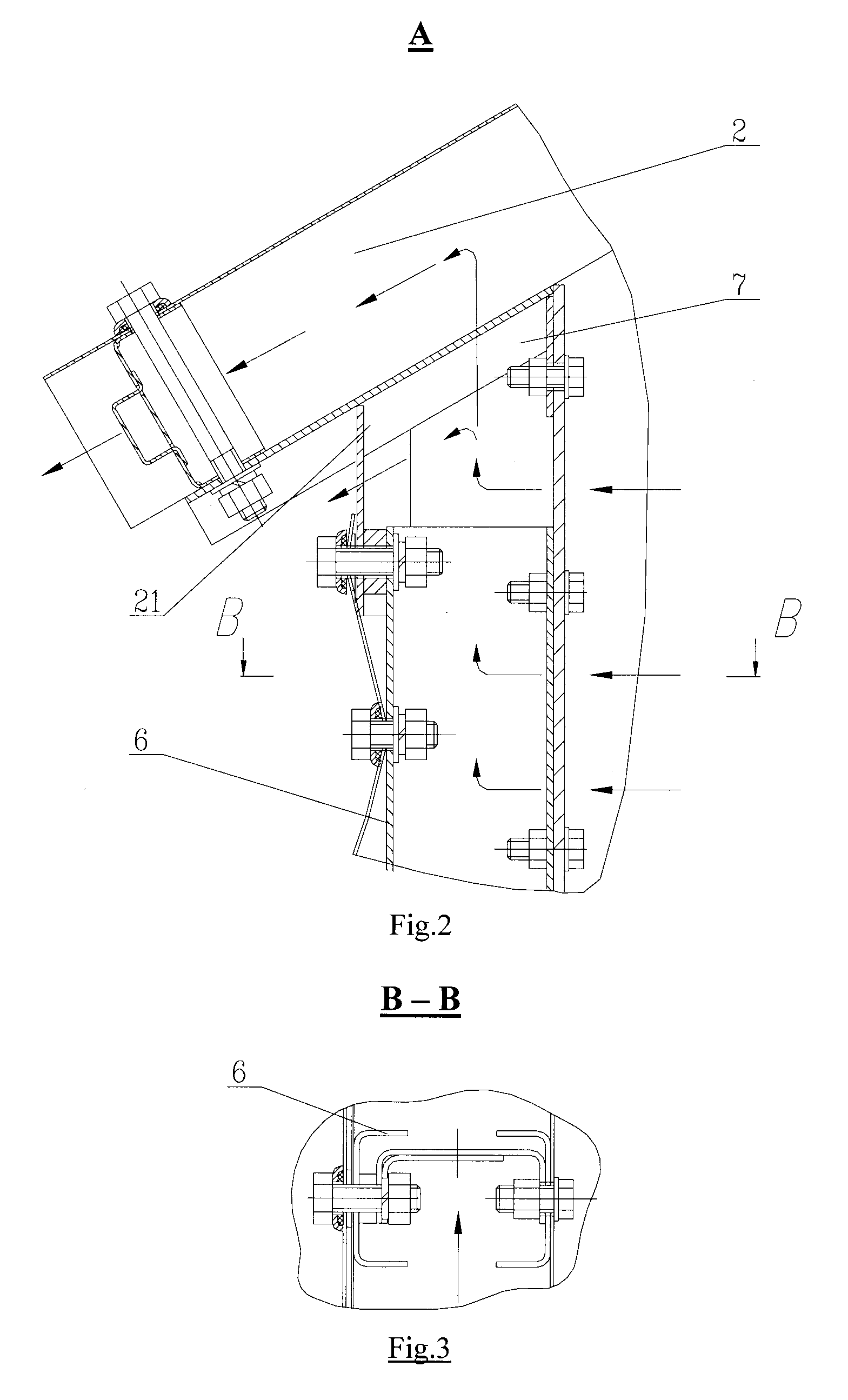

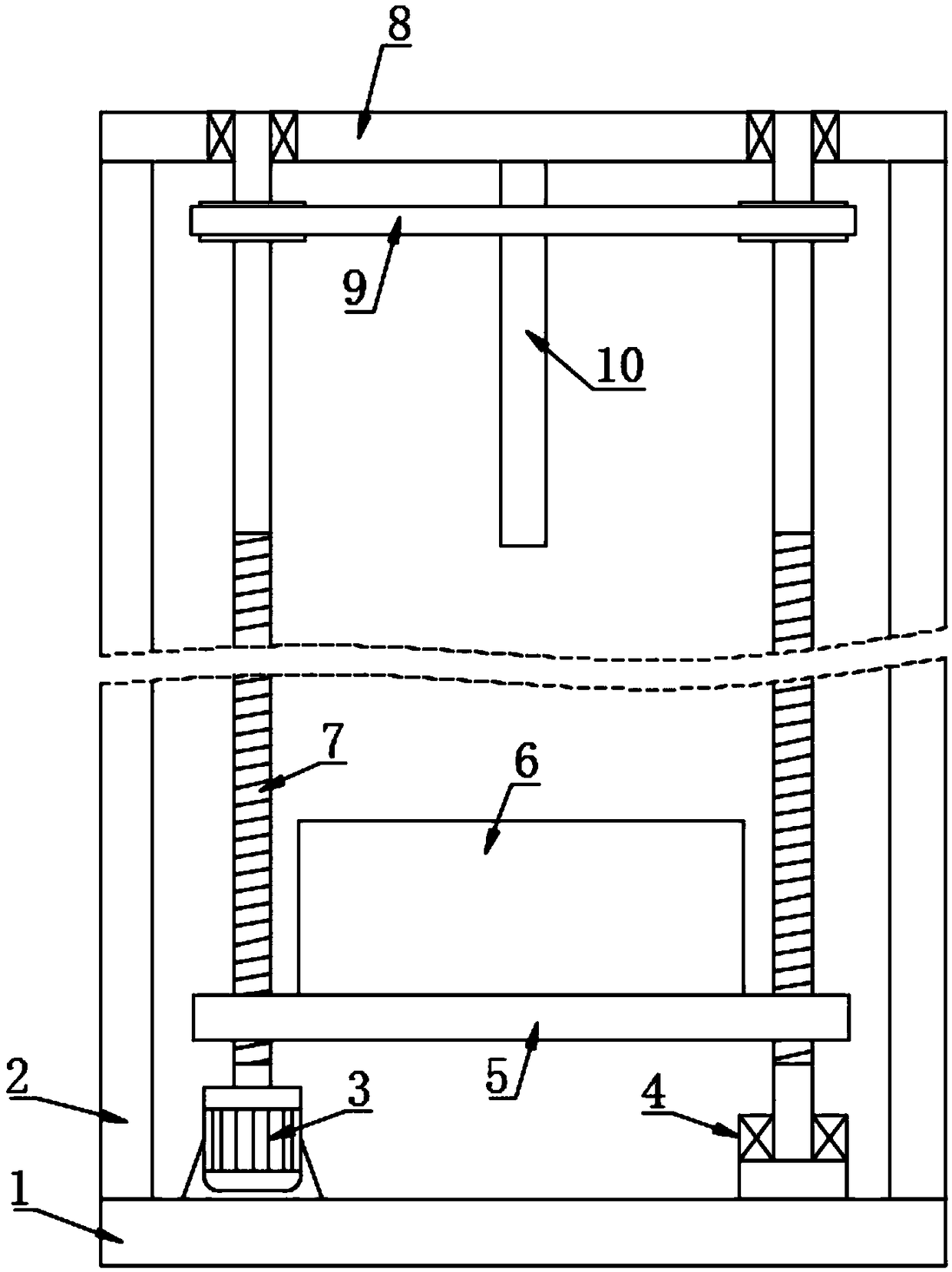

An improved vertical aeration system is provided for a grain bin having a sloped hopper bottom with a discharge opening. A pyramid frame includes legs with lower ends attachable to the hopper bottom. Concave perforated walls are attached to the legs. Braces extending between the legs provide structural support for the walls. An air duct extends upwardly and centrally into the interior of the frame, to supply air into the aeration system for flow outwardly through the perforated walls.

Owner:WOODHAVEN CAPITAL

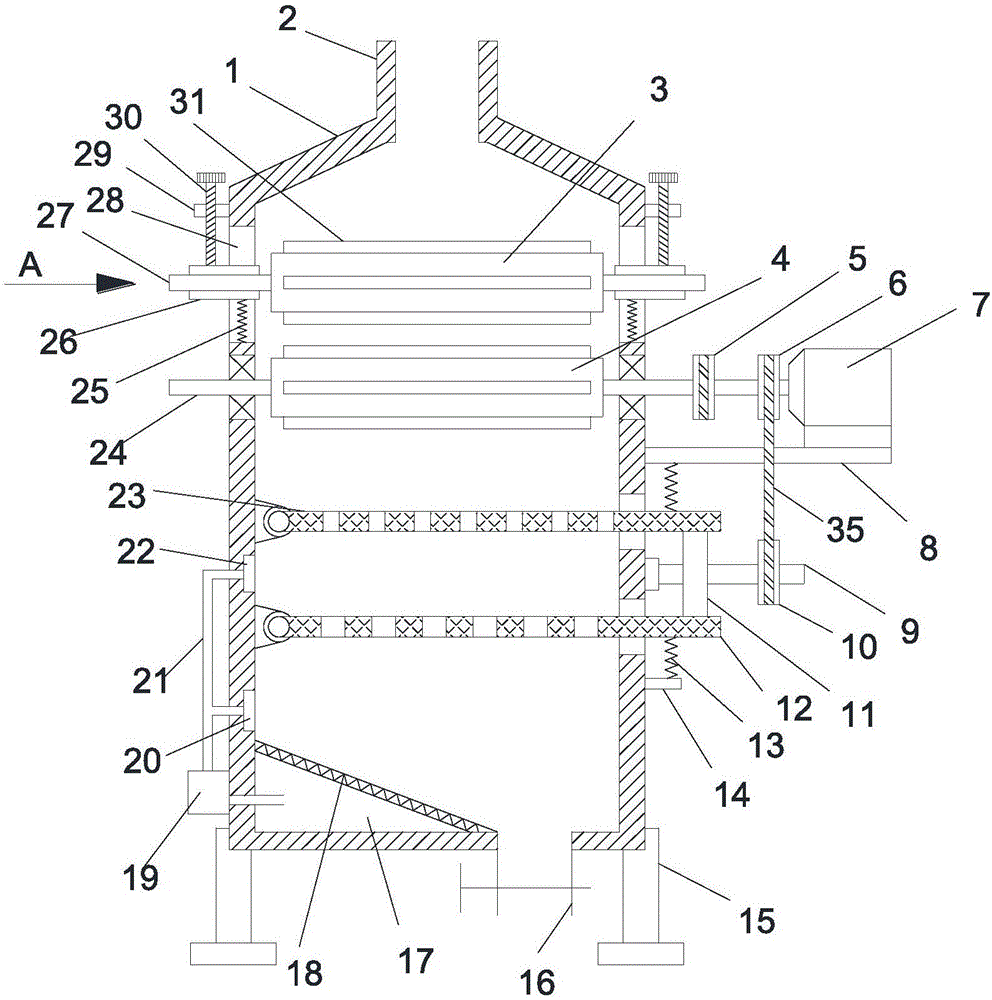

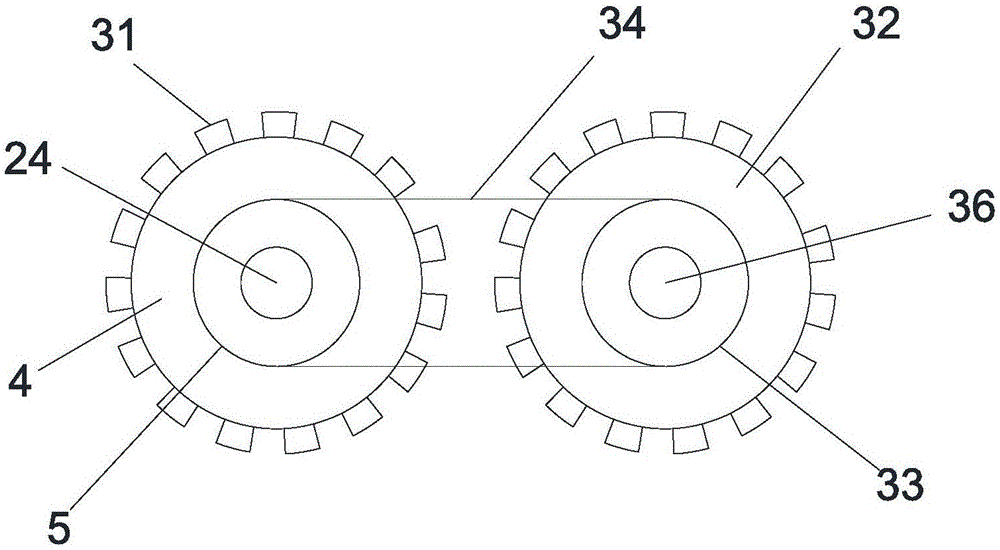

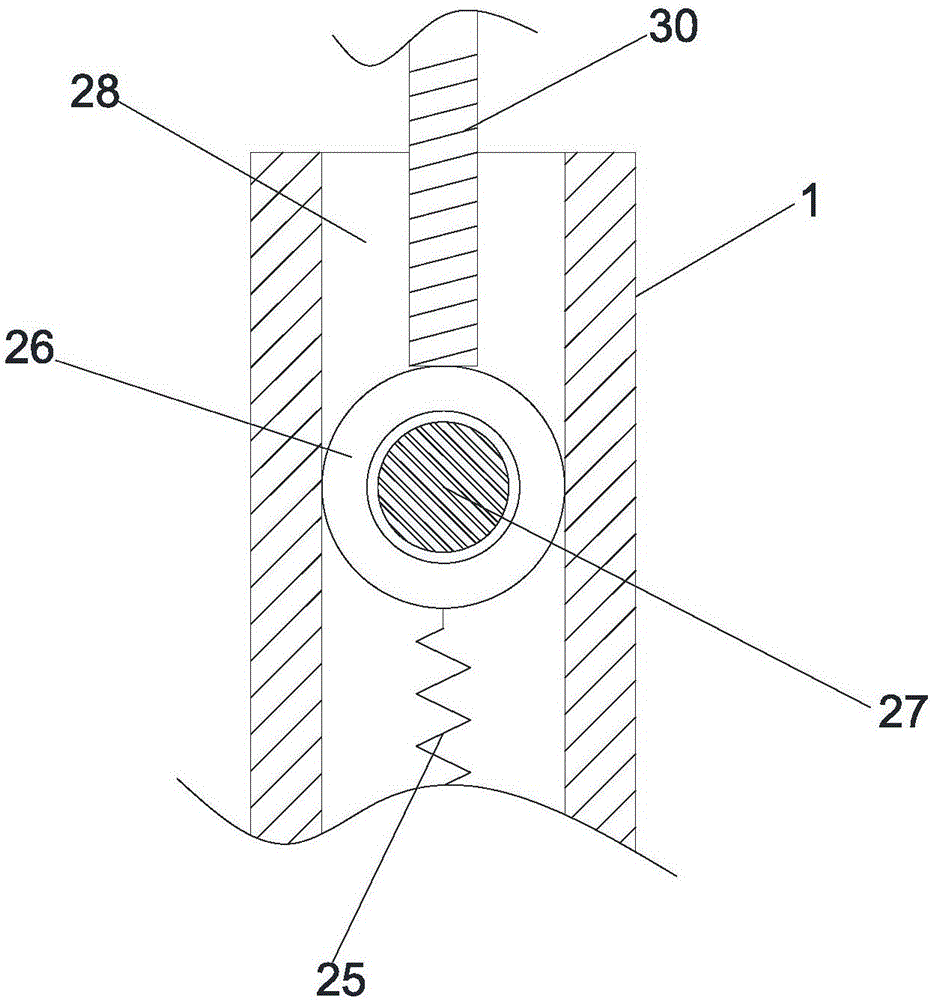

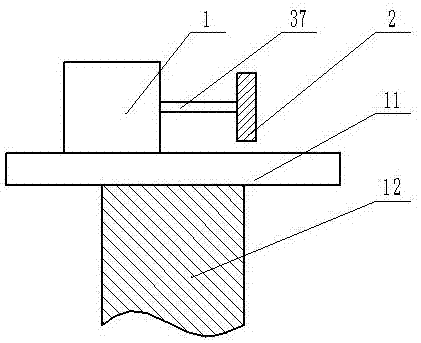

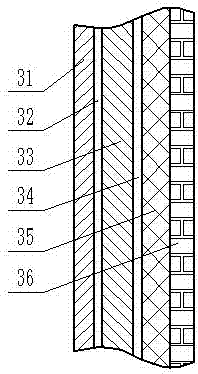

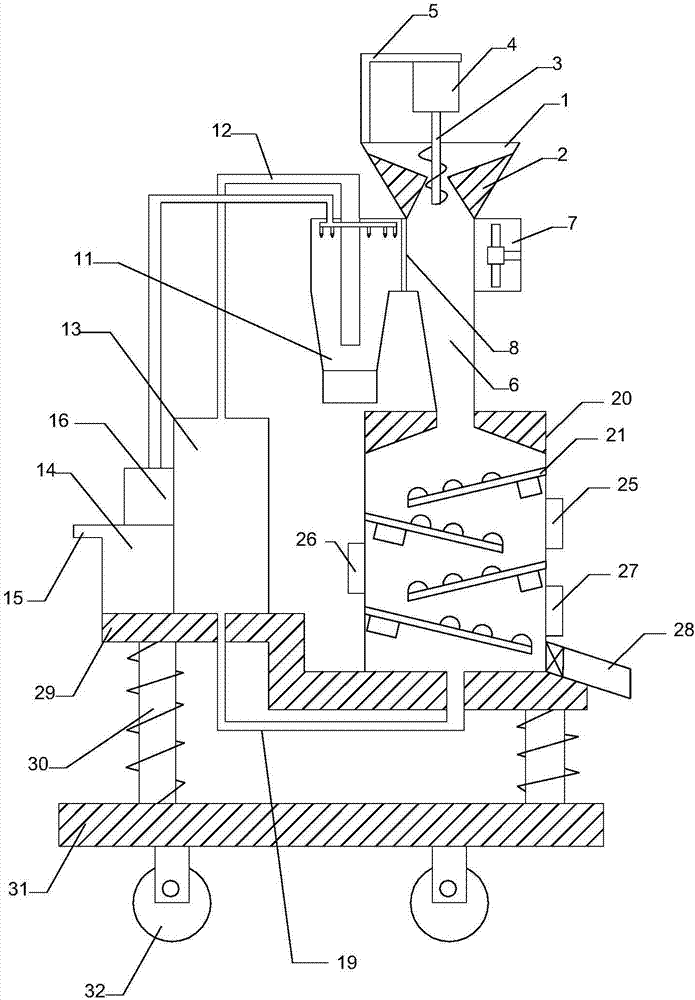

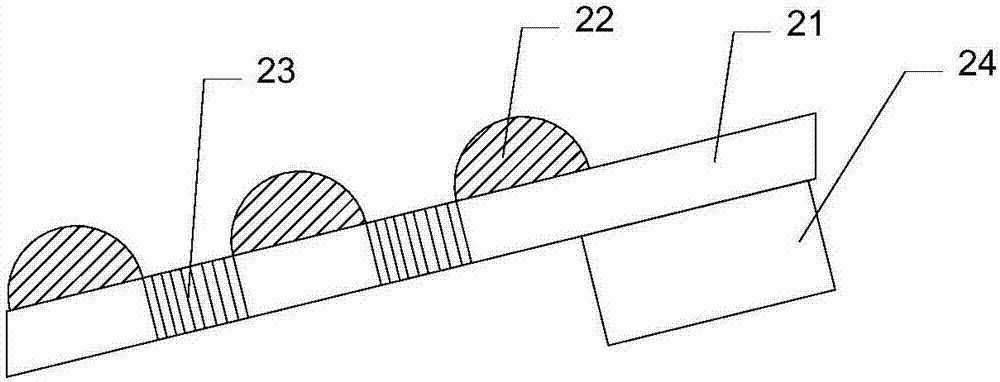

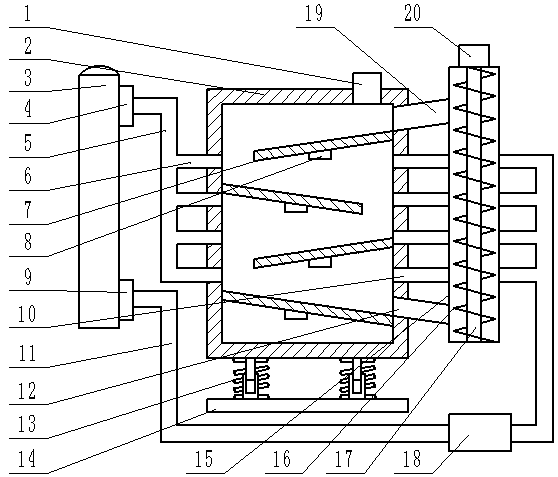

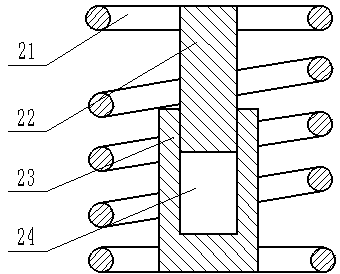

Rice hulling device with screening function

The invention discloses a rice hulling device with a screening function. The device comprises a hulling box; a feeding pipe is fixedly mounted at the top of the hulling box; a limiting plate is arranged on the side wall of the hulling box, and is in vertical threaded connection with a lead screw; a support plate is fixedly mounted on the right side wall of the hulling box; a driving motor is fixedly mounted on the support plate; a driven shaft parallel to a driving shaft is rotationally arranged in the hulling box; and a second driving belt wheel is fixedly mounted on the driving shaft. The device is convenient to hull and screen rice, low in workload and high in efficiency, rotationally hulls the rice through rotation of an adjusting pressure roller, a first hulling rotating roller and a second hulling rotating roller, greatly improves the rice hulling efficiency, and realizes quick hulling of the rice; and the up-down position of the adjusting pressure roller can be adjusted through a rotating lead screw, so that the position adjustment of the adjusting pressure roller and the first hulling rotating roller and the second hulling rotating roller is realized, the hulling extrusion acting force is increased, and the rice hulling is more thorough.

