Multifunctional temperature and humidity control device for barn

A temperature and humidity control and multi-functional technology, applied in the direction of control input related to air characteristics, space heating and ventilation control input, application, etc., can solve the problems that do not meet the development needs of industrial equipment, difficult to achieve energy saving and emission reduction, high operating costs, etc. problem, to achieve the effect of improving storage stability and storage quality, good quality of low-temperature storage of grain, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

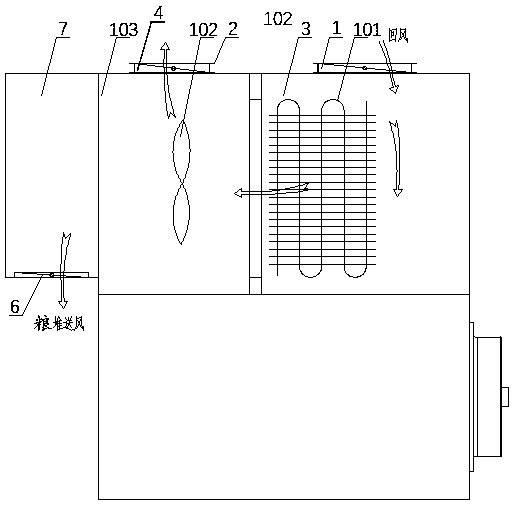

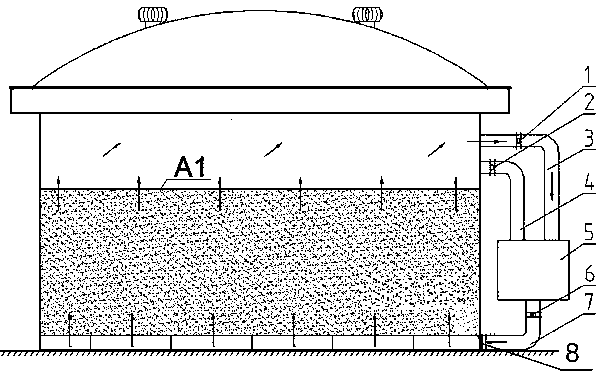

[0059] Example 1: as Figures 1 to 3 As shown, a multifunctional temperature and humidity control device for a granary, it includes a cooling device 5 arranged outside the granary, and the granary passes through the return air duct 3 in the warehouse and the air supply duct in the warehouse, which are arranged in the upper space of the warehouse wall. 4 is connected to the air path of the cooling equipment 5; it also includes an air duct 7 arranged on the grain pile, and the air duct 7 of the grain stack is connected to the bottom of the granary and connects the granary to the cooling equipment 5; the return air in the warehouse The pipeline 3 is provided with an in-store return air valve 1 , the in-store air supply pipeline 4 is provided with an in-store air supply valve 2 , and the grain-pile air-way pipeline 7 is provided with a grain-pile air-way valve 6 .

[0060] As preferred, such as Figure 4 As shown, the cooling device 5 includes a refrigeration system 101, one end ...

Embodiment 2

[0078] Embodiment 2: as figure 1 , image 3 with Figure 4 As shown, it is a temperature adjustment control method realized by using a technical solution of an optimally set cooling device 5. When the cooling device is used to cool the grain pile, the return air valve and the grain pile air path valve in the warehouse are opened. Close the air supply valve in the compartment. The return air in the warehouse is processed by the filter, and after being cooled and dehumidified by the evaporator in the refrigeration system through the return air pipe in the warehouse, the air reaches the air supply static pressure box, and the evaporating fan sends the low-temperature air into the grain stack air duct, and then passes through The grain stack air valve is sent into the granary through the vent of the cage on the ground of the grain depot. The low-temperature air passes through the grain pile and enters the refrigeration equipment through the return air duct connected to the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com