Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

266results about How to "Improve threshing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

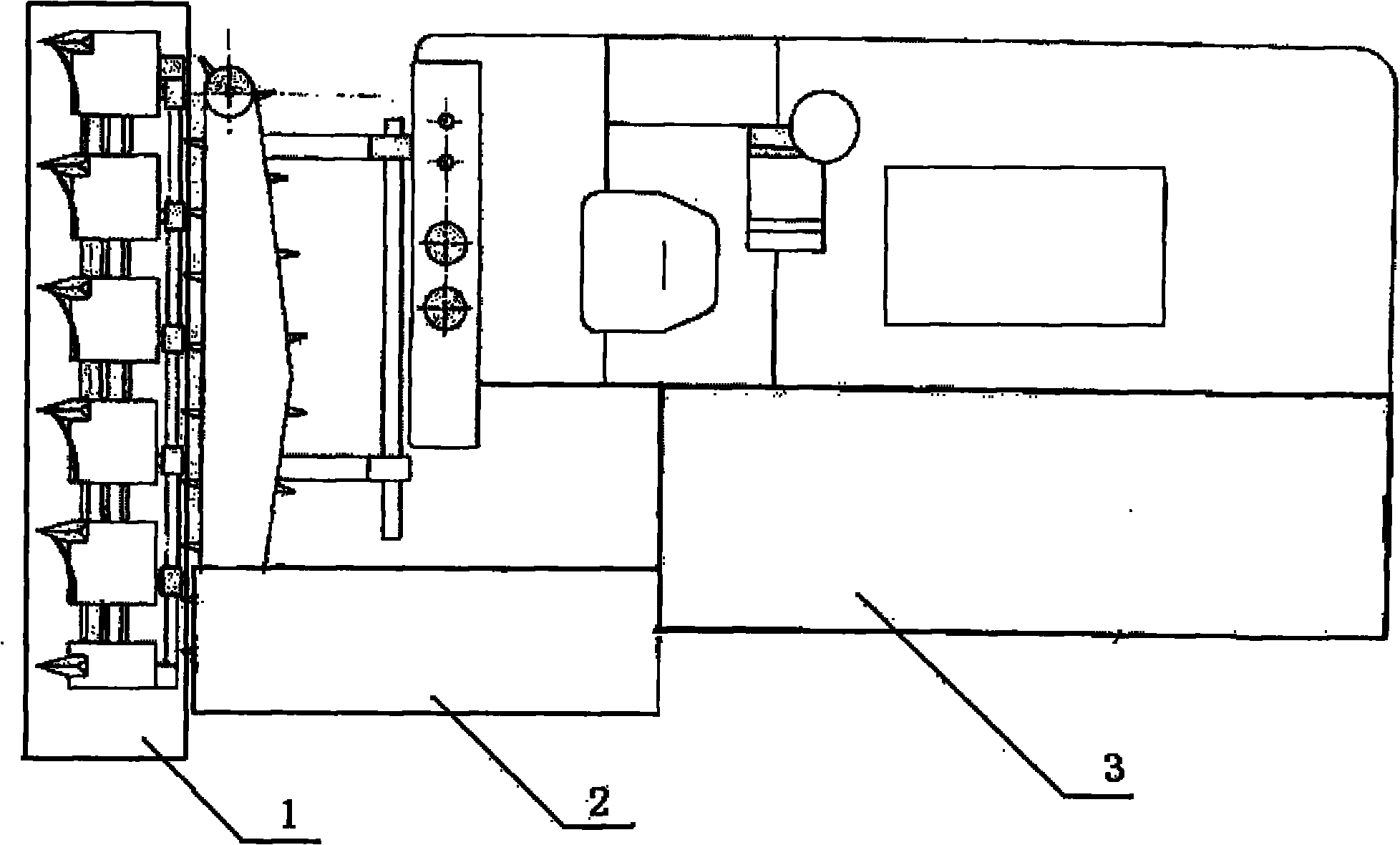

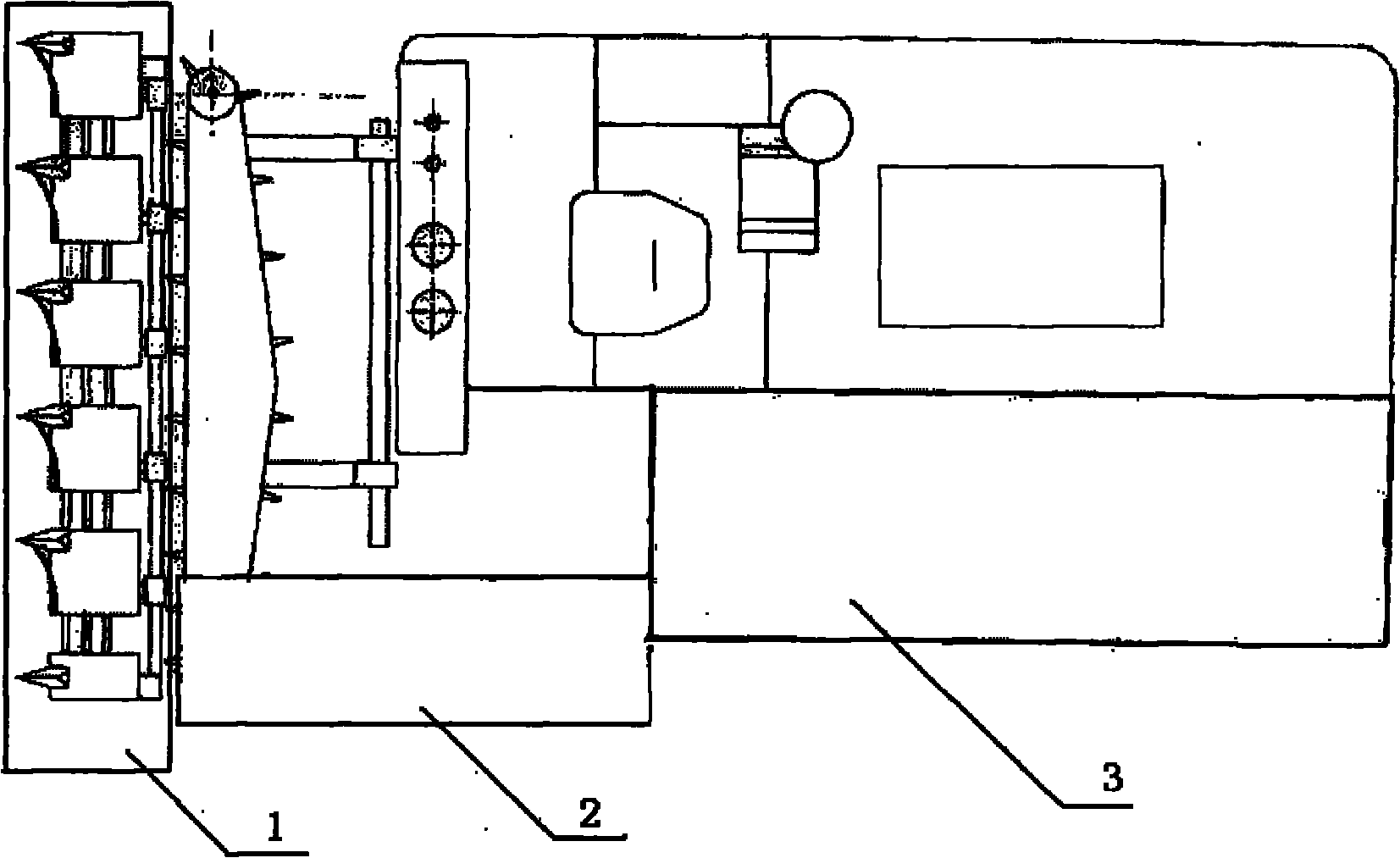

Threshing separation cylinder, threshing separation device and combine harvester

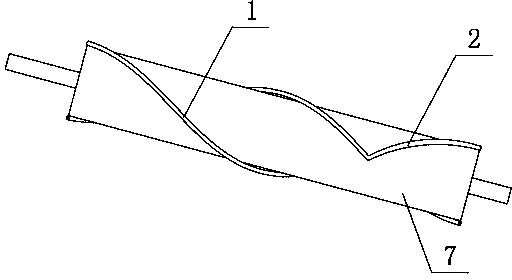

The invention relates to a threshing separation cylinder, a threshing separation device including the threshing separation cylinder and a combine harvester. The threshing separation cylinder is provided with a spin axis and comprises an truncated cone part and a cylindrical part in an axially flowing axis AA' direction in the threshing separation device respectively, wherein the truncated cone part comprises an truncated cone main body, the small diameter end part of the truncated cone main body is at the front end part of the threshing separation cylinder, the truncated cone main body is extended from the small diameter end part along the spin axis direction, the cylindrical part is extended from the big diameter end part of the truncated cone part to the rear end of the threshing separation cylinder along the spin axis of the threshing separation cylinder, wherein helical blades and corn adjusting components are arranged on the truncated cone main body. Separating teeth including spike teeth, bar teeth, plate teeth and arch teeth are arranged on the cylindrical part.