Owner:安徽林胜农业科技有限公司

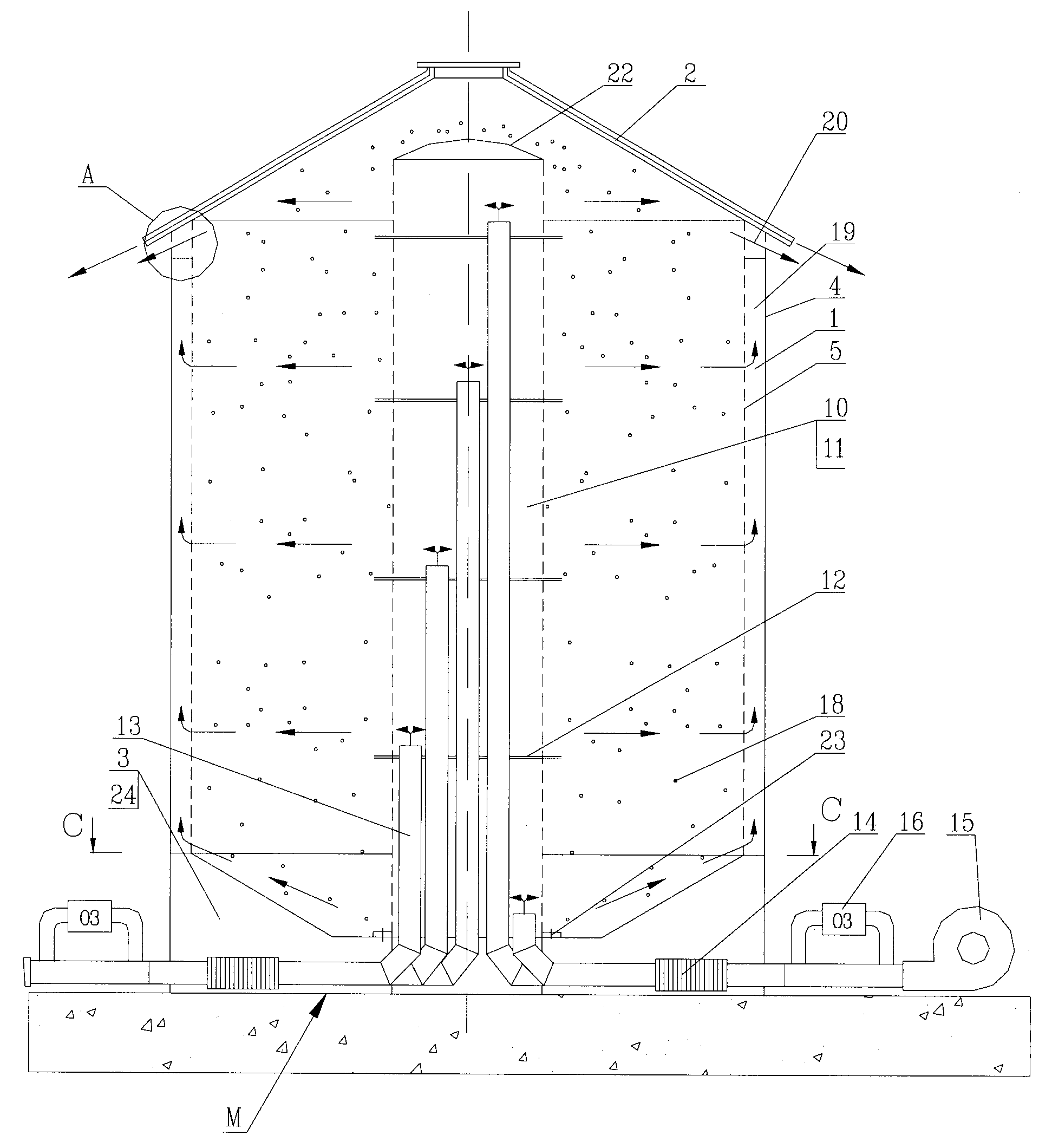

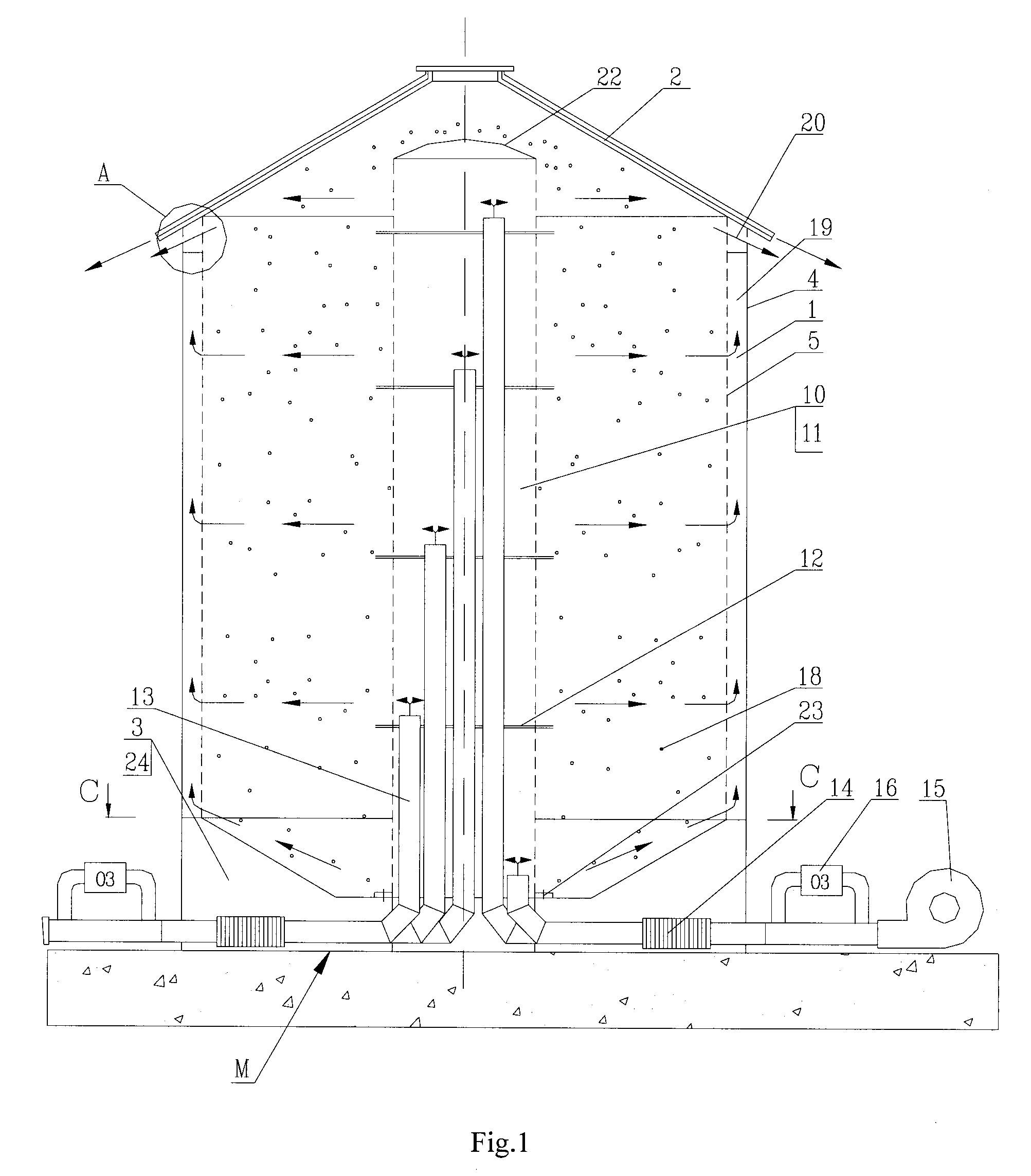

Method of Aeration Disinfecting and Drying Grain in Bulk and Pretreating Seeds and a Transverse Blow Silo Grain Dryer Therefor

ActiveUS20090191091A1Avoid disadvantagesQuality improvementDrying using combination processesDrying solid materials with heatDesiccantWater flow

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

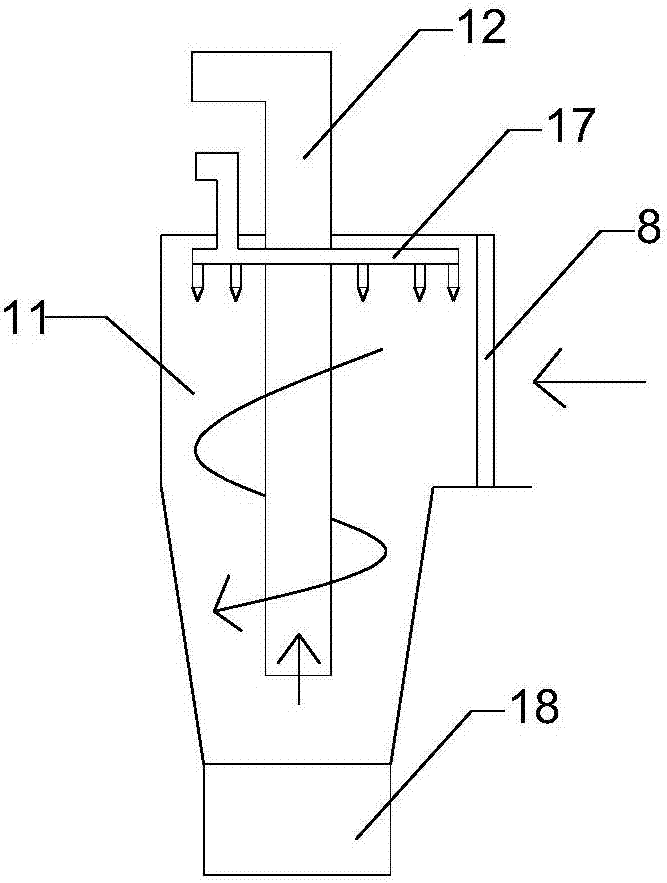

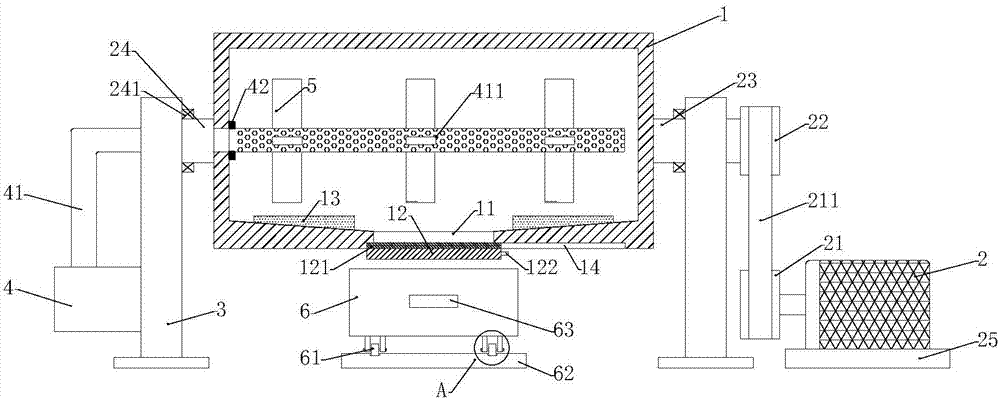

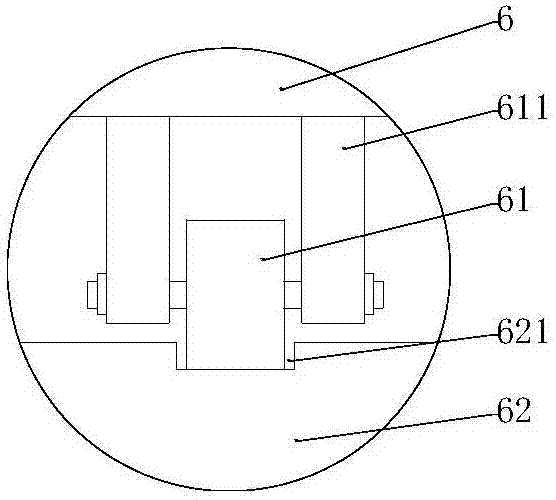

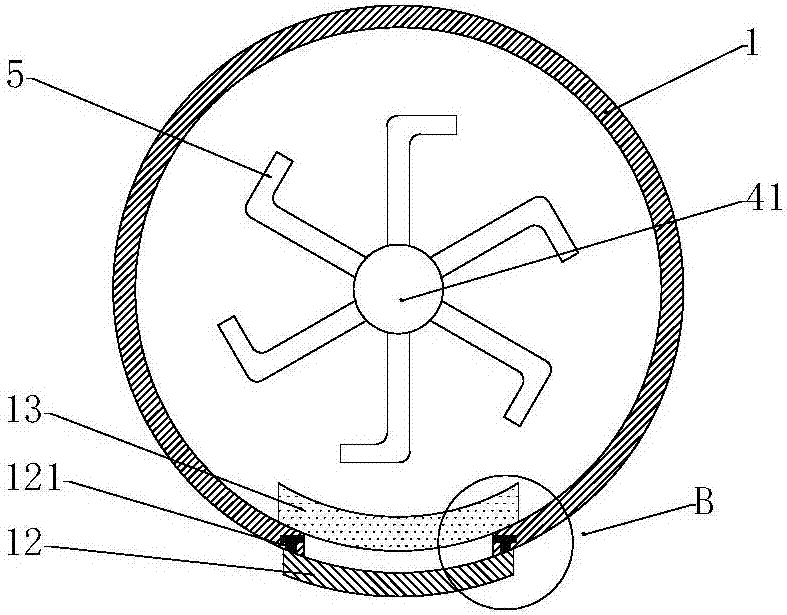

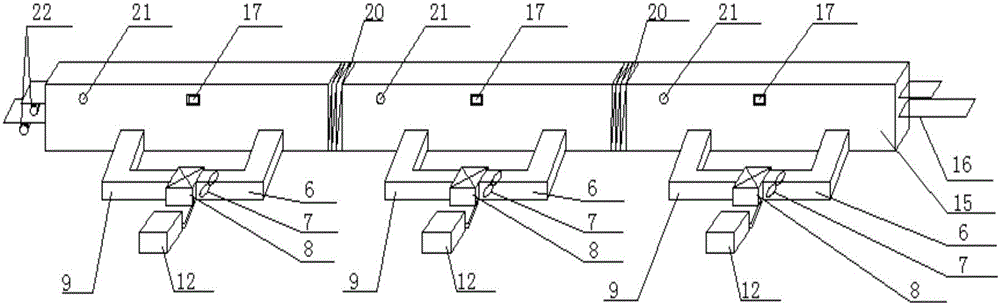

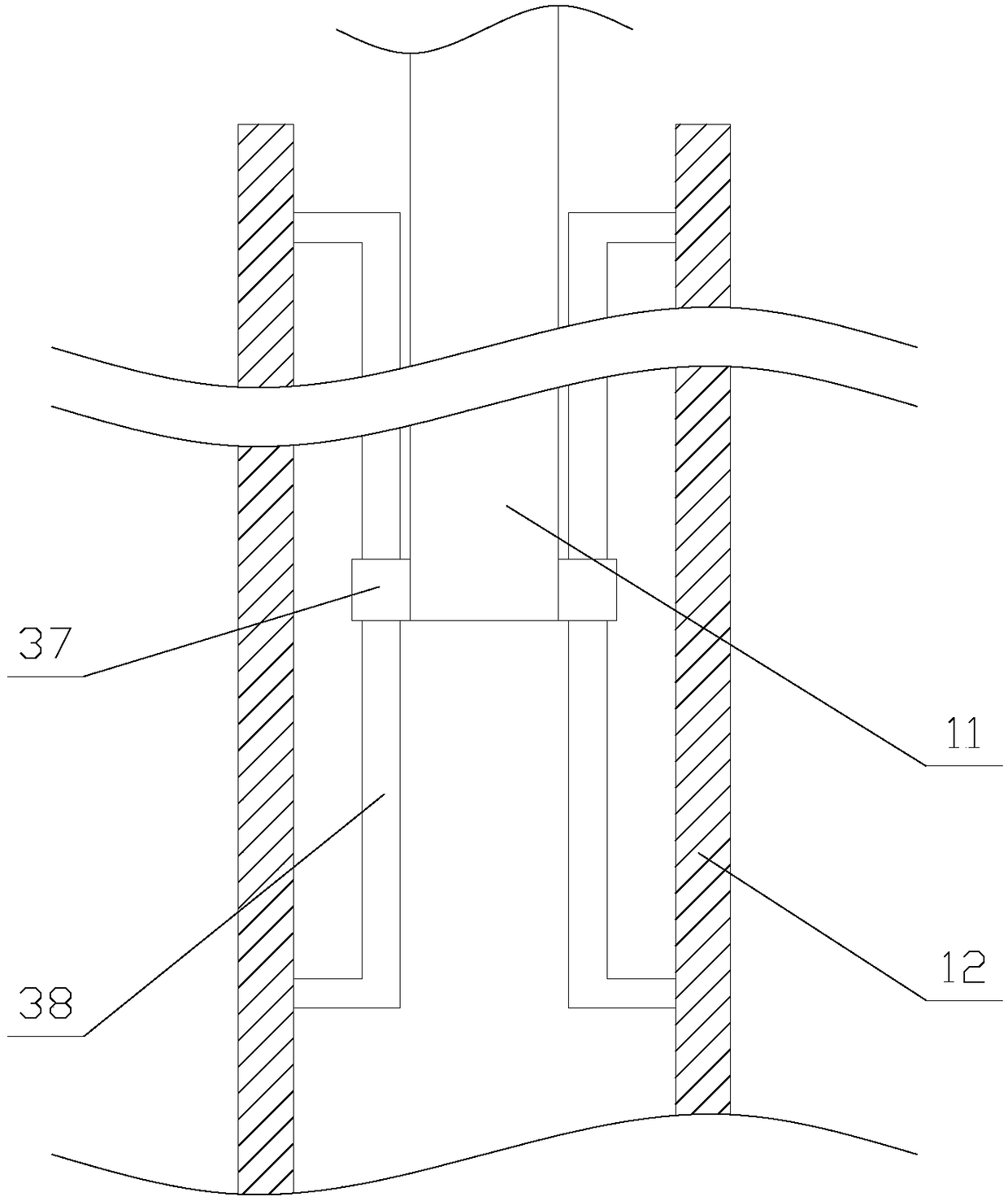

Stirring-type drying device for cereal

InactiveCN107484823AEfficient dryingImprove uniformityDrying gas arrangementsSeed preservation by dryingPulp and paper industryInjection air

The invention discloses a stirring type drying device for grain, which comprises a casing, an upper cover is provided on the upper end of the casing, and a feeding pipe, a rotating baffle, an agitating shaft, an air pump and a motor are arranged on the upper cover; There are stirring fan rods, stirring fan blades, and rotating bearings; the right wall of the housing is provided with a discharge pipe and a circulating air outlet pipe, the left wall of the housing is provided with a circulating air intake pipe, and the rear side of the housing is provided with an air pump. There are one-way air intake pipe, one-way air outlet pipe, piston block, electric push rod, heating pipe and inclined block on the top, and the bottom of the shell is provided with a support rod and a support base plate. The invention uses a hollow stirring shaft and a stirring fan rod to inject air to stir and dry the grain, cooperate with a heatable air extraction cylinder, circulate air extraction and air injection and heat the air at the same time, can promote the movement of the grain in the shell and remove water vapor, and improve drying efficiency.

