Multifunctional hammer drill

A percussion drilling rig, multi-functional technology, applied in percussion drilling, reciprocating drilling rigs, drilling equipment, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive drilling in hard rock formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

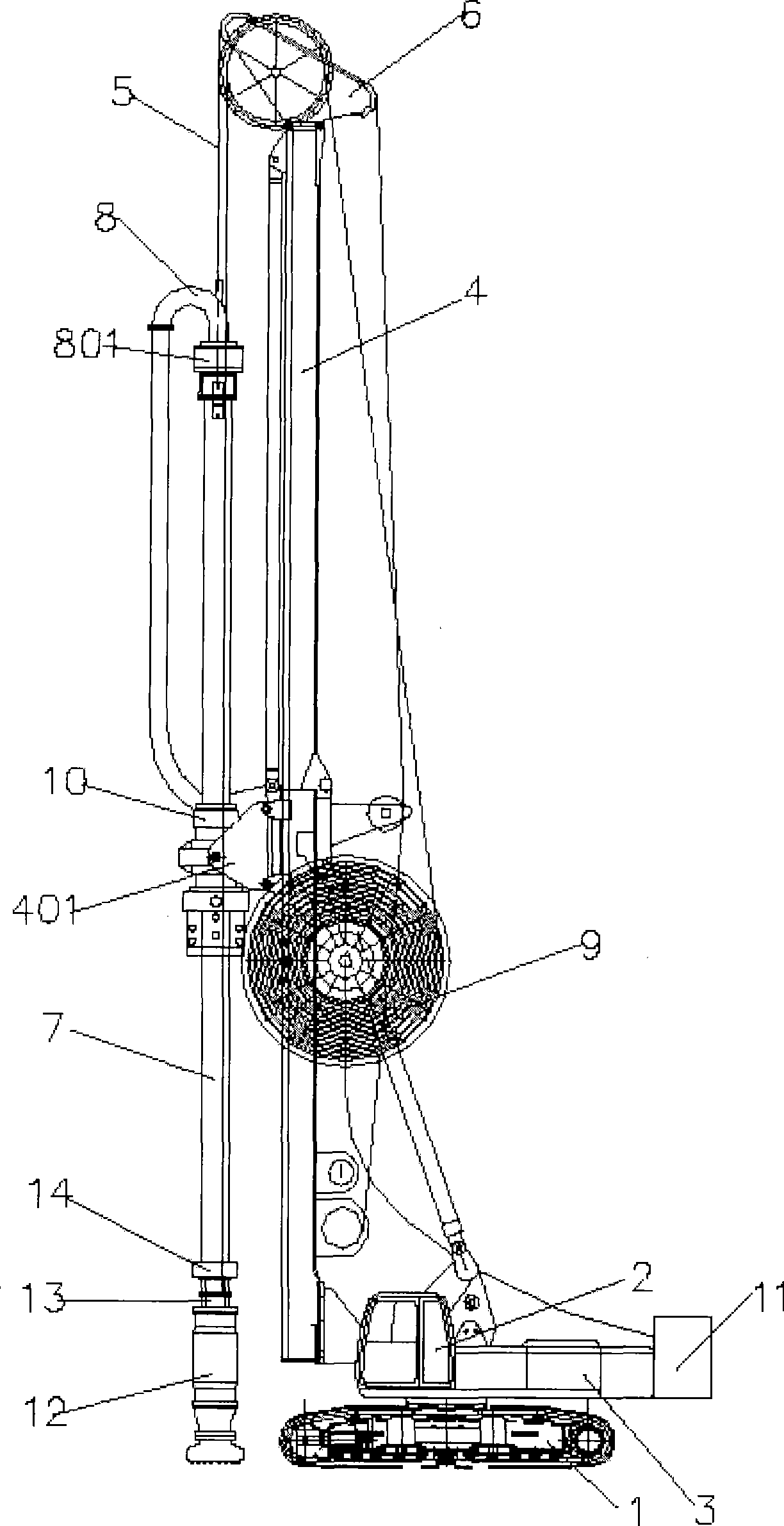

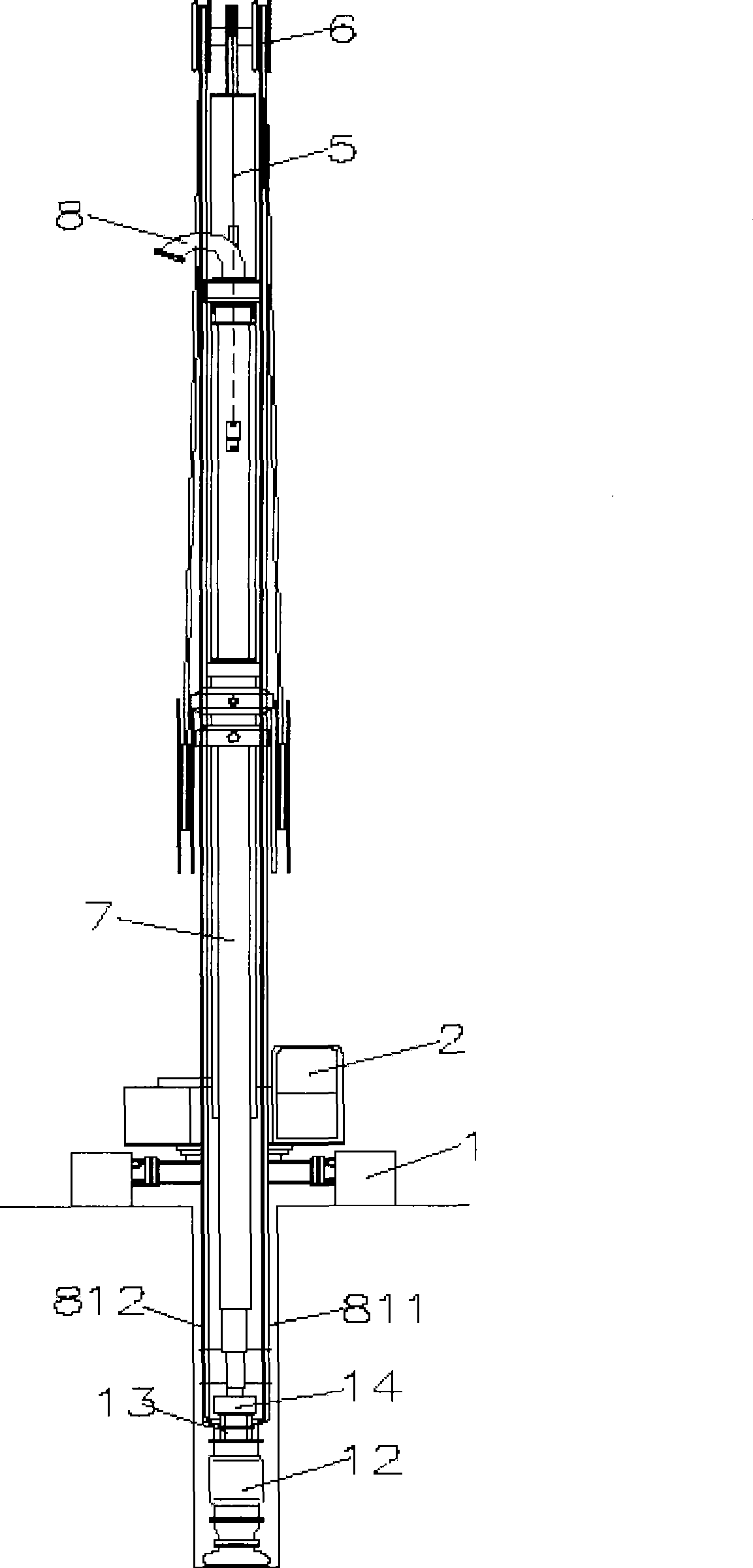

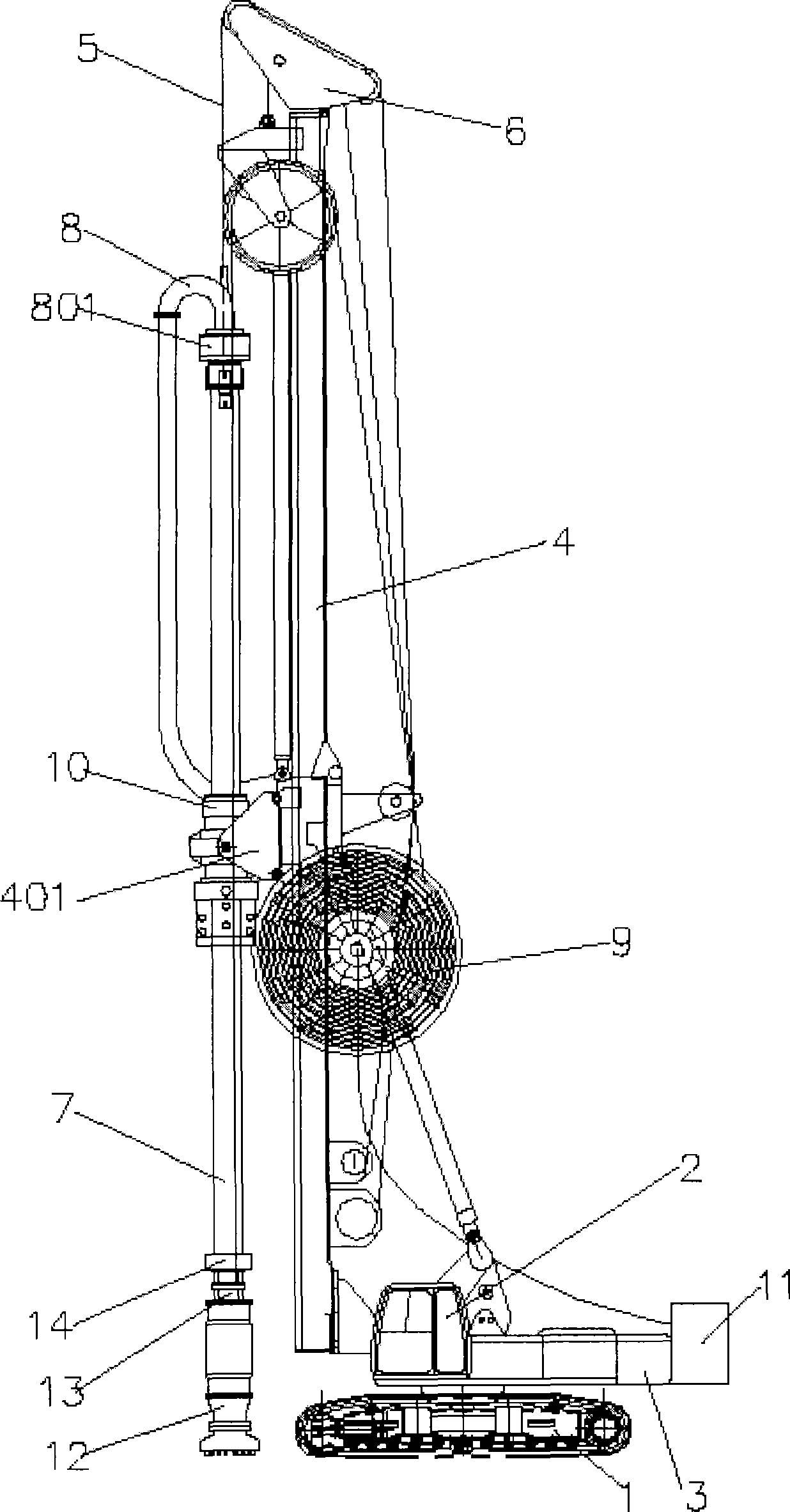

[0025] see figure 1 , figure 2 and combine image 3 , as shown in the figure: a multifunctional percussion drilling rig, which includes a hydraulic crawler chassis 1, a control room 2, a drilling rig main engine 3 and an upright mast system 4 are arranged on the chassis 1, a steel wire rope 5 is arranged on the mast system 4, and a top is provided There is a crown block 6, which is connected to the drill pipe 7 through the wire rope 5 driven by the hoist and the fixed frame 401. The drill pipe 7 is a multi-layer hollow sealed telescopic drill pipe. The lower part of the drill pipe 7 is connected with a working device 12. There is a slagging faucet 8 for reverse circulation slagging or a slag collecting cylinder 14 connected to the lower part for positive circulation slagging, which also includes:

[0026] The power unit 11 of the working device 12 is arranged on the chassis 1 and powered by the main engine 3 of the drilling rig;

[0027] A number of flexible pipelines 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com