Corn thresher capable of carrying out deflecting threshing

A thresher and corn technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of short threshing trajectory and low threshing rate, reduce production costs, improve threshing rate, and reduce non-threshing The effect of the work segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

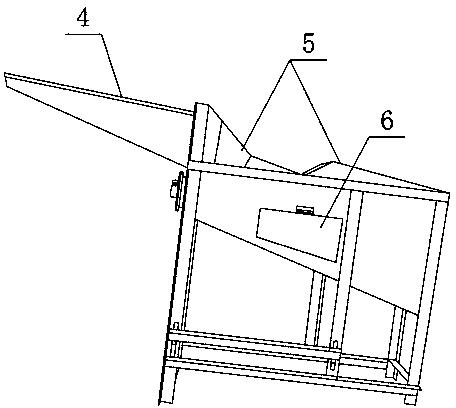

[0044] The variable-direction threshing corn thresher includes a feed inlet 4, a threshing drum 7, a silo shell 5, a corn kernel discharging port and a corn cob discharging port 6, and the threshing drum 7 is arranged obliquely.

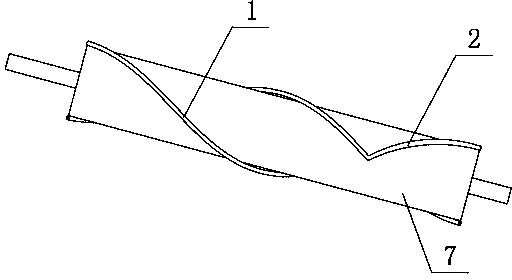

[0045] Such as figure 1 As shown, the barrel 7 is cylindrical, and the barrel wall surface of the barrel 7 is provided with only one layer of spiral barrel ribs. The spiral barrel includes an upper barrel 1 and a lower barrel 2 with opposite spiral directions. The upper barrel is threshed. The spiral direction of the rib 1 is opposite to the rotation direction of the barrel 7, and the spiral direction of the lower barrel 2 is the same as the rotation direction of the barrel 7; the corncob outlet 6 is set in the upper barrel 1 and the lower barrel 2 to connect At the corresponding side. The change of the spiral direction of the threshing bar changes the direction of movement of the corn cobs in the threshing bin. After being cleaned, the corn cobs are di...

Embodiment 2

[0054] The variable-direction threshing corn thresher includes a feed port 4, a threshing barrel 7, a silo shell 5, a corn kernel discharging port and a corn cob discharging port 6, and the threshing drum 7 is arranged obliquely.

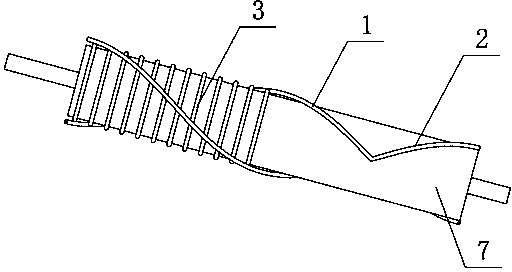

[0055] The threshing barrel 7 is cylindrical, and the barrel wall surface of the barrel 7 is provided with an inner threshing bar 3 and an outer threshing bar. The outer threshing bar includes an upper threshing bar 1 and a lower threshing bar 2, an upper threshing bar 1 and a lower threshing bar. Ribs 2 are all spiral threshing ribs. The spiral direction of upper threshing rib 1 and lower threshing rib 2 are opposite, the spiral direction of upper threshing rib 1 is opposite to that of barrel 7, and the spiral direction of lower threshing rib 2 is the same as that of barrel 7. The rotation direction is the same; the inner threshing bar 3 is a ring-shaped threshing bar, and the density of the inner threshing bar 3 is significantly greater than the densi...

Embodiment 3

[0073] The variable-direction threshing corn thresher includes a feed port 4, a threshing barrel 7, a silo shell 5, a corn kernel discharging port and a corn cob discharging port 6, and the threshing drum 7 is arranged obliquely.

[0074] The threshing barrel 7 is cylindrical or truncated.

[0075] When only one layer of threshing bars is provided, the arrangement of the threshing bars is consistent with the structure in Example 1.

[0076] When two layers of threshing bars are provided, the arrangement of the threshing bars is consistent with the structure in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com