Owner:石岩

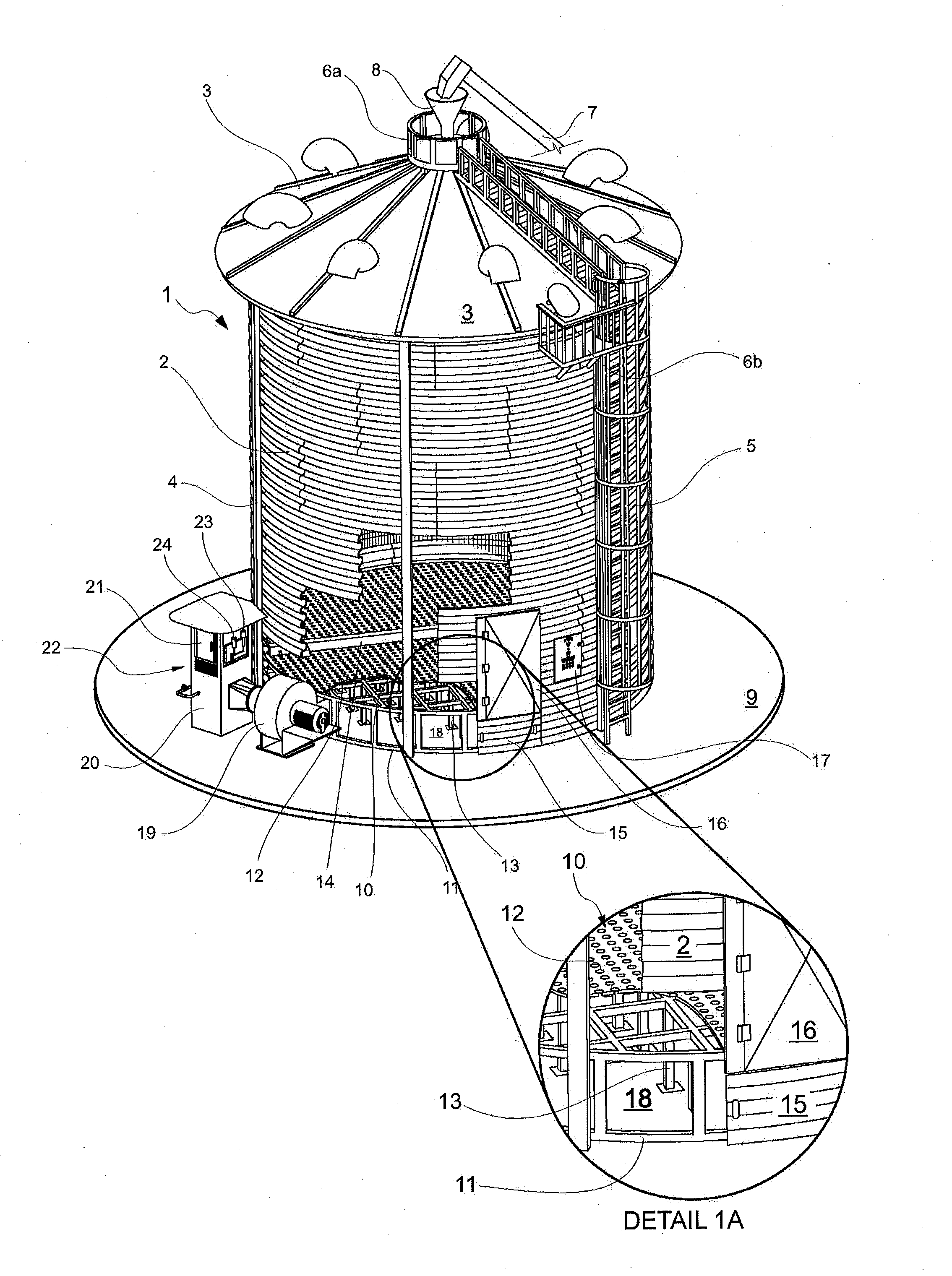

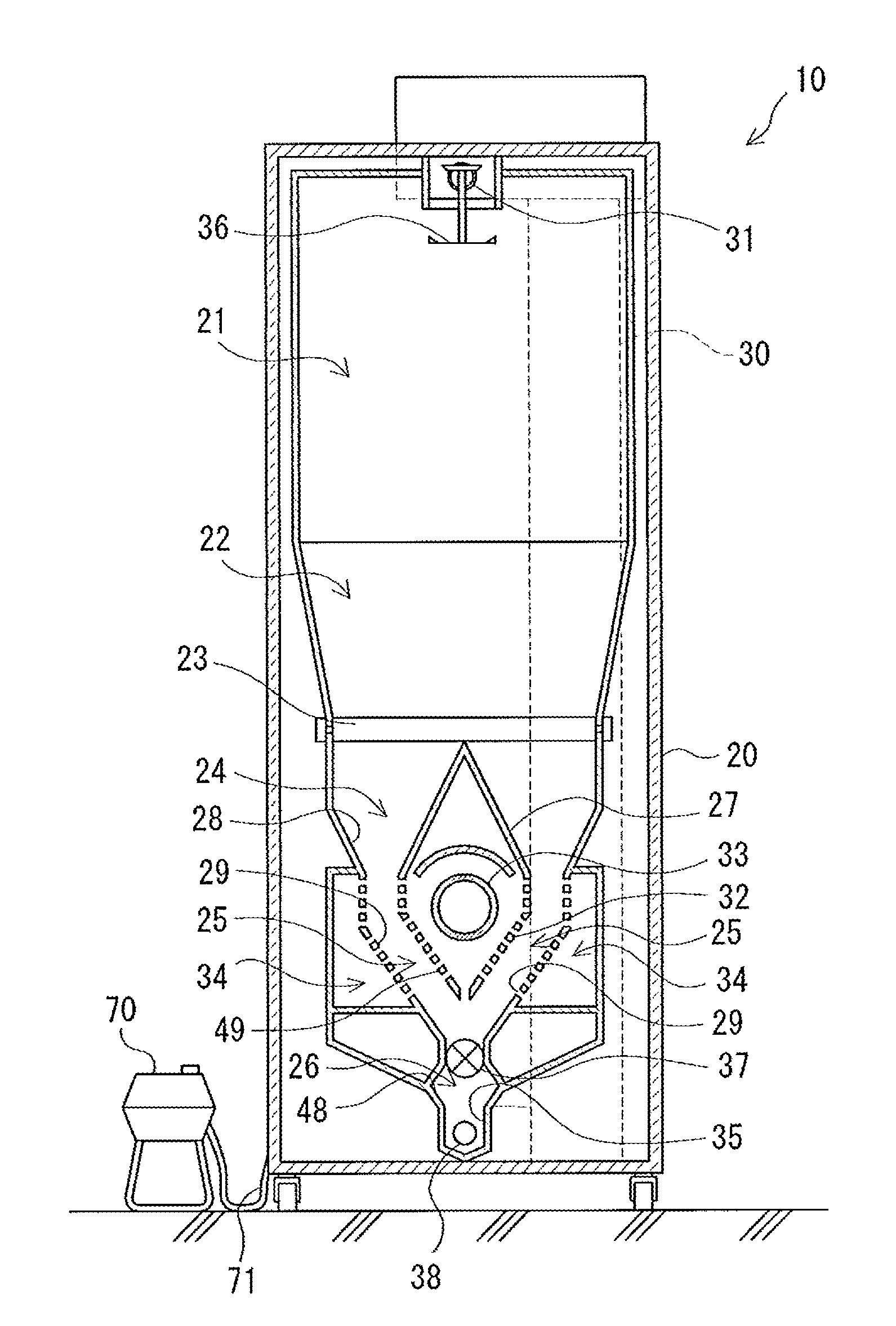

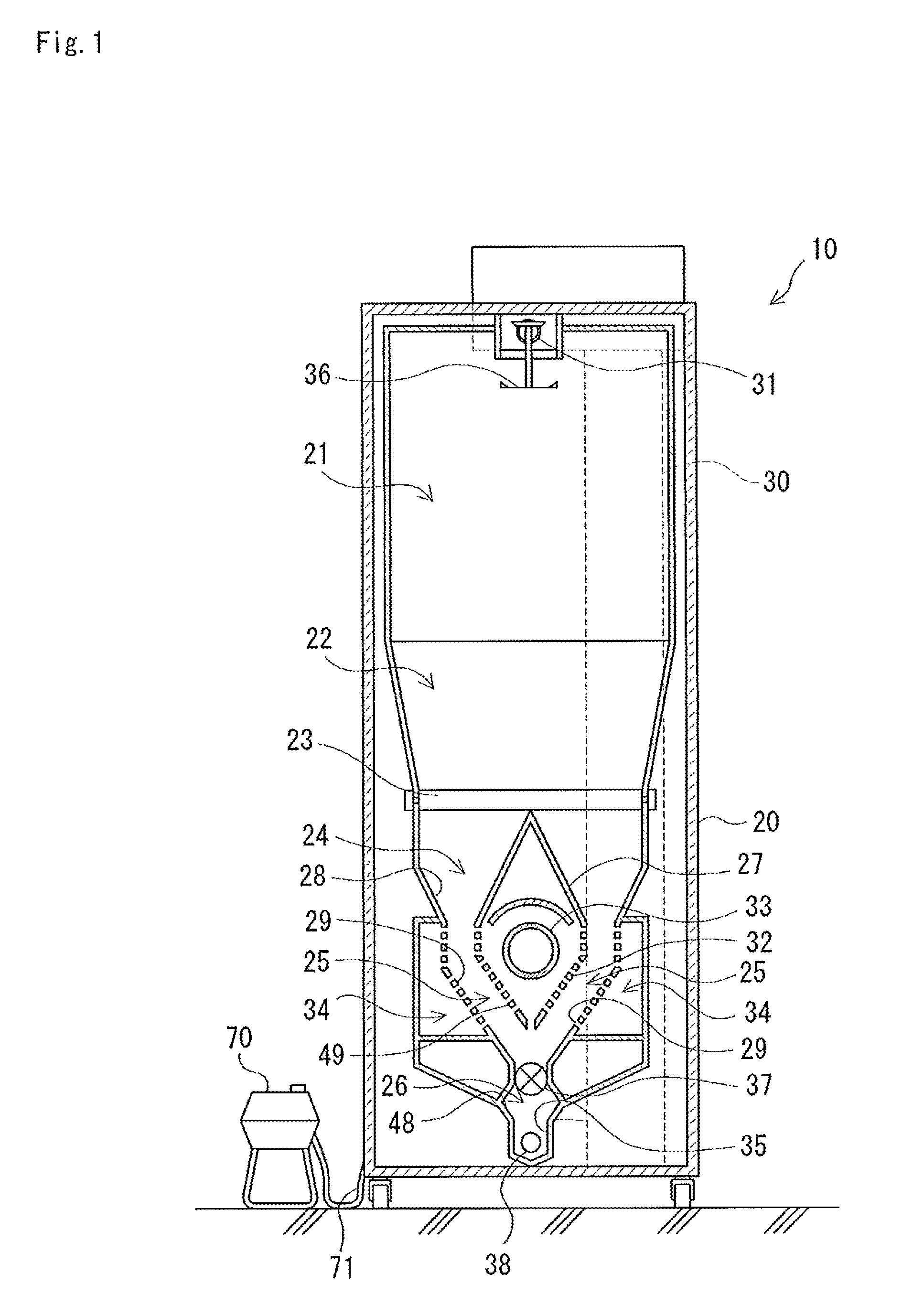

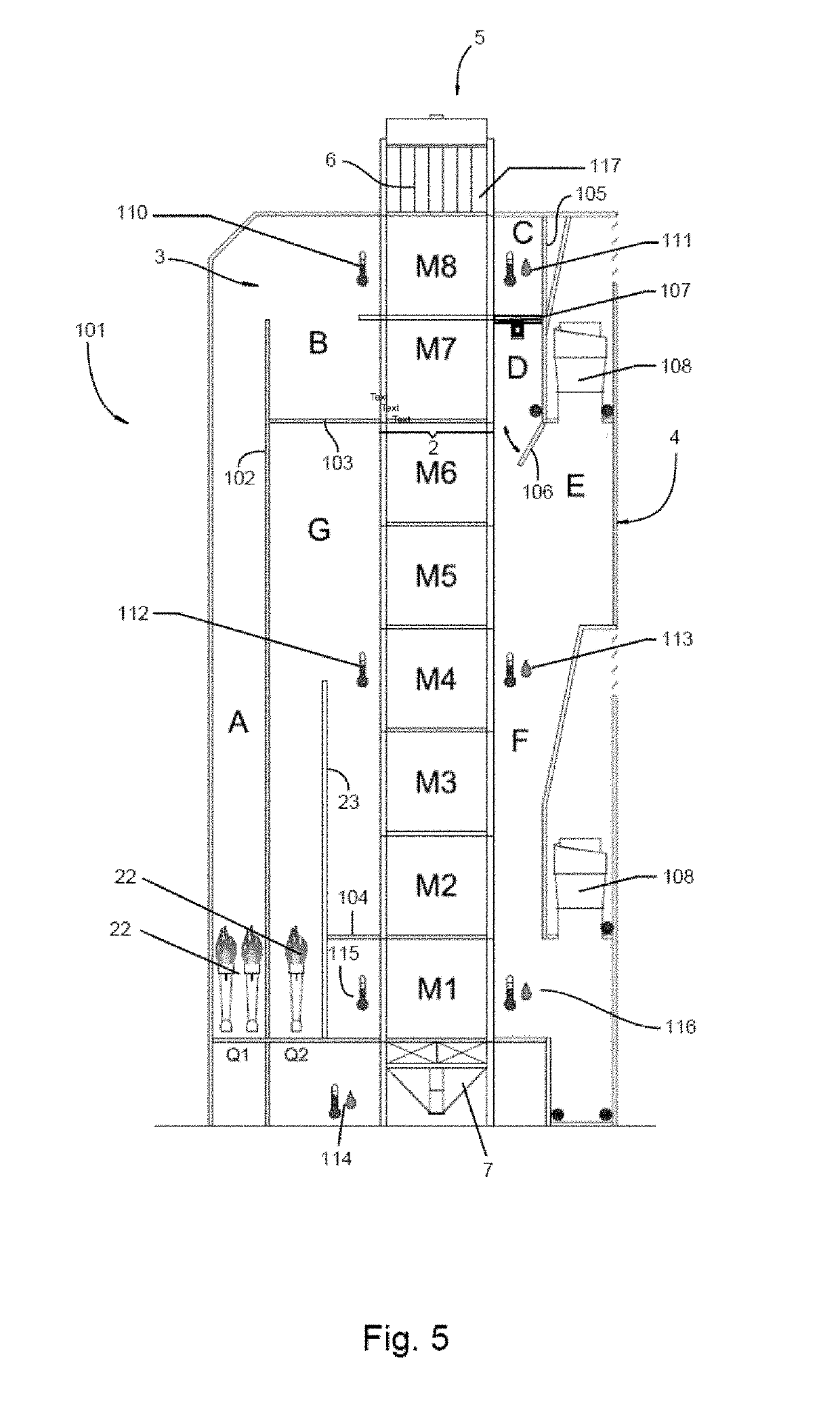

Procedure and facility for grain moisture control

ActiveUS20140360045A1The process is simple and effectiveEasy to set upAgriculture tools and machinesDrying solid materials with heatGrain storageEngineering

A facility for controlling the grain moisture provided with a grain storage silo conveniently installed on a hard flat floor and inside of which an elevated floor comprising air passageways is provided, determining an air chamber inside the silo and below the perforated floor, into which previously conditioned air is blown by an air heater, wherein the control of hot air blowing times is determined based on means of modeling and calculating on and off times applied through an electronic control means, with the ability to read and record manual input data entered by an operator and reading data from a temperature sensor in the air chamber, below the perforated floor, further aided with an ambient temperature and moisture sensor, thereby causing the application of different stages of drying, re-humidification and maintenance of the grain moisture.

Owner:INST NACIONAL DE TECNOLOGIA AGROPECUARIA

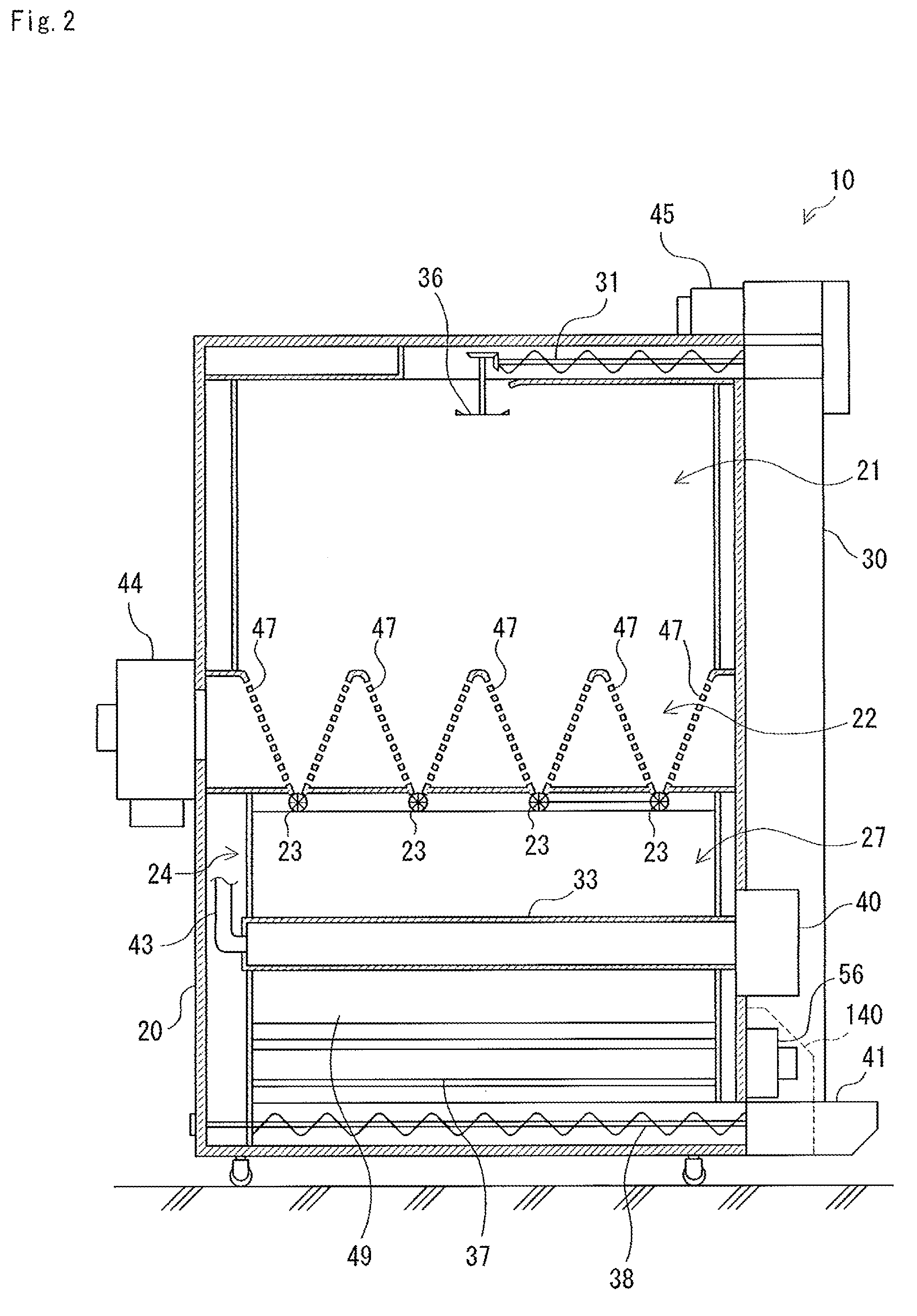

Nutrition-enriched gain manufacturing apparatus and gain drying facility including the same

InactiveUS20120066924A1Enrich a content of gamma aminobutyric acid in grain easily and efficientlyMilk preservationDrying solid materials with heatCombustorRotary valve

A nutrition-enriched grain manufacturing apparatus includes a heating processing portion including a far infrared ray radiator which emits far infrared rays to a flow-down path along which grain flows down, an upper rotary valve device and a lower rotary valve device which adjust a flow rate of the grain, an accumulation portion which accumulates the grain, a lower screw conveyer and a bucket conveyer which transport the grain which has flown down from the heating processing portion to the discharge portion to the accumulation portion, a moisture meter which measures a moisture content of the grain, a grain temperature sensor which measures a grain temperature, a main controller which controls output from a burner and operations of the upper rotary valve device and the lower rotary valve device such that the grain temperature is a predetermined grain temperature.