Owner:DEERE & CO

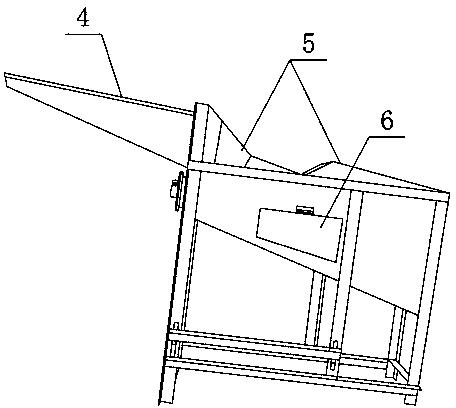

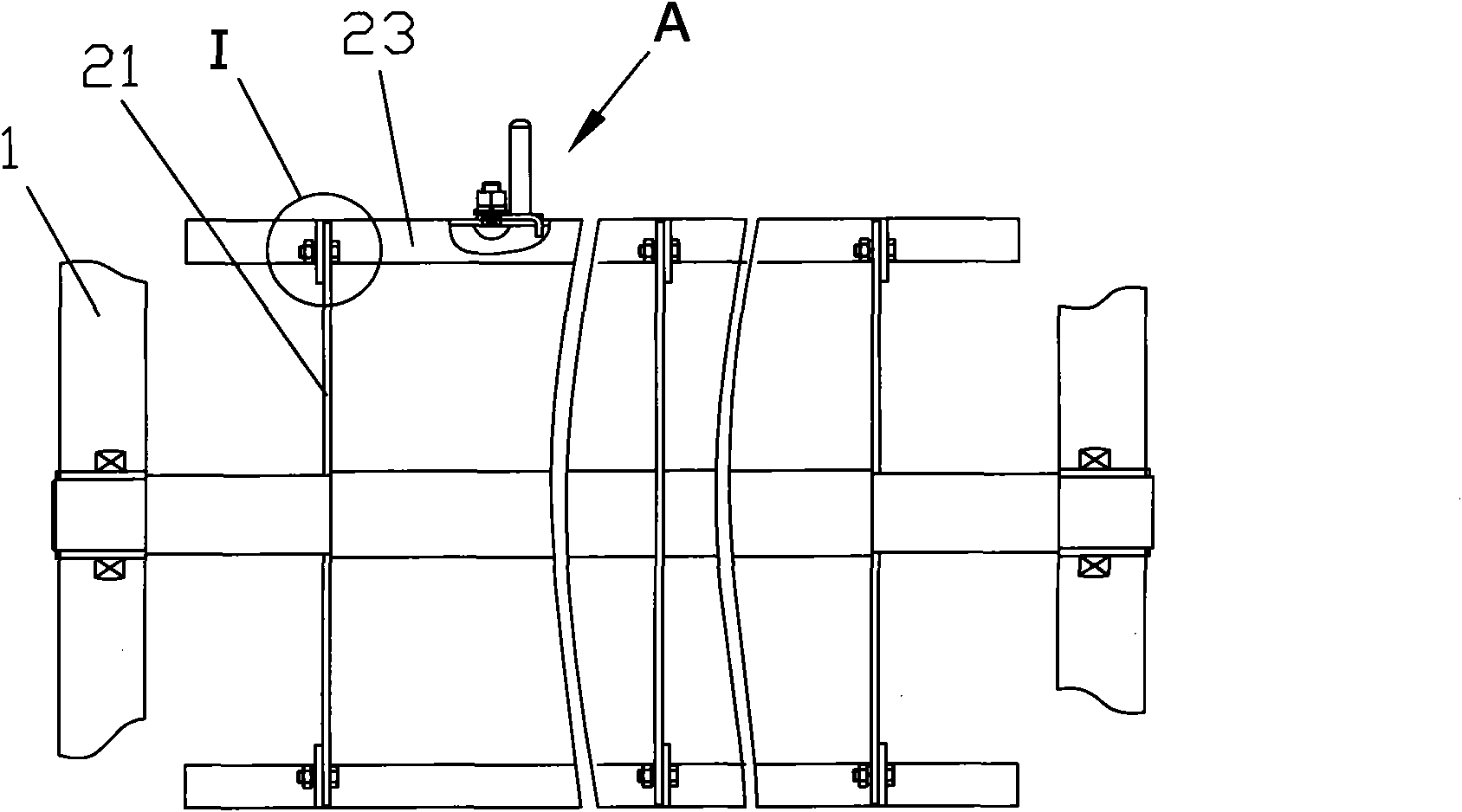

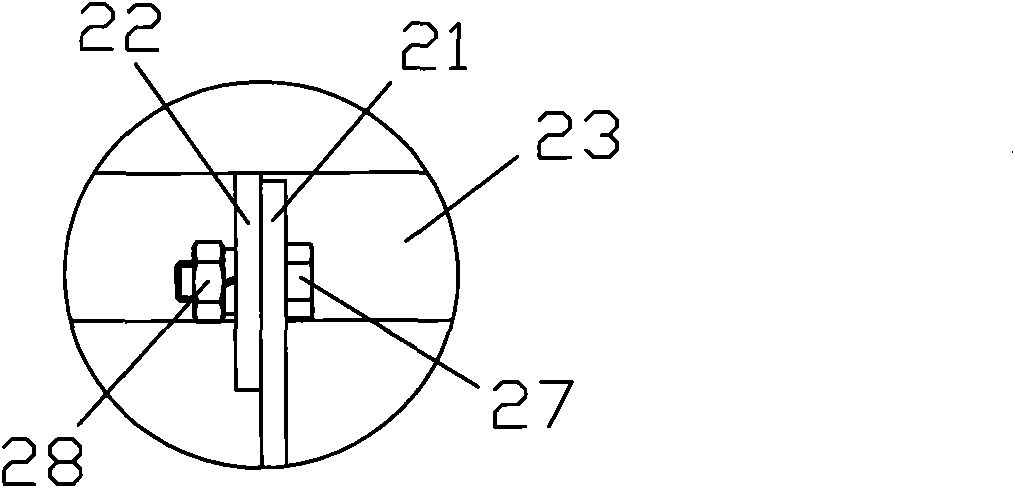

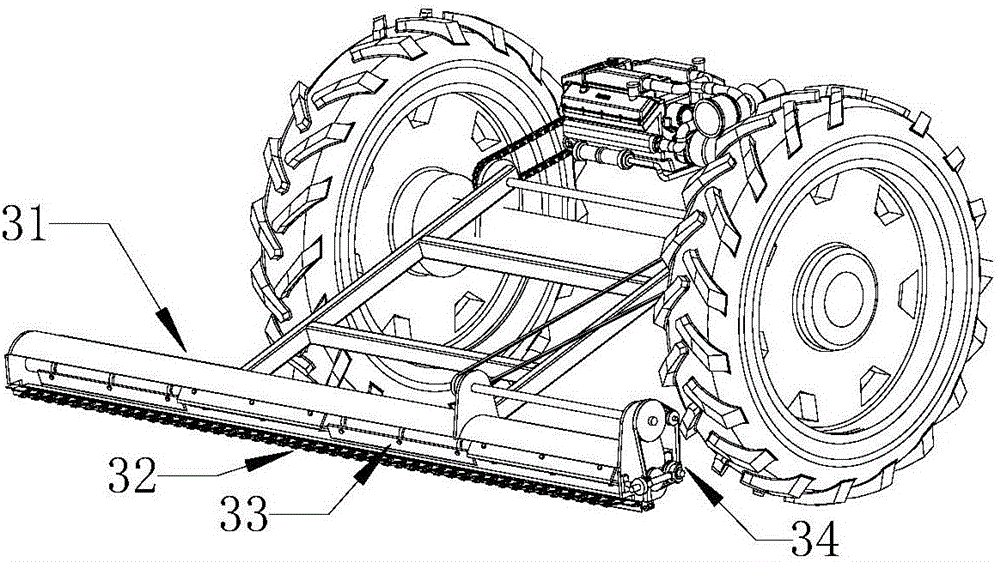

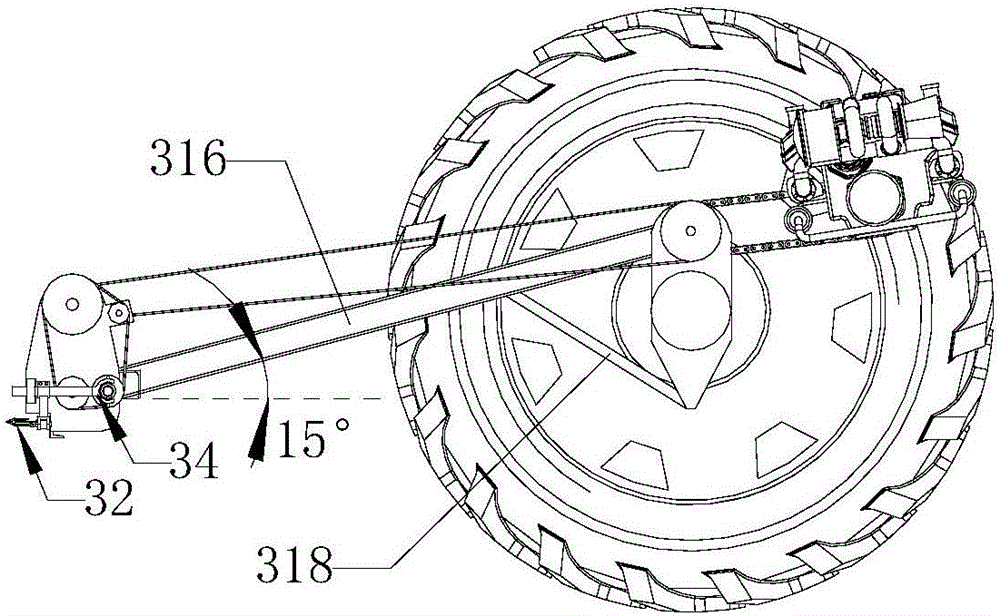

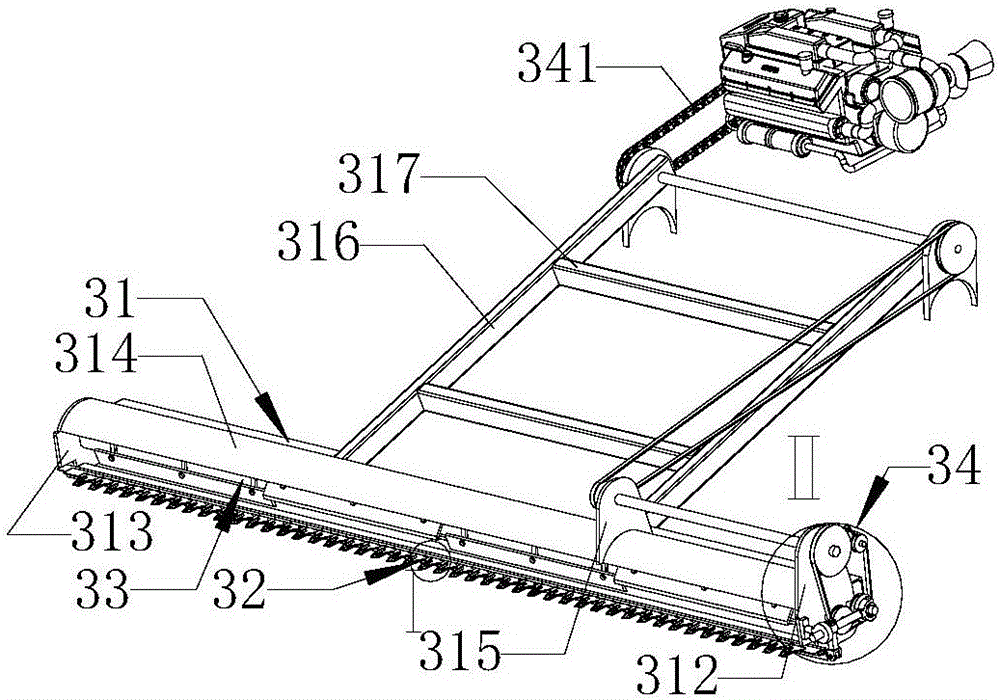

Harvester provided with protective ladder and lifting type lower header capable of smashing straw and preventing smashed straw from splashing

The invention discloses a harvester provided with a protective ladder and a lifting type lower header capable of smashing straw and preventing the smashed straw from splashing. The harvester comprises the lower header and the protective ladder, and the lower header is hinged to a front axle of the harvester. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism. Blocking angle iron is further fixedly connected with the rear portion of a shield of the lower header main frame. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper base and a lower header lifting oil cylinder lower base. The harvester provided with the protective ladder and the lifting type lower header capable of smashing straw and preventing the smashed straw from splashing can cut and smash straw left after grain harvesting, and the feed quantity of the harvester is reduced. Cutting stubbles are short and flat so that tillage can be convenient. The straw cutting and smashing efficiency is high, smashing is uniform, and the smashed straw cannot splash. The lower header can ascend and descend so as to control the height of the cutting stubbles and avoid obstacles to protect equipment safety. The arranged protective ladder makes people climb safely and conveniently, and can also be used as a safety guardrail.

Owner:纪小坤

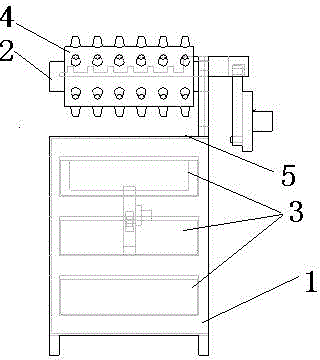

Floating directional feeding type corn bionic threshing machine

InactiveCN106489443AGood threshing effectGuaranteed rotation workThreshersAgricultural engineeringBreakage rate

The invention relates to the field of agricultural machinery, in particular to a floating directional feeding type corn bionic threshing machine. The floating directional feeding type corn bionic threshing machine comprises a machine frame, wherein two differential rollers, a dispersing roller and a threshing roller are arranged on the machine frame; a dispersing area for destroying a corn particle integrated arrangement structure on corn ears and a threshing area for completely stripping the corn particles from the corn ears are formed between the dispersing roller and the threshing roller as well as the two differential rollers correspondingly; a feeding device which is used for conveying the corn ears to the dispersing area one by one along the axial direction between the two differential rollers is arranged on one side, provided with the dispersing area, of the machine frame; height floating adjusting devices are arranged between each of roller shafts of the dispersing roller and the threshing roller as well as the machine frame; and the height floating adjusting devices perform floating adjustment on the height of the dispersing roller and the height of the threshing roller according to the diameter difference of the corn ears which enter the dispersing area and the threshing area. The floating directional feeding type corn bionic threshing machine has the advantages of extremely low breakage rate, high threshing rate and avoidance of corncob breakage, and is suitable for subsequent processing after the corn ears are picked.

