Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239results about How to "Improve threshing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seed germination acceleration seedling culturing method for polygonatum cyrtonema

InactiveCN104920198APromote germinationEnsure moistureAgriculture gas emission reductionCultivating equipmentsSeed dormancyPolygonatum cyrtonema

The invention provides a seed germination acceleration seedling culturing method for polygonatum cyrtonema. The seed germination acceleration seedling culturing method comprises the steps of conducting fermentation treatment on fruits through valve bags, conducting low-temperature lamination treatment, conducting hormone treatment, breaking seed dormancy, inducing dormant seeds to germinate and grow to seedlings and the like. According to the seed germination acceleration seedling culturing method, by breaking seed dormancy and bud dormancy of polygonatum cyrtonema, the seedling culturing period of polygonatum cyrtonema can be greatly shortened, the production cost is reduced, the propagation coefficient of polygonatum cyrtonema is improved, and the problem that high-quality polygonatum cyrtonema seedlings are in short supply is solved.

Owner:安徽省应用技术研究院

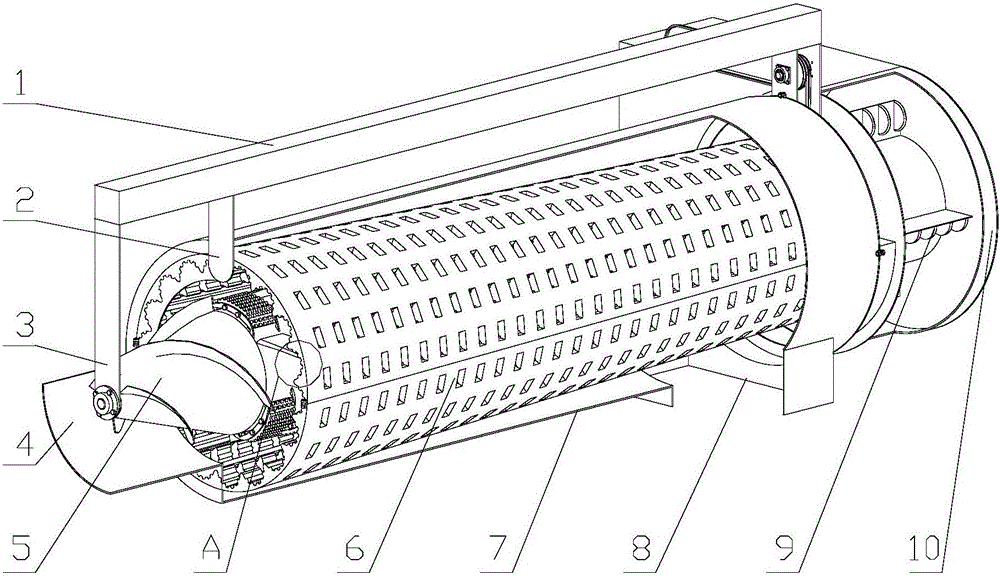

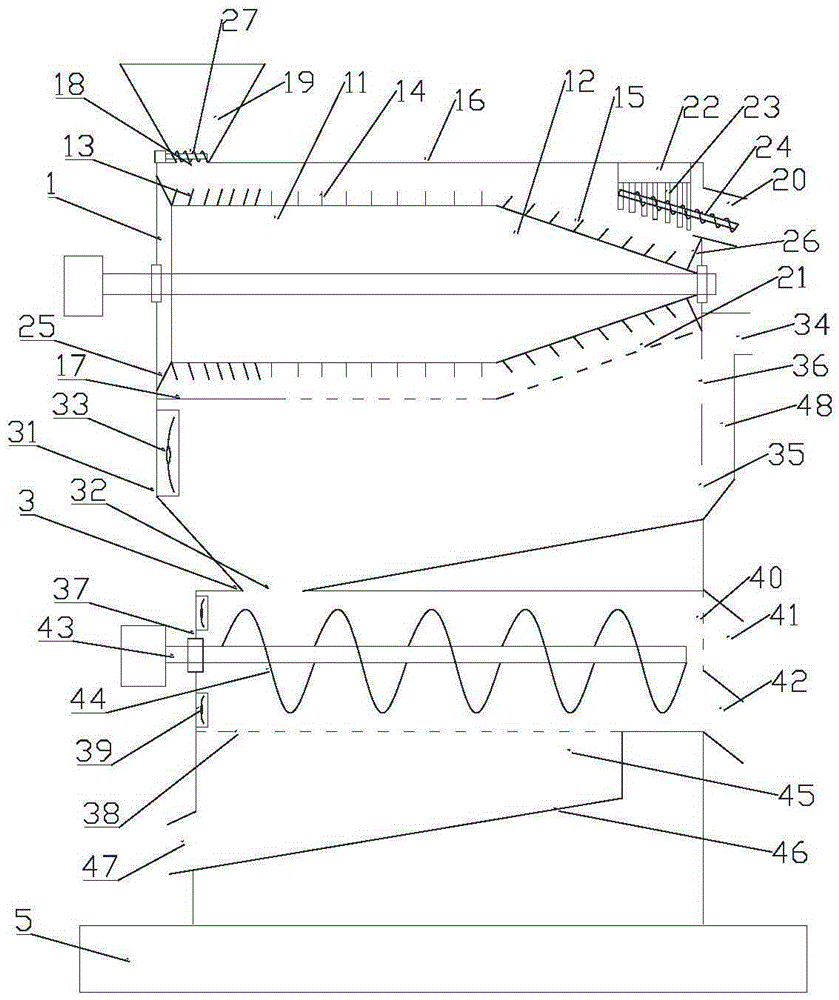

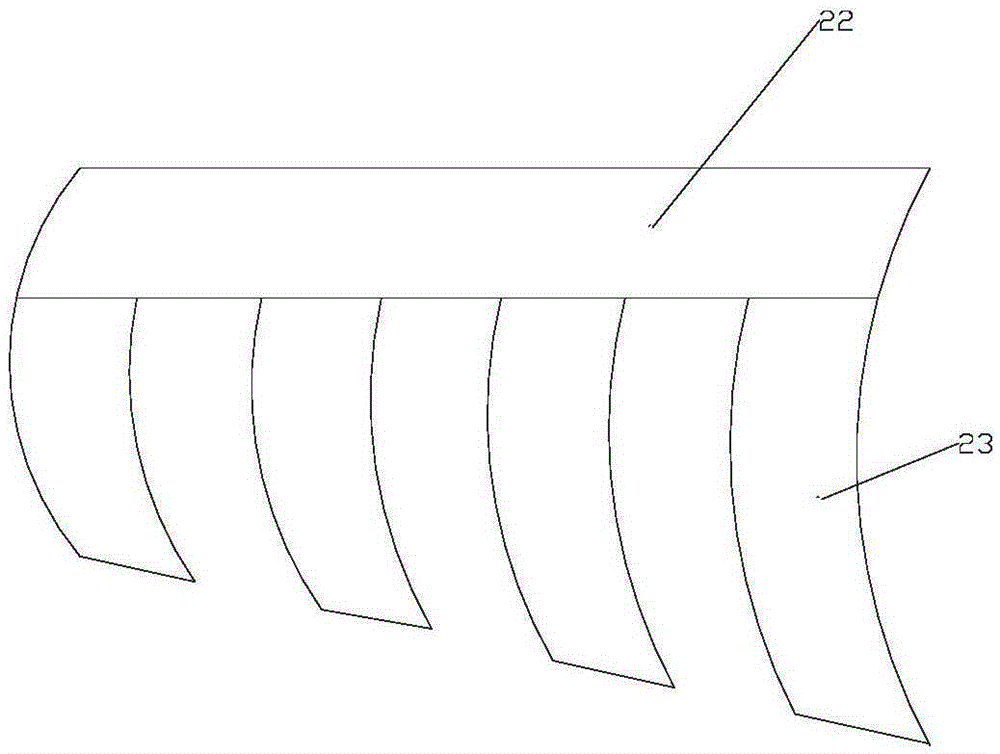

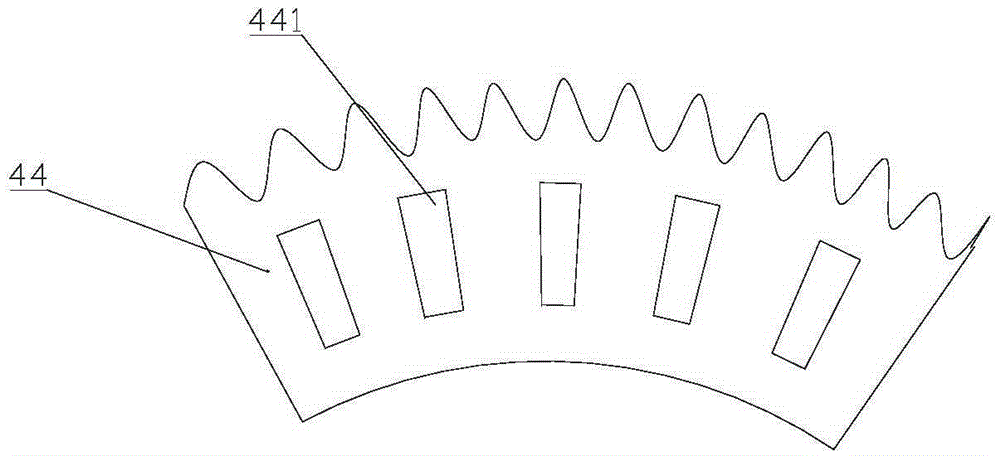

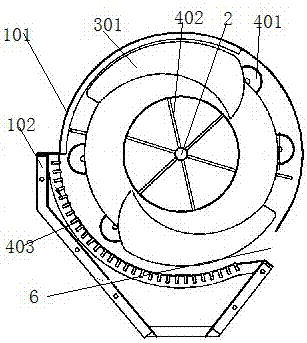

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

Corn threshing machine

The invention discloses a corn threshing machine comprising a housing, a threshing unit arranged in the housing, and a kernel and core separation device arranged in the housing. The kernel and core separation device is arranged below the threshing unit. A sound insulation layer is arranged in a shell layer of the housing; and the thickness of the sound insulation layer is the half of the thickness of the shell layer. The corn threshing machine also includes a corncob feeding device arranged at the top of the housing. The corncob feeding device contains a feeding cylinder and a rotation cylinder. The feeding cylinder connected with the inner cavity of the housing is fixed at the top of the housing and is protruded outwardly; and the rotation cylinder connected with the feeding cylinder in a rotation mode is in transmission connection with a first power unit. Multiple corncob that are going to be processed by threshing are laid on the inner wall of the rotation cylinder in a loop mode. According to the invention, on the basis of improvement of the existing corncob feeding device, the corn threshing machine has the automatic feeding function; and with the sound insulation layer at the housing, noises caused during the equipment running processing can be effectively reduced.