Owner:ANDO TOSHIHARU +1

Corn thresher with drying and screening functions

The invention discloses a corn thresher with drying and screening. B. Driven pulley, heating plate, belt, elastic telescopic rod, filling door, filling hopper, motor B, driving pulley, filter screen, air outlet pipe, threshing rod, roller, threshing box, sorting plate, roller , slide rail, corn collection box, cob core collection box, and material retrieving door; the invention adds a heating plate before threshing, which can dry corn cobs, facilitate threshing, and has a sorting board after threshing, which can sort out Corn kernels with different diameters can be used in different categories. There is a shell outside the threshing device, which can effectively reduce dust entering the atmosphere, protect the environment and prevent operators from absorbing a large amount of dust.

Owner:惠安益源信息技术咨询有限公司

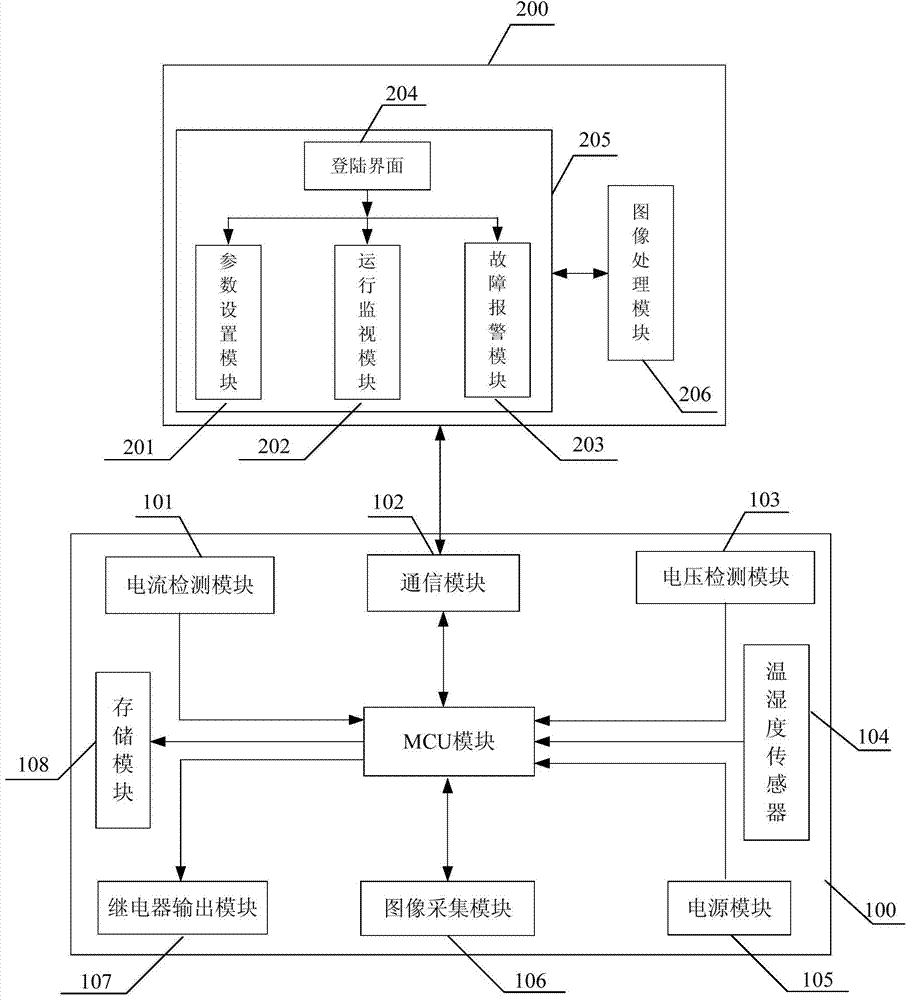

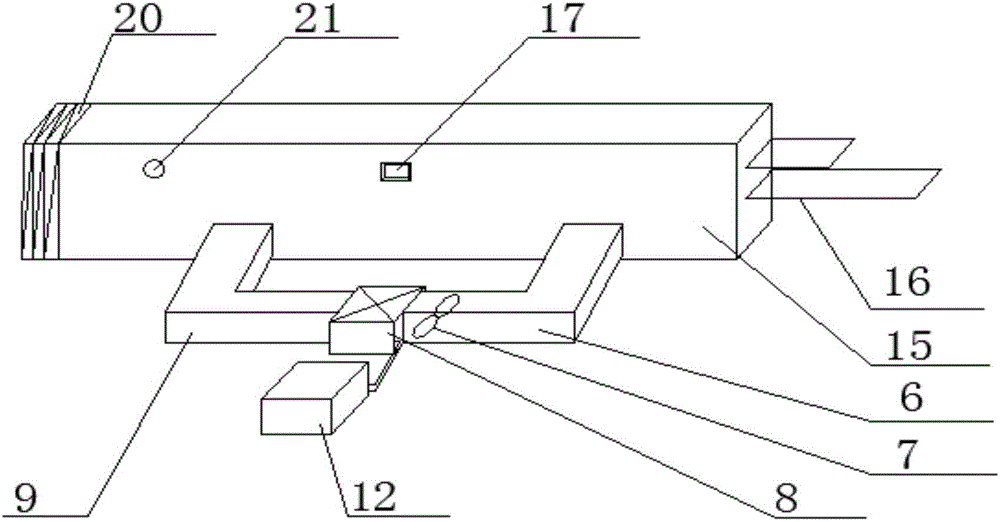

Heat pump drying controller for crop drying and control method thereof

ActiveCN104729174APrecise temperature adjustmentPrecisely regulate humidityDrying gas arrangementsDrying solid materialsNutritive valuesHuman–machine interface

The invention discloses a heat pump drying controller for crop drying and a control method thereof. The heat pump drying controller for crop drying comprises a control panel and an upper computer system. The upper computer system comprises a human-computer interface and an image processing module. The three-section variable temperature cyclic drying process is adopted for a controller. After an operator selects a required drying mode on the upper computer system according to the initial conditions of crops, the controller automatically controls the drying process of materials; meanwhile, the upper computer system monitors and records the system running conditions; the controller samples images of the materials through an industrial camera in real time in the drying process and slightly adjusts the drying mode according to the processing results of the material images. The heat pump drying controller for crop drying realizes the heat pump automatic crop drying technology and can guarantee the appearance quality and the nutritive value of the dried crops; the controller is reliable in operation; the quality of the dried materials is stable; the system drying efficiency is high, energy consumption is low, manual intervention is not needed, the drying cost is lowered, no pollutant emission and no noise pollution happen in the drying process.

Owner:河北省机电一体化中试基地有限公司

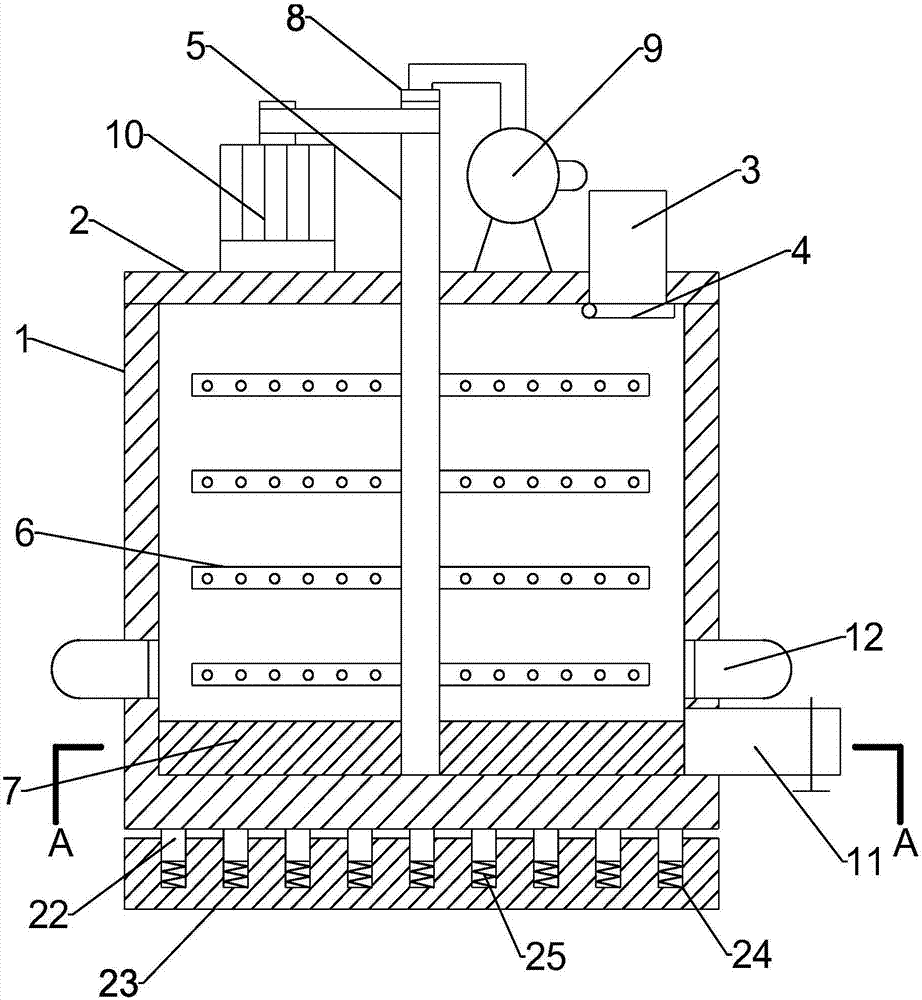

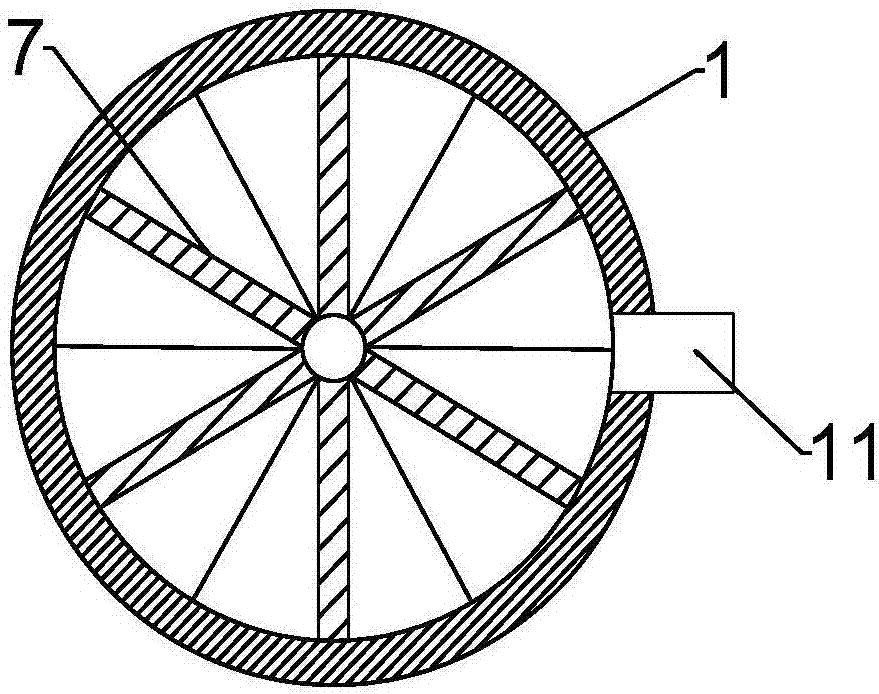

Self-vibrating grain drying and sieving equipment

InactiveCN107339878AImprove the vibration effectPrevent fallingSievingScreeningEngineeringVacuum pump

The invention discloses self-vibrating grain drying and sieving equipment. The equipment comprises a shell, a support and a condensation chamber; the support is arranged outside the shell, sliding blocks are fixedly connected to the middle of the outside of the shell, sliding grooves are formed in both sides of the support, and the sliding blocks are connected with the sliding grooves in a sliding mode; connecting plates are arranged at the upper ends of the sliding grooves, the connecting plates are fixedly connected with the support, and floating devices are arranged between the connecting plates and the sliding blocks; a first sieving net and a second sieving net are fixedly connected to the inner side wall of the shell from top to bottom in sequence, a dehumidification pipe is arranged at the upper end of the shell, a vacuum pump is connected to the middle of the dehumidification pipe, one end of the dehumidification pipe is communicated with the interior of the shell, and the other end of the dehumidification pipe is connected with a condensation pipe in the condensation chamber. According to the self-vibrating grain drying and sieving equipment, the structure is simple, the design is reasonable, sieving of grain is completed through self-vibrating of the shell, and the sieving quality and efficiency are improved; meanwhile, drying equipment is added, the functionality of the device is enhanced, and rapid dehumidification can be conducted, so that the drying efficiency is improved.

Owner:俞纪洪

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

Cereal circular drying equipment

InactiveCN107687757AAvoid accumulationImprove drying qualityDrying gas arrangementsSeed preservation by dryingEngineeringHot blast

The invention discloses cereal circular drying equipment. The cereal circular drying equipment comprises a box body, a hot-blast stove and a lifting drum. A plurality of guide plates are arranged in the box body; the box body communicates to the lifting drum through a discharge pipe and a feeding pipe; a bottom plate is arranged below the box body; a plurality of damping devices are arranged between the bottom plate and the bottom surface of the box body; a plurality of air inlet branch pipes are uniformly arranged on the outer side wall of the left end of the box body; the air inlet branch pipes are connected to the air outlet of the hot blast stove through a main air inlet pipe; a plurality of air outlet branch pipes are uniformly arranged on the outer side wall of the right side of thebox body and are connected to the air inlet of the hot blast stove through a main air outlet pipe; the main air outlet pipe is connected to a dedusting and dehumidifying device; and the dedusting anddehumidifying device comprises a barrel. The cereal circular drying equipment disclosed by the invention is simple in structure and reasonable in design, can utilize human energy to the maximum extentby means of circulating air, and is very high in drying efficiency on cereals, and furthermore, the drying quality of cereals is very good and the dehydrating rate is very high.

Owner:俞纪洪

Efficient grain drying device capable of achieving feeding easily

InactiveCN106979674AFully contactedGuaranteed drying effectDrying gas arrangementsSeed preservation by dryingAgricultural engineeringStacker

The invention discloses a high-efficiency and easy-to-cut grain drying device, which includes a drying cylinder, a motor, symmetrically arranged support columns, a hot air blower and a material receiving frame; the drying cylinder is arranged between two support columns; The center position of the bottom of the drying cylinder is provided with a discharge opening, and a cover plate is arranged on the discharge opening, and the bottom of the drying cylinder is located on both sides of the discharge opening, and counterweights are fixed symmetrically; the hot air blower is installed on the left side On the supporting column, the hot air blower is connected to the hot air pipe, and the hot air pipe runs through the connecting shaft from the axis of the connecting shaft and goes deep into the right side of the drying cylinder. The hot air pipe is densely provided with air outlets; the hot air pipe is deeply dried A plurality of turning plates are fixed on the periphery of the tube body of the cylinder; a material receiving frame is arranged at the position directly facing the discharge opening under the drying cylinder. The grain drying device of the present invention has good drying effect and is convenient for unloading.

