Maintenance-free type multifunctional longitudinal axial flow threshing and separation roller

A threshing separation and multi-functional technology, applied in the direction of threshing equipment, cutters, agricultural machinery and implements, etc., can solve the problem that the reliability and versatility of the use cannot meet the needs of users, and no longer meet the needs of harvesting large plots. Problems such as the destruction of the original dynamic balance can achieve the effect of increasing market share, smooth surface, and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

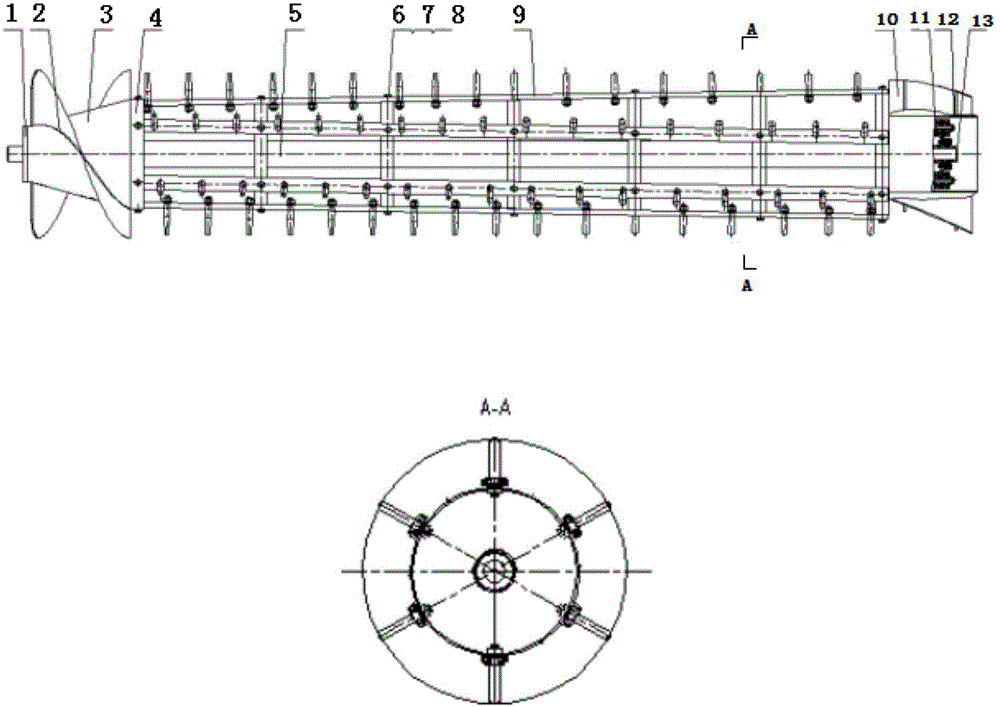

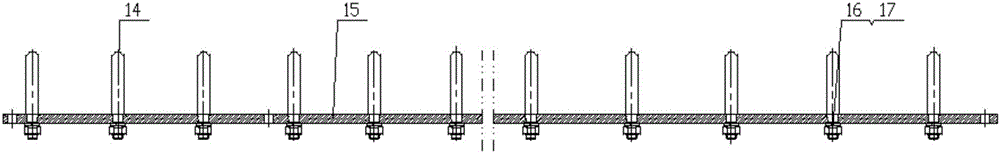

[0027] Such as figure 1 , 2 , A maintenance-free multifunctional longitudinal axial flow threshing and separating drum shown in 3 and 4, including: anti-winding grass ring 1, screw feeding plate 2, cone drum 3, web plate 4, drum shaft 5, bolts 6, Nut 7, spring washer 8, threshing gear rod assembly strip 9, grass discharge plate 10, cylinder 11, elastic coupling 12 and spline wheel disc 13, and the described cone 3 is welded on the front part of the drum shaft 5, There are multiple discs 4, preferably seven, which are evenly welded to the middle of the drum shaft 5, and fixed holes are evenly open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com