Owner:秦朝东

Grain thresher

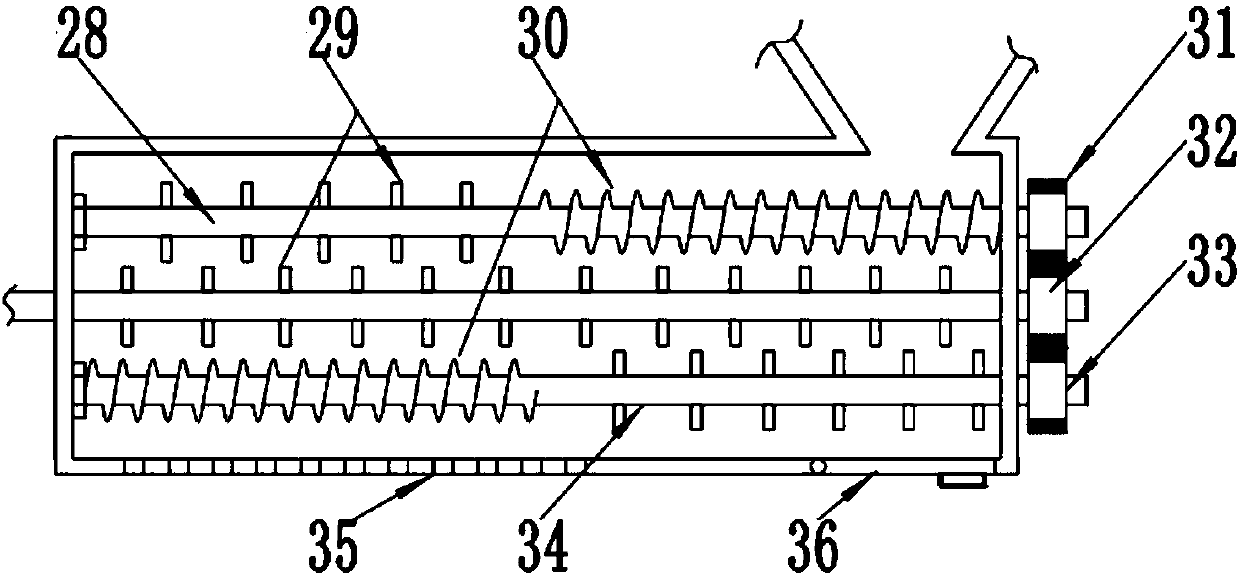

The invention discloses a grain thresher which comprises a threshing device, a screening device and a frame. The threshing device comprises a threshing roller, a first housing, a grabbing plate and a first packing auger as well as a baffle plate, wherein the threshing device comprises a first threshing roller and a second threshing roller which are integrally formed; a first threshing tooth which inclines rightward and a second threshing tooth which is vertically arranged are sequentially arranged on the outer wall of the first threshing roller from left to right; a third threshing tooth which inclines rightward is arranged on the outer wall of the second threshing roller; the first housing comprises an upper housing positioned above the threshing roller and a lower housing positioned below the threshing roller; the threshing roller is positioned in a cavity formed by the upper housing and the lower housing; and the grabbing plate is an arc-shaped plate which vertically arranged right above the second threshing roller. The grain thresher disclosed by the invention has the beneficial effects of high threshing rate and high threshing efficiency, thorough separation of grains and grain dregs, high in grain yield, high in grain neatness and the like.

Owner:湖南省富瑞机电设备制造有限公司

Corn thresher

The invention discloses a corn thresher. The corn thresher comprises a bottom plate, a support device, a collecting device, a fastening device, a frame, a first rubbing device, a feeding device and a second rubbing device. The bottom plate is provided with a first collecting box and a first fixing block; the support device comprises a first support, a first cross bar, a second cross bar and a first inclined bar; the collecting device comprises a first supporting rod, a first rotating shaft, a second collecting box, a first filter screen, a baffle ring and a vibrator; the fastening device comprises a first fastening rod, a first spring, a second fixing block, a second fastening rod and a gripping rod; a second inclined bar and a distributing block are provided inside the frame; the first rubbing device comprises a first roller, a first lug, a second lug, a second roller and a third lug; the feeding device comprises a feeding hopper, a centralizing block, a moving block, a pushing rod, a cylinder, a first fixing rack and a third cross bar; and the second rubbing device comprises a discharging hopper and a second fixing rack. The corn thresher provided by the invention can be used for threshing corn effectively, and is high in threshing efficiency.

Owner:重庆潼双机械制造有限公司

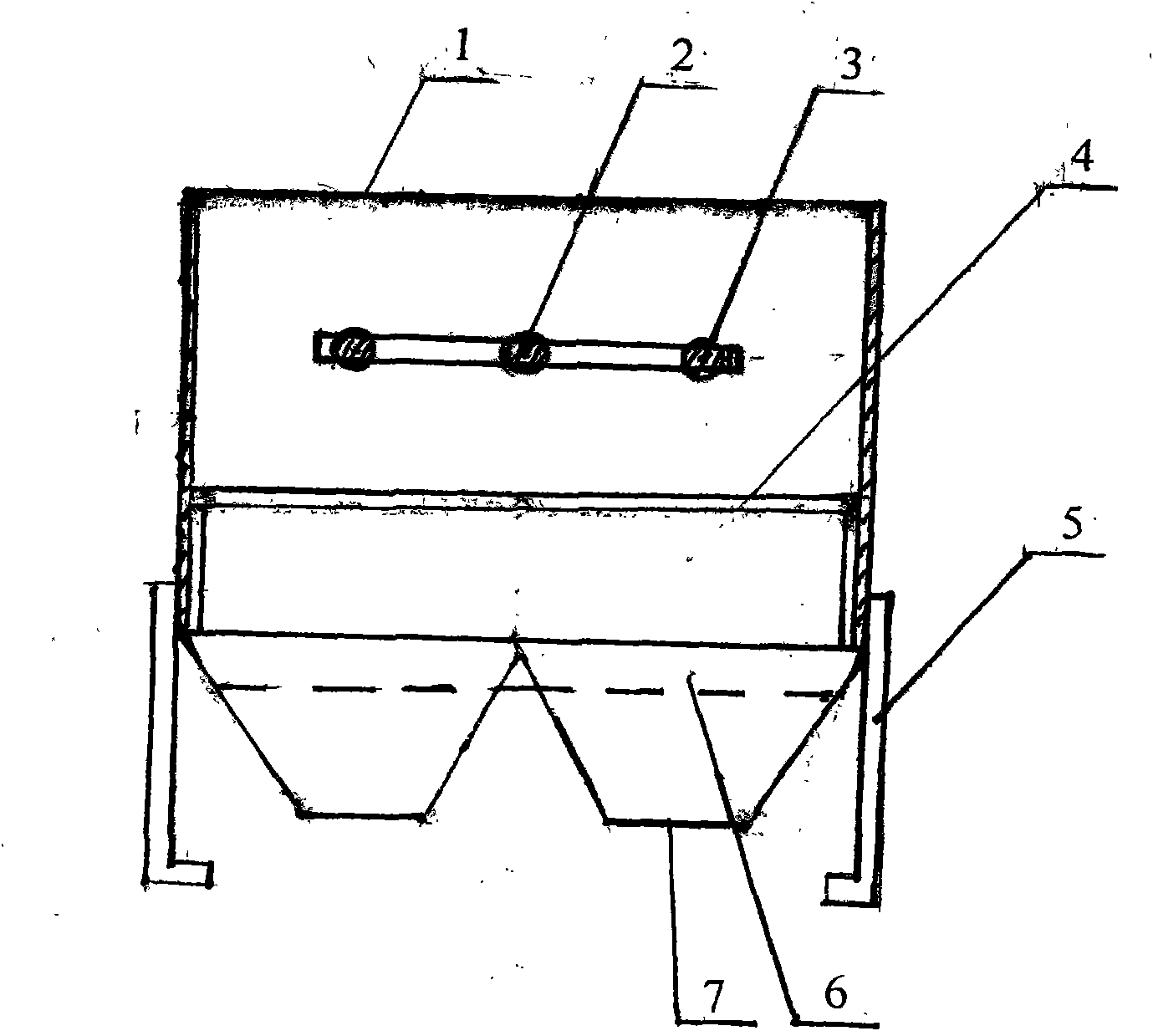

Efficient corn-threshing method

An efficient corn-threshing method mainly solves the problems that existing corn-threshing methods are low in threshing efficiency and poor in threshing and separating effect. The efficient corn-threshing method is characterized by comprising conveying corn cobs or corn cobs with skins to a main threshing barrel (1) through a feeding device; performing primary threshing on the corn cobs, and performed primary screening; performing secondary threshing on the corn cobs through an auxiliary threshing roller (4), and performing primary screening; performing secondary screening out of corns by swinging an upper sieve plate (9), a middle screen (10) and a lower sieve plate (11); performing third screening out of the corns above the upper sieve plate (9), the middle screen (10) and the lower sieve plate (11) through a suction fan (13) of a careful selection device; performing fourth screening out of the corns through a blower (14) of a cleaning device; and finally bagging the corns or loading the corns to a vehicle through an output loading device. The efficient corn-threshing method has the advantages of being high in efficiency and guaranteeing quality.

