Small-sized corn thresher

A thresher and corn kernel technology, which is applied in the field of agricultural science and technology, can solve the problems of inability to thresh corn ears and low work efficiency, and achieve the effect of good threshing effect, improved practicability, and simple and effective operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

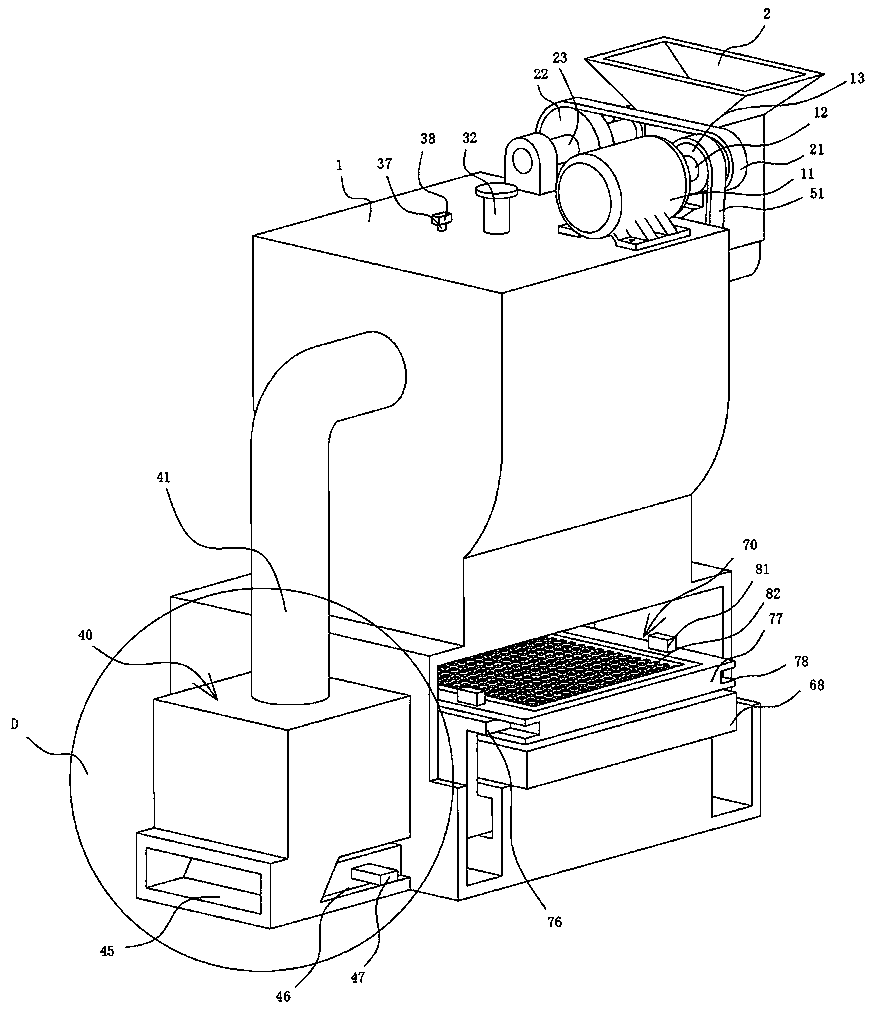

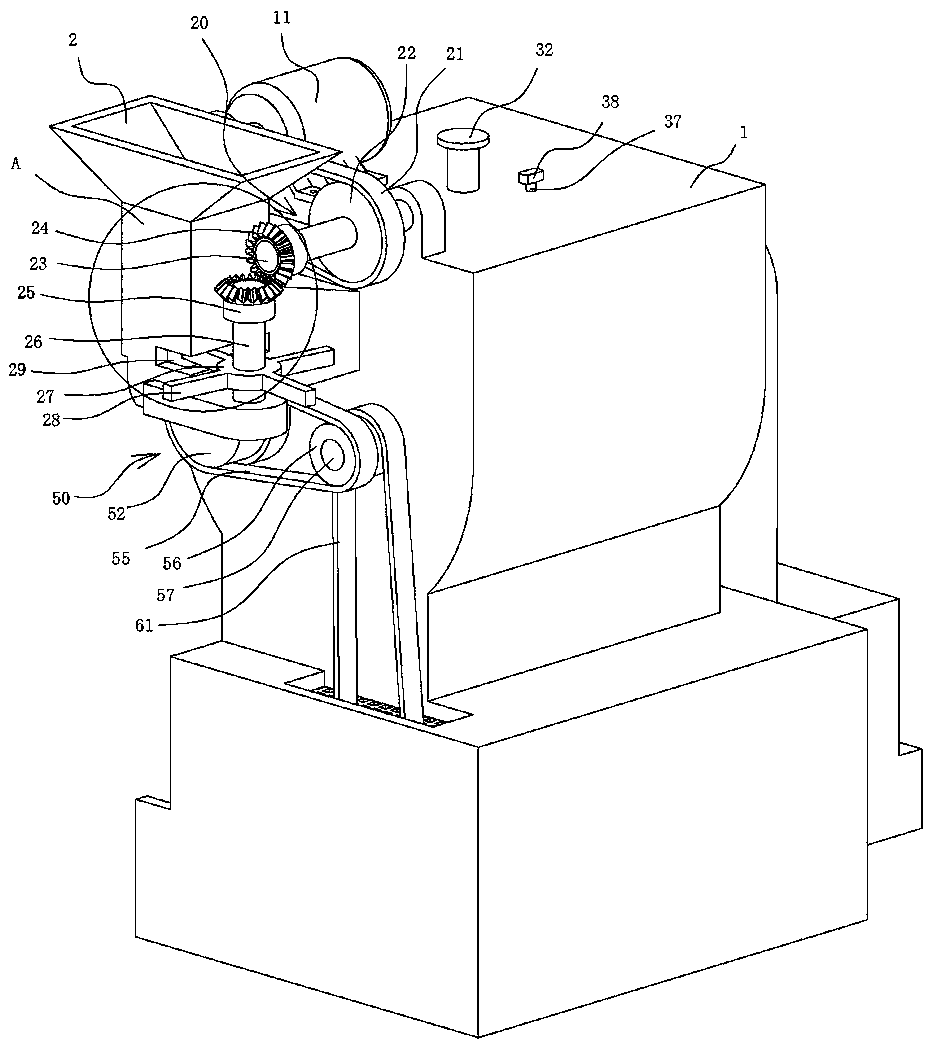

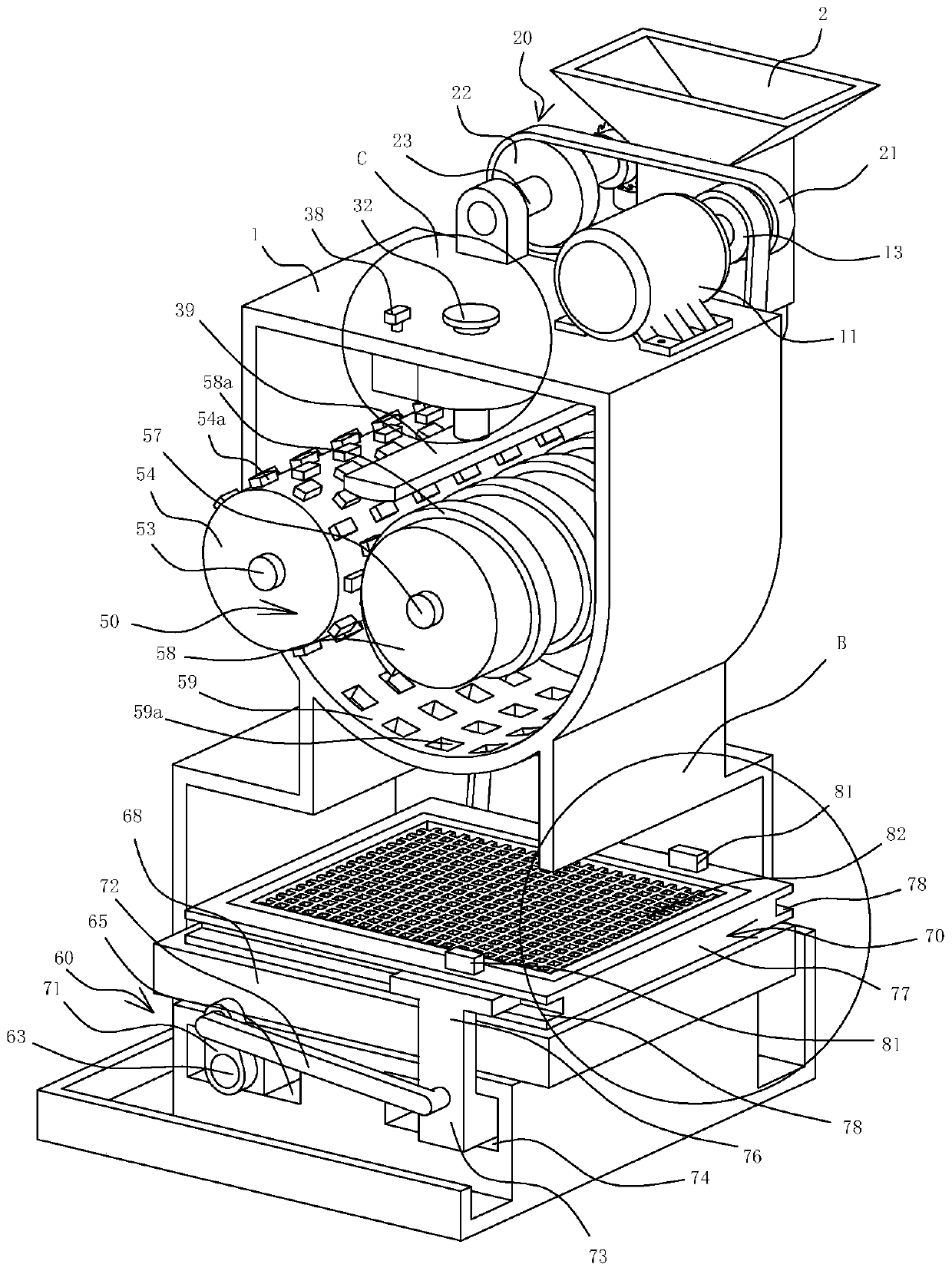

[0029] Such as figure 1 and figure 2As shown, the small corn thresher of the present invention includes a frame 1, the upper end of the frame 1 is provided with a material inlet 2, the upper end of the frame 1 is provided with a motor 11, the front end of the motor 11 is provided with a power shaft 12, and the front end of the power shaft 12 is provided with a second One belt pulley 13, the first belt pulley 13 is screwed with the power shaft 12, the front side of the first belt pulley 13 is provided with a feeding mechanism 20, and the lower side of the first belt pulley 13 is provided with a threshing machine for separating the cob of corn from the kernels of corn Mechanism 50, the upper side of threshing mechanism 50 is provided with pressing mechanism 30, the rear side of frame 1 is provided with discharge mechanism 40, and the lower side of threshing mechanism 50 is provided with the first sub-sieving mechanism 60 that screens corn kernels, the first sub-sieving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com