Owner:合肥智慧殿机械设计有限公司

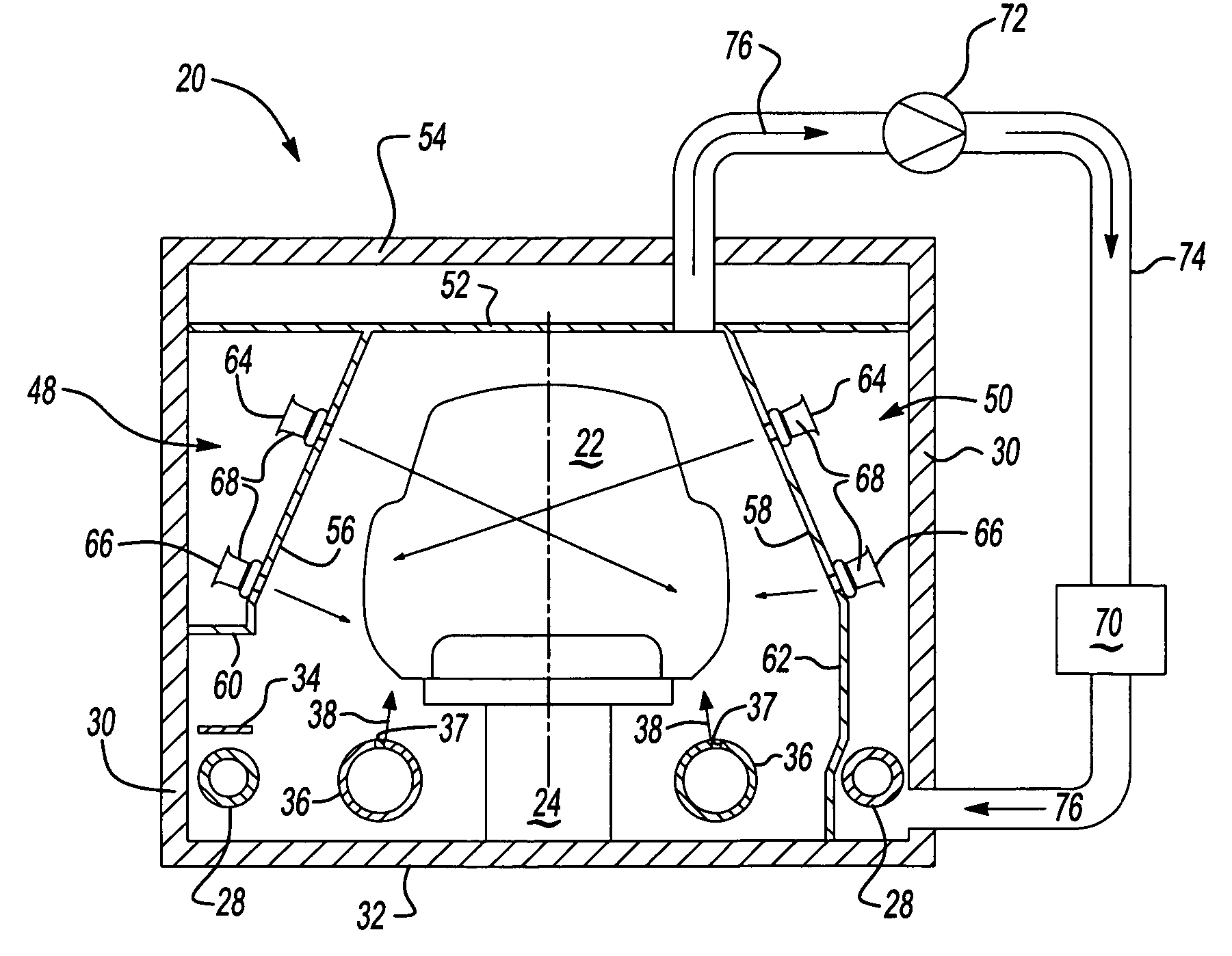

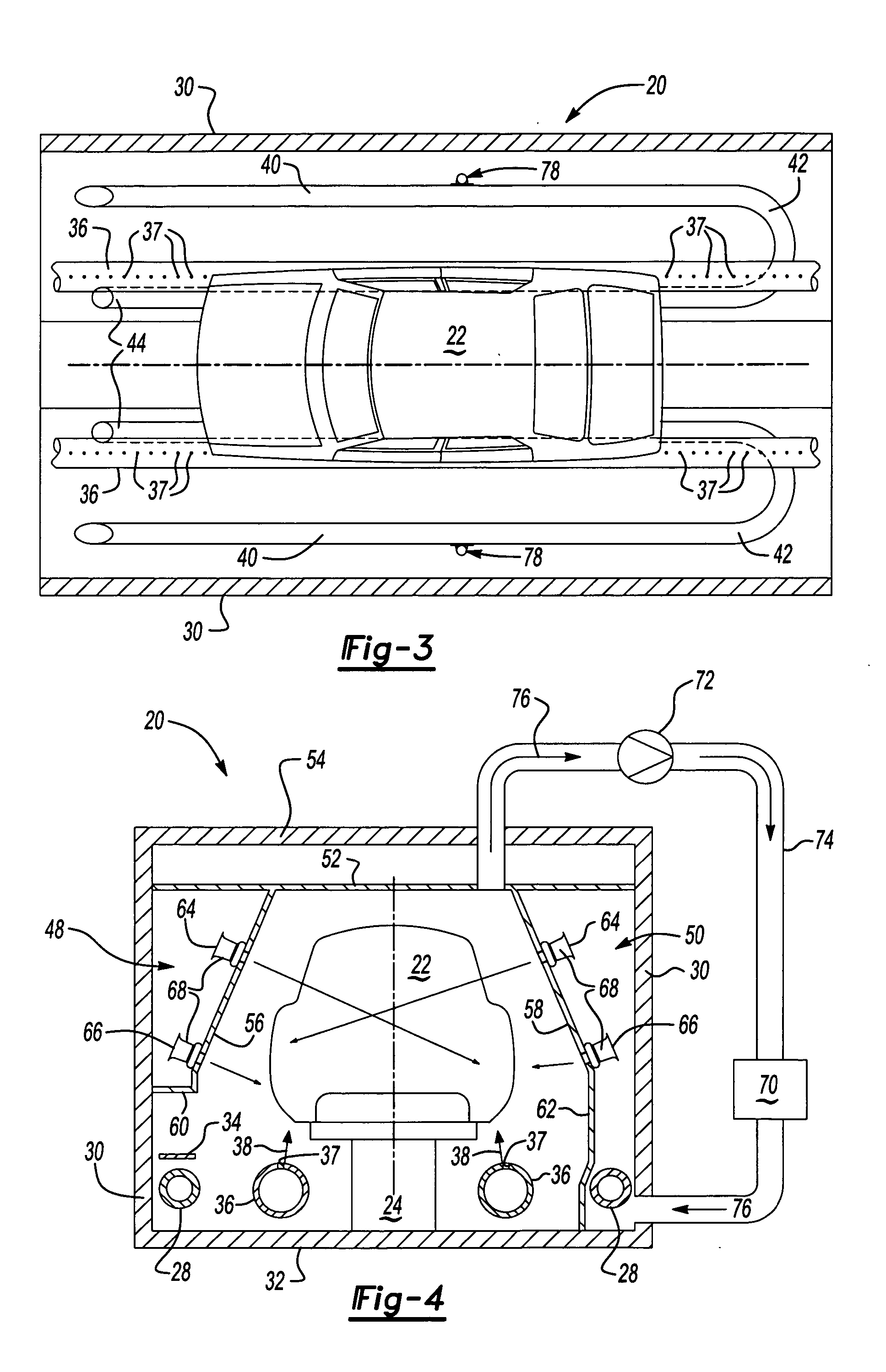

Radiant tube and convection oven

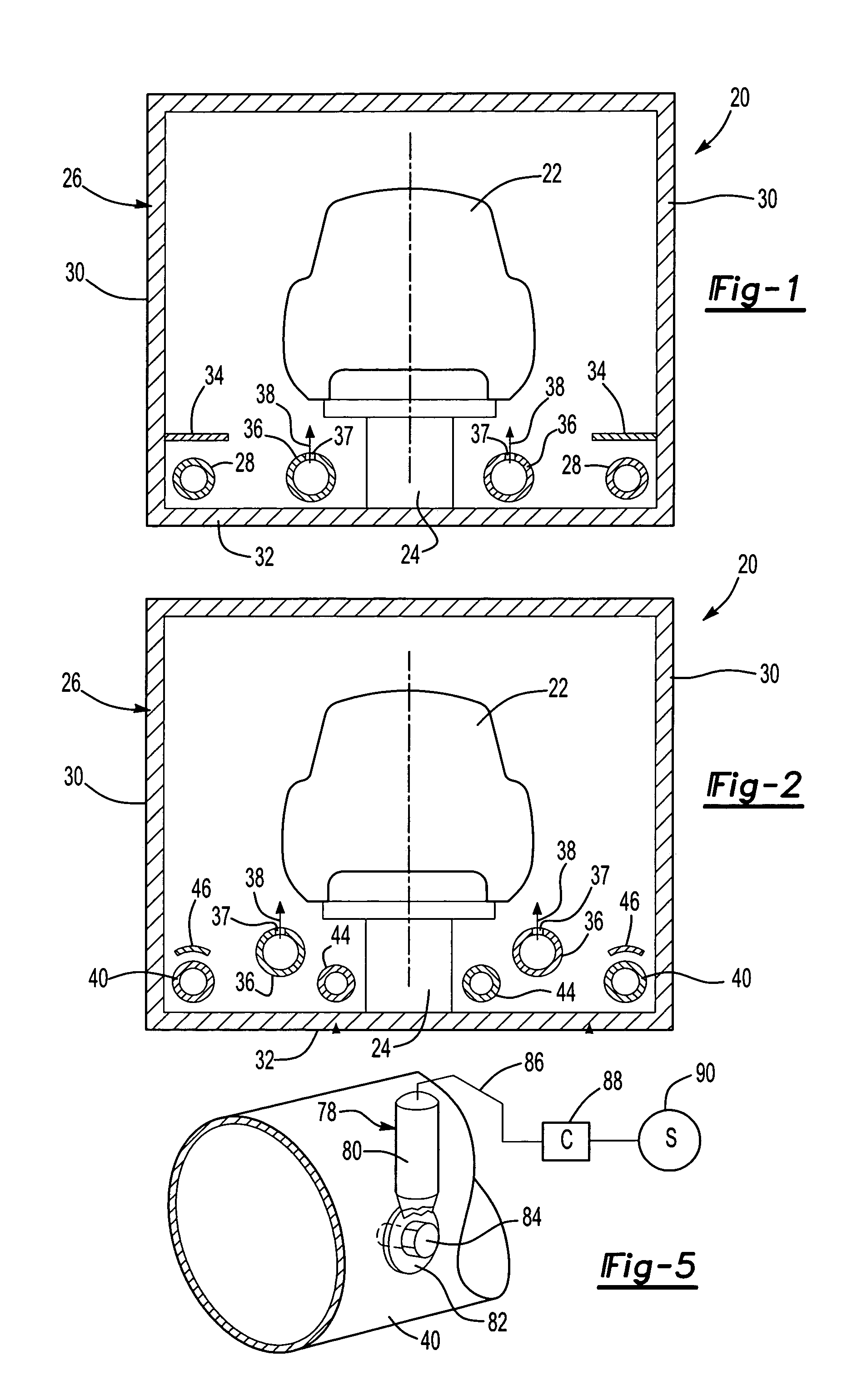

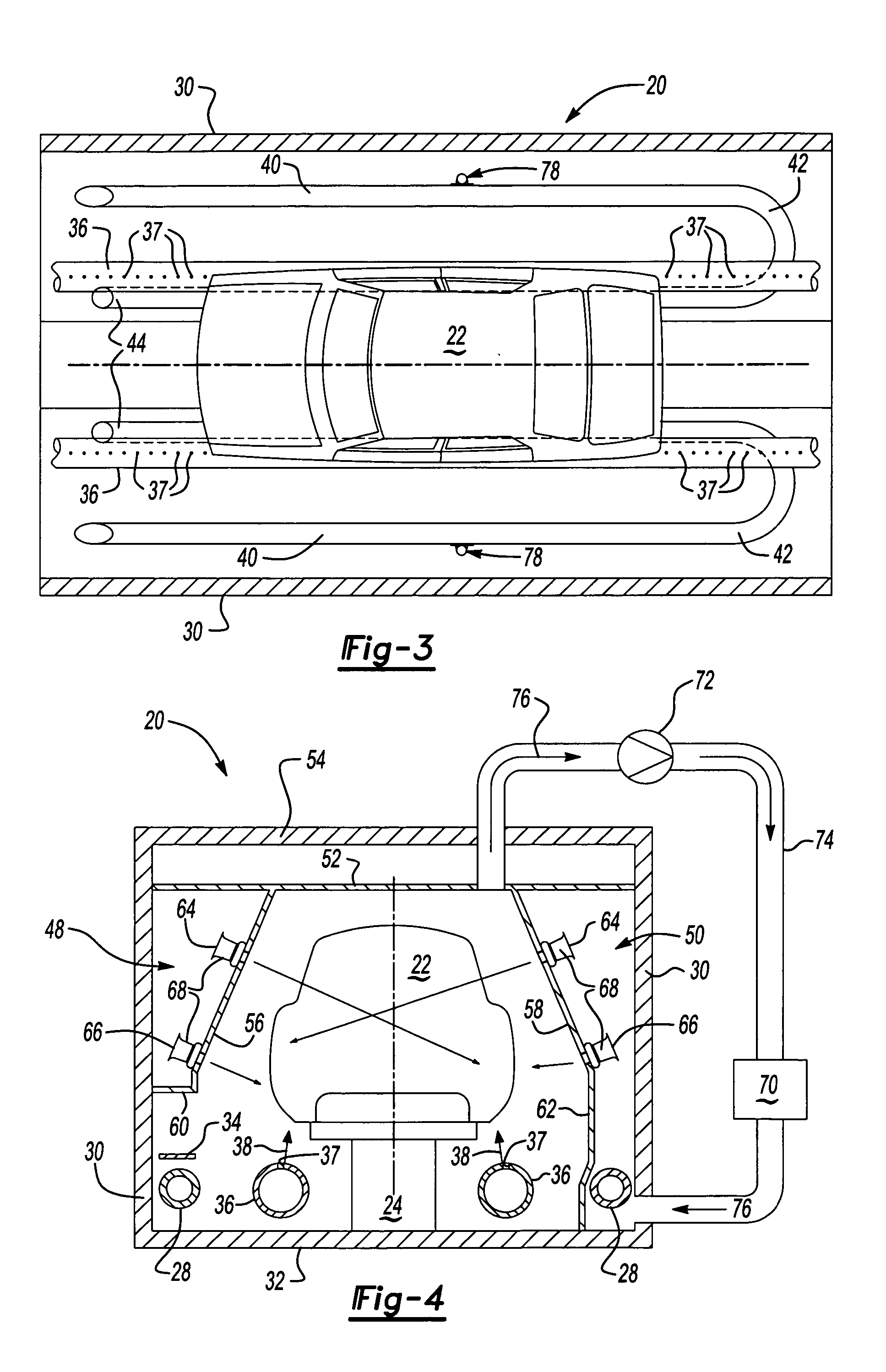

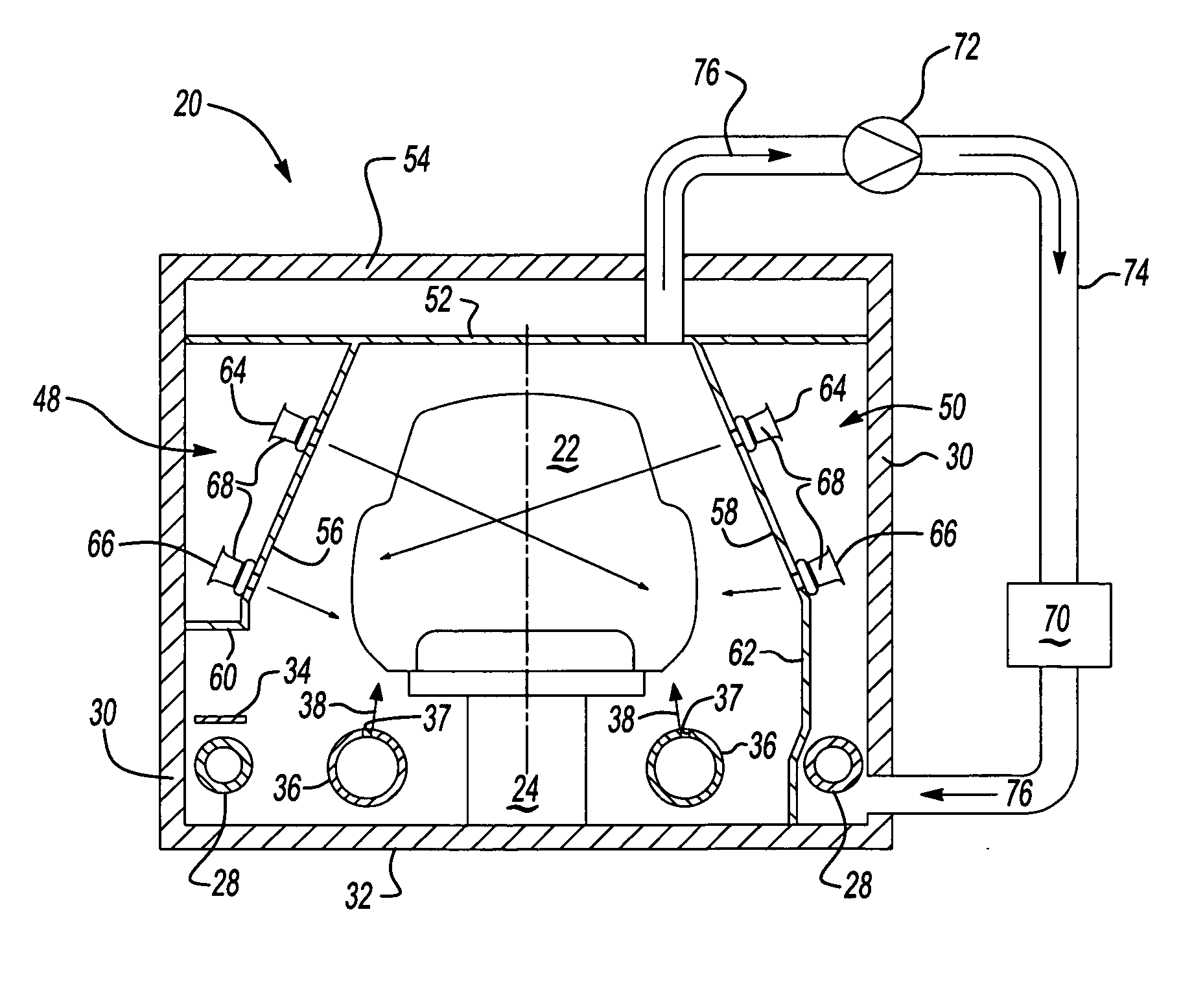

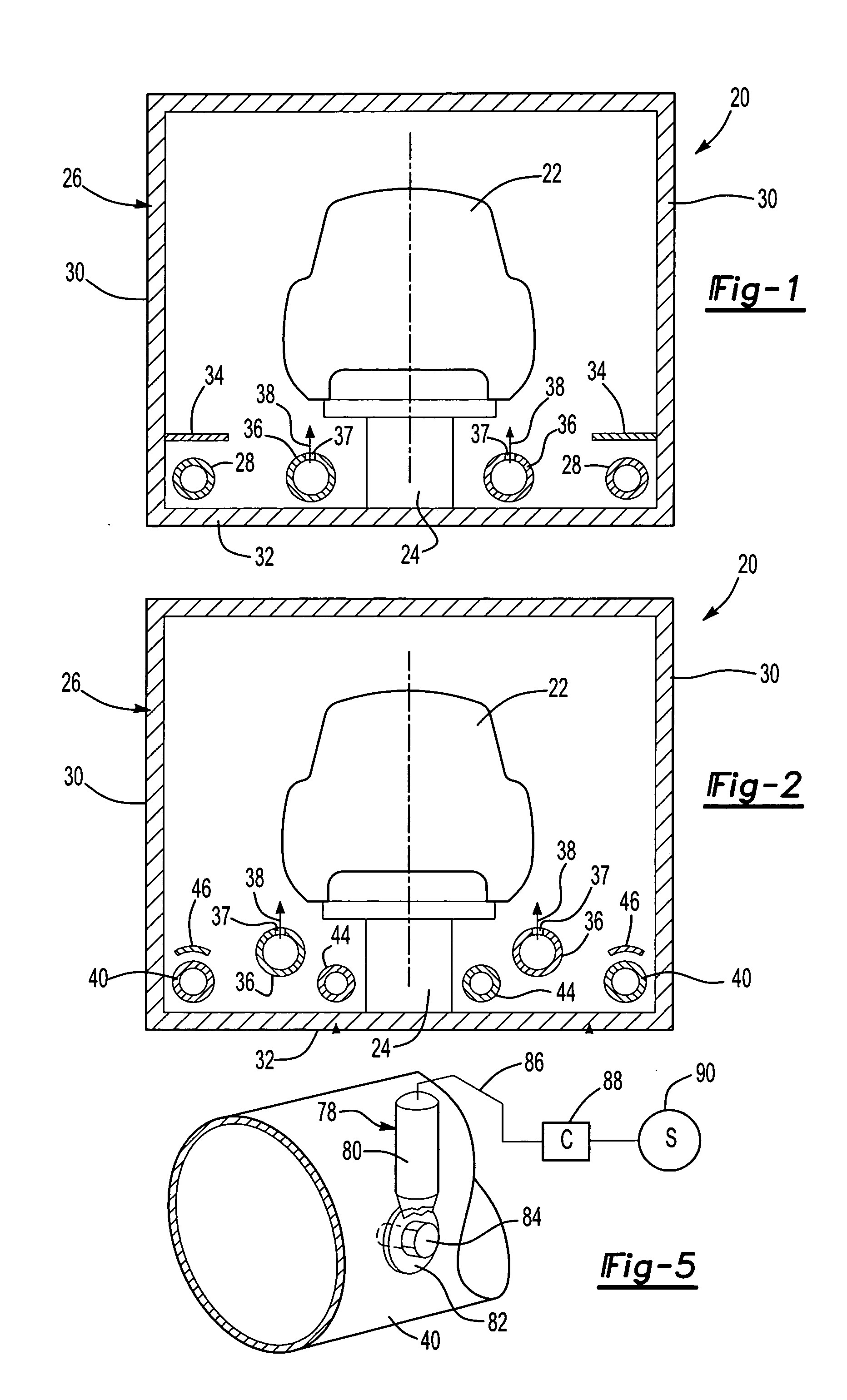

InactiveUS7063528B2Great utility and efficiencyImprove heat distributionDrying solid materials with heatDrying gas arrangementsControl systemEngineering

An oven for heating a coating on a substrate, such as a painted vehicle body, including a first zone having radiant tubes and shields above the tubes and a second zone including side heat chambers having nozzles directing heated air onto a coated substrate and a hold zone. The radiant tubes may include a first linear portion extending through the oven and return loop beneath the substrate to conserve energy and sill ducts directing heated air against the underside of the vehicle body. The temperature is controlled by sensors contacting the radiant tubes and a proportional integral control system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Radiant tube and convection oven

InactiveUS20050087183A1Avoid overall overheatingAvoid explosionDomestic stoves or rangesDrying solid materials with heatControl systemEngineering

An oven for heating a coating on a substrate, such as a painted vehicle body, including a first zone having radiant tubes and shields above the tubes and a second zone including side heat chambers having nozzles directing heated air onto a coated substrate and a hold zone. The radiant tubes may include a first linear portion extending through the oven and return loop beneath the substrate to conserve energy and sill ducts directing heated air against the underside of the vehicle body. The temperature is controlled by sensors contacting the radiant tubes and a proportional integral control system.