Owner:HENAN UNIV OF SCI & TECH

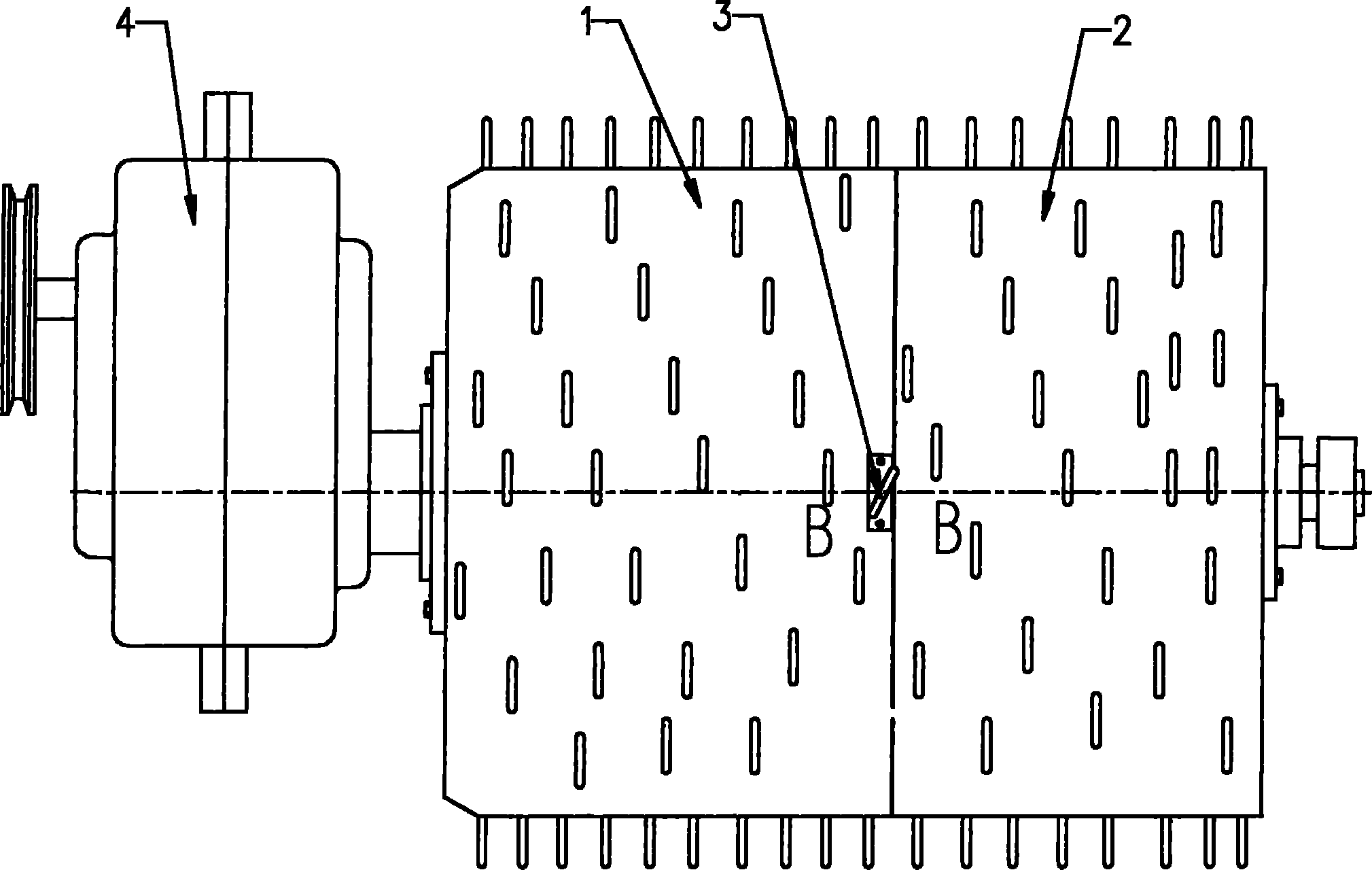

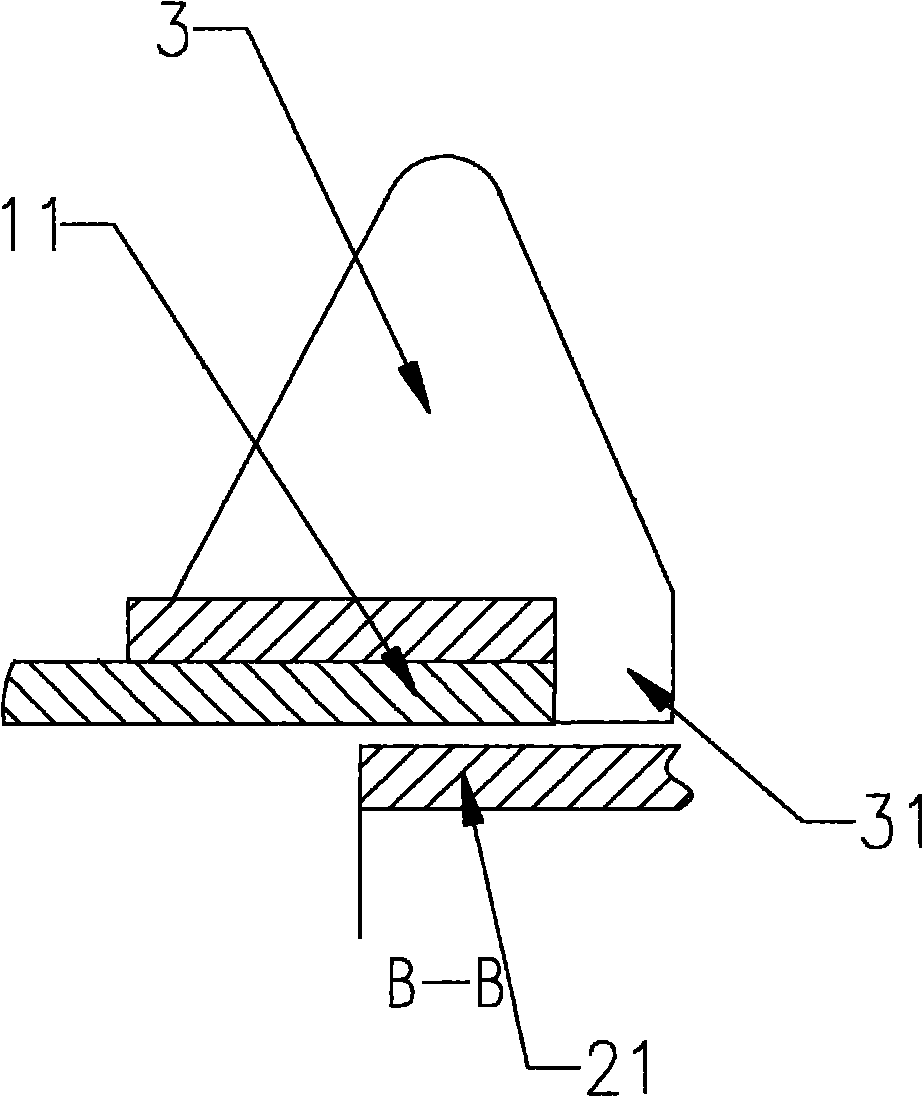

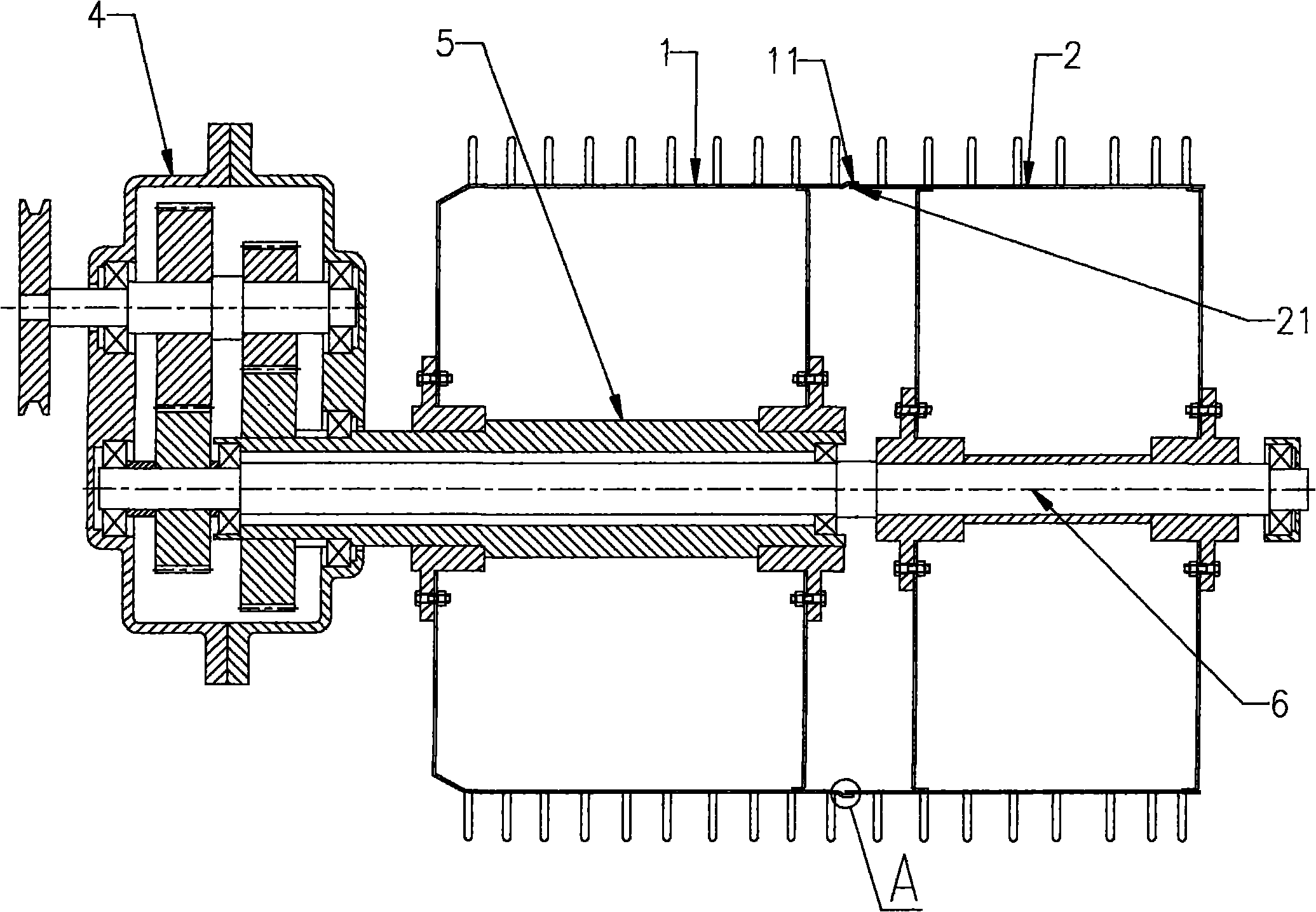

Coaxial double-speed threshing cylinder

The invention discloses a coaxial double-speed threshing cylinder of a threshing device of a half-feed combine harvester. The coaxial double-speed threshing cylinder comprises a high-speed cylinder and a low-speed cylinder, wherein the low-speed cylinder is positioned on the left side of the high-speed cylinder; the outside diameter of the high-speed cylinder is less than the inside diameter of the low-speed cylinder on the connection part of the high-speed cylinder and the low-speed cylinder; the left end of the body of the high-speed cylinder is 15 to 25mm extended into the body of the low-speed cylinder to form a socket joint structure; the low-speed cylinder is provided with threshing plate teeth on the socket joint part with the high-speed cylinder; and the threshing plate teeth are 3 to 5mm extended out of the right end face of the body of the low-speed cylinder. The coaxial double-speed threshing cylinder has the advantages of high integral structural strength, simple manufacturing, reliable work and good anti-blockage effect, and can excellently adapt to different characteristics of physical states of materials at a front threshing section and a rear threshing section in the threshing chamber, and several main performance indexes such as threshing rate, damage rate, loss rate and energy consumption well are simultaneously considered.

Owner:琚夏利

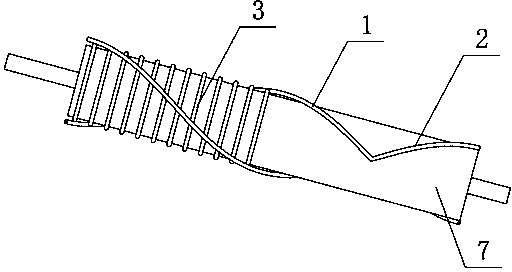

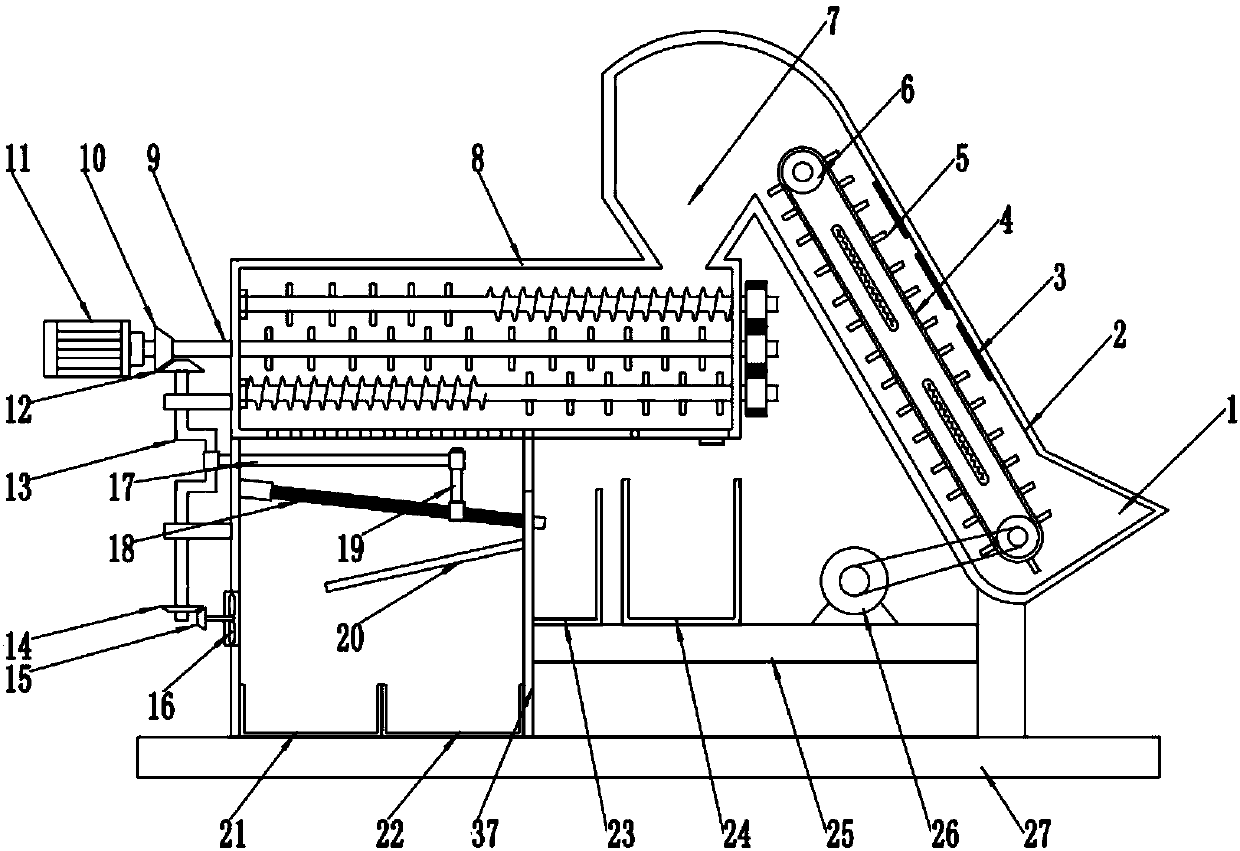

Corn thresher capable of carrying out deflecting threshing

ActiveCN103931358AShorten the lengthReduce non-threshing operation sectionThreshersAgricultural engineeringStructural engineering

The invention discloses a corn thresher capable of carrying out deflecting threshing. The corn thresher comprises a feeding port, a threshing barrel, a bin shell, a corn kernel discharge port and a corncob discharge port, the threshing barrel is obliquely arranged, at least one layer of threshing ribs is arranged on the threshing barrel, each threshing rib comprises an upper threshing rib segment and a lower threshing rib segment, the upper threshing rib segments and the lower threshing rib segments are all spiral threshing ribs and are opposite in spiral direction, the spiral direction of the upper threshing rib is opposite to the rotating direction of the threshing barrel, and the spiral direction of the lower threshing rib segments is identical to the rotating direction of the threshing barrel. The corncob discharge port is formed in the side face corresponding to the connecting positions of the upper threshing rib segments and the lower threshing rib segments. The motion track of corn cobs entering a threshing bin is limited by arranging the deflecting ribs, the height of the threshing bin is changed by changing the barrel diameter of the threshing barrel or the double-layer ribs, and therefore the corn cobs can be fully threshed in different spaces of the threshing bin, the threshing performance can be greatly improved, and the non-threshing work sections of the threshing bin are reduced.

Owner:李禄海

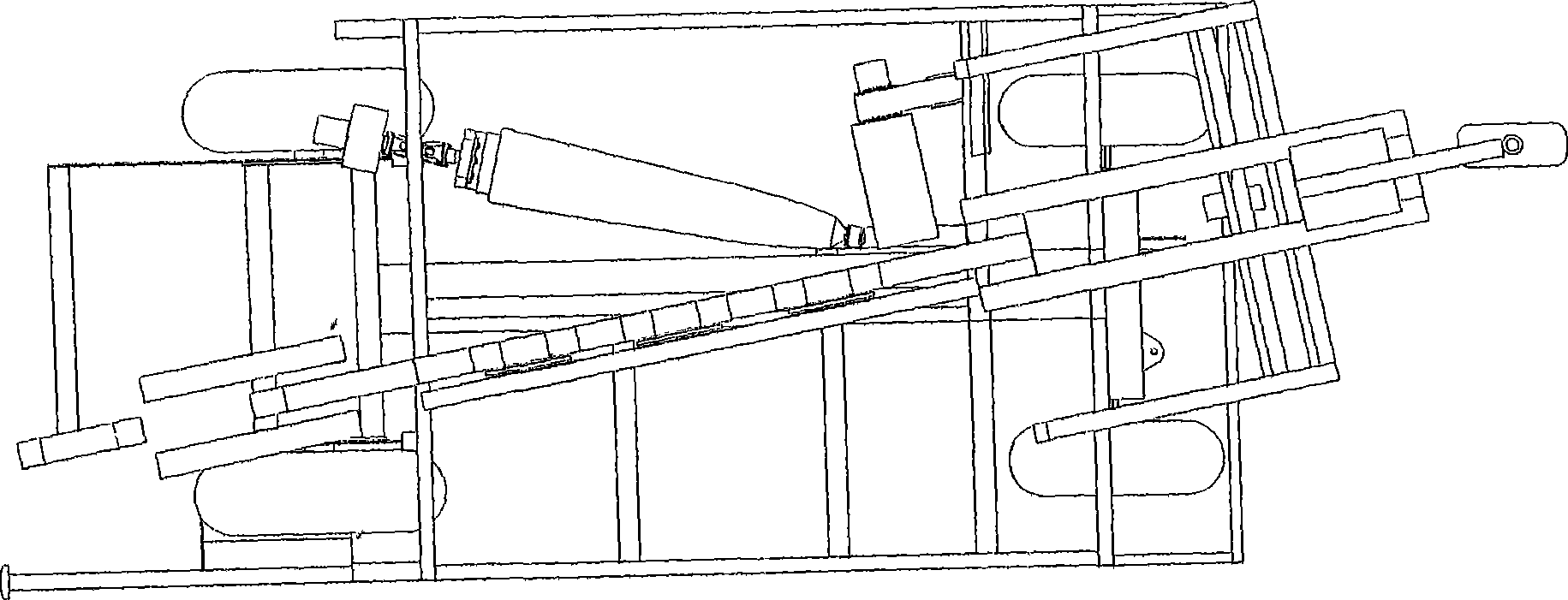

Threshing device of harvester

The invention relates to a harvester, in particular to a threshing device of a harvester. According to the technical scheme, the threshing device of the harvester comprises an underframe, a threshing frame, a main threshing mechanism, a rethreshing mechanism, a separation, cleaning and vibration screen and an impurity lifting screw, wherein the threshing frame is fixed on the underframe, both the main threshing mechanism and the rethreshing mechanism are connected to the threshing frame and disposed along the travelling direction of the harvester, the separation, cleaning and vibration screen is fixedly connected to the threshing frame and positioned between the underframe and the main threshing and rethreshing mechanisms, and the impurity lifting screw is disposed between the position below the rear end of the separation, cleaning and vibration screen and the rethreshing mechanism. The main threshing mechanism comprises a main threshing roller, a large concave screen and a main roller cover, wherein the main threshing roller is hinged to the threshing frame, the large concave screen is fixed to the threshing frame and encloses the main threshing roller, and the main roller cover covers an opening of the large concave screen. The main threshing roller is slantingly disposed along the advancing direction of the harvester. A corner between the main threshing roller and a conveying chute of the threshing device compared with the prior art is reduced, so that conveying of crops is smooth, and the shortages of the prior art are made up.

