Threshing device of harvester

A technology of threshing device and harvester, which is applied in threshing equipment, agricultural machinery and implements, application, etc. It can solve the problems of large conveying trough and main threshing drum, increase the length of threshing drum, prolong threshing time, etc., so as to prolong the cleaning time , prolong the threshing time, increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

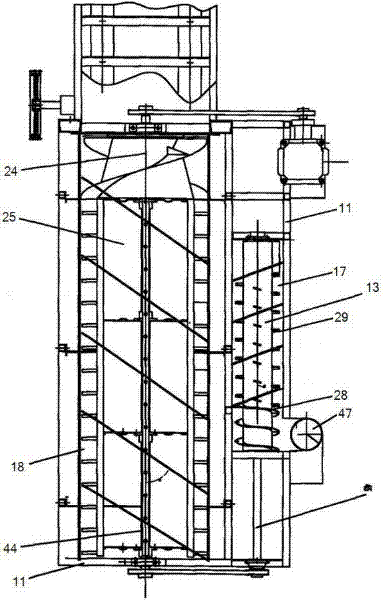

[0038] Such as Figure 1-9 As shown, a harvester is provided with a harvesting mechanism 8, a conveying trough 2 and a threshing device sequentially along the front end of the harvester to the rear end.

[0039] The threshing device comprises an underframe 5, a threshing frame 11 fixed on the underframe 5, a main threshing mechanism and a multiple threshing mechanism which are all connected to the threshing frame 11 and arranged along the walking direction of the harvester, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com