Owner:GM GLOBAL TECH OPERATIONS LLC

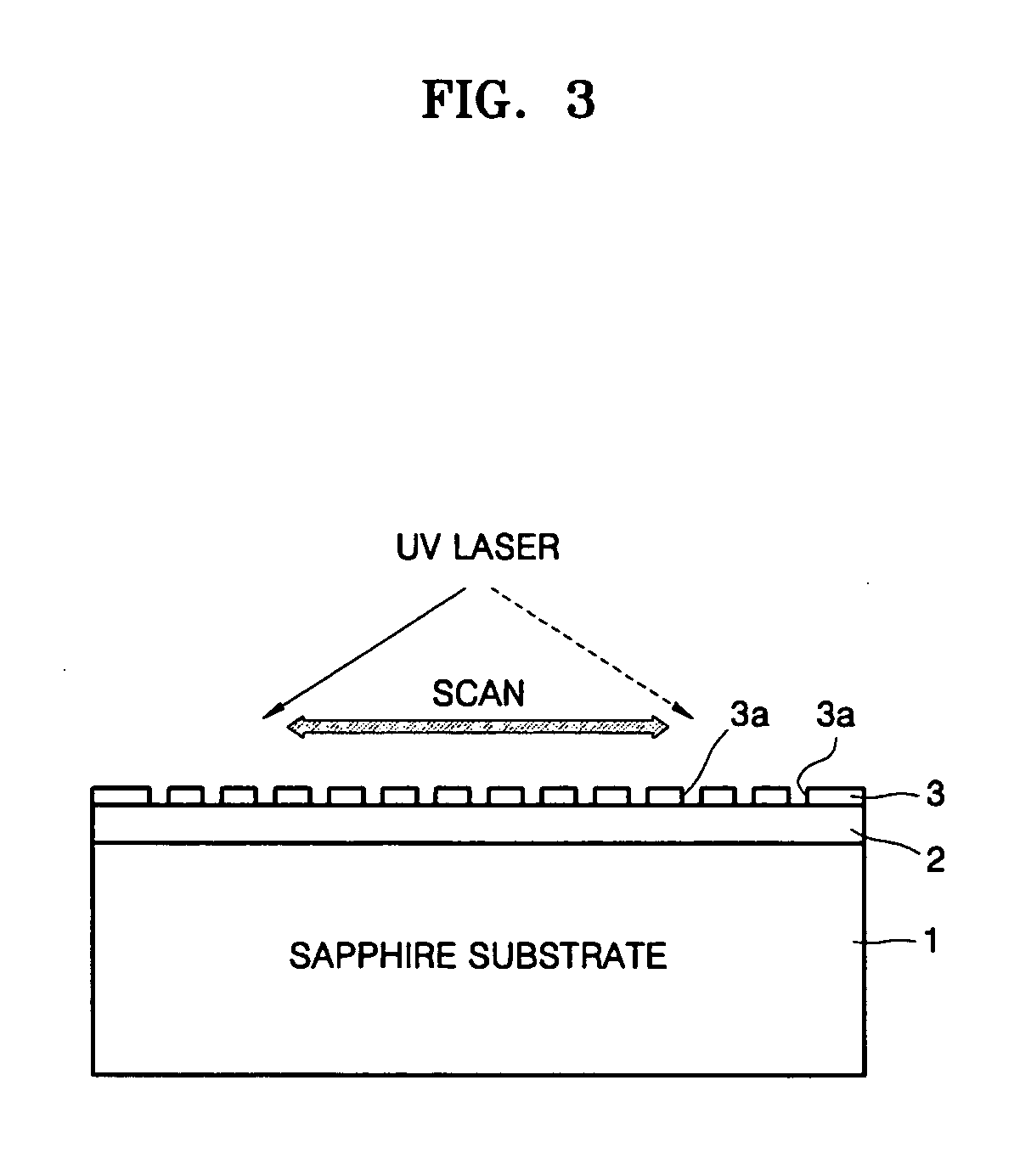

Grain drying aeration system

InactiveUS20070234587A1Drying solid materials with heatDrying chambers/containersAeration systemWaste management

An improved vertical aeration system is provided for a grain bin having a sloped hopper bottom with a discharge opening. A pyramid frame includes legs with lower ends attachable to the hopper bottom. Concave perforated walls are attached to the legs. Braces extending between the legs provide structural support for the walls. An air duct extends upwardly and centrally into the interior of the frame, to supply air into the aeration system for flow outwardly through the perforated walls.

Owner:WOODHAVEN CAPITAL

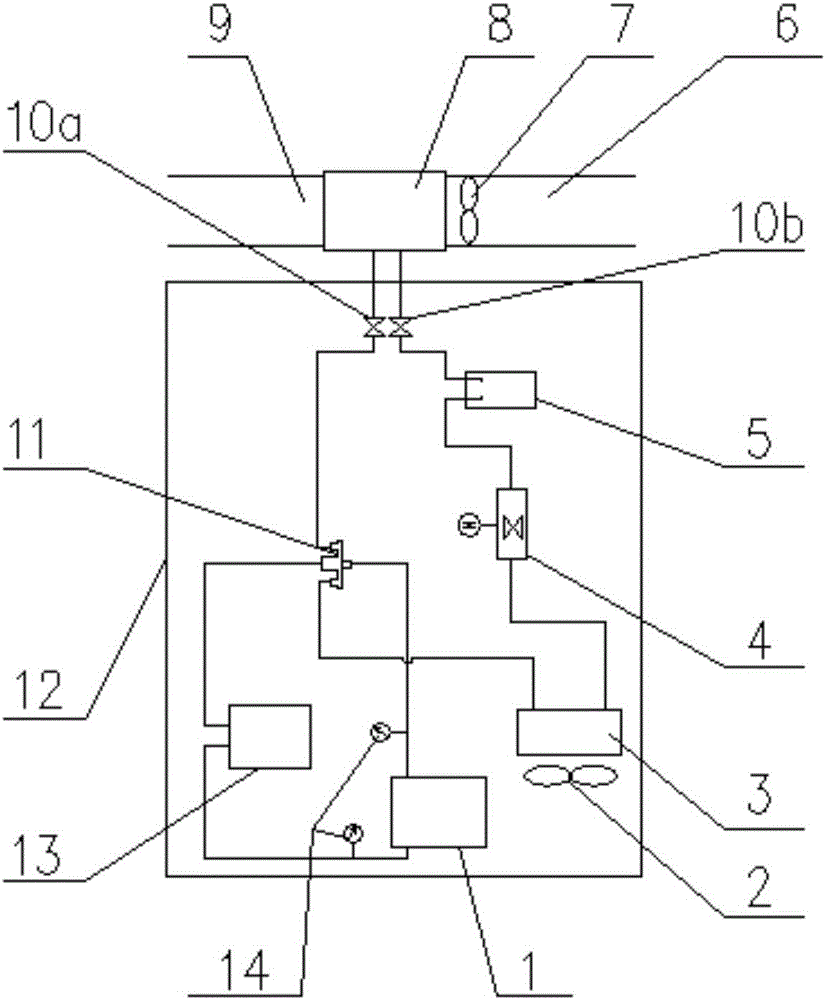

Belt-type temperature-variable type grain heat pump drying device

InactiveCN106568317AFull heat and moisture exchangeImprove storage efficiencyHeat recovery systemsFood processingNatural ventilationEngineering

The invention provides a belt-type temperature-variable type grain heat pump drying device which comprises at least three drying modules which are connected in sequence. Each drying module comprises a heat pump system, an air flue system connected with the heat pump system and a drying channel connected with an air supply opening and an air return opening of the air flue system. By means of the belt-type temperature-variable type grain heat pump drying device, the phenomenon of grain crack can be effectively prevented, quality of dried grains is improved, and the yield of the dried grains is raised; cooling is conducted directly after the grains are dried, and the defects that natural ventilation cooling time is long, and the grains absorb environmental moisture are overcome; time is saved, work efficiency is improved, the grains are dried in a layered manner in the drying channel, space can be effectively utilized, quality of the grains is improved, and the yield of the grains is raised.

Owner:浙江豪瓦特节能科技有限公司

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

Grain dryer

ActiveUS20190174782A1Reduce energy consumptionEasy to handleThermometer detailsDrying gas arrangementsEngineeringMoisture

Grain dryer of the type comprising a vertical main structure consisting of a central body through which the grain to be dried passes, a front hot air intake chamber and a rear used air outlet chamber, being that the main body has in its upper part an entrance from where wet grains are loaded, underneath which there is a loading hopper that communicates with the central body, wherein the grain descends along the central body within which it is dried during its fall by a flow of hot air that passes through the mass of grain, finally exiting through a discharge hopper arranged at the lower end of the dryer, the dryer of the invention being characterized in that it allows to significantly reduce the energy consumption in order to obtain a better quality of grain and a process much faster than conventional ones due to the arrangement of one or more preheating chambers without extraction of moisture from the grain.

Owner:ING MEGA

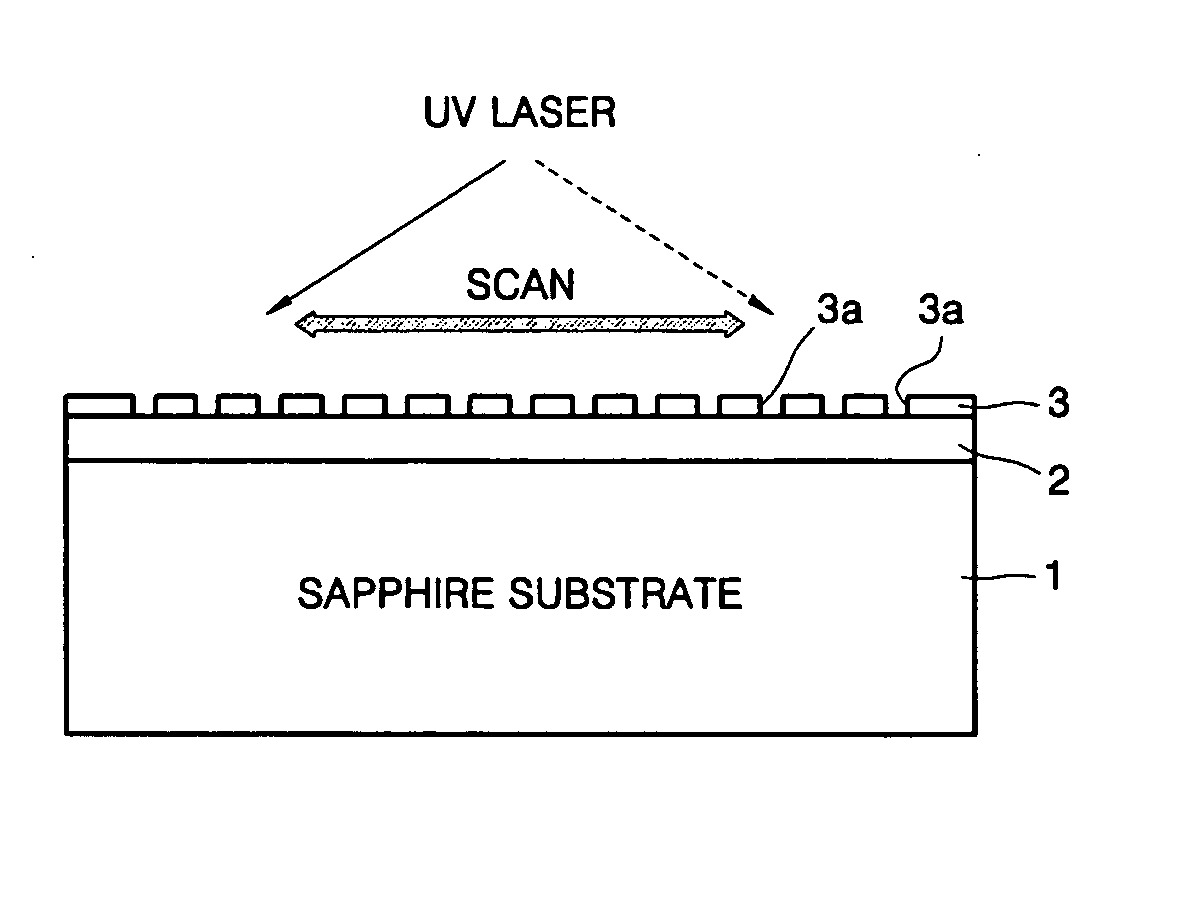

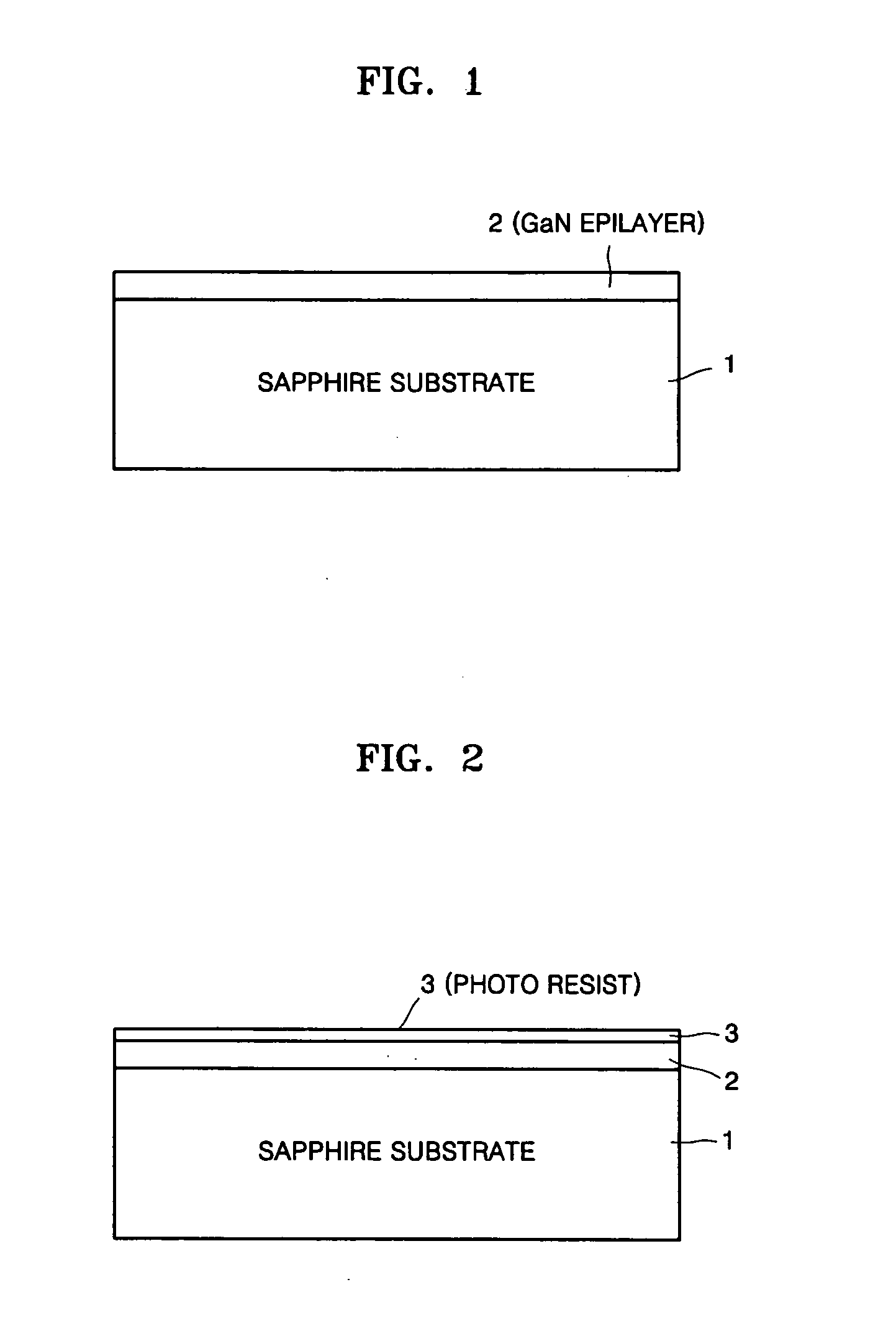

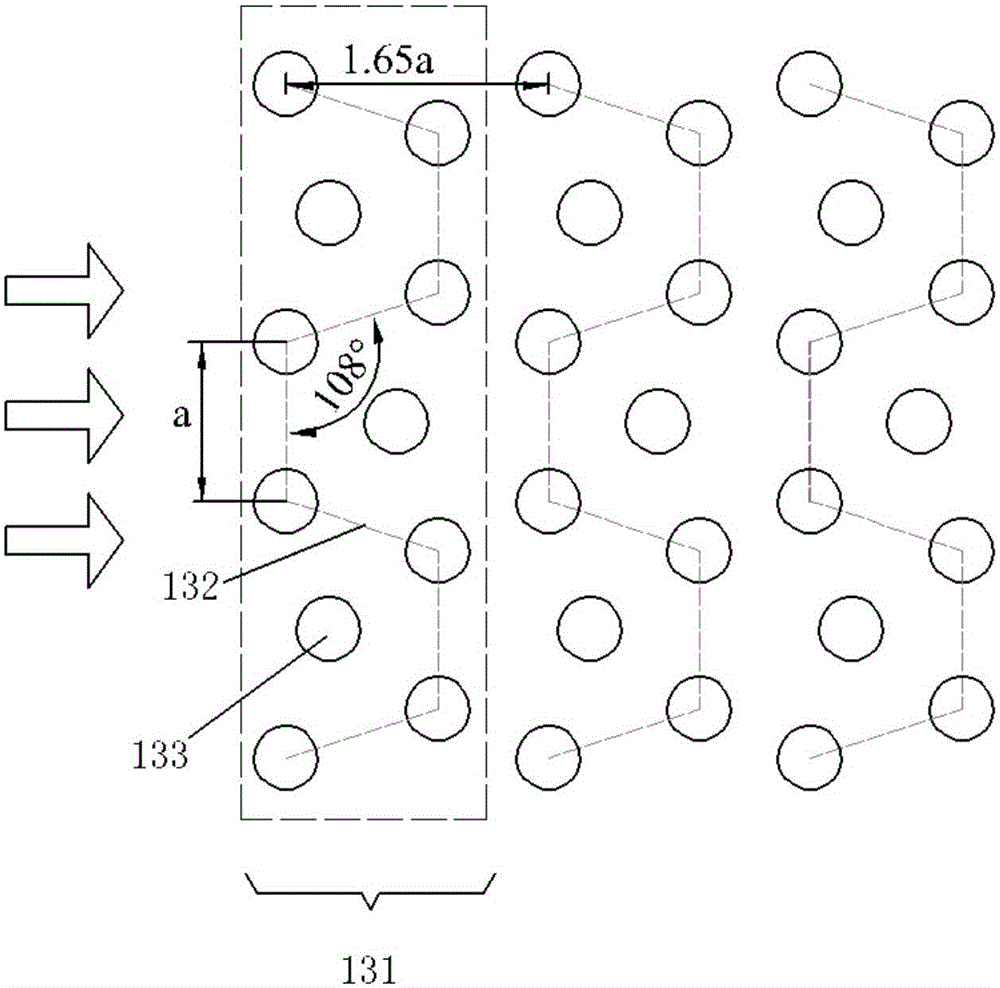

Epitaxial growth method

InactiveUS20060160334A1Low costWell formedDrying solid materials with heatDrying gas arrangementsCrystalline materialsSingle crystal