Owner:ZHONGJI SOUTHERN MACHINERY

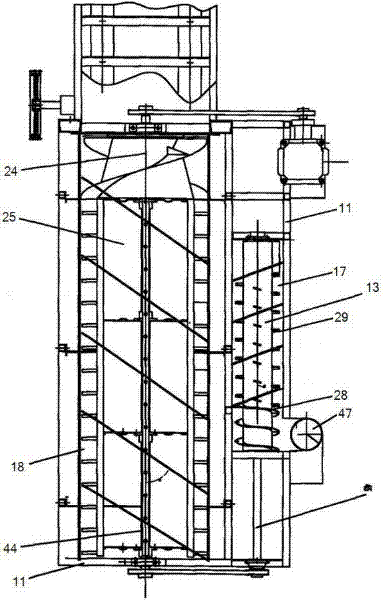

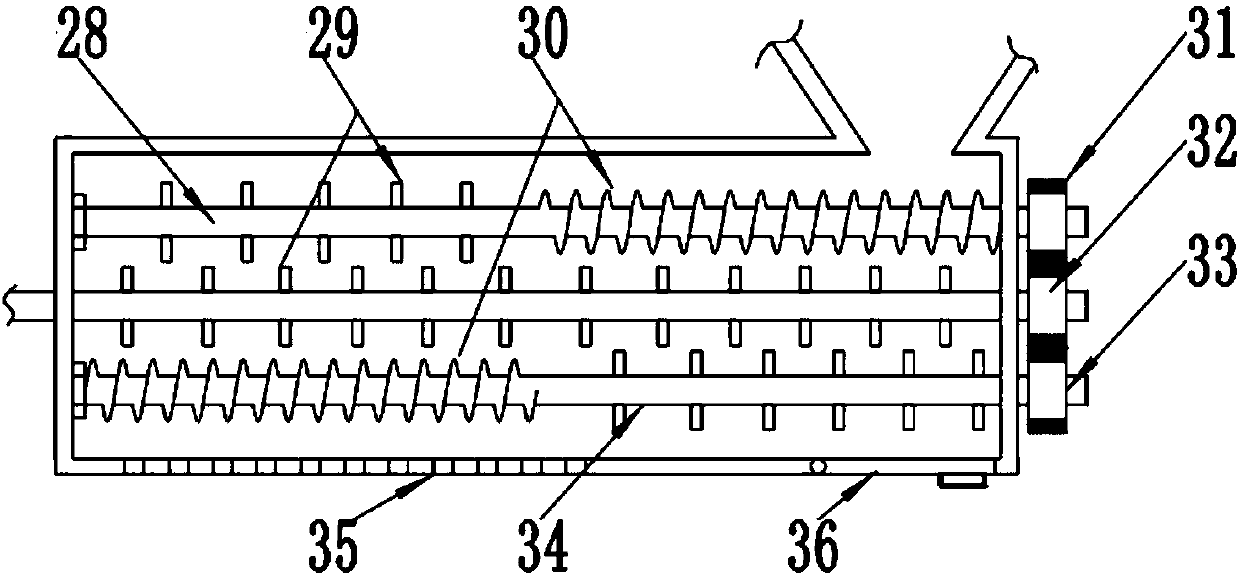

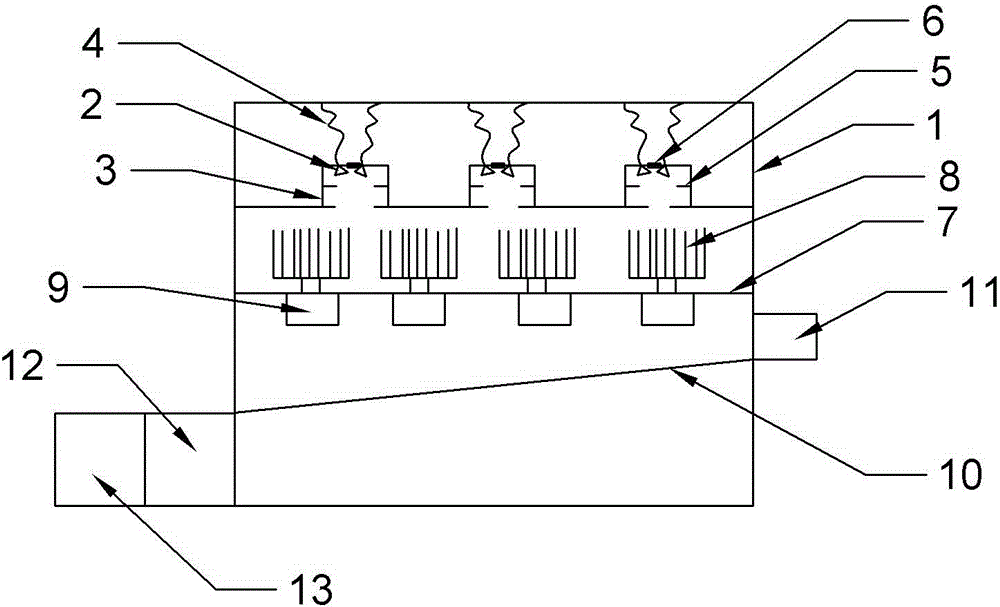

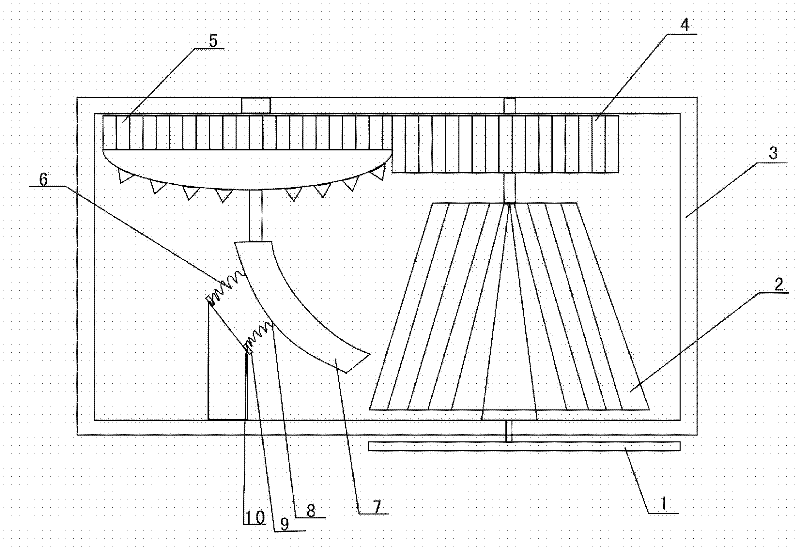

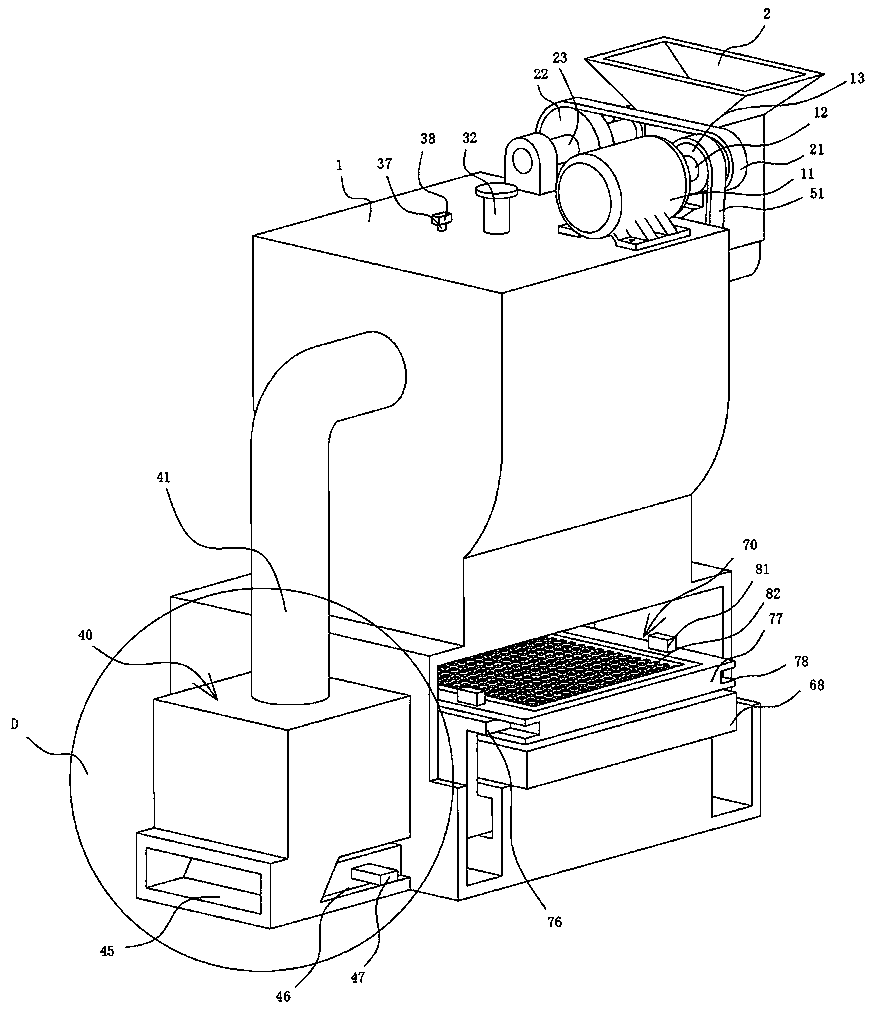

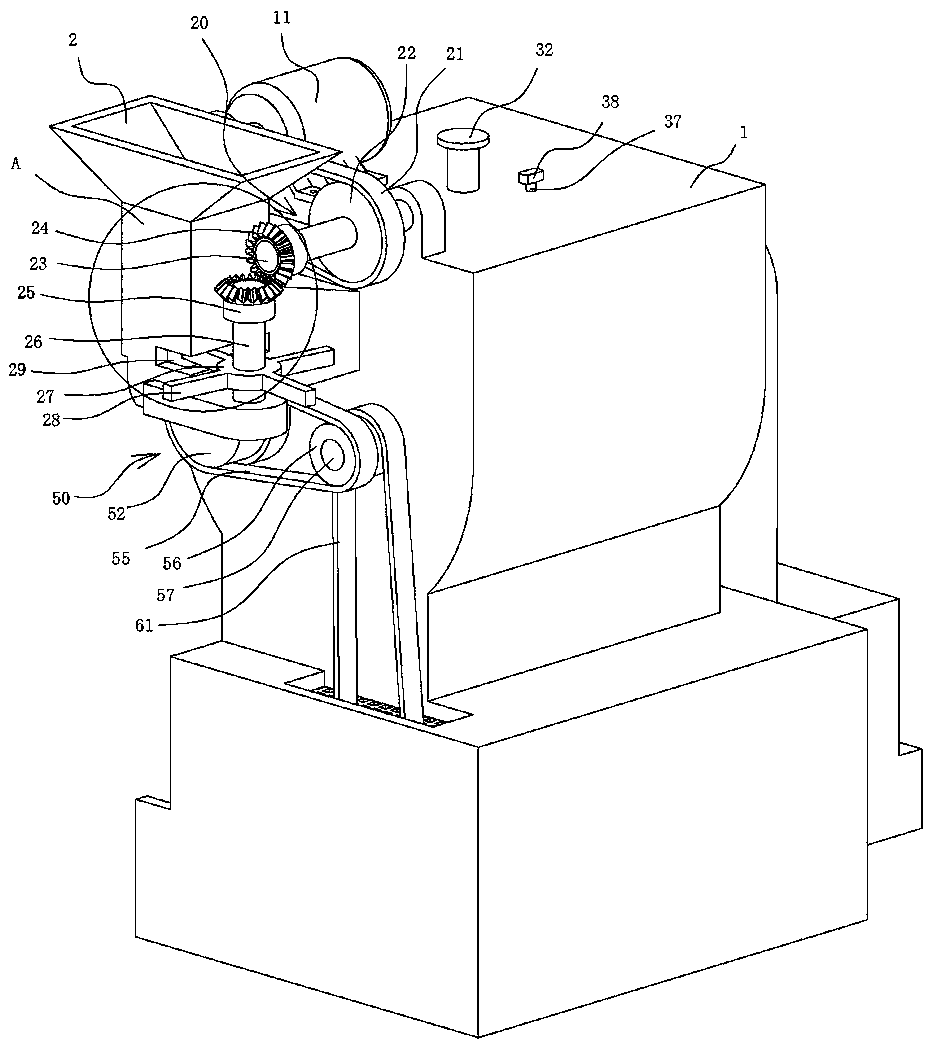

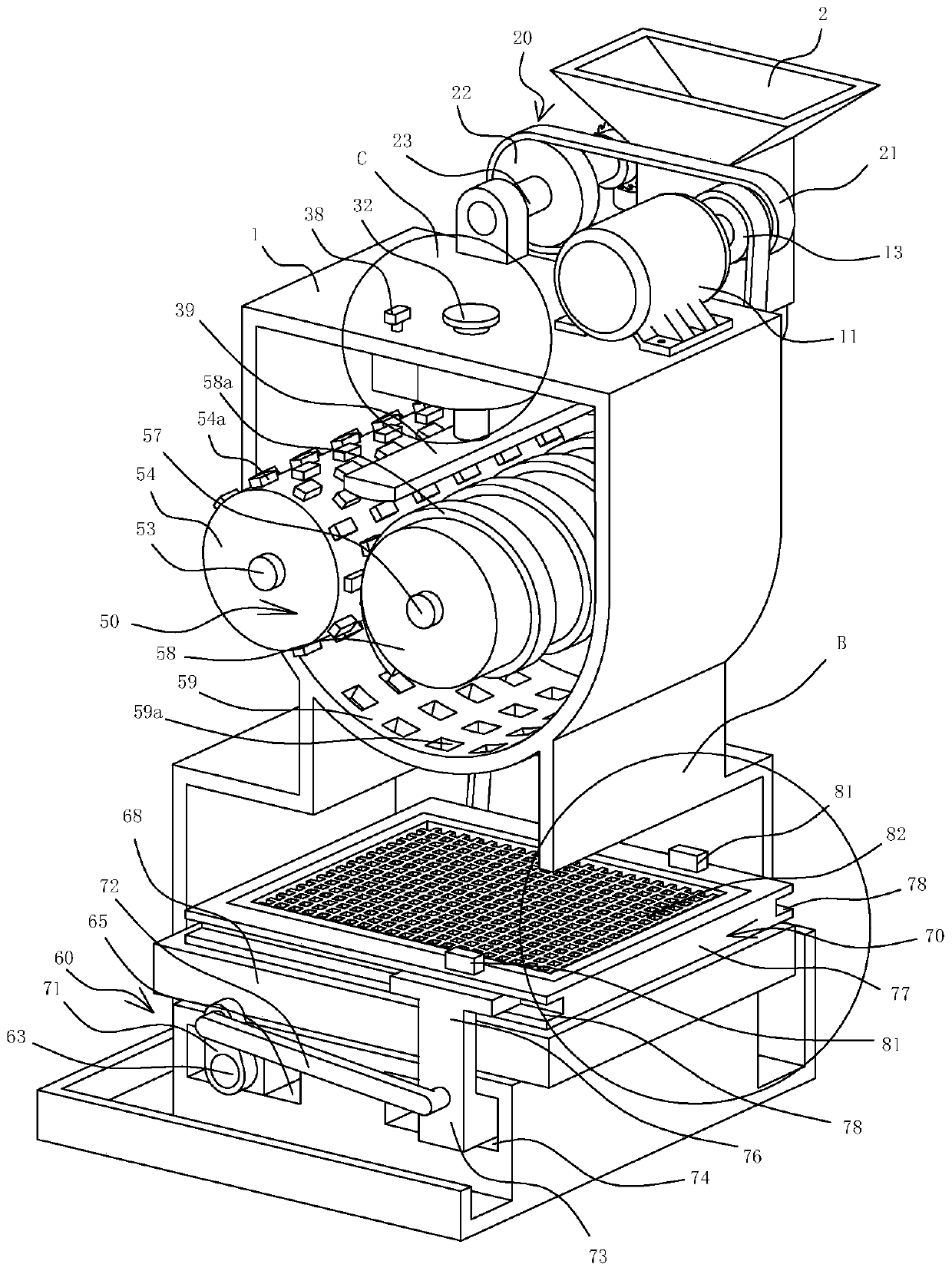

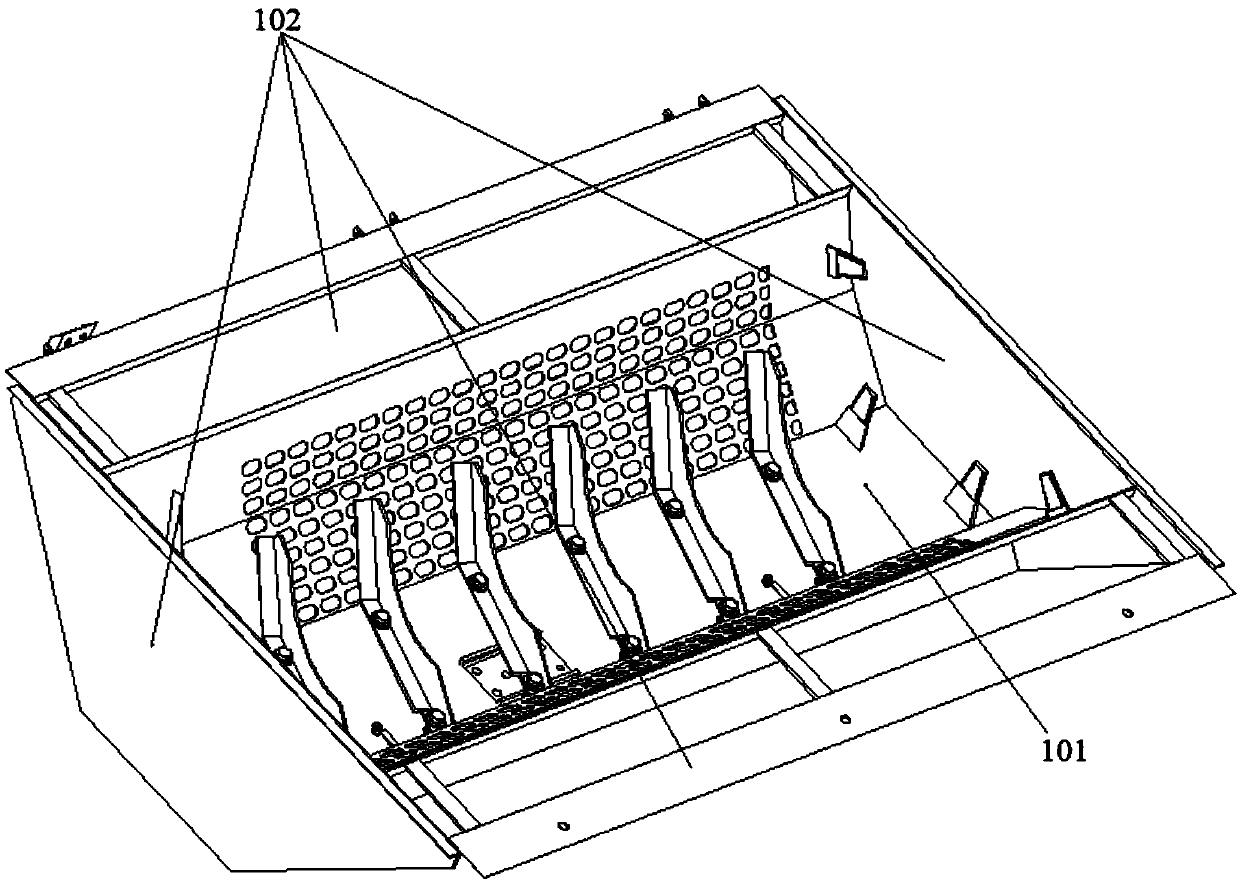

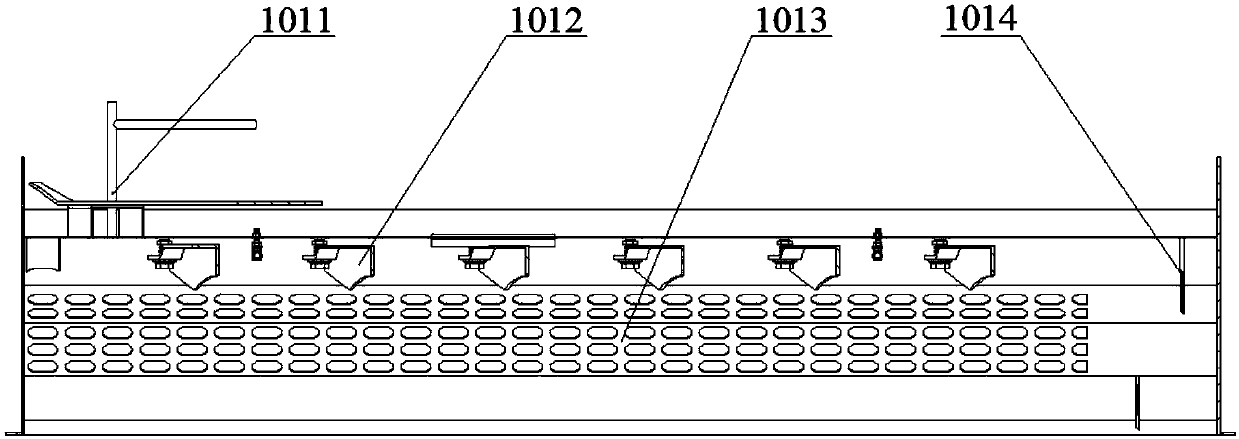

Full-automatic grain separation system for high-accuracy single plant inspection

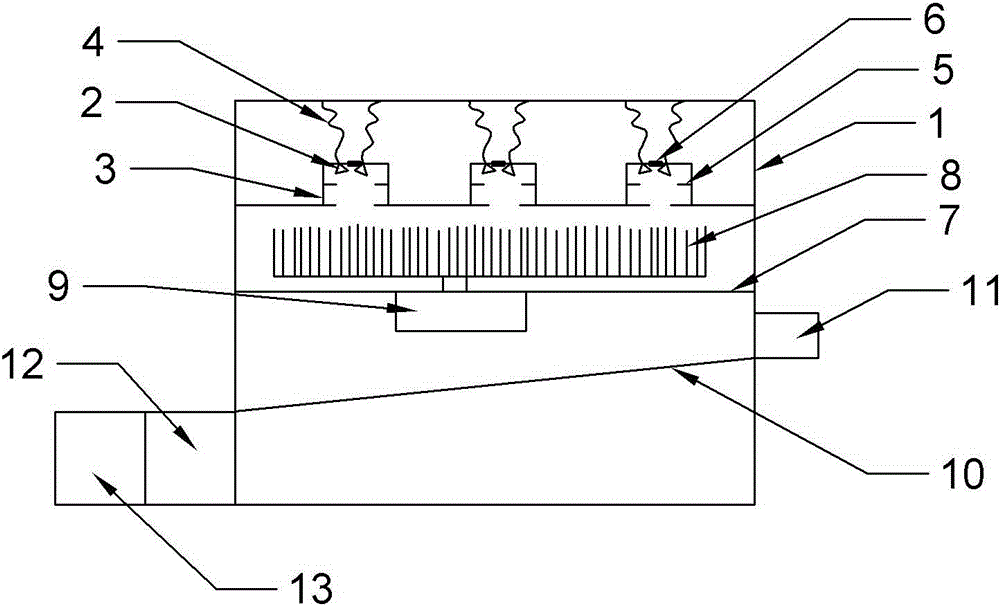

ActiveCN101933436AGood threshing effectGood adaptabilityClimate change adaptationThreshersTechnical supportAutomatic processing

The invention relates to a full-automatic grain separation system for high-accuracy single plant inspection. The system comprises a rice spike conveying line, a full grain threshing mechanism, an empty grain threshing mechanism, a vibratory screening mechanism, an air drying device and a controller, wherein a threshing part of the full-automatic grain separation system consists of the full grain threshing mechanism and the empty grain threshing mechanism; a photoelectric switch is arrange at the inlet of the rice spike conveying line; a signal wire of the photoelectric switch is connected with the input end of the controller; and signal wires of the rice spike conveying line, the full grain threshing mechanism, the empty grain threshing mechanism, the vibratory screening mechanism and the air drying device are connected with the output end of the controller. The full-automatic grain separation system has the advantages of small threshing error, high automation degree, suitability for automatic treatment on rice spikes at an early stage of the high-accuracy single plant inspection and capability of providing useful technical support for precision agricultural researches and digitized agricultural researches.

Owner:HUAZHONG UNIV OF SCI & TECH

Corn sheller

ActiveCN104350891AReduce harmSolve the high breakage rateThreshersBreakage rateMechanical transmission

The invention discloses a corn sheller, which comprises a box and at least one pair of shelling rollers connected with a pair of engaged gears, the middle of each shelling roller is concave, a plurality of ribs are radially and evenly distributed on each shelling roller, each rib is big-end-down, and a plurality of notches are evenly distributed on each rib; the shelling rollers are mounted on a frame, the front and back of the box are provided with openings, a corncob discharge hopper for discharging corncobs without niblets is arranged at the opening of the back of the box, a hopper for receiving shelled niblets is arranged under the shelling rollers, and the discharge outlet of the hopper is extended out of the box; the shelling rollers are connected with an engine through a mechanical transmission. Compared with the prior art, the corn sheller can solve the current problems of poor corn shelling effect and high breakage rate.

Owner:钦州皇马资产经营集团有限公司

Corn threshing device with classified screening function

