Corn thresher

A technology for thresher and corn, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of reduced threshing efficiency and inability to adjust distance, achieve high threshing efficiency, improve storage efficiency and benefits, and reduce rebound time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

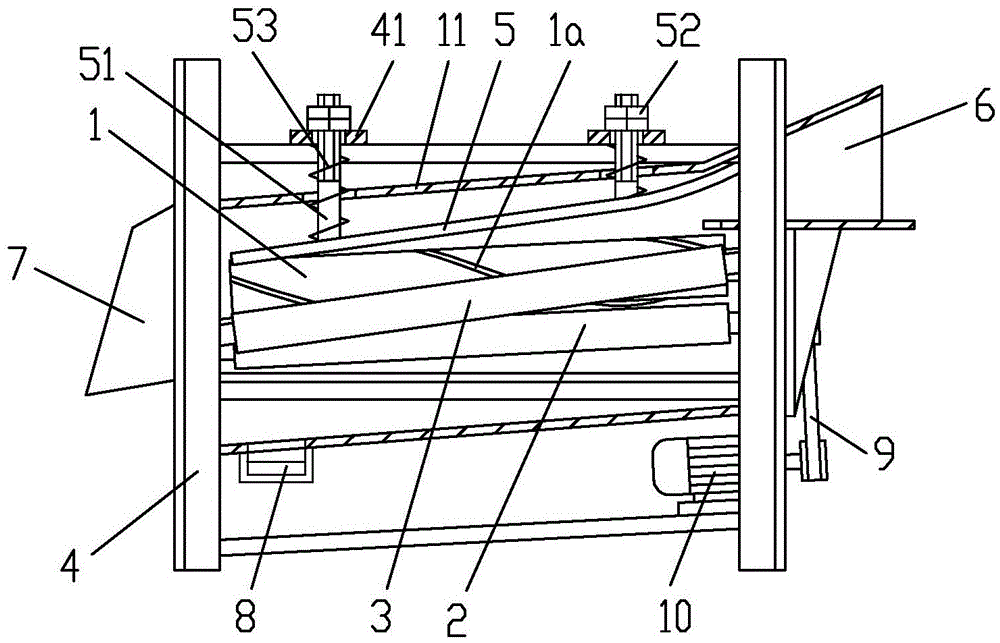

[0019] see figure 1 , figure 2 , a corn thresher, comprising a threshing device located in the threshing bin, the threshing device is provided with a threshing roller 1 and a support roller 2 driven by power, and the threshing roller 1 is provided with two right-handed spiral threshing tendons 1a, The threshing roller 1 and the support roller 2 rotate in the same direction and have a set distance; the front and rear ends of the threshing bin are respectively provided with a feed hopper 6 and a core outlet 7, and a discharge port 8 is provided under the rear of the threshing bin; the threshing roller 1 is The inclined arrangement with the front high and the rear low; among them, the supporting roller 2 is located on the left side of the threshing roller 1, the diameter of the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com