Provided is an epitaxial growth method for forming a high-quality crystalline growth semiconductor wafer. The method includes forming a buffer layer on a single crystalline wafer using a single crystalline material; forming a mask layer on the buffer layer; forming a plurality of holes in the mask layer using a laser to expose portions of the buffer layer; forming wells having a predetermined depth in the exposed portions of the buffer layer by injecting an etchant into the holes; removing the mask layer and annealing the buffer layer to form a porous buffer layer having cavities obtained by the wells; and forming a crystalline material layer on the porous buffer layer using an epitaxial growth process.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

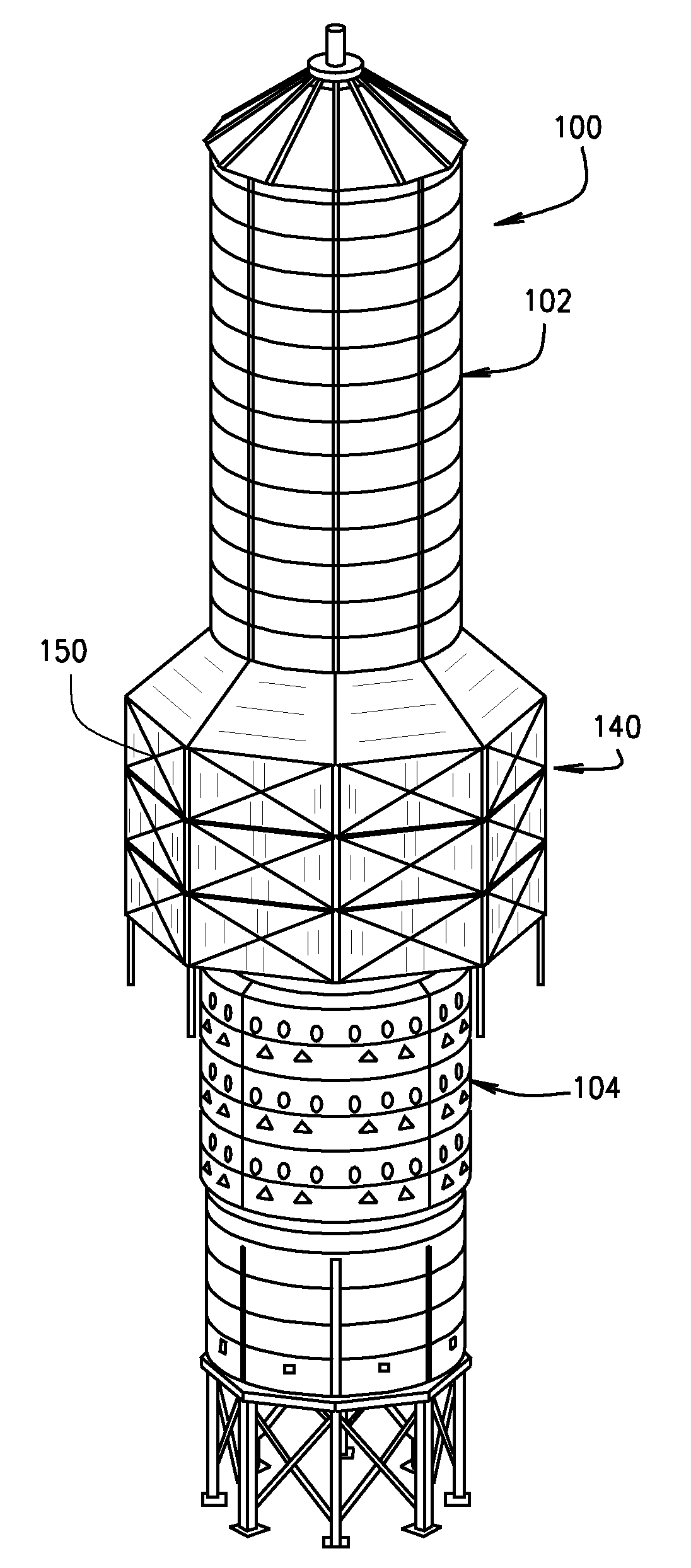

Tower grain dryer with improved heat reclamation and counter-flow cooling section

A grain drying tower comprises a heater and blower separating a heating plenum and a cooling plenum. The dryer is provided with a heat reclamation / heat recycling system and / or counter-flow cooling to reduce the energy requirements of the tower dryer. The heat reclamation system comprises a chamber external to the outer wall of the tower and which is and located at a point along the drying path. The bottom of the chamber is open to the atmosphere. Hot exhaust air enters the heat reclamation chamber at the top of the chamber and is drawn back into the tower by the blower as the exhaust air exits the open bottom of the chamber. In the counter-flow, the walls defining the grain path of the in the cooling section are not air permeable, and air is drawn into the cooling section through outer wall ducts which are closed at the inner wall. The entering air travels up through heated grain to be warmed, and then enters the plenum through inner wall ducts, which are closed at the outer wall of the tower.

Owner:THE GSI GRP LLC

Uniformly-heated and convenient-to-choose intelligent grain dryer

InactiveCN108375294AEvenly heatedEasy to absorb heat and dryDrying gas arrangementsDrying solid materialsAgricultural engineeringGrain drying

The invention relates to a uniformly-heated and convenient-to-choose intelligent grain dryer, which comprises a drying tank, a hot air chamber, an air inlet pipe, an air outlet pipe, a hopper, a discharge pipe, a controller and a plurality of supporting legs, wherein an air guide mechanism is arranged in the hot air chamber, a mesh plate and an agitating mechanism are arranged in the drying tank,the agitating mechanism comprises a first motor, a first driving shaft, a rotary shaft, a transmission assembly and two agitating plates, the transmission assembly comprises a transmission unit, a reciprocating unit, a fixed plate and two collars, and the air guide mechanism comprises an air guide assembly, a plurality of electric heating wires and two switching assemblies. The uniformly-heated and convenient-to-choose intelligent grain dryer can use different specifications of electric heating wires by means of the air guide mechanism, so that the temperature of heated air can be convenientlycontrolled, and thereby the dryer can dry different types of grains; in addition, by means of the agitating mechanism, the agitating plates can reciprocate up and down in the process of rotation, consequently, piled grain can be thoroughly uniformly heated, the drying effect is improved, and the practicability of the dryer is increased.

Owner:南安市智德机械设备有限公司

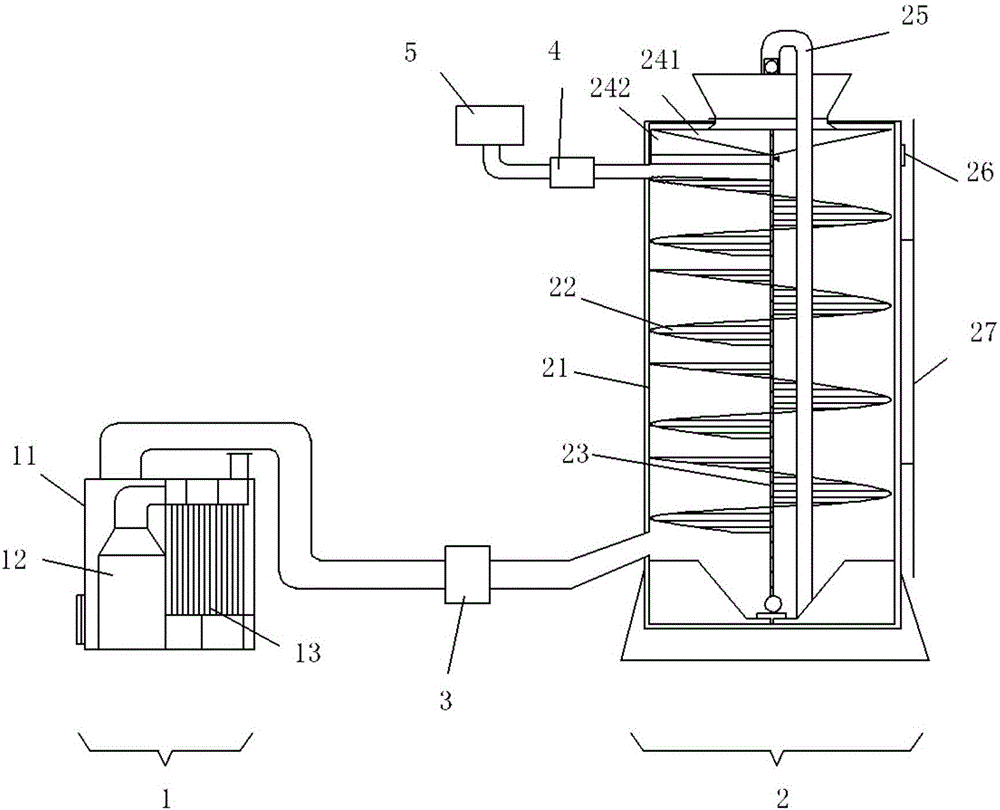

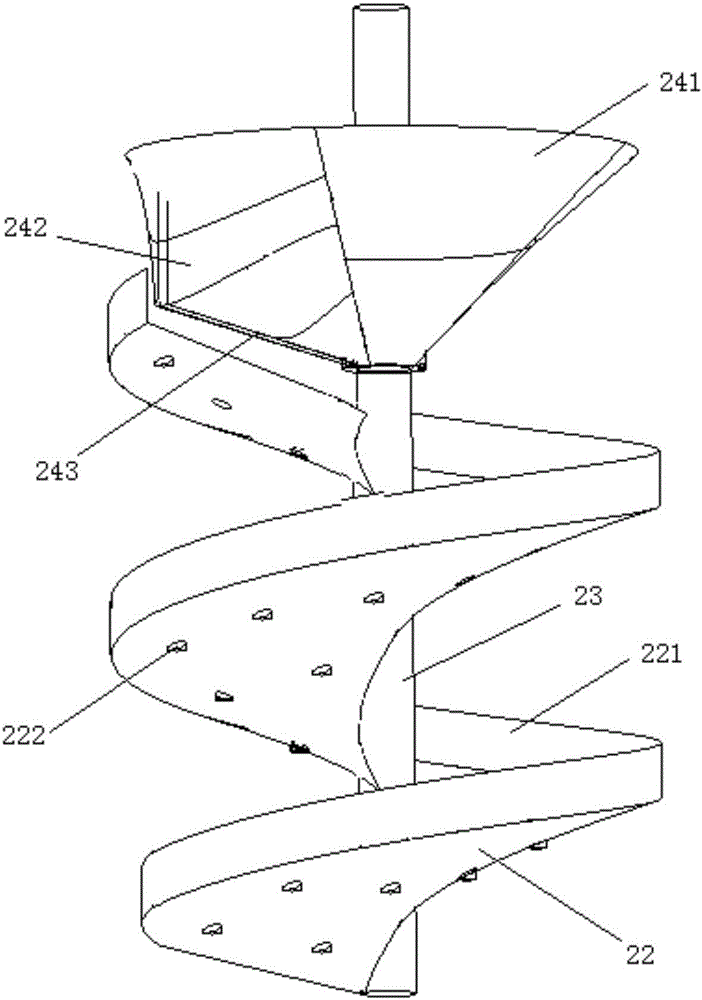

Grain drying device

ActiveCN107178987AExtended retention timeUniform qualityFood processingDrying gas arrangementsSpiral bladePorous medium

The invention discloses a grain drying device. The grain drying device comprises a hot-blast stove, an air blower and a drying tower, and is characterized in that a shaft rod is arranged in a tower body of the drying tower; spiral plates are arranged on the shaft rod; the spiral plates outwards extend from the surface of the shaft rod; two or more stages of spiral plates are arranged on the shaft rod; blowing holes are formed in the spiral plates, and penetrate through the surfaces of the spiral plates; and the hot-blast stove adopts the scheme of arranging heat exchange pipes in a pentagonal form and filling porous mediums in the heat exchange pipes. Compared with the prior art, the grain drying device has the following advantages: the drying speed can be adjusted through adjusting the rotating speed of a rotating shaft according to different grain characteristics; the overturning of materials is realized through multiple sections of spiral blades; the heat exchange efficiency is improved through arranging the heat exchange pipes in a pentagonal form and filling the porous mediums in the pipes; the problems of high production cost, energy consumption and low drying efficiency in the grain drying device can be effectively solved; and the grain drying device is used for drying grains, and reduces the drying cost, saves the energy, and improves the drying efficiency.

Owner:HEFEI UNIV OF TECH

Processing method of microwave-vacuum dried quick-cooking coarse grains and microwave-vacuum dried quick-cooking coarse grains processed by processing method

InactiveCN107969612ASolve the problems of pre-soaking, long cooking time and poor tasteRetain nutrientsFood freezingDrying solid materials with heatRoom temperatureMicrowave power

The invention relates to a processing method of microwave-vacuum dried quick-cooking coarse grains and the microwave-vacuum dried quick-cooking coarse grains processed by the processing method. The processing method of the microwave-vacuum dried quick-cooking coarse grains comprises the following steps: 1, pretreatment of raw materials; 2, freezing treatment: putting the predried raw materials ina freezing chamber and performing freezing treatment at low temperature; 3, microwave-vacuum treatment: thawing the frozen raw materials obtained in the step 2 to room temperature and performing microwave-vacuum drying treatment by using a microwave-vacuum drier, wherein the microwave power is 100-850W, the vacuum degree is -0.05 to -0.1Mpa, the temperature is 50-90 DEG C, the microwave-vacuum drying time is 5-30min and the thickness of a material layer is 1-3cm, thereby obtaining the microwave-vacuum dried coarse grains of which the moisture content is 8-13%; 4, cooling; and 5, screening andmixing to obtain the quick-cooking coarse grains. The quick-cooking coarse grains prepared by the processing method disclosed by the invention can serve as an auxiliary nutritional product of rice andalso can be cooked singly into congee for eating, and the quick-cooking coarse grains can be cooked with rice or cooked singly by performing cooking for 20min, so the quick-cooking coarse grains arequick and convenient.

Owner:曹龙奎

Efficient grain drying and sieving-in-one machine

InactiveCN107356073AAvoid accumulationEvenly heatedDrying gas arrangementsSeed preservation by dryingEngineeringAir blower

The invention discloses a high-efficiency integrated grain drying and screening machine, which comprises a support frame, a drum, a hot air pipe, and a sieve plate; the drum is rotatably arranged in the support frame; Connect the feeding pipe; one end of the hot air pipe is connected to the hot air blower, and the other end passes through the right rotating shaft from the center of the right rotating shaft of the drum and penetrates into the drum. The hot air pipe is densely arranged on the drum body. Air outlet; the hot air pipe is located at both ends of the tube body of the drum, and a group of straight rods are arranged, each group of straight rods has two and symmetrically distributed, and the end of the straight rod away from the hot air pipe is rotated and connected with a turning rod; The sieve plate is arranged below the feeding port. The invention can turn the grains during the grain drying process, avoid the accumulation of the grains, make the grains heated evenly, thereby ensuring the drying effect; meanwhile, it also has the function of screening.