The invention discloses a corn threshing device with a classified screening function. The corn threshing device with the classified screening function comprises a bottom plate, a lifting mechanism, athreshing mechanism and a screening mechanism, wherein the lifting mechanism is arranged above the bottom plate; the threshing mechanism is arranged on the left of the lifting mechanism and composed of a feeding hopper, a threshing cavity, a first rotating shaft, a second rotating shaft, a ratch, helical blades, a driven gear A, a driving gear, a driven gear B, a third rotating shaft, dischargingholes and a moving door; the screening mechanism is arranged under the threshing mechanism and composed of a connecting rod, a screening plate, a support rod, a guide plate, a first collecting tank, asecond collecting tank, a third collecting tank, a fourth collecting tank and a screening cavity. The corn threshing device with the classified screening function is good and thorough in threshing effects and capable of sorting corn kernels with different diameters and facilitating classified application.

Owner:季彪

Improved household double-drum corn threshing machine

The invention discloses an improved household double-drum corn threshing machine, which comprises a threshing machine box, the middle part of the right wall of the threshing machine box is bent toward the inside of the threshing machine box, and the upper end of the left side wall of the threshing machine box is connected with a feeding channel. The front rocker arm drives the feed baffle to reciprocate up and down, and the rear sliding arm reciprocates up and down on the fixed frame synchronously, so that the corn enters the threshing machine quantitatively, without the need for staff to operate. After entering the threshing drum, it first passes through the upper corn threshing drum. Threshing, and then enter the lower corn threshing drum to improve the threshing effect. The threshing motor is driven by the transmission chain to drive the shaft to rotate at high speed. The crushed corn kernels are screened out, and the corn kernels are subjected to deslagging treatment without additional slag removal treatment, which improves work efficiency, and the blower accelerates the separation of corn kernels and crushed corn dregs.

Owner:长兴曼尔申机械科技有限公司

Corn thresher

The present invention discloses a corn thresher. The corn thresher comprises a threshing device disposed in a threshing bin; the threshing device is provided with a threshing roll and a supporting roll which are driven by power; the threshing roll is provided with spiral threshing ribs; the threshing roll and the supporting roll rotate in the same direction and have a set distance; front and rear ends of the threshing bin are respectively provided with a feed hopper and a core outlet; a discharge port is disposed below a rear portion of the threshing bin; the supporting roll is positioned below one side of the threshing roll; an auxiliary supporting roll without power input is disposed over the other side of the supporting roll; the auxiliary supporting roll can be rotatably disposed on a frame of the thresher and fixedly connected with the frame via a detachable connecting structure; a V-shaped threshing space is formed among roller surfaces of the auxiliary supporting roll, the supporting roll and the threshing roll; and a distance between two rollers of the auxiliary supporting roll and the threshing roll is gradually reduced in a corn cob threshing moving direction. The corn thresher has the beneficial effects that threshing efficiency is high, corn kernels are prevented from damaged, and the capability adapted to corn cob diameter sizes is high.