Owner:QIQIHAR BEIKUN AGRI MACHINERY MFG

Corn threshing device with classified screening function

The invention discloses a corn threshing device with a classified screening function. The corn threshing device with the classified screening function comprises a bottom plate, a lifting mechanism, athreshing mechanism and a screening mechanism, wherein the lifting mechanism is arranged above the bottom plate; the threshing mechanism is arranged on the left of the lifting mechanism and composed of a feeding hopper, a threshing cavity, a first rotating shaft, a second rotating shaft, a ratch, helical blades, a driven gear A, a driving gear, a driven gear B, a third rotating shaft, dischargingholes and a moving door; the screening mechanism is arranged under the threshing mechanism and composed of a connecting rod, a screening plate, a support rod, a guide plate, a first collecting tank, asecond collecting tank, a third collecting tank, a fourth collecting tank and a screening cavity. The corn threshing device with the classified screening function is good and thorough in threshing effects and capable of sorting corn kernels with different diameters and facilitating classified application.

Owner:季彪

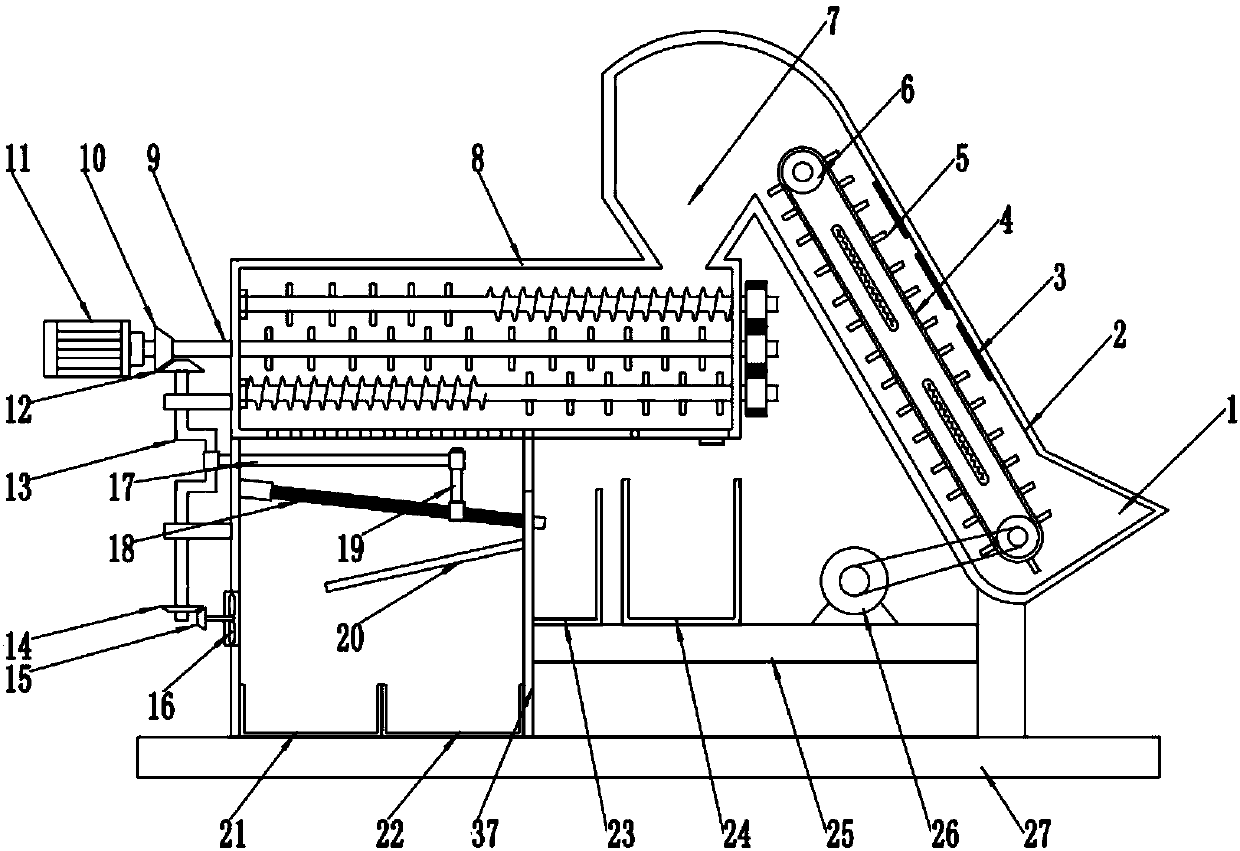

Highly-efficient corn thresher facilitating feeding and discharging

InactiveCN107896646AHigh degree of automationWith dust removal effectThreshersReduction driveEngineering

The invention discloses a highly-efficient corn thresher facilitating feeding and discharging. The highly-efficient corn thresher comprises a fixed chassis, pulleys and fixed thread lift-drop seats, wherein the left and right ends of the fixed chassis are respectively provided with a stop nut; the upper end of the fixed chassis is provided with a conveying drum; the temporal part of the conveyingdrum is provided with a second rotating shaft; a screw conveying mechanism is arranged on the second rotating shaft; the left end of the second rotating shaft is provided with a speed reducer; the left side of the speed reducer is provided with a conveying motor; the right end of the conveying drum is provided with a discharge outlet; the upper end of the conveying drum is provided with a threshing box; and the left side of the threshing box is provided with a lift drum. The highly-efficient corn thresher provided by the invention has simple and reasonable structural design, is simple and rapid to operate in use, is used for the work of corn threshing, has high degree of automation in the process of working, saves a great amount of labor, has high threshing efficiency and dedusting effect,is convenient for feeding and discharging, and has great practicability.

Owner:房立洲

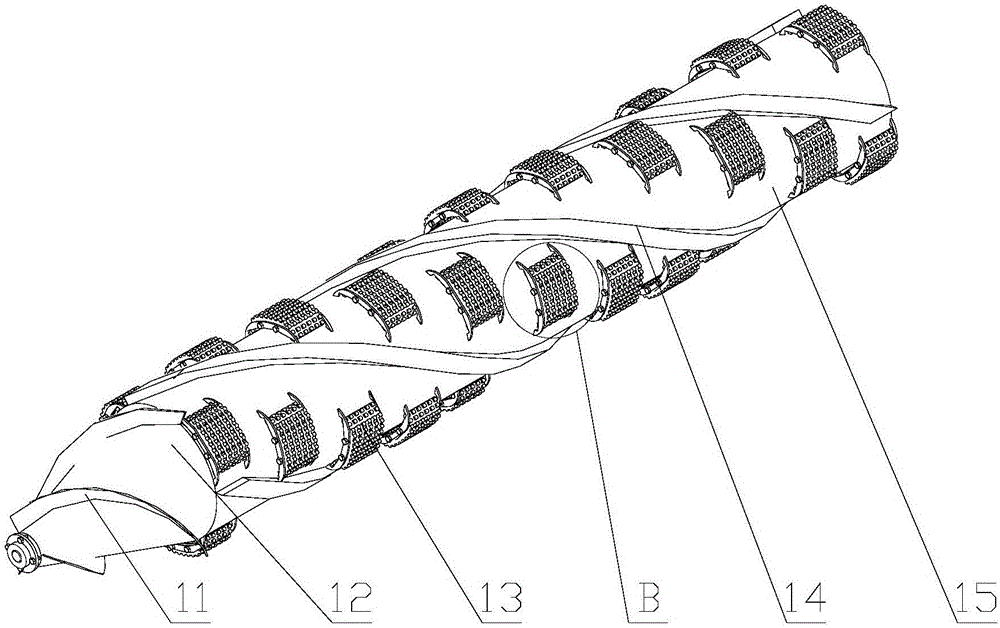

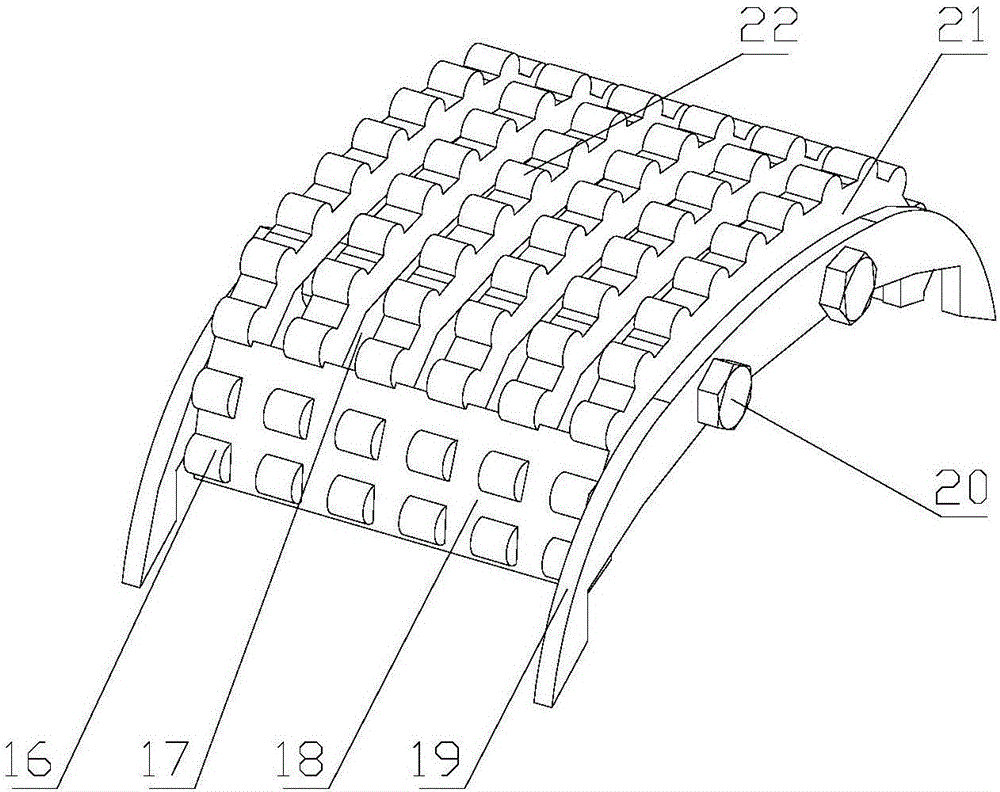

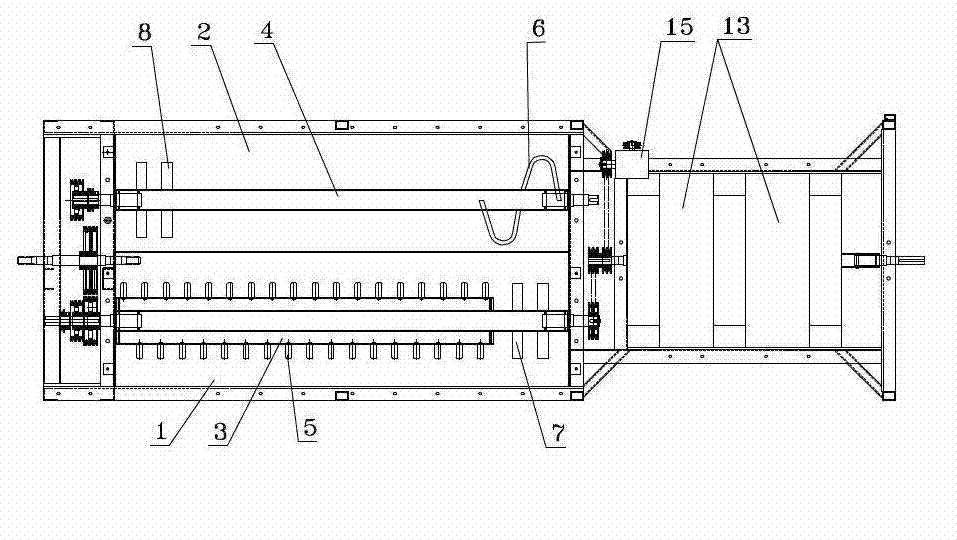

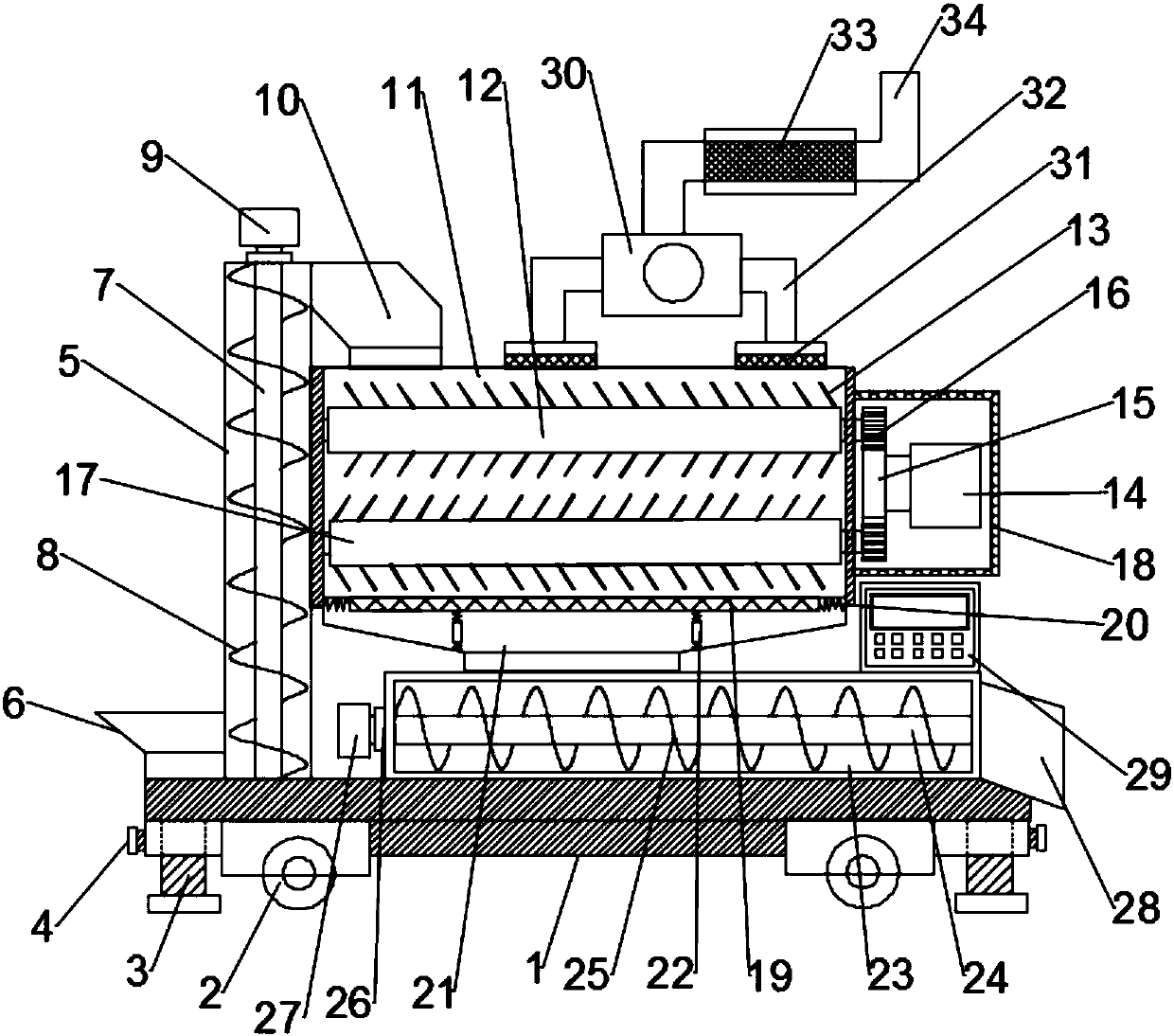

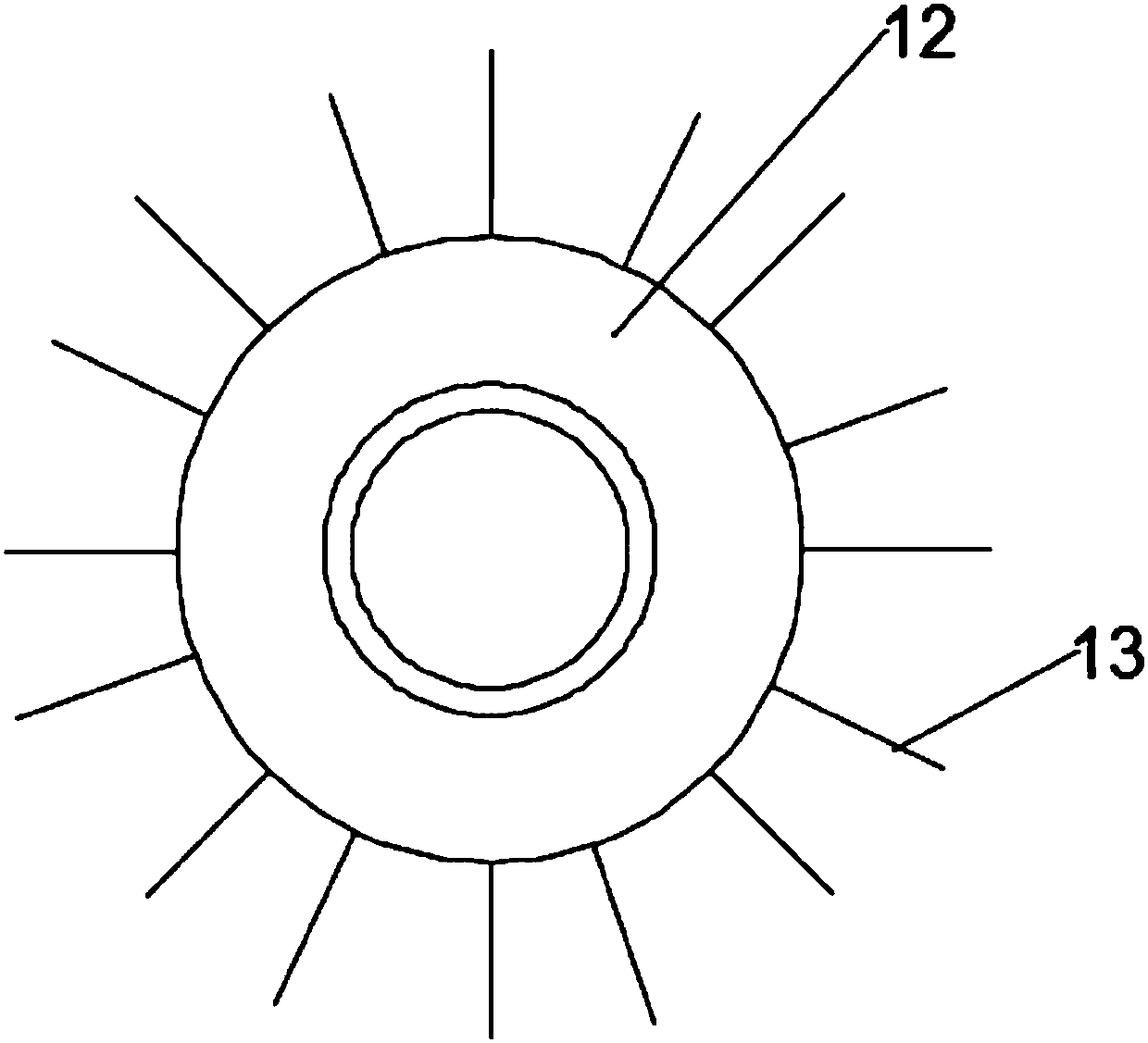

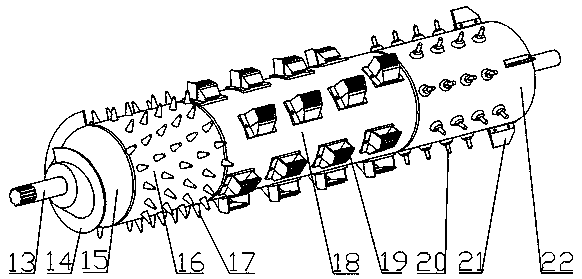

Longitudinal axis flow nested differential type corn threshing device

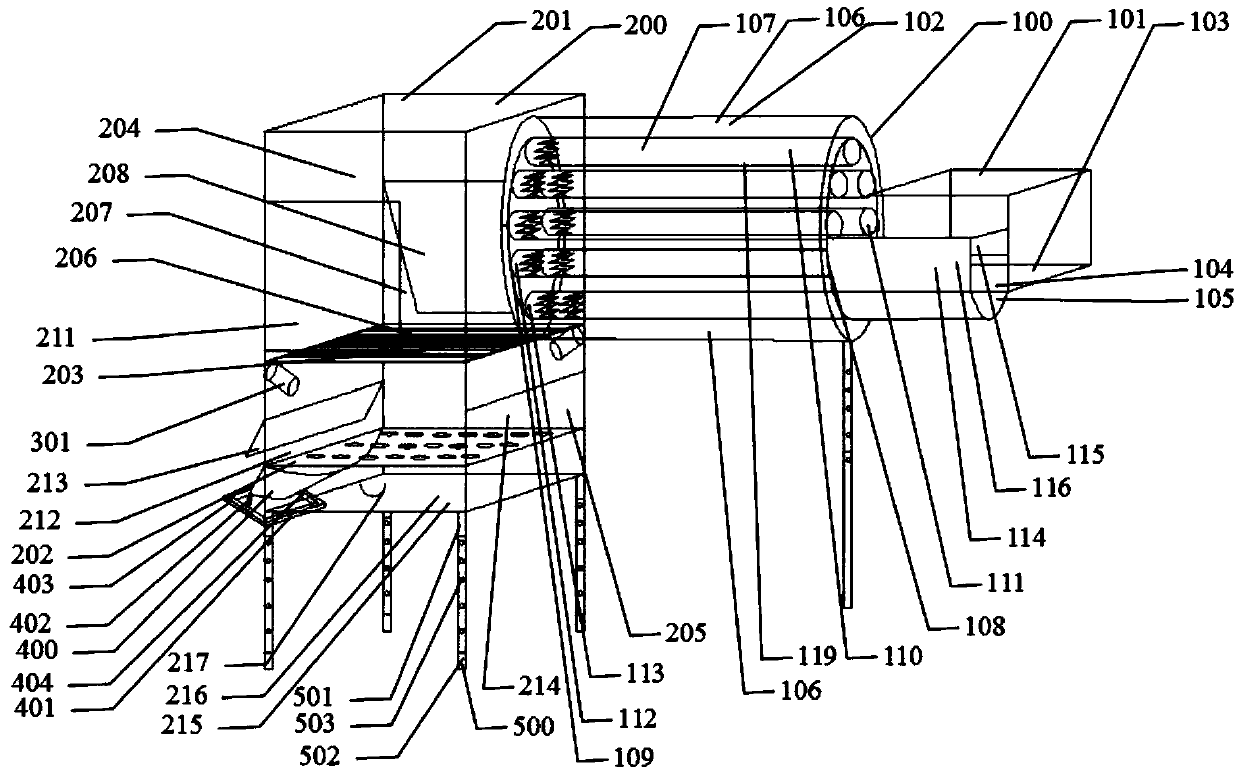

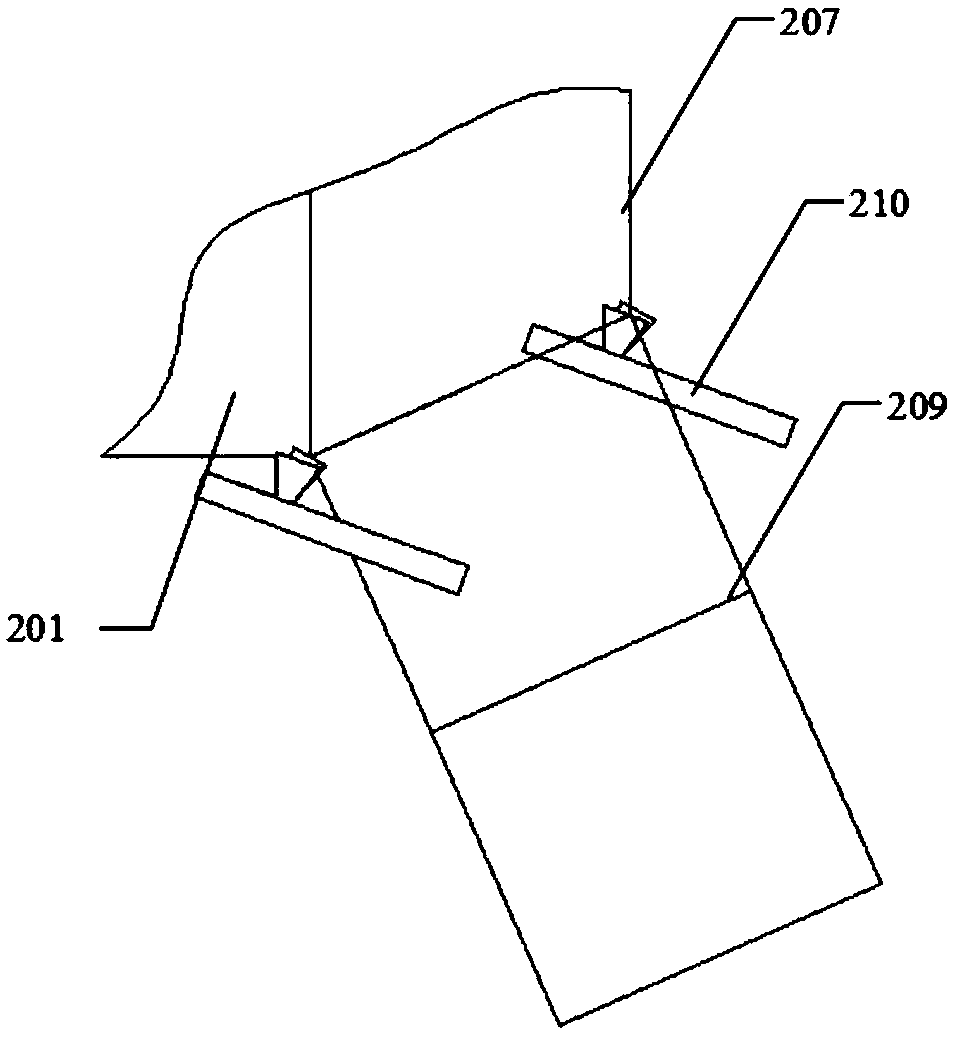

A longitudinal axis flow nested differential type corn threshing device comprises a front bearing seat, a threshing roller, a cylindrical concave plate screen, a concave plate screen gear ring, an upper flow guide cover, a rear bearing seat, a rear support, a lower cleaning screen, a belt wheel, a concave plate screen driving gear, a middle support and a front support; the threshing roller comprises a transmission shaft, a conical cylinder, a coarse threshing roller, a fine threshing roller, a crushing and guiding roller and a differential mechanism; the differential mechanism comprises a stargear, a star gear fixing seat, a fixed connecting rod, a first bearing, a flat key, a threshing roller driving gear, a second bearing, a transmission shaft fixing seat, a fixing rod, a fixed baffle plate, a blocking plate, a star gear support and a roller gear ring; the transmission ratio of the threshing roller driving gear and the star gear is different from the transmission ratio of the star gear and the roller gear ring, the rotation speeds of the coarse threshing roller, the fine threshing roller and the crushing and guiding roller are different, and the rotation directions thereof are same. The threshing efficiency and quality are improved, the damage and loss of corn grains can be reduced, and the winding and blocking of impurities such as straws are reduced.

Owner:JILIN UNIV

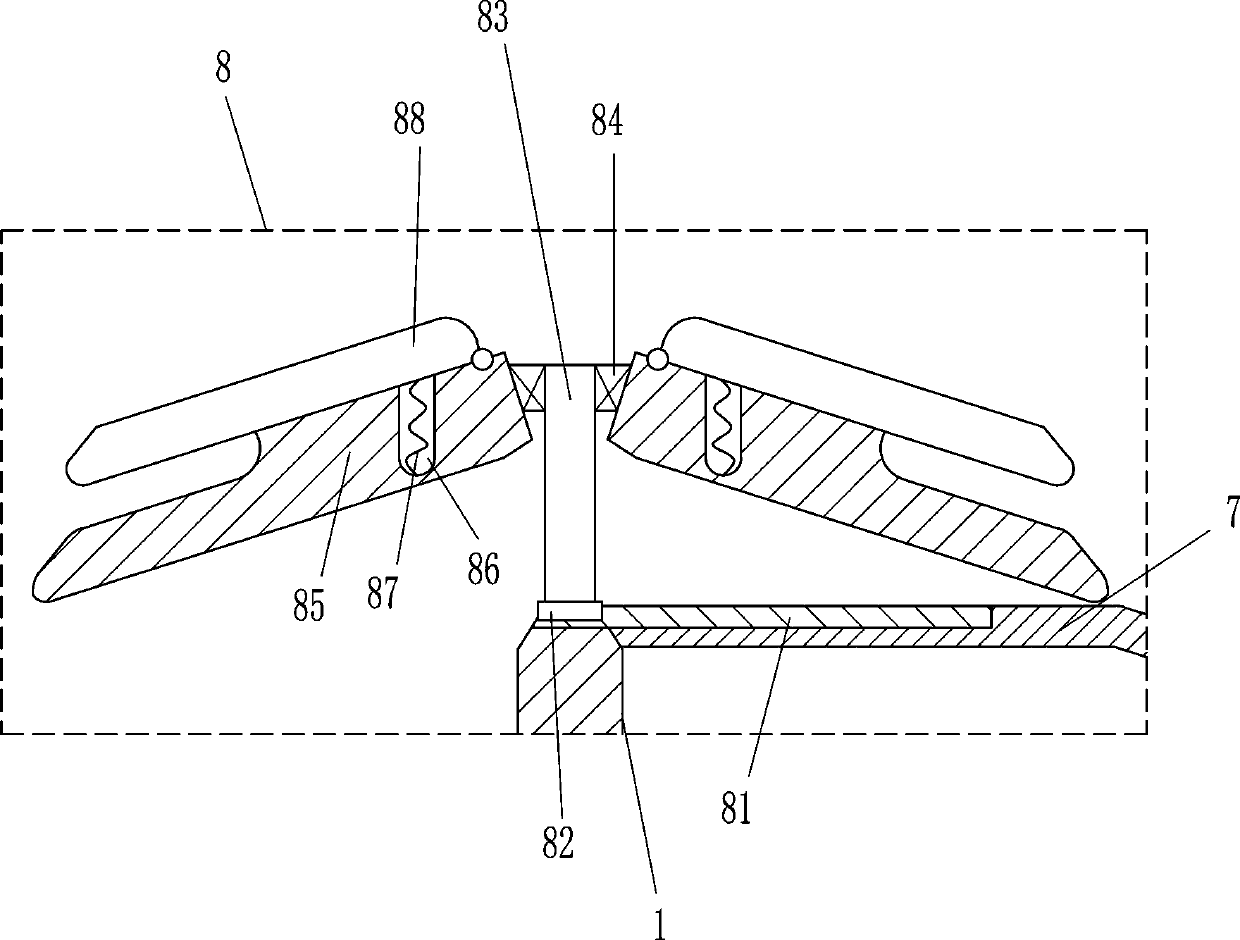

Sun-dried soybean threshing equipment

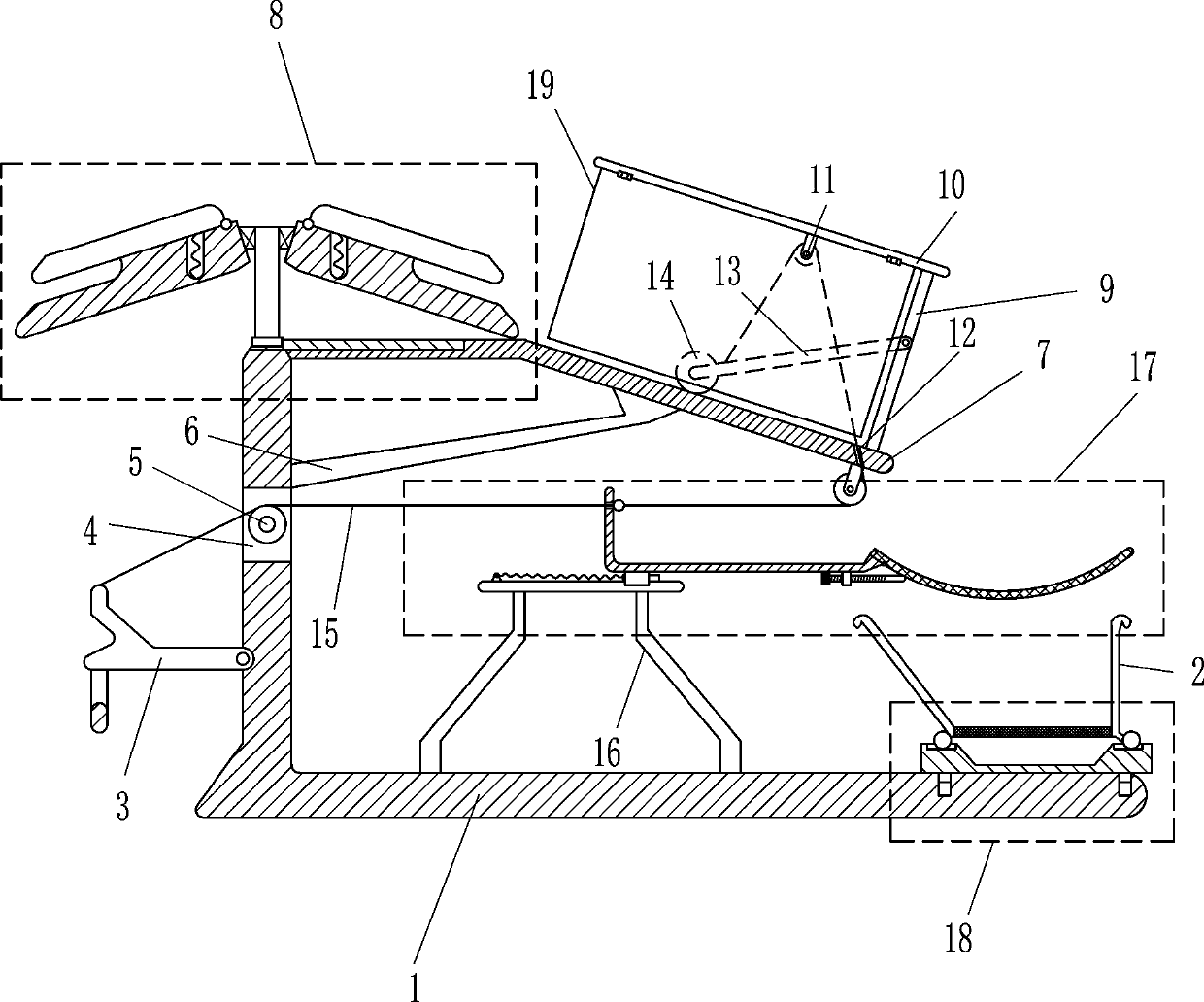

The invention relates to threshing equipment, in particular to sun-dried soybean threshing equipment, and aims at providing a sun-dried soybean threshing equipment capable of preventing sore arms andimproving the threshing efficiency of soybeans. The sun-dried soybean threshing equipment comprises a mounting rack, a collecting frame, a pedal, a first pulley, a first strut, a mounting plate, a placing device, a support rod, a baffle, a second pulley and the like; the collecting frame for storing soybeans is placed on the right side of the bottom of the mounting rack; the pedal is rotationallyconnected to the lower part of the left side surface of the mounting rack; and a through hole is formed in the upper part of the left side surface of the mounting rack. According to the equipment, preliminary threshing can be performed on the soybeans by the placing device, and a user can step on the pedal to enable a flapping rod to swing up and down to thresh the soybeans, therefore, the user does not need to hold a flapping plate to thresh the soybeans, aching pain of arms can be prevented and the threshing efficiency can be improved.

Owner:赵鸣

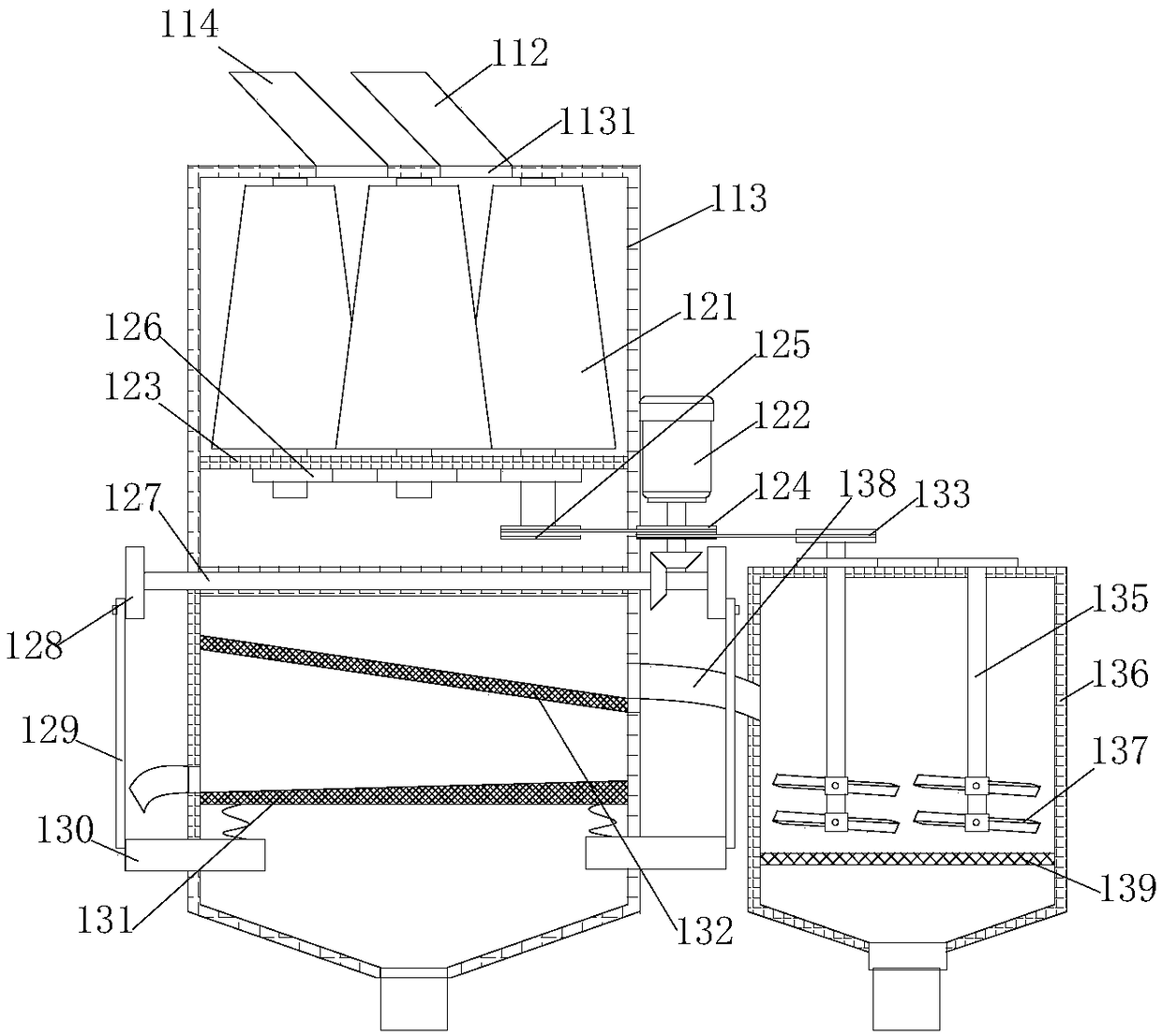

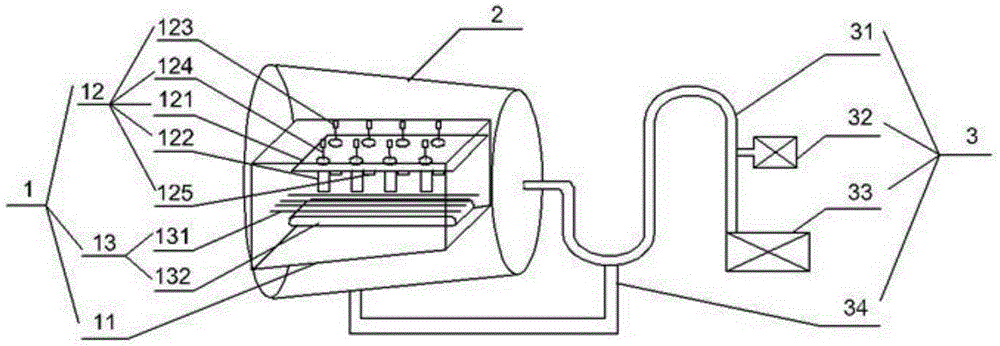

Agricultural machine for producing edible powder

InactiveCN108617277AReduced labor requirementsFree handsTransportation and packagingMixersAgricultural engineeringCorn flour

The invention discloses an agricultural machine for producing edible powder. The agricultural machine sequentially comprises a corn cob processing device, a corn grain crushing device, a powder mixingdevice and a powder operation device according to a process flow. The corn cob processing device comprises a feeding unit and a processing unit. The powder mixing device comprises a material mixing tank body and a material mixing upper cover which covers the material mixing tank body. A first material mixing and sieving plate, a first mixing chamber, a second material mixing and sieving plate, and a crushing / mixing integrated chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. The powder operation device comprises an operation conveying belt, a turnoverdischarging device, an operation baffle, a conveying hopper, an operation elastic device and an operation lifting base table. The agricultural machine provided by the invention has the advantages that the processing efficiency of corn cobs is improved, the quality of the produced corn flour is ensured, the mixing effect of the corn flour and the flour is good, the corn flour and the flour do notcake easily, blocking does not occur easily, the working continuity is strong, the feeding amount of a single time is accurate, and the working efficiency is high.

Owner:芜湖拓云农业技术有限公司

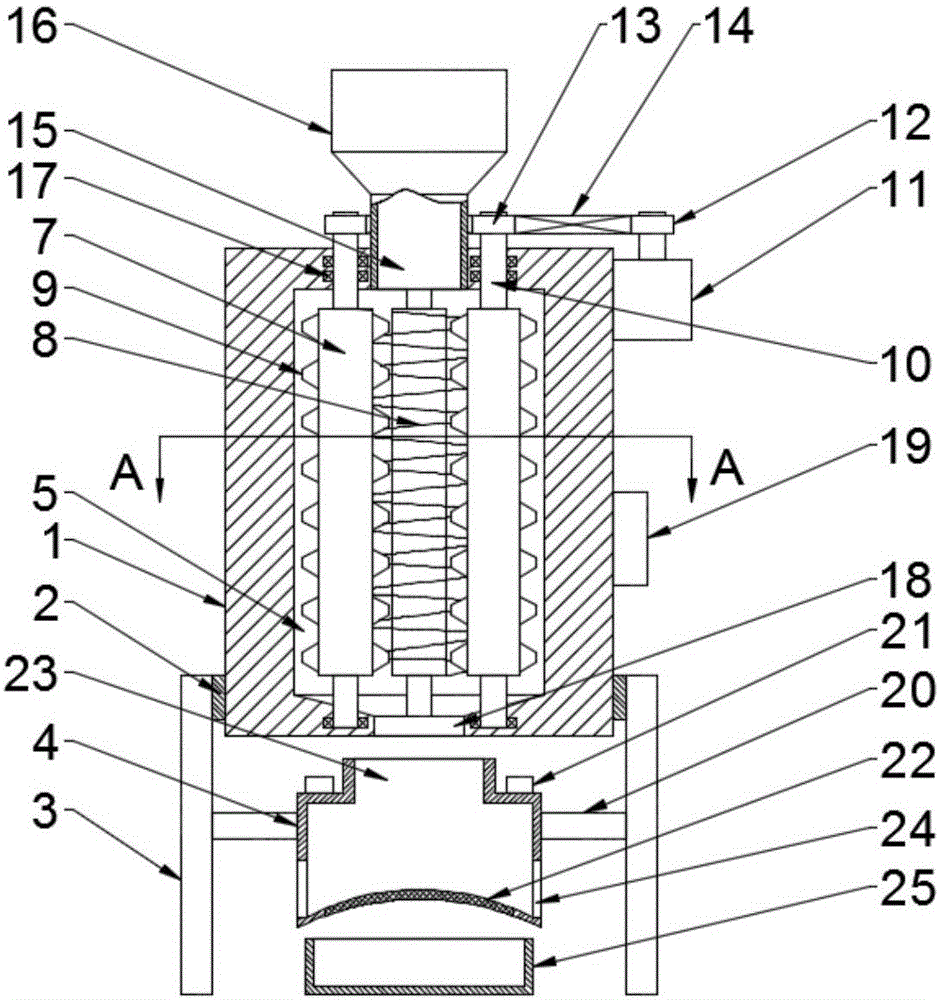

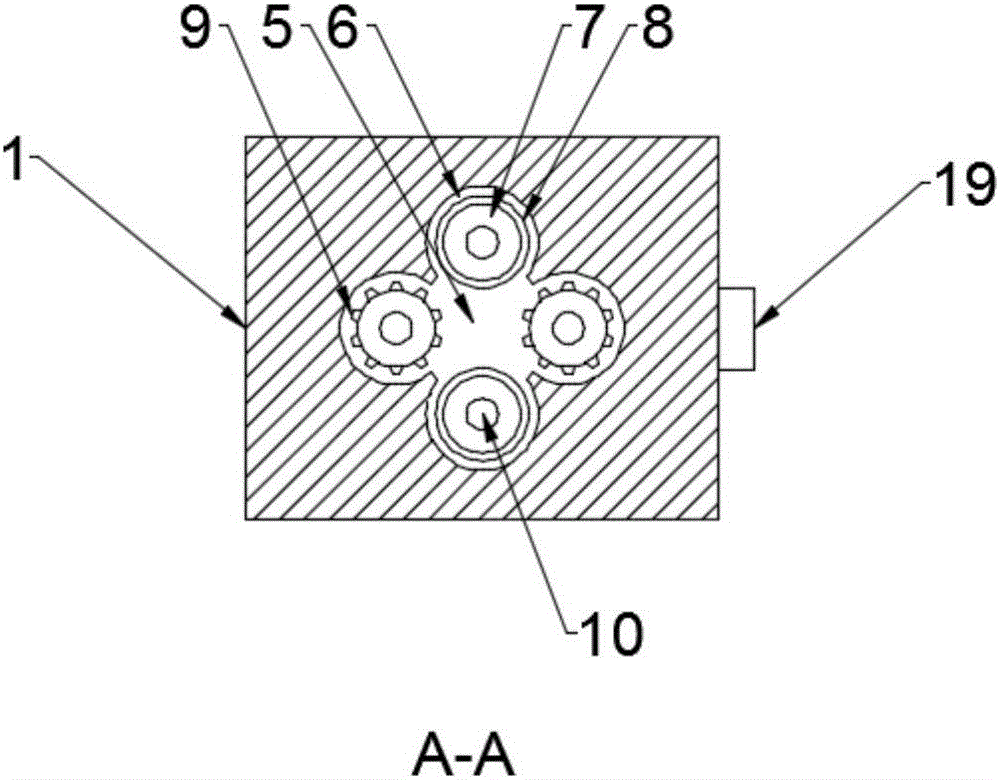

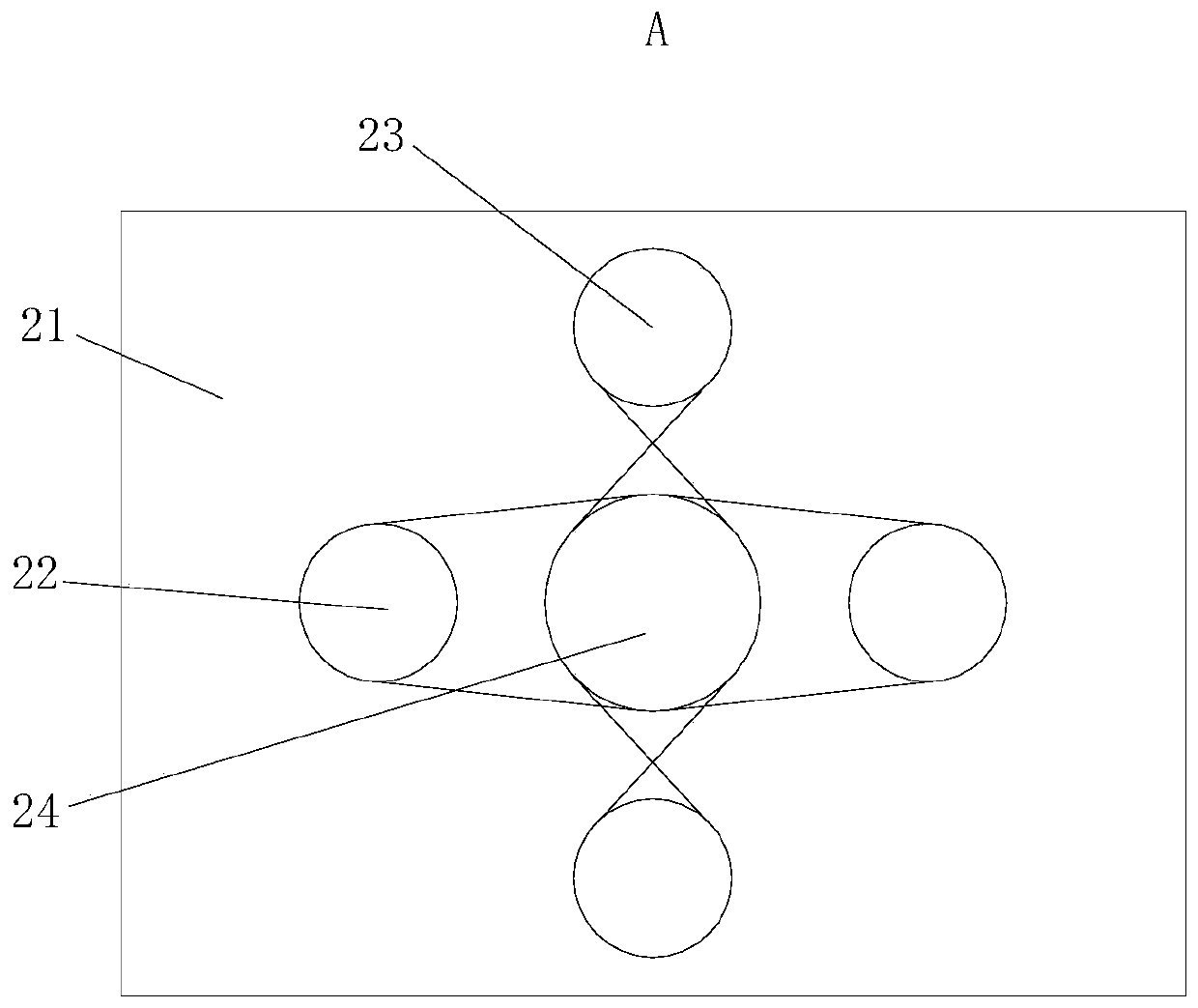

Novel vertical corn thresher

The invention discloses a novel vertical corn thresher which comprises a machine body. The bottom end of the outer side of the machine body is sleeved with a fixed frame, a plurality of supporting legs are evenly arranged on the fixed frame, and the machine body is internally provided with a main threshing cavity and four auxiliary threshing cavities. Threshing rollers are arranged in the four auxiliary threshing cavities and connected with machine body through rotating shafts, the top ends of the rotating shafts are protruded out of the machine body and fixedly connected with driven wheels, a motor is arranged on one side of the machine body, a motor shaft of the motor is fixedly connected with a driving wheel, and the driving wheel is connected with all the driven wheels through a belt. Screening boxes are fixedly connected between all the supporting legs through connecting rods, and vibrators are arranged at the top ends of the screening boxes in a bilateral symmetry mode. The four threshing rollers are all positioned around the main threshing cavity, two groups of spiral threshing teeth and reminding threshing teeth jointly interact, so that cob threshing efficiency is greatly improved, the threshing cycle is reduced, and device operation efficiency is improved. The four threshing rollers act jointly, loads on the threshing rollers are reduced, and the service life of the novel vertical corn thresher is prolonged.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Cooked-corn threshing device and application method thereof

PendingCN108127703AReduce walking resistanceControl depthMetal working apparatusSaving energy measuresEngineeringMechanical engineering

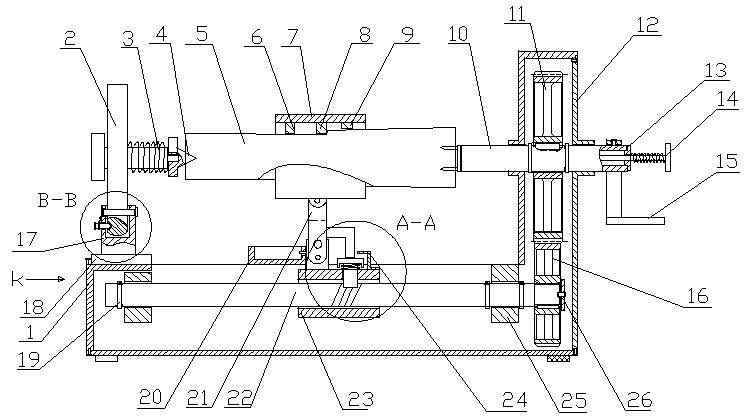

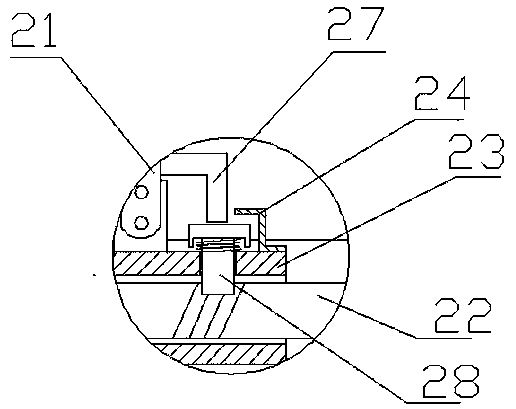

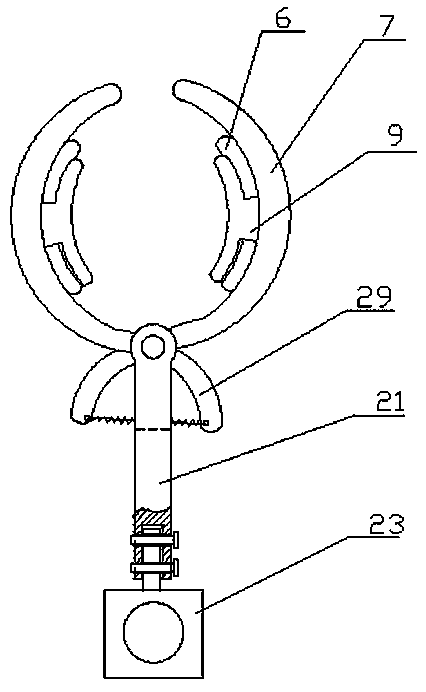

