Bucket-type grain elevator with blast heat exchange function

A hoist and grain technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of increased grain damage rate, prolonged operation time, and occupied space, so as to save equipment procurement costs and space occupation, reduce Grain damage rate and the effect of reducing the overall operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

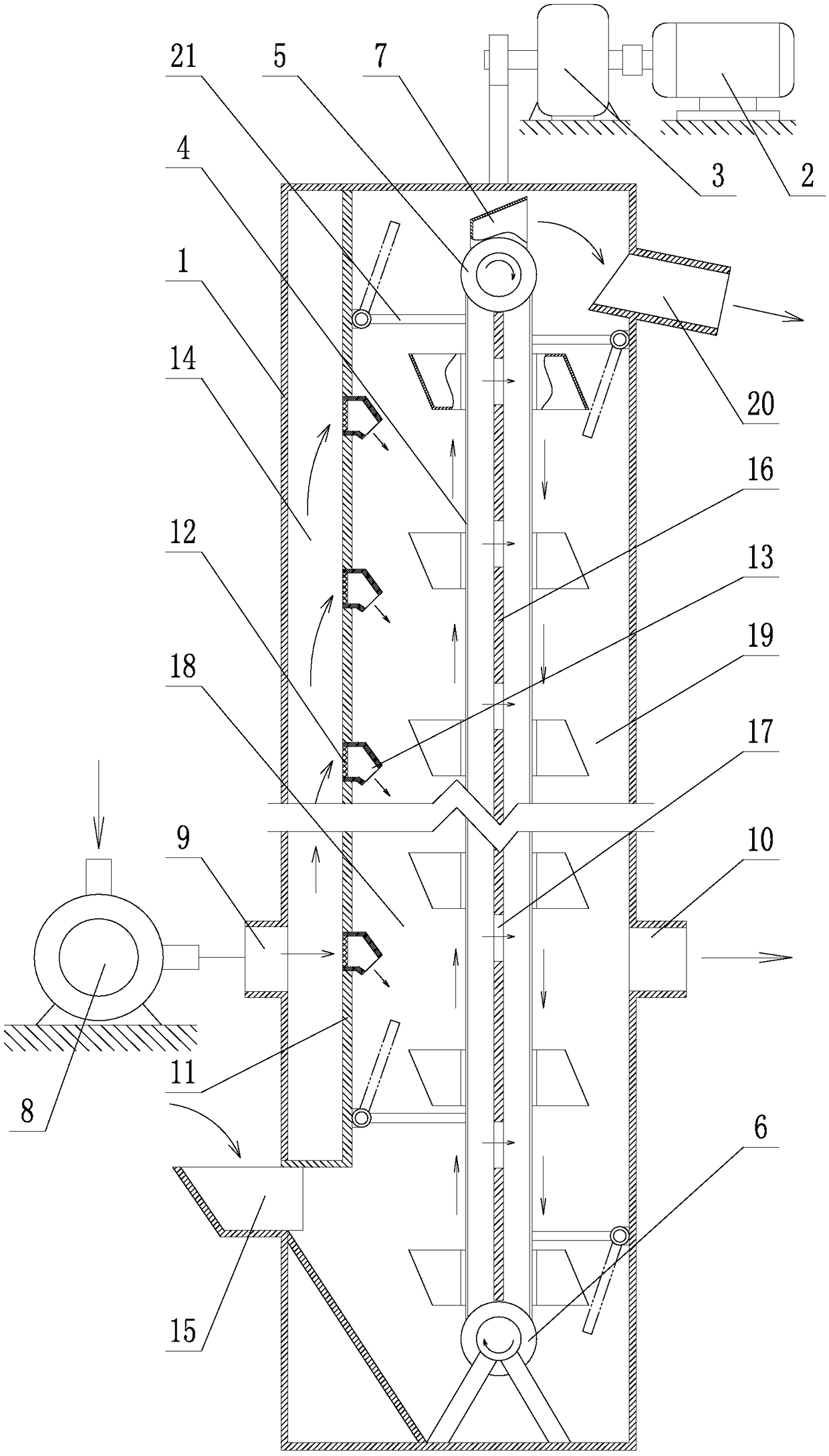

[0014] Such as figure 1 As shown, a bucket type grain elevator with blast heat exchange function includes a housing 1, a lifting drive motor 2, a transmission 3, a hoop traction chain / belt 4, a driving traction chain / pulley 5, a driven traction Chain / pulley 6 and hopper 7, the housing 1 adopts a cylindrical structure and is vertically arranged, the driving traction chain / pulley 5 is installed on the top of the interior of the housing 1, and the driven traction chain / pulley 6 Installed at the inner bottom of the housing 1, the active traction chain / pulley 5 and the driven traction chain / pulley 6 are connected through the hoop traction chain / belt 4, and are evenly distributed on the hoop traction chain / belt 4. Several hoppers 7; the motor shaft of the lifting drive motor 2 is fixedly connected with the power input shaft of the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com