Owner:安庆海维环保设备有限公司

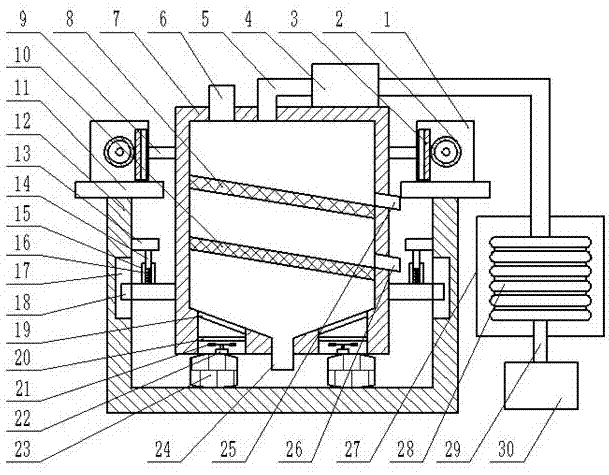

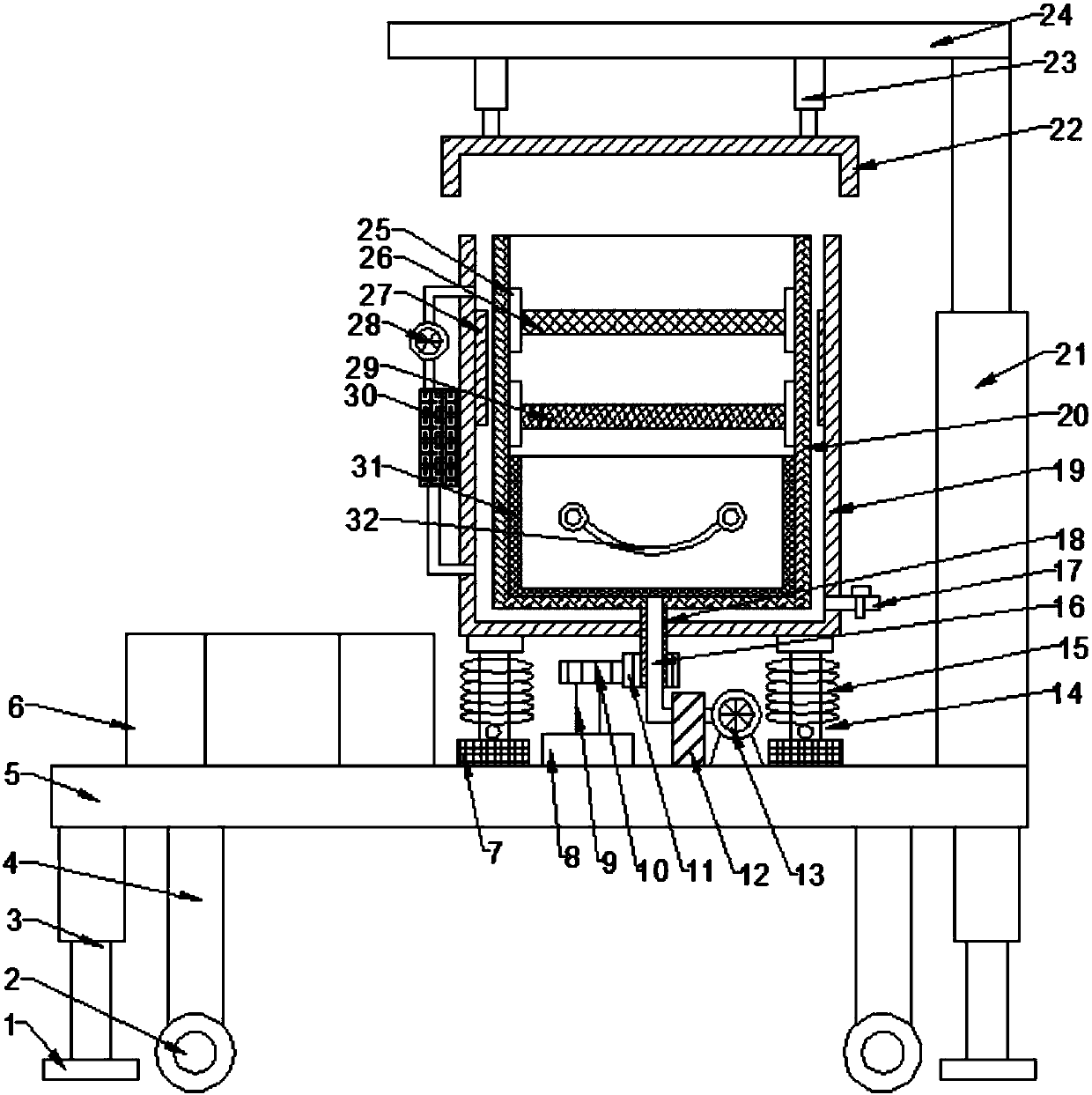

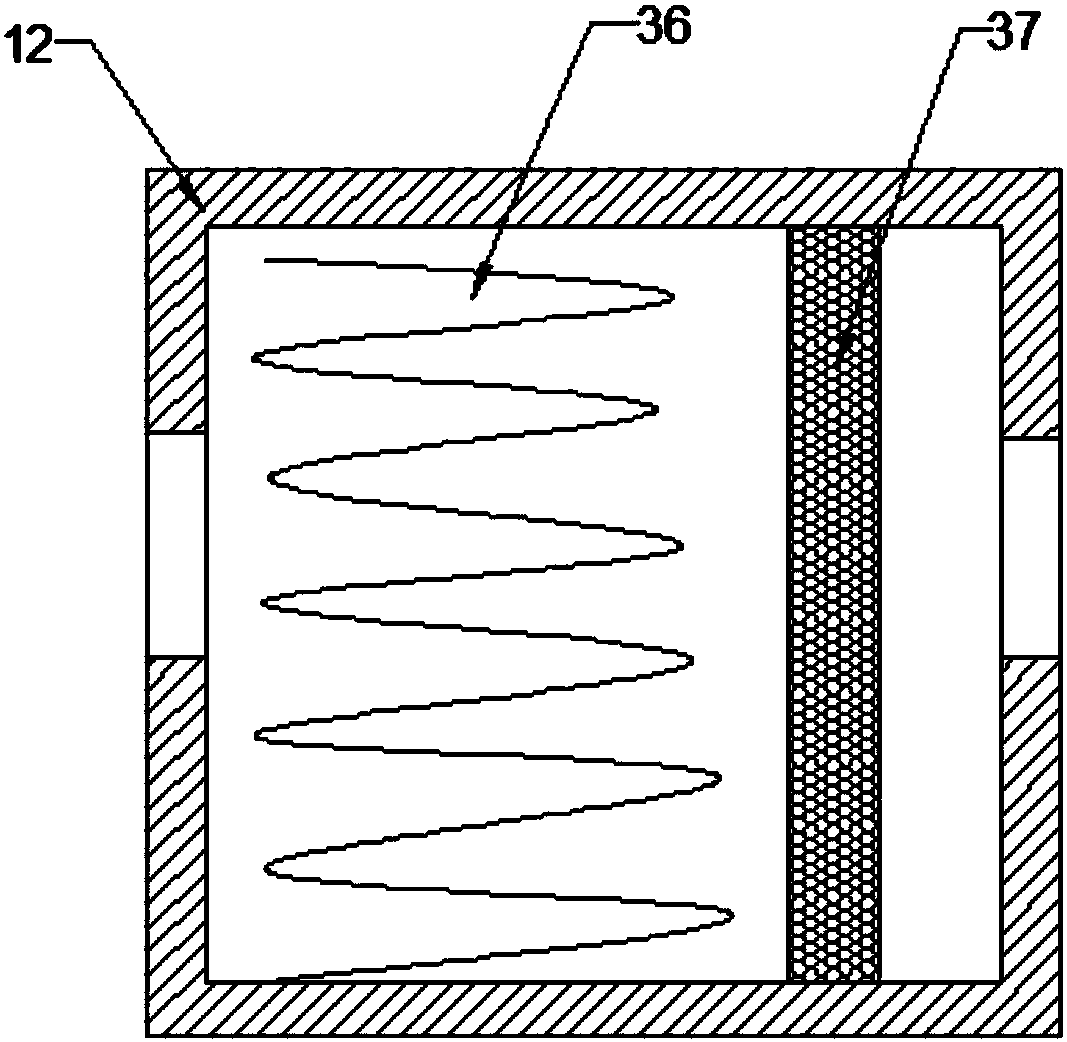

Device capable of drying cereal based on gravity variations and carrying out autonomous discharging based on gravity variations

ActiveCN110500856AEvenly heatedIncrease the drying areaDrying gas arrangementsDrying chambers/containersEngineeringMoisture

The invention relates to the technical field of agriculture, and discloses a device capable of drying cereal and carrying out autonomous discharging based on gravity variations. The device comprises an outer bucket, and a drying chamber is movably connected in the outer bucket. The drying chamber is isolated from the outer bucket and can independently move. A rotary shaft rotates to drive stirringblades to rotate, cereal in the drying chamber can be turned over in the drying process, the drying speed is increased, and the work efficiency is improved. Four springs are arranged at the bottom ofthe drying chamber, the weight is reduced in the drying process, subsequent reactions are driven, and the whole device is more environment-friendly. The design of the whole device saves more time andlabor, and the device does not need to be manually watched nearby. A separation plate is designed into an asymmetric shape, and therefore the separation plate cannot be directly opened in the movingprocess, and the separation plate can be in a completely opened state only when much moisture is dried and reaches requirements. Therefore, manual watching nearby is not needed, and excessive drying or incomplete drying is avoided.

Owner:JIAXING DAMING INDAL

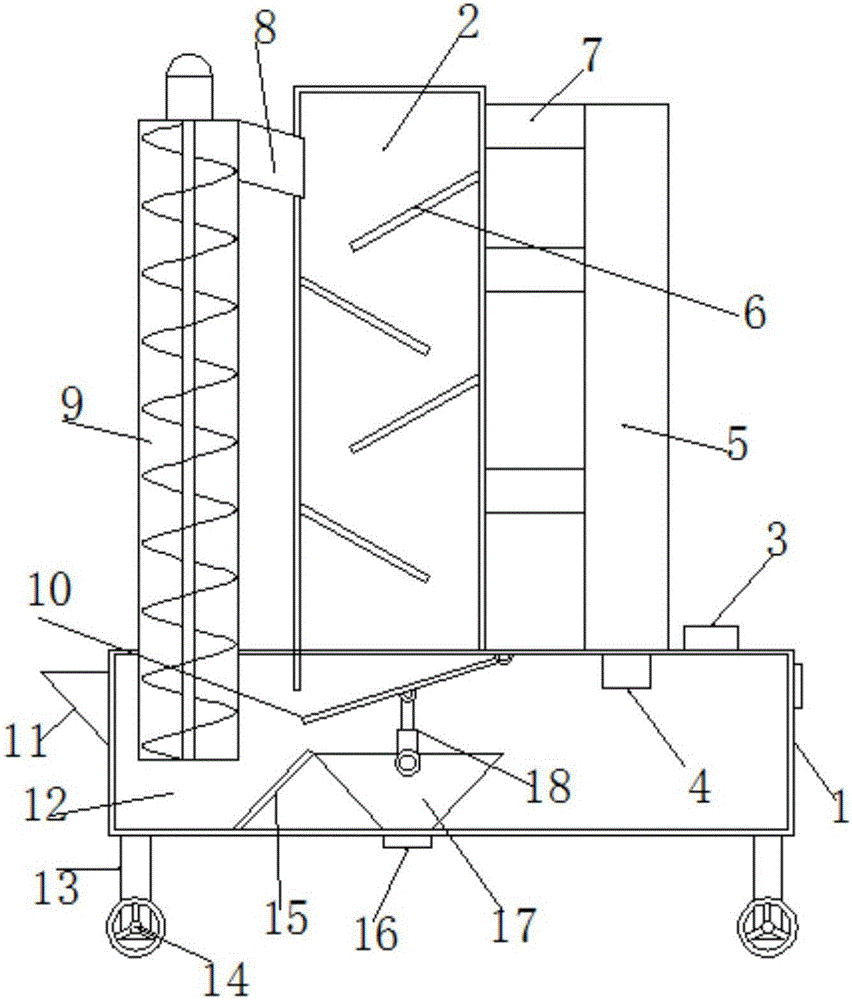

Cereal drying, cooling and dust removing tower

ActiveCN106403565AEasy to collectCycle helpsDrying gas arrangementsSeed preservation by dryingTowerAerospace engineering

The invention discloses a cereal drying, cooling and dust removing tower. The cereal drying, cooling and dust removing tower comprises an installing box and a cooling and dust removing box. Landing legs are symmetrically arranged on the two sides of the lower end of the installing box. Wheels are arranged at the lower ends of the landing legs. The cooling and dust removing box is arranged at the upper end of the installing box and is a cylindrical cylinder. The lower end of the cooling and dust removing box communicates with the installing box. A feeding barrel is vertically arranged on the part, on the left side of the cooling and dust removing barrel, of the installing box and internally provided with a feeding packing auger. The lower end of the feeding barrel stretches into the installing box. A feeding hopper is arranged on the left side of the part, close to the lower end of the feeding barrel, of the installing box. A material guiding pipe is arranged between the upper end of the feeding barrel and the cooling and dust removing box. A plurality of oblique material overturning plates are arranged on the left inner wall and the right inner wall of the cooling and dust removing box in a crossed manner. A dust collecting box is arranged on the right side of the cooling and dust removing box. A plurality of dust suction pipes are arranged between the dust collecting box and the cooling and dust removing box. The cereal drying, cooling and dust removing tower is simple and reasonable in structure and convenient to carry, accordingly, the problem that an existing device cannot conduct discharging conveniently is solved, and practicability is high.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

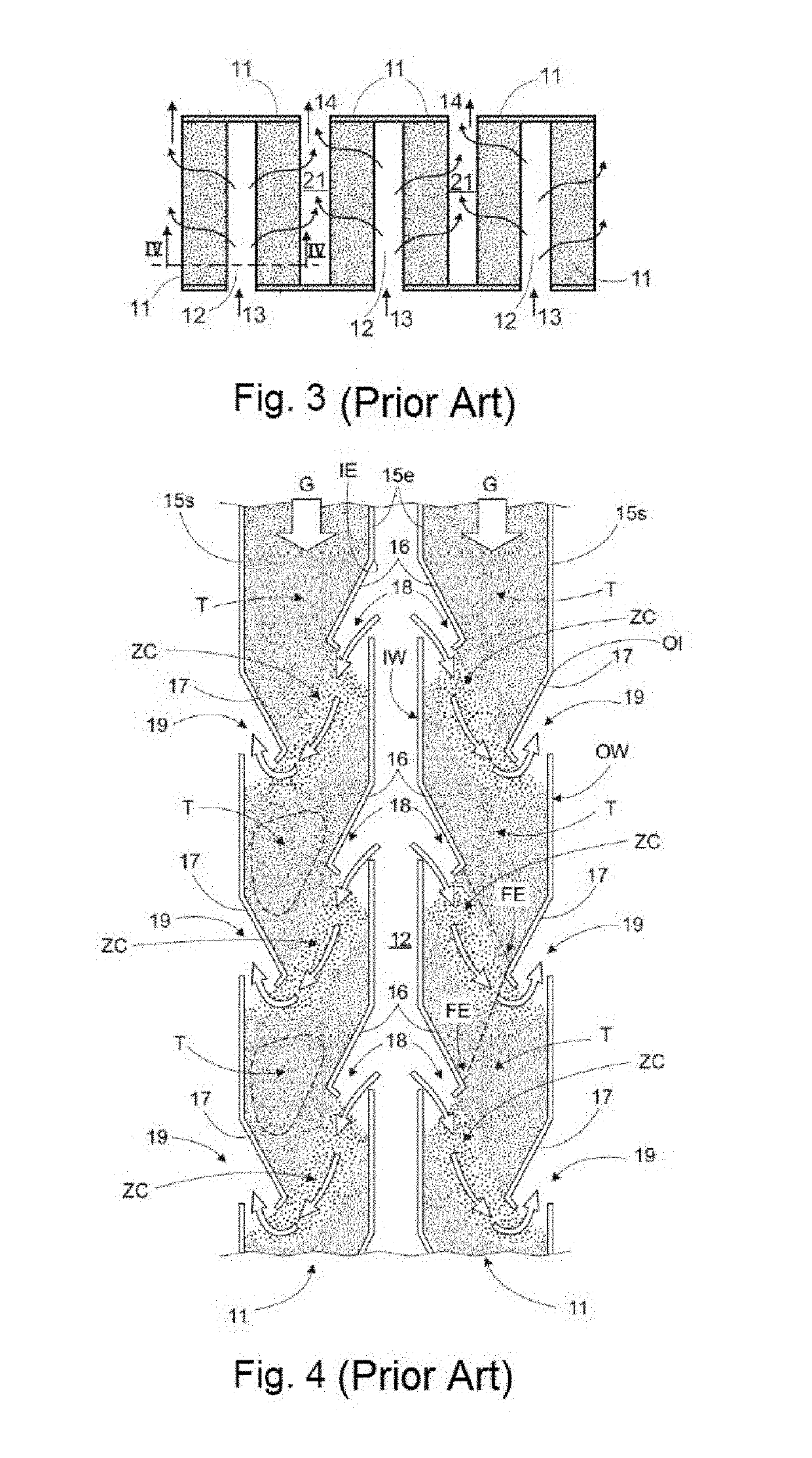

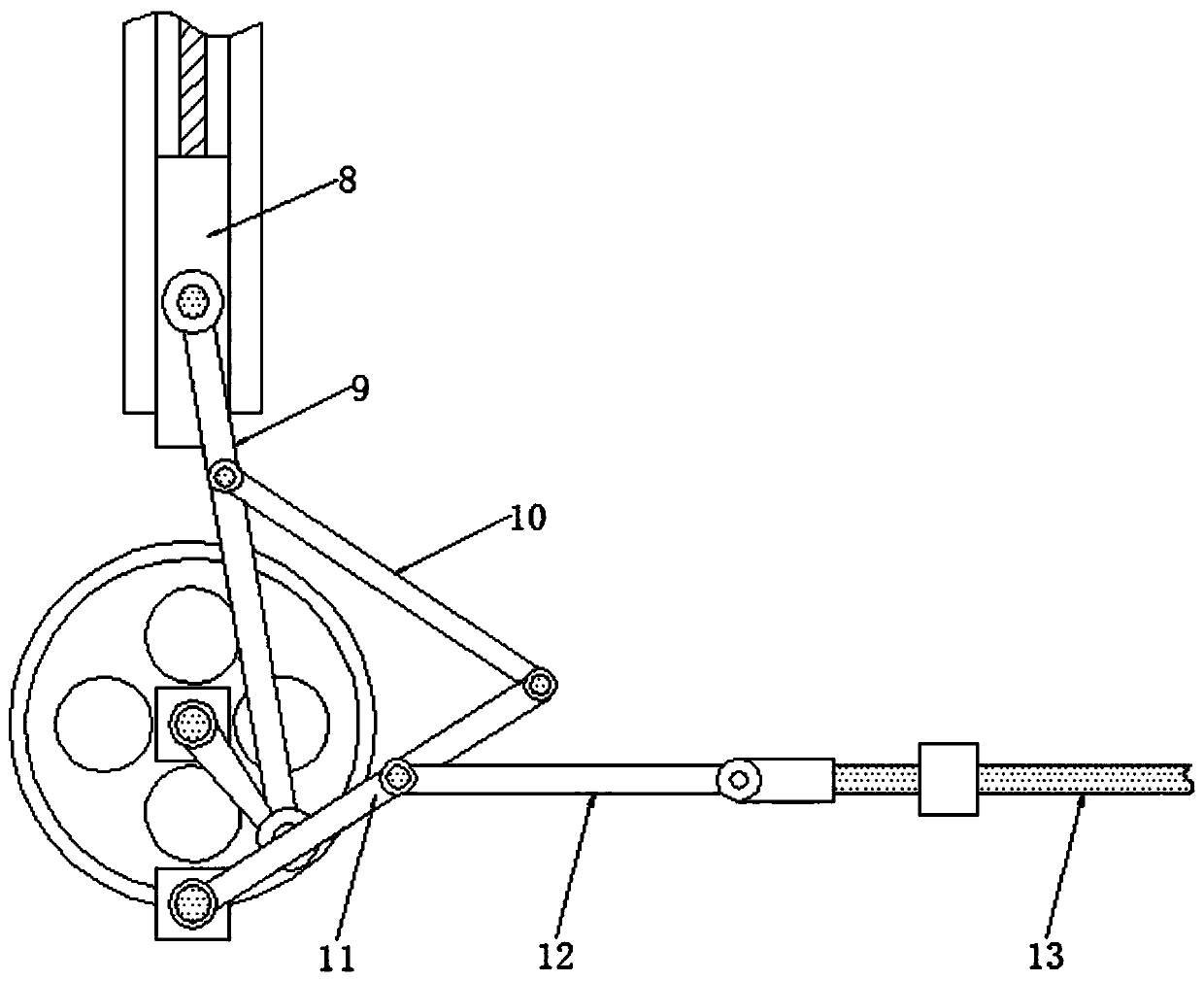

Grain turner for tower grain dryer and method of drying

A grain turner for turning grain in a drying tower includes opposed generally vertical side walls and a generally vertical dividing plate (which is shorter than the side walls) extending between the side walls; the dividing plate defining inner and an outer vertical channels in a portion of the turner. An inner inclined plate is pivotally connected to one side wall to be within the inner channel and an outer inclined plate is connected to the other side wall to be within the outer channel. The inclined plates are pivotal between a first position in which they are inclined downwardly in a opposite widthwise directions and a second position in which they are generally adjacent their respective side walls. The inclined plates have a length such that when they are in the first position, their lower edges are proximate a bottom of the divider plate. Further, the inner and outer inclined plates each define a curve such that when the inclined plates are in the raised position, the inner inclined plate directs grain from the inner channel to the space below outer channel and the outer inclined plate directs grain from the outer channel to the space below the inner channel.

Owner:THE GSI GRP LLC

Method of drying material by membrane dehumidified air

InactiveUS20140150287A1Less energyFew safety concernDrying solid materials with heatDispersed particle separationRoom temperatureProduct gas

Various embodiments of the present invention relate to a method of drying a feed gas mixture. The method includes contacting a first side of one or more membranes with a feed gas mixture. The feed gas mixture includes at least water and a second gas component. Contacting the first side of the one or more membranes with the feed gas mixture produces a permeate gas mixture on a second side of the one or more membranes and a retentate gas mixture on the first side of the one or more membranes. The permeate gas mixture is enriched in water, and the retentate mixture is depleted in water. The one or more membranes have a H2O vapor permeability coefficient of at least about 25,000 Barrer at room temperature. Various embodiments of the present invention relate to a method of drying a material. The method includes contacting a material with the retentate gas mixture, to provide a dried material. Various embodiments also relate to membranes useful for performing the drying method, devices or machines that can perform the drying method, and materials dried by the drying method.

Owner:DOW CORNING CORP

Agricultural grain dewatering and drying device with screening function

The invention provides an agricultural grain dewatering and drying device with a screening function and belongs to the technical field of agriculture. The agricultural grain dewatering and drying device comprises a support device and a dewatering and drying device body. A barrel cover is fixedly arranged below a transverse plate through a hydraulic cylinder. A first screening mesh plate is fixedlyarranged on the upper side of an inner cavity of an inner barrel through an fixing block. A second screening mesh plate is arranged in the inner barrel and is arranged on the lower side of the firstscreening mesh plate. A collection mesh vessel is arranged at the bottom of the inner cavity of the inner barrel. Electric heating pieces are fixedly arranged on the left side and the right side of aninner cavity of a box. A grain holding frame is fixedly arranged on the left side on a bottom plate. According to the agricultural grain dewatering and drying device, the inner barrel is fixedly welded to the upper end of a rotary shaft and is made of a compact filter screen, and thus a fast dewatering function is achieved by rotating the inner barrel. The first screening mesh plate and the second screening mesh plate are arranged in the inner barrel and have the screening function for grains. The agricultural grain dewatering and drying device has the characteristics of being simple in structure, high in practicability and good in dewatering and screening effect.

Owner:温子墨

Grain dryer which can improve drying efficiency

InactiveCN107062886AAvoid cakingFalling smoothlyDrying gas arrangementsSeed preservation by dryingEngineeringAir blower

The invention relates to a grain dryer which can improve the drying efficiency. The grain dryer comprises a main body, a winnowing mechanism, a conveying mechanism, a heating mechanism and a material guide mechanism, wherein the winnowing mechanism comprises a first motor, a first support plate, a limiting block, a second support plate, a spring, a support rod and a scattering plate; the conveying mechanism comprises a first conveyor and a second conveyor; the heating mechanism comprises a hot-air blower, a rotation shaft, a bearing, a worm gear, a worm and a second motor; the material guide mechanism comprises a connecting plate, a first baffle plate, a second baffle plate, a second spring and a third spring. Grains are added to the second conveyor, then are sent to the scattering plate through the conveying mechanism, and finally are winnowed down from scattering holes through up and down vibration of the scattering plate, and therefore the uniform dropping out of the winnowed grains is realized. Meanwhile, hot air is blown out from hot air holes and the rotation shaft rotates, therefore the grains are uniformly heated in the falling process. The grains can be guided into the second conveyor again through the material guide mechanism to realize circular drying, and therefore the drying efficiency is improved.

Owner:吉林省允祥环保设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com