Combined corn thresher and threshing method thereof

A corn threshing and combined technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve a large number of problems that cannot achieve threshing effects, achieve high efficiency, reduce motor load, and achieve good threshing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

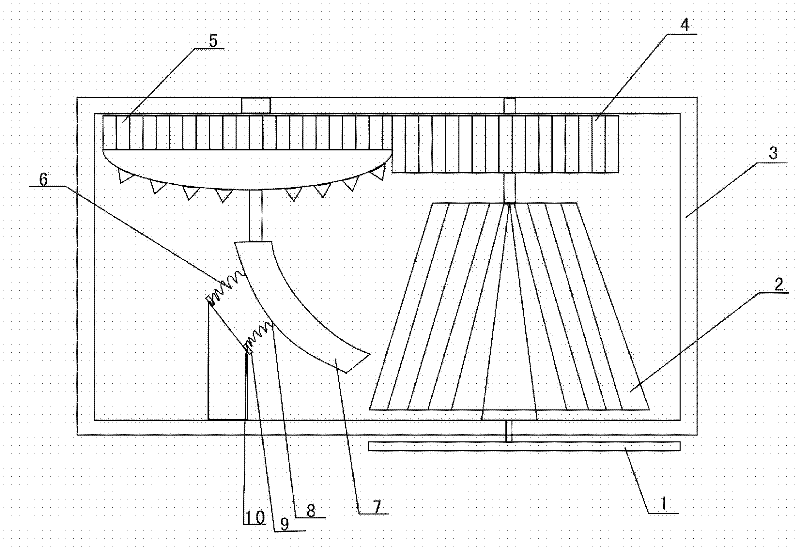

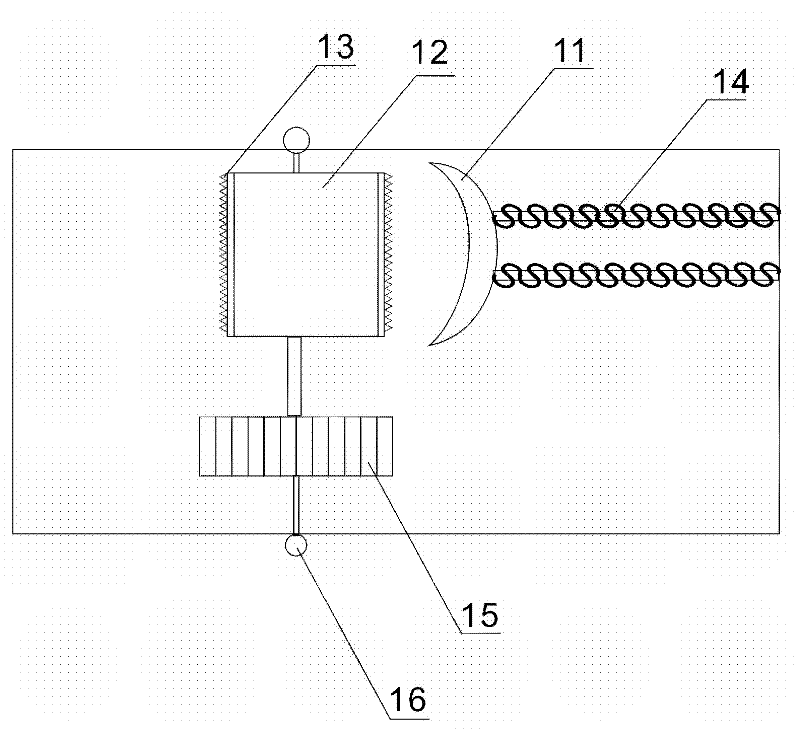

[0012] A combined corn thresher and its threshing method of the present invention, the specific implementation mode is combined with the attached figure 1 , attached figure 2 To elaborate further:

[0013] The combined corn thresher of the present invention consists of a horizontal thresher figure 1 and longitudinal threshing device figure 2 Two parts are formed, and the two are connected by a gear meshing with the nail plate gear 5 . figure 1 Middle: The horizontal threshing device is composed of a motor, a pulley 1, a bevel gear 2, a frame 3, a transmission gear 4, a nail plate gear 5, a regulator bracket 6, a baffle plate 7, a spring 8, a nut 9 and a screw rod 10; figure 2 Middle: The longitudinal threshing device is composed of a concave thresher 11, a threshing roller with nail teeth 12, a roller threshing tooth 13, an adjustment device 14, a transmission gear 15 and a bearing seat 16.

[0014] The frame 3 of the horizontal threshing device is provided with a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com