Threshing device of self-propelled flax threshing reverse-laying device

A threshing device, self-propelled technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low cleaning rate, high processing cost, poor threshing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

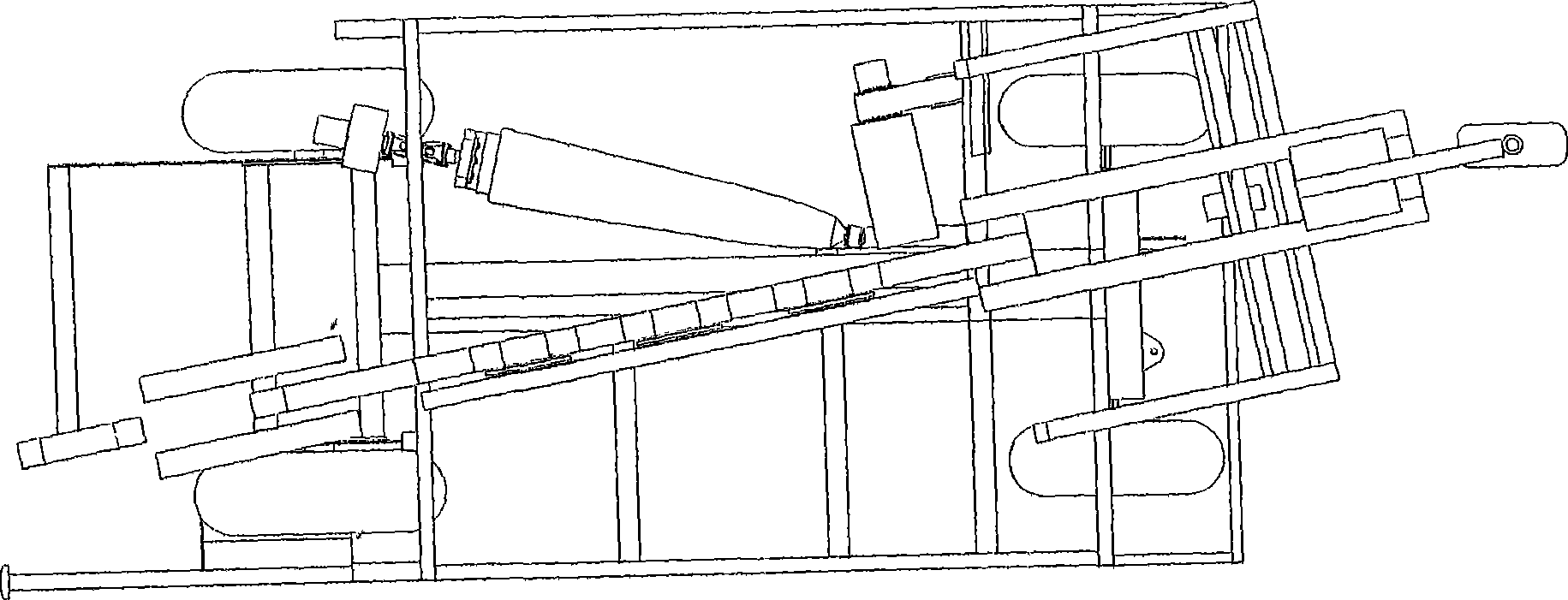

[0013] Such as figure 1 , 2 As shown, the self-propelled flax threshing and turning machine of the present invention comprises a pick-up device 1, a turning device 5, a conveying device 2, a threshing device 3 and a transmission device 4, and the flax retting in the field is carried out by the grain picker of the turning device. Pick it up, transport it to the rear of the machine by the conveying device, and put it in strips at the rear of the machine after turning over and aligning the roots. During the conveying process, the threshing device completes the threshing of flax and the cleaning and collection of flax seeds.

[0014] As shown in Figures 3 and 4, the threshing device includes a frame 14, a pair of calendering rollers 6 arranged up and down, and a pair of threshing cone rollers 16 arranged up and down, and one end of the calendering rollers 6 is set by a fixed mount 13 On the frame, the other end is supported by two supporting wheels fixed on the frame, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com