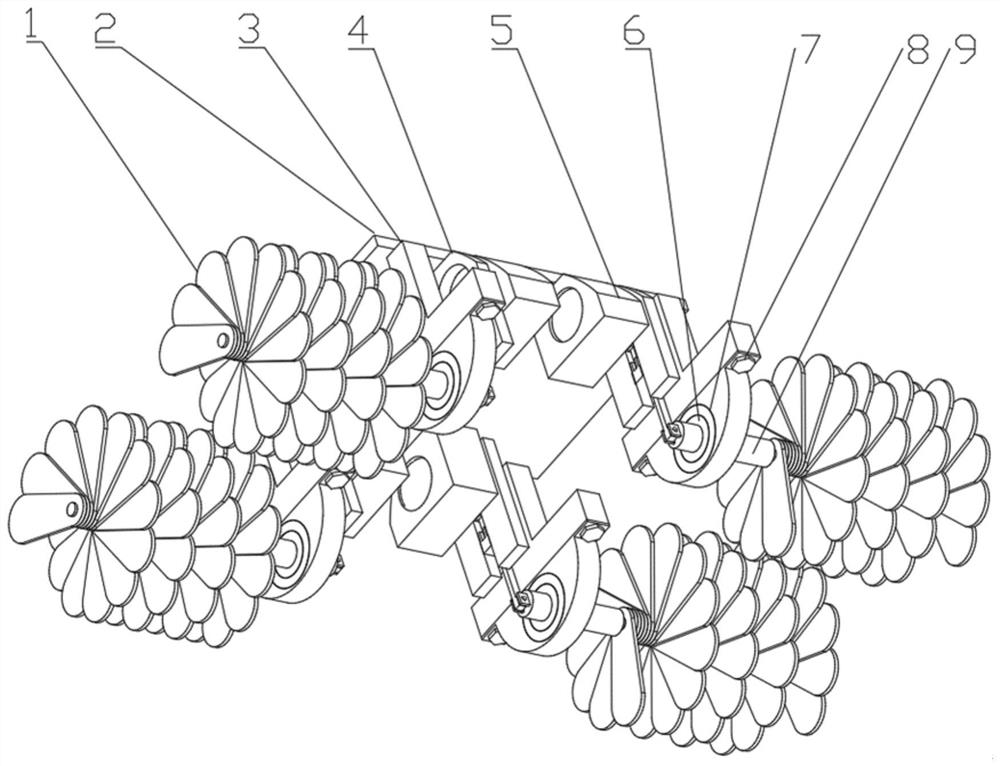

A warehouse detection robot

A robot and warehousing technology, applied in the field of grain condition detection, can solve the problems of low grain condition detection efficiency in granary, many grain damage, high manufacturing difficulty and high cost, and achieve the effect of high temperature and humidity detection efficiency and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] When the grain surface of the granary or the inside of the granary is moved forward, the control panel controls the forward driving motor to rotate, and the output shaft is driven to rotate through the coupling connecting device, and the screw wheel is driven to move forward to realize the straight forward movement.

[0032] When it is necessary to drill into the grain inside the granary, the straight forward drive system of the front and rear wheels works normally to keep the forward movement. At the same time, the control panel controls the operation of the lift drive motor to drive the output shaft of the lift drive motor to rotate, and the crank slider mechanism rotates to drive the crank slider to move up and down. The crank slider connecting piece is connected to one end of the joint bearing shaft, and the joint bearing fixing device As the fulcrum, the up and down swing of the helical wheel is realized by lifting the joint bearing shaft to ensure the diving and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com