Owner:LIANGPING CHUNXIONG MACHINERY

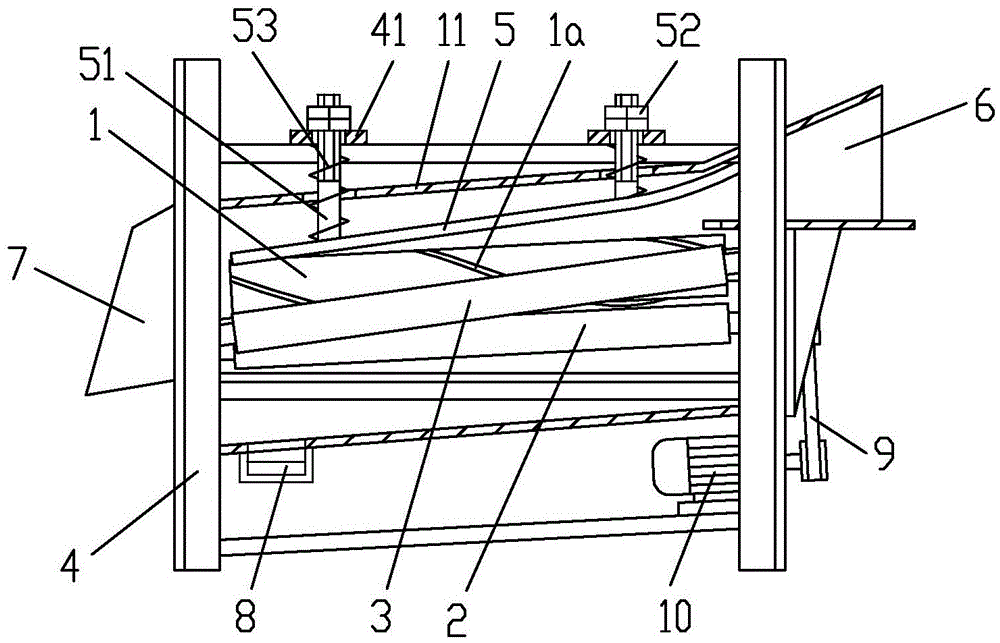

Whole-feed type combine harvester with vertical reaper

The invention provides a whole-feed type combine harvester with a vertical reaper. The invention is characterized in that the vertical reaper is wider than the reaper of a half feeding type combine harvester; a compulsory clamp turning conveyor is arranged on an ear feeding device which is formed by respectively adding a double teeth clamp chain between the two rows of conveying chains and at a turning; press steel wires are arranged between the upper and lower tooth of the double teeth clamp chain, and the height thereof is lower than the prong height of the double teeth clamp chain; a driving wheel for driving the double teeth clamp chain and a driven wheel of the conveying chains are coaxial. A threshing device uses a design of a longitudinal axial-flow type threshing cylinder, the threshing tooth of the threshing cylinder are in a spiral belt shape revolving a shaft and are fixed on the surface of the cylinder; and the angle of the threshing tooth and the cylinder shaft can be regulated. The invention derives advantages of the whole-feed type harvester and the half feeding type harvester, thereby solving the problem that the traditional whole-feed type combine harvester is hard to harvest lodging rice, has more threshing constraints and the threshing is unclean; and the invention has the advantages of clean threshing, complete separation, low broken rate and less trash content.

Owner:GUANGXI GUIGANG COMBINE HARVESTER

Pat-type oilseed rape threshing machine

A pat-type oilseed rape threshing machine comprises a chassis; a platform is arranged on the top of the chassis; a patting board is arranged above the platform; at least one mesh screen is arranged below the platform; one end of the platform is provided with a roller for compacting feed materials; a gap exists between the roller and the platform; the patting board, the mesh screen and the roller are respectively connected with a drive device; the patting board oscillate up and down, the mesh screen swing horizontally and the roller rotates under the actuation. Due to the threshing process and the crushing process are separated in the pat-type oilseed rape threshing machine, the oilseeds are firstly threshed completely, and the shells of the threshed oilseeds are crushed, the waste of oilseeds is avoided; the oilseed rape is threshed by the patting board, the patting force of the patting board is adjustable; and the oilseeds are unlikely to be broken by patting; the work efficiency is high; and the threshing effect is good.

Owner:王苏放

Two-type combine harvester

The invention provides a two-type combine harvester comprising a support, two groups of grain lifters, a vertical conveying chain, a rice reaping device, a grain reel, a horizontal conveying chain, a threshing unit and a transmission mechanism. A main travelling wheel and an auxiliary travelling wheel matched with the same in use are arranged on two sides of the bottom respectively, and are connected with each other to travel through a caterpillar track. The rice reaping device comprises an upper reaper and a lower reaper which are mounted on the support, the threshing unit is mounted on the support and comprises a barrel, a threshing cylinder is arranged inside the barrel, and a screw conveyer, and an air blower and a vibrating screen shaft are arranged at the bottom of the barrel. The two-type combine harvester has the advantages of simple structure, low cost, convenience in maintenance, good threshing effect, capability of harvesting laid rice and the like; production cost of the two-type combine harvester is only one fifth of that of combine harvesters imported from Japan, a quarter of that of domestic head-feed harvesters and two thirds of that of domestic full-feeding harvesters, so that purchasing burden of farmers is reduced greatly.

Owner:官福堂

Multifunctional threshing device of combine harvester

InactiveCN101595789AImprove threshing and separation abilityReduce in quantityThreshersLoss rateEngineering

The invention discloses a multifunctional threshing device of combine harvester, comprising a threshing roller shelf, wherein, the threshing roller shelf is provided with a threshing roller and a top cover of the threshing roller; and a concave grid is arranged at the bottom of the threshing roller; a radialis disc is arranged axially on the threshing roller, rectangular toothed bars are evenly arranged on the circumference of the radialis disc by a fixing plate; threshing components are arranged on the rectangular toothed bars, threshing components are fixedly connected onto the rectangular toothed bars by a fixing device; the fixing device comprises long slots arranged on the rectangular toothed bars along the extending directions of the rectangular toothed bars; the fixing device also comprises a bolt I and a screw nut I, wherein, the bolt I passes through the long slot and then is connected with the threshing components, and the screw nut I is screwed into the bolt I and the threshing components are fixedly connected onto the rectangular toothed bars. The invention has the advantages of low threshing loss rate, low broken rate, and good threshing effect, meanwhile, users can arbitrarily combine the types and numbers of the threshing components according to actual situations, thereby the threshing is cleaner, and the power consumption is smaller.

Owner:ZHONGJI SOUTHERN MACHINERY

Threshing device of self-propelled flax threshing reverse-laying device

The invention discloses a threshing mechanism of a self-propelled flax threshing spreading machine, including a rack, a pair of smooth rollers for pressing flax arranged up and down and a pair of threshing awl rollers arranged up and down, wherein, the smooth rollers for pressing flax are driven by a pair of hydraulic motors, the rotation of the threshing awl rollers at same speed and in different directions is realized by a universal joint through two output shafts of a gear box which is driven by another hydraulic motor, and a plurality of stirrups are alternately arranged on the threshing awl rollers along the axial direction. The spreading machine picks up the retted flax in the field, transports the flax to a turning belt behind the machine by a delivery mechanism and puts the flax in strips; during the transportation process, a pair of smooth rollers for pressing flax grind the flax peaches, a plurality of smooth stirrups alternately arranged on the threshing awl rollers carry out hackling and threshing to the flax peaches, and the flax threshing in the flax turning process is realized. The threshing mechanism has simple structure, steady work, high threshing efficiency and small damage to the straws, and reduces the cost of activity and the labor intensity.

Owner:黑龙江省农业机械运用研究所

Sunflower threshing machine

InactiveCN105165275AEasy to operateImprove threshing effectThreshersAgricultural engineeringAgricultural machinery

The present invention relates to the technical field of agricultural machinery and especially relates to a sunflower threshing machine. The sunflower threshing machine comprises a rack, and a threshing mechanism, a power mechanism and a discharging box which are disposed on the rack, wherein an inclined grain catching plate is disposed below the threshing mechanism, and an end part of the grain catching plate is disposed at an entrance of the discharging box. The sunflower threshing machine also comprises fixing mechanisms which are used for fixing stalk parts of sunflower disks and disposed above the threshing mechanism. The fixing mechanisms are adopted to fix the stalk parts of the sunflower, threshing can be carried out without injuring the sunflower disks, and the threshing efficiency is high.

Owner:CHONGQING SHUANGEN AGRI MACHINERY MFG

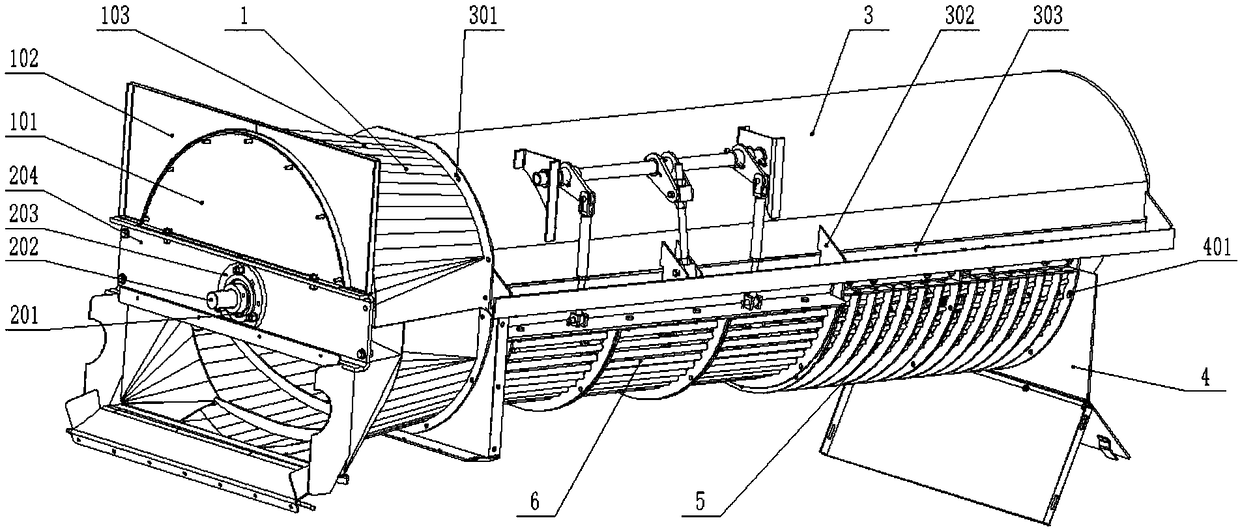

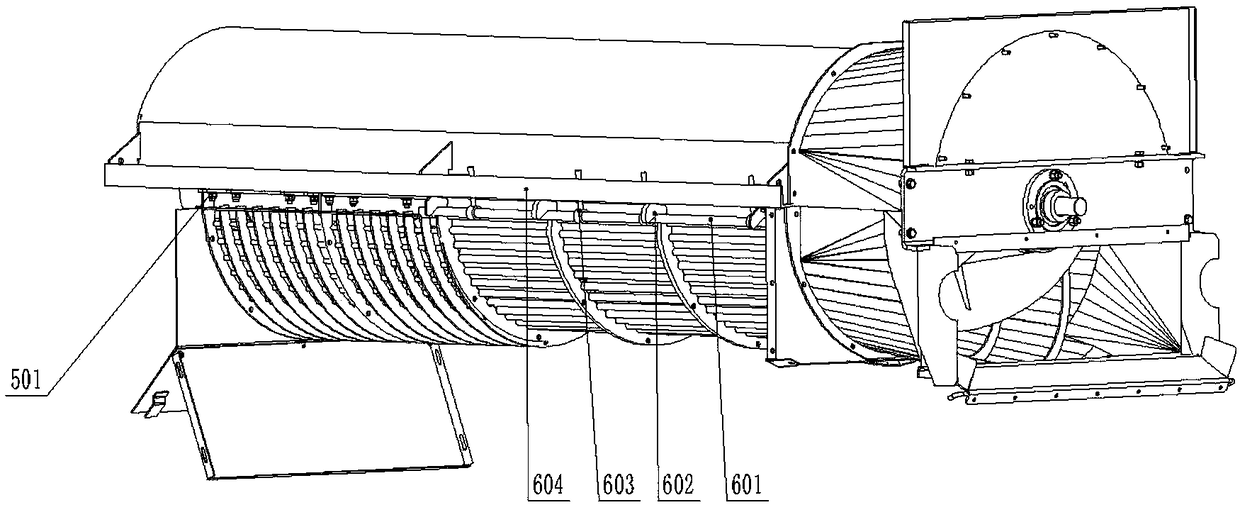

Low-damage anti-clogging gap-adjustable longitudinal-axial-flow high-water-content corn threshing and separation device

The invention discloses a threshing and separation device. The device comprises a feeding protection cover, a threshing roller, a top cover, a separation concave plate, a threshing concave plate and racks; the threshing roller is rotatably mounted on the rear rack, the feeding protection cover is mounted on the front rack and located in front of the threshing roller, the top cover is mounted abovethe threshing roller, the threshing concave plate and the separation concave plate are mounted below the threshing roller separately, and the distance between the threshing concave plate and the feeding protection cover is smaller than that between the separation concave plate and the feeding protection cover. The threshing and separation device can ensure that the corn threshing process under high water content is completed, and reduce the grain breakage rate or even ensure that no grains are broken.

