Centrifugal threshing device for coarse cereal crops

A threshing device and centrifugal technology, applied in the agricultural field, can solve the problems of easy clogging threshing efficiency, poor separation effect, high grain damage rate, etc., and achieve the effect of reasonable and reliable structural design, reduced damage rate, and reduced impurity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

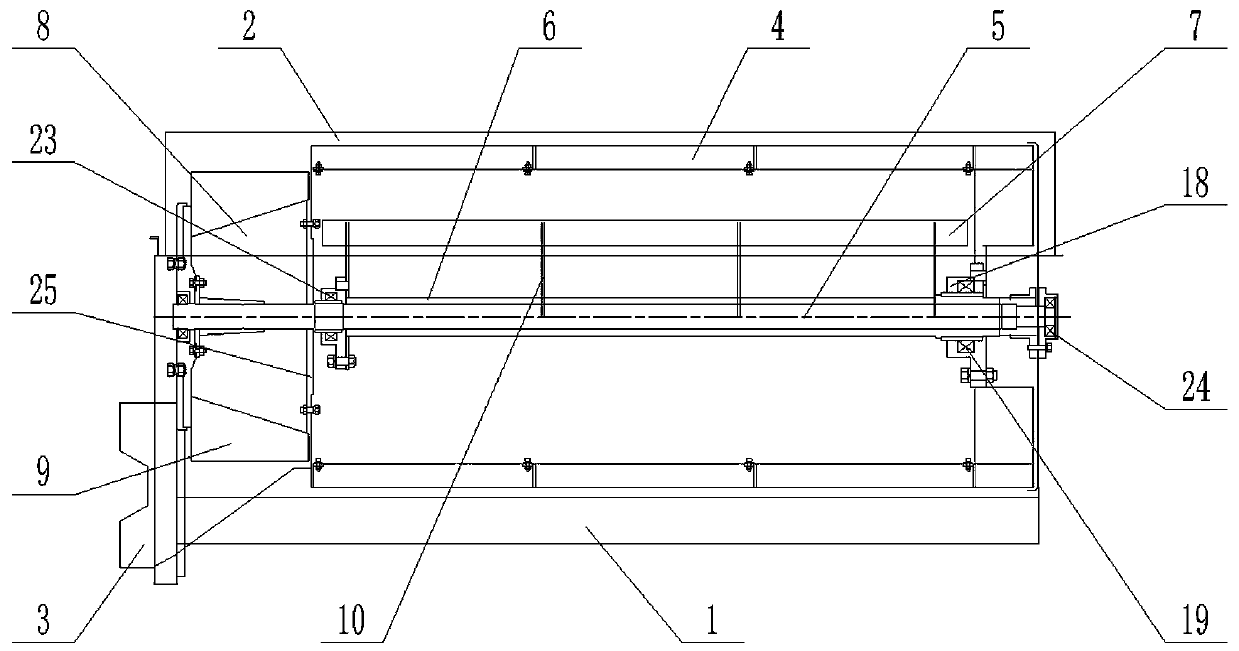

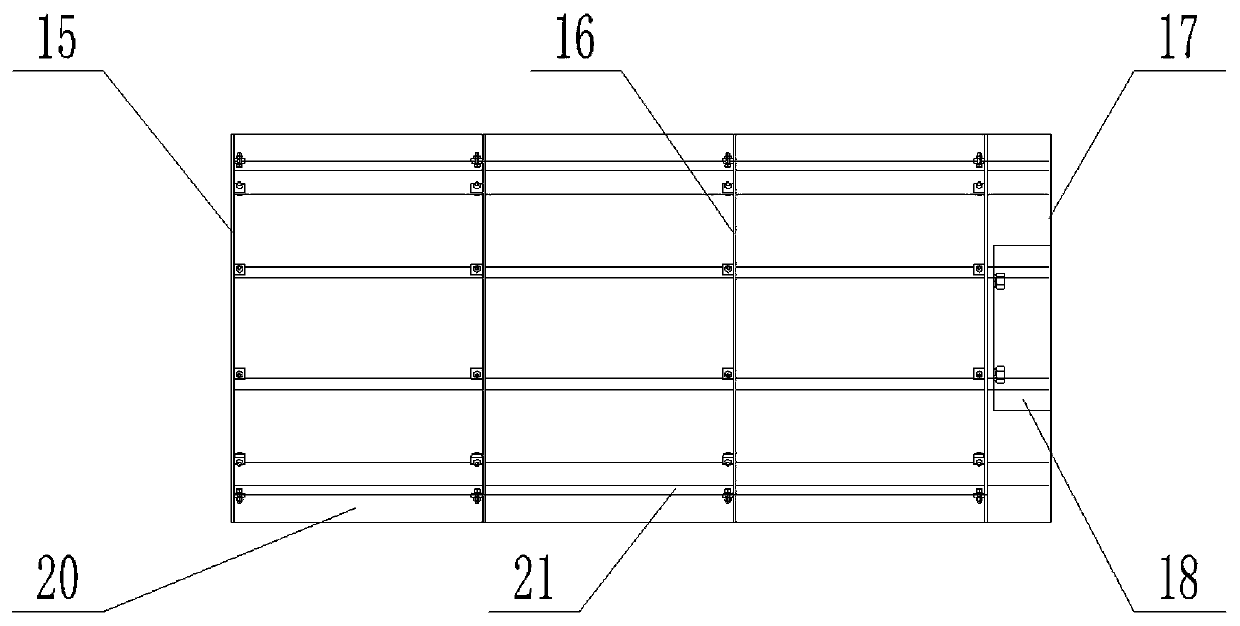

[0019] A centrifugal threshing device for miscellaneous grains, comprising a box-type frame 1, the upper end of the box-type frame 1 is provided with a top cover 2 with an arc-shaped inner wall, and the lower part of the left side wall of the box-type frame 1 is provided with a feeding port 3 , the box-type frame 1 is provided with a screw feeding device and a threshing drum 4 distributed left and right and connected to each other, and a coaxial transmission shaft 5 connected with the screw feeding device and the threshing drum 4 is arranged in the box-type frame 1, The transmission shaft 5 is covered with a hollow shaft sleeve 6 fixed to the box frame 1, and the hollow shaft sleeve 6 is provided with a screw pushing device 7;

[0020] The screw feeding device includes a conical feeding cylinder 8 fixed on the transmission shaft 5, and a helical blade 9 arranged along its axial direction is fixed on the conical feeding cylinder 8;

[0021] The screw propulsion device 7 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com