Owner:CHINA AGRI UNIV

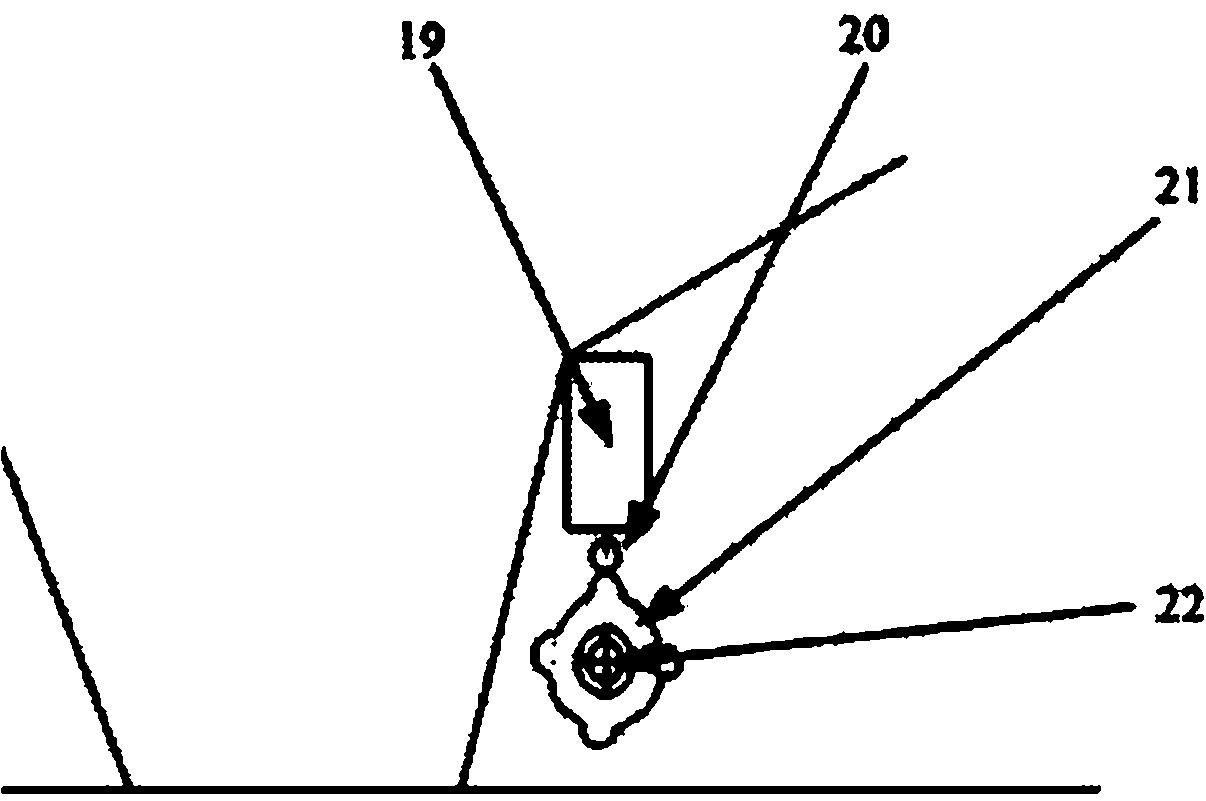

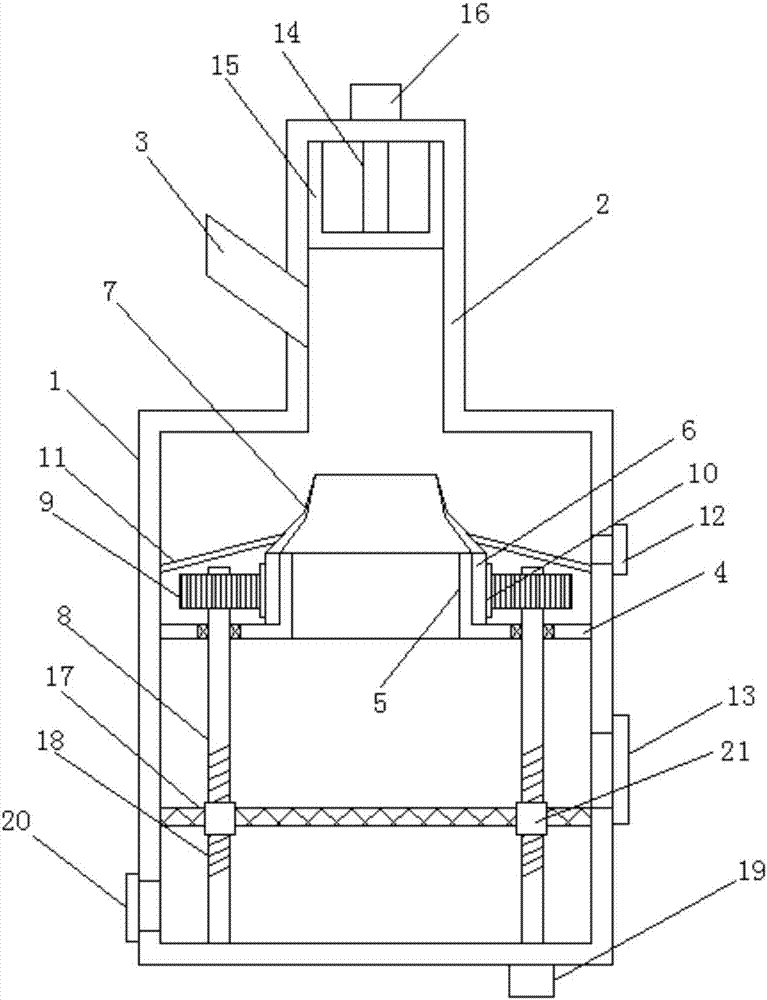

Household corn thresher

The invention discloses a small-size household corn thresher for threshing corn cobs through machinery. The small-size household corn thresher is characterized by comprising a rack (3) containing rubber and wound on a cylindrical wood rotary drum (2) consisting of two semicircular woods (33 and 35), a threshing barrel upper cover (6) and a threshing barrel base (16) which are matched to form a whole threshing barrel, a soft pad (18) which generates friction with corn cobs and contains rubber, inclined grinding strips (17), a longitudinal strip baffle (22), a plurality of bottom screening holes (19) which can be used for automatically sorting corn particles and the corn cobs, a corn particle collection bucket (20) and a corn cob collection hopper (24). According to the small-size household corn thresher, the tedious labor for realizing threshing by manually moving the corn cobs by corn farmers is eliminated, and the aim of threshing through household machinery is fulfilled.

Owner:江苏佳联农业发展有限公司

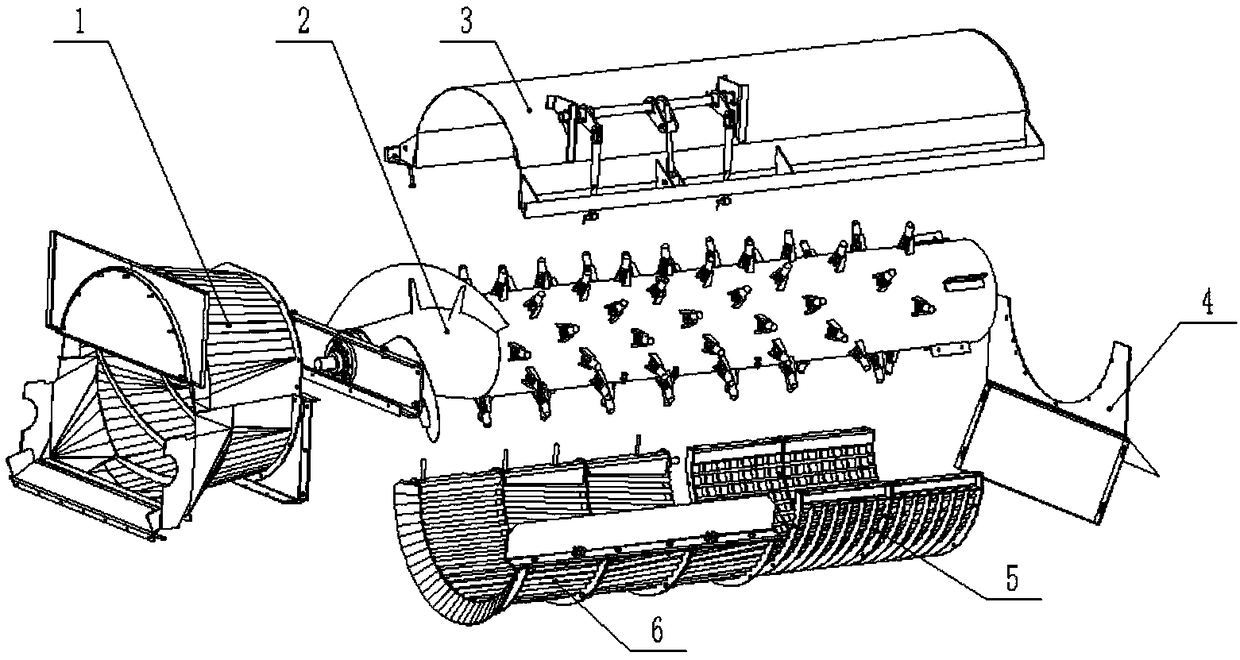

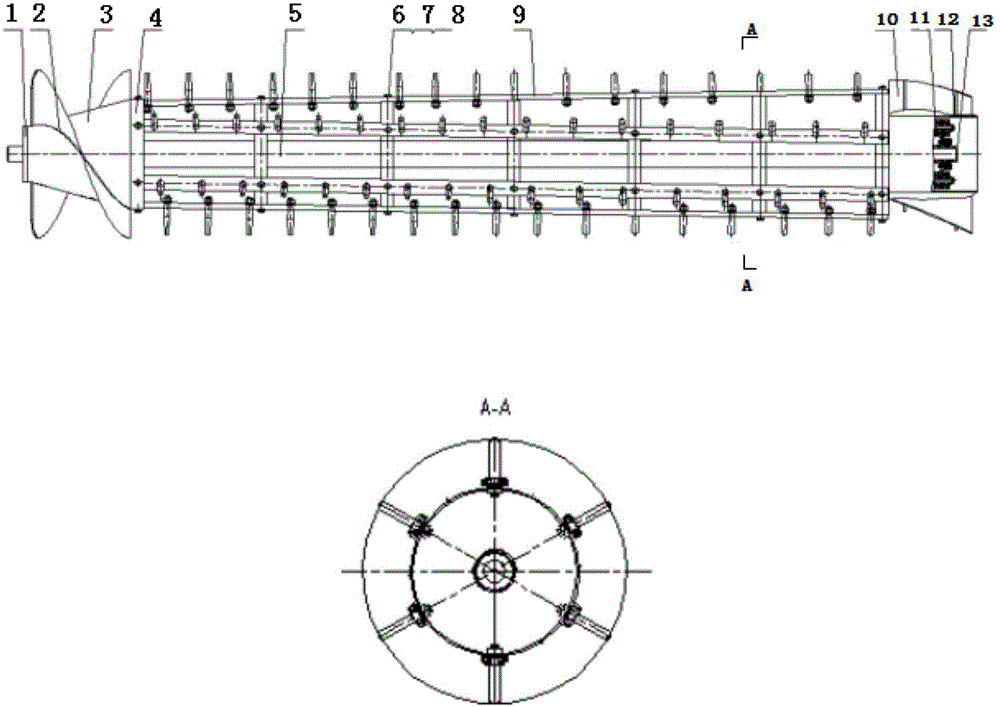

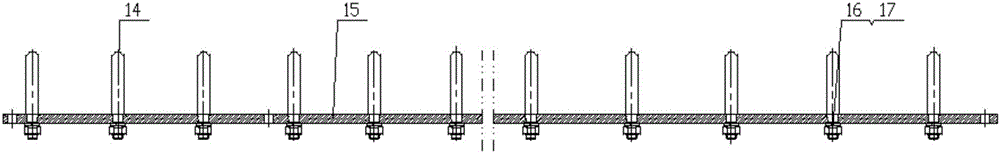

Maintenance-free type multifunctional longitudinal axial flow threshing and separation roller

The invention discloses a maintenance-free type multifunctional longitudinal axial flow threshing and separation roller, comprising a winding-proof grass coil, a spiral feeding plate, a tapered barrel, amplitude discs, a roller shaft, bolts, nuts, spring washers, threshing tooth rod assembling strips, grass discharging plates, a round barrel, an elastic shaft coupler and a spline wheel disc, wherein the tapered roller is welded at the front part of the roller shaft; the plurality of amplitude discs are arranged and are uniformly welded in the middle of the roller shaft; fixed holes are uniformly formed in the amplitude discs; the round barrel is welded at the rear part of the roller shaft; the winding-proof grass coil is mounted on the tapered barrel; the spiral feeding plate is welded on the surface of the tapered barrel; the threshing tooth rod assembling strips are fixed on the fixed holes of the amplitude discs through fastening bolts, the nuts and the spring washers; a plurality of threshing tooth rod assembling strips are arranged, and a plurality of grass discharging plates are arranged; and the grass discharging plates are uniformly welded on the surface of the round barrel, the elastic shaft coupler is fixed at the rear end of the roller shaft, and the spline wheel disc is connected with the elastic shaft coupler through a fastening part. The maintenance-free type multifunctional longitudinal axial flow threshing and separation roller has the advantages of simple structure, good utilization effect, wide market prospect and the like.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

Combined corn thresher and threshing method thereof

The invention provides a combined corn thresher which consists of a transverse threshing device and a longitudinal threshing device. The transverse threshing device and the longitudinal threshing device are in occlusion connection through a gear and a gear with a nail disk, wherein the transverse threshing device consists of a motor, a belt pulley, a cone gear, a rack, a transmission gear, the gear with the nail disk, a regulator bracket, a baffle, a spring, a regulating nut and a screw; and the longitudinal threshing device consists of a concave thresher, a threshing roller with spike teeth, roller threshing teeth, a regulating device, a transmission gear and a bearing support. In a threshing method disclosed by the invention, a transverse and longitudinal alternate threshing technology is adopted. The threshing method has good threshing effect and high efficiency. Corncobs are not crushed. The threshing method is suitable for vast rural market.

Owner:FENGGANG FENGMING AGRI MACHINERY MFG

Small-sized corn thresher

PendingCN111492807AReduce labor intensityConvenient threshing processThreshersAgricultural engineeringEngineering

The invention discloses a small-sized corn thresher. The small-sized corn thresher comprises a rack, wherein a feeding port is formed in one end of the rack; a motor is arranged at one end of the rack; a power shaft is arranged at one end of the motor, and a first belt wheel is arranged at the other end of the power shaft; the first belt wheel and the power shaft are screwed in a threaded mode; afeeding mechanism is arranged on one side of the first belt wheel, and a threshing mechanism for separating corncobs from corn kernels is arranged on the other side of the first belt wheel; a materialpressing mechanism is arranged on one side of the threshing mechanism; a discharging mechanism is arranged on one side of the rack; a first screening mechanism for screening the corn kernels is arranged on the other side of the threshing mechanism; and a second screening mechanism for screening the corn kernels is arranged at one end of the first screening mechanism. The small-sized corn thresherhas the beneficial effects that corncobs can abut against the threshing mechanism through the material pressing mechanism, the corncobs can be fully threshed, meanwhile, the height of the material pressing mechanism can be freely adjusted, a large number of corn kernels are prevented from being broken, and the threshing quality of the corn thresher can be improved.

Owner:杭州和源园艺有限公司

Corn threshing method and corn threshing machine

The invention provides a corn threshing method. The method comprises the following steps of: firstly, artificially shaking or utilizing a motor to drive a threshing machine to rotate; putting corns into a receiving hopper and dropping the corns into a threshing cavity by guiding through a guide plate when the corns drop into a machine cavity along the receiving hopper; threshing the corns through threshing teeth on a threshing disc and threshing strips on a guide disc, wherein threshed shelled corns and corncobs all drop into a corn mesh screen; sieving by the corn mesh screen and respectively flowing out the shell corns and the corncobs from a shell corn outlet and a corncob outlet to finish the corn threshing. The machine provided by the invention has the advantages of simple structure, good threshing effect, long service life, and integration of manual / electric operations.

Owner:HUNAN JINSONG MACHINERY

Forced feeding, threshing, separating and smashing integrated device for first-harvest rice

PendingCN109588120AClear division of laborReduce breakage rateMowersThreshersSpiral bladeEngineering

The invention provides a forced feeding, threshing, separating and smashing integrated device for first-harvest rice. The forced feeding, threshing, separating and smashing integrated device for first-harvest rice comprises a closed multifunctional threshing cylinder, a flow guide separable grass breaking top cover and a combined concave plate, wherein the threshing cylinder comprises a cylinder shaft feeding head and a cylinder body, a spiral blade is mounted on the feeding head, and an arc tooth group, a spike tooth group and a roller rotating blade group are distributed on the circumferenceof the cylinder body sequentially; the combined concave plate is located below the closed multifunctional threshing cylinder and comprises a transition concave plate, a threshing concave plate, a separating concave plate and a grass guiding concave plate sequentially; the flow guide separable grass breaking top cover is mounted above the closed multifunctional threshing cylinder and comprises a top cover inner shell and reinforcing plates, and the top cover inner shell comprises an adjusting mechanism, flow guide bars, punching plates and top cover fixed blades. The forced feeding, threshing,separating and smashing integrated device is applicable to feeding, threshing, separating and smashing of the first-harvest rice with different characteristics, has the advantages of compact structure, large separation area, light weight and the like, can effectively improve threshing performance and efficiency of the first-harvest rice and has lower power consumption.

Owner:JIANGSU UNIV

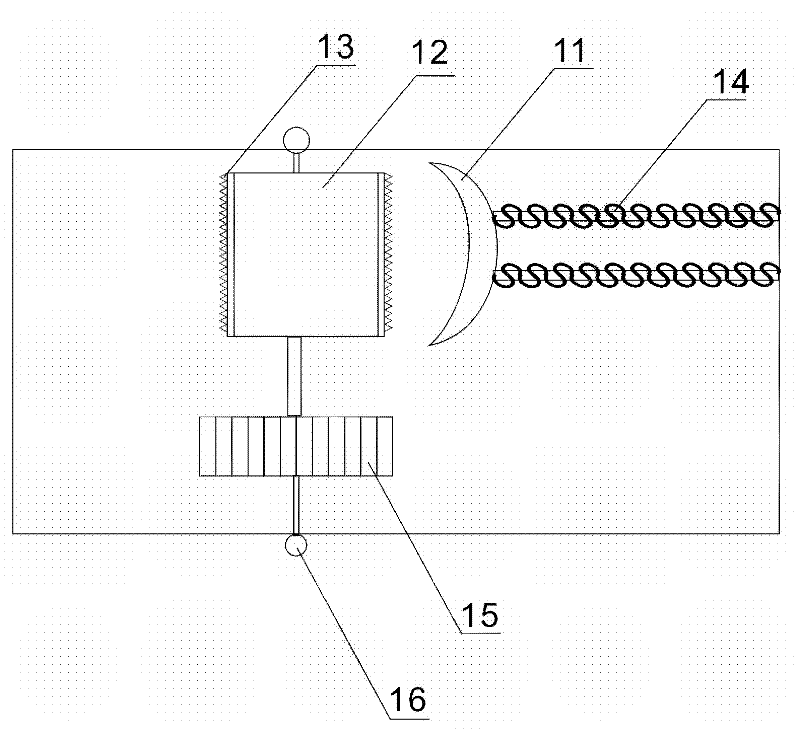

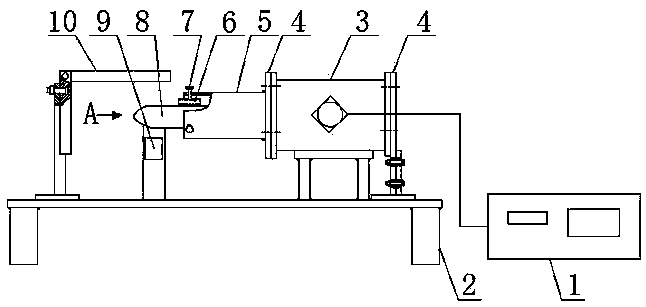

Device and method for measuring corn ear threshing force of bare hands

InactiveCN103822744AImprove threshing effectReduce loss rateApparatus for force/torque/work measurementTorque sensorData processing

Provided are a device and method for measuring corn ear threshing force of bare hands. The device comprises a torque measurement instrument, a rack and a torque sensor, the signal output end of the torque sensor is connected with the torque measurement instrument, and a flexible clamp used for fixing a corn ear sample is arranged at one end of the torque sensor. The measurement method comprises the steps that the corn ear sample is divided into a plurality of equal-length regions to be measured in the axial direction of the corn ear sample, one end of the sample is clamped in the flexible clamp, a scaleplate is adjusted to be aligned at the starting threshing position of the nth region to be measured, the suspension end of the corn ear sample is manually rotated for threshing, when the suspension end of the corn ear sample is rotated to the finial position from the starting threshing position, a final trigger is triggered at the same time, the torque of the current position is displayed through the torque measurement instrument, and the threshing force of the nth region to be measured at different threshing moments can be obtained through data processing. According to the device, the threshing force borne by corn ears is measured in the bare hand threshing process, and theoretical foundations are provided for parameter setting of the threshing device.

Owner:HENAN UNIV OF SCI & TECH

Agricultural squeezing type corn threshing device

InactiveCN107960210AHigh efficiency in threshing operationsEasy to separateThreshersHydraulic cylinderAgricultural engineering

The invention discloses an agricultural squeezing type corn threshing device which comprises a threshing tank. A feed channel is arranged in the middle of the top of the threshing tank, a release opening is formed in a side wall of the feed channel, a push-pull hydraulic cylinder is arranged on the top of the feed channel, a hydraulic push rod is arranged at the lower end of the push-pull hydraulic cylinder, a plurality of threshing fins which are annularly arrayed are arranged at a port of a rotary sleeve, an annular rack is arranged on the outer side wall of the rotary sleeve, two rotary shaft levers which penetrate a fixing transverse plate are further arranged inside the threshing tank, transmission gears which mesh with the annular rack are arranged on the tops of the two rotary shaftlevers, and guide plates which are positioned on the upper side of the fixing transverse plate are further arranged inside the threshing tank. The agricultural squeezing type corn threshing device has the advantages that the agricultural squeezing type corn threshing device is simple in structure and high in corn threshing operational efficiency and practicality, threshed cobs and corn kernels can be easily separated from one another by the agricultural squeezing type corn threshing device, and good separating and threshing effects can be realized by the agricultural squeezing type corn threshing device.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

Harvester of fixed lower header capable of preventing splashing of broken straws

The invention discloses a harvester of a fixed lower header capable of preventing splashing of broken straws. The harvester comprises the lower header, wherein the lower header is firmly welded on a front axle of the harvester and comprises a lower header main frame, a lower cutting mechanism, a straw breaking mechanism and a transmission mechanism. The harvester also comprises a fixation rod and blocking angle iron, wherein a first right angle edge of the blocking angle iron is welded on the lower edge of the rear part of a blocking cover; and a second right angle edge is located under the first right angle edge and perpendicular to the horizontal ground. Each cutting blade is parallel to the horizontal ground. The transmission mechanism comprises a chain, a driven chain wheel, a first transmission shaft, a first pulley, a first belt, a second pulley, a second transmission shaft, a third pulley, a third belt, a tensioning pulley and a tensioning pulley installation shaft. The harvester of the fixed lower header capable of preventing the splashing of the broken straws disclosed by the invention has the advantages that straw parts left after cereal reaping can be cut and smashed, so a feeding amount of the harvester can be reduced, and machine losses and threshing loads can be reduced; stubble cutting is low and smooth, so ploughing becomes easier; and straw smashing efficiency is high, and the broken straws will not be splashed.

Owner:纪小坤

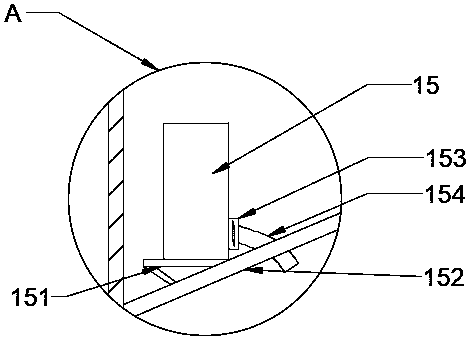

Harvester capable of chopping straw and provided with fixed lower cutting table

The invention discloses a harvester capable of chopping straw and provided with a fixed lower cutting table. The harvester comprises the lower cutting table. The lower cutting talbe is fixedly welded on a front axle of the harvester, and comprises a lower cutting table main frame, a lower cutting mechanism, a straw chopping mechanism and a transmission mechanism. One end of each of lower cutting table connecting rods is fixedly welded on the front axle. The lower cutting mechanism comprises a plurality of fixed tool bits which are arranged in a straight line and fixedly arranged on a base. Each cutting blade is parallel to the horizontal ground. The straw chopping mechanism is mounted in an accommodating space defined by the base, a covering shelter, a first sealing plate and a second sealing plate. The harvester has the advantages that the straw parts left after harvesting of crops can be cut and chopped, the feeding quantity of the harvester is reduced, the machine loss and the threshing load are reduced, the threshing effect is improved, the cut stubble heights are consistent, low and level and convenient for ploughing, the cutting and chopping efficiency of the straw is high, the chopped straw can be directly plough down in the soil in ploughing, and the straw is used as a base fertilizer after returning to the field.

Owner:纪小坤

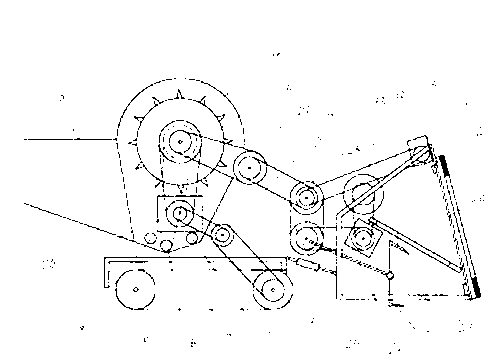

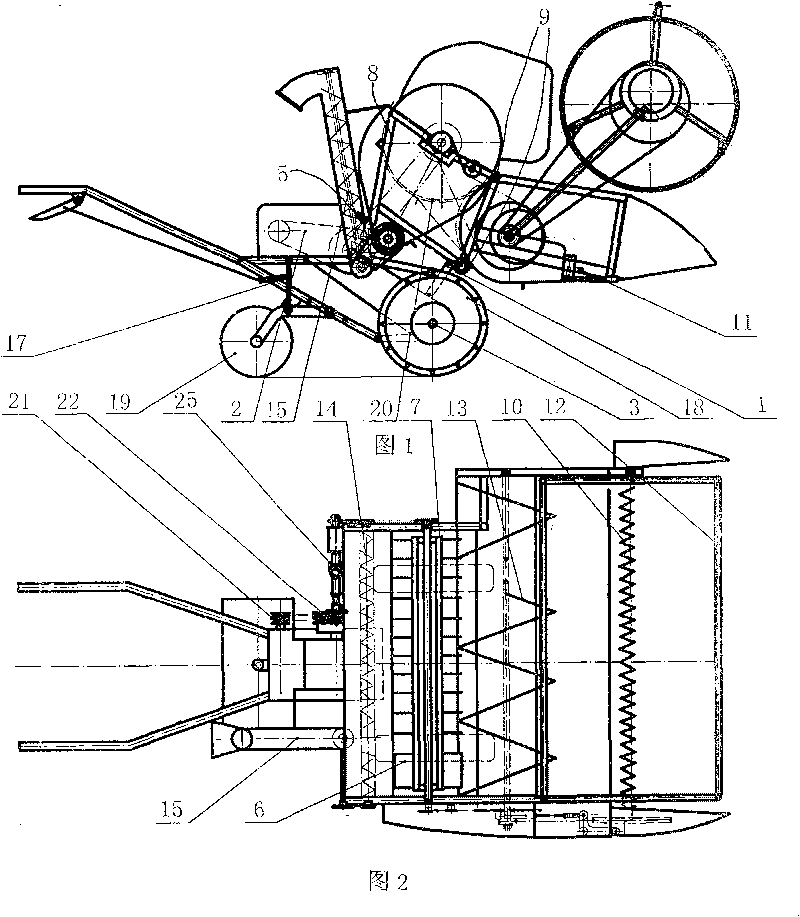

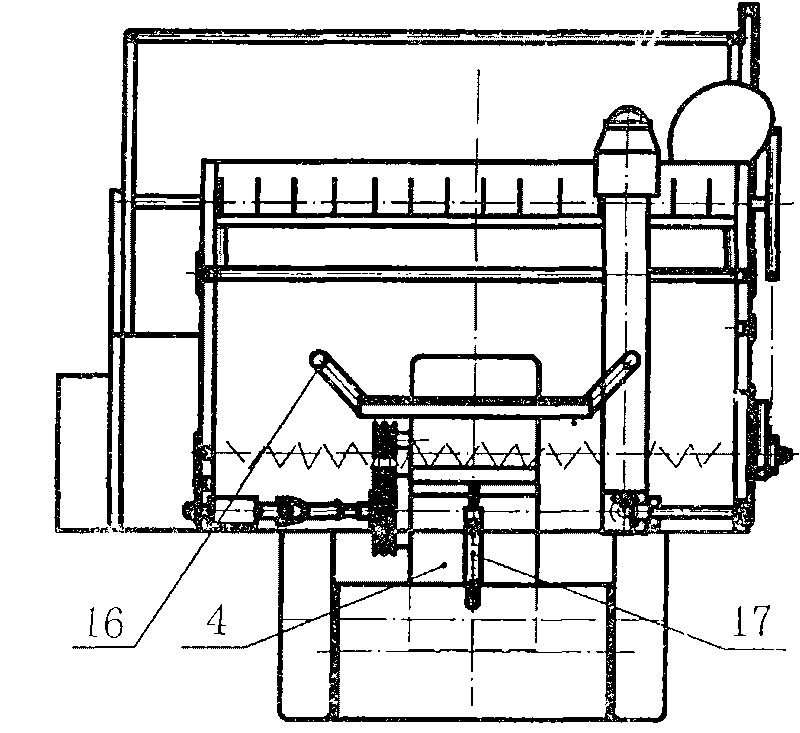

Miniature rapid-assembly paddy and drought dual-purpose rice and wheat harvester

InactiveCN101743802AReduce weightImprove versatilityAgricultural machinesMowersLand TravelSteering wheel

The invention provides a miniature rapid-assembly paddy and drought dual-purpose rice and wheat harvester, which comprises a stand, an engine arranged on the stand, a transmission case, a threshing cylinder with a threshing roller driven by the engine through a driving mechanism, a gain-collecting auger, an output auger, a gathering auger, a cutting table with a cutting knife assembly, a driving wheel arranged on an output shaft of the transmission case, a steering wheel positioned at the front end of the stand, a railing and a cutting table lifting device. The miniature rapid-assembly paddy and drought dual-purpose rice and wheat harvester is characterized in that first rapid assembly and disassembly mechanisms (5) are arranged at corresponding positions of the stand and the threshing cylinder; second rapid assembly and disassembly mechanisms (9) are arranged at corresponding positions of the threshing cylinder and the cutting table; and the driving wheel is a paddy filed wheel or a drought land traveling wheel which is rapidly assembled with the output shaft of the transmission case. The invention has light weight, can realize rapid disassembly, assembly and carry of large components, has strong university and convenient operation, can operate in drought land and paddy fields in winter and is particularly applicable to mountain areas and hills.

Owner:成都鑫道成农牧机械有限公司

Cutting device of rice harvester

InactiveCN107736125AEfficient separationImprove threshing effectMowersAgricultural engineeringConveyor belt

The invention relates to the field of agricultural technology, in particular to a rice harvester cutting device, comprising a cutting box, a fixed base is provided at the bottom of the cutting box, a conveyor belt is installed on the left side of the fixed base, and a support plate is provided above the inside of the cutting box to support the One end of the plate is fixedly connected with the cutting box, the right side of the cutting box is provided with a material inlet, the left side of the cutting box is provided with a material outlet, and the inside of the cutting box is provided with a first cutting mechanism and a second cutting mechanism from right to left. Mechanism, the third cutting mechanism, and the ash collection chamber. The invention uses a unique connection structure to make the rice enter the cutting box and then cut through the combination of the three-layer cutting mechanism, so that the straw and rice ear can be effectively separated, and the threshing performance of the harvester can be improved. As a result, the straw is cut multiple times inside the cutting box, which greatly improves the cutting efficiency of the harvester; and through the set ash collection chamber, it can effectively prevent machine damage caused by straw dust blocking the internal parts of the harvester after long-term use.

Owner:邛崃市桑园宏吉果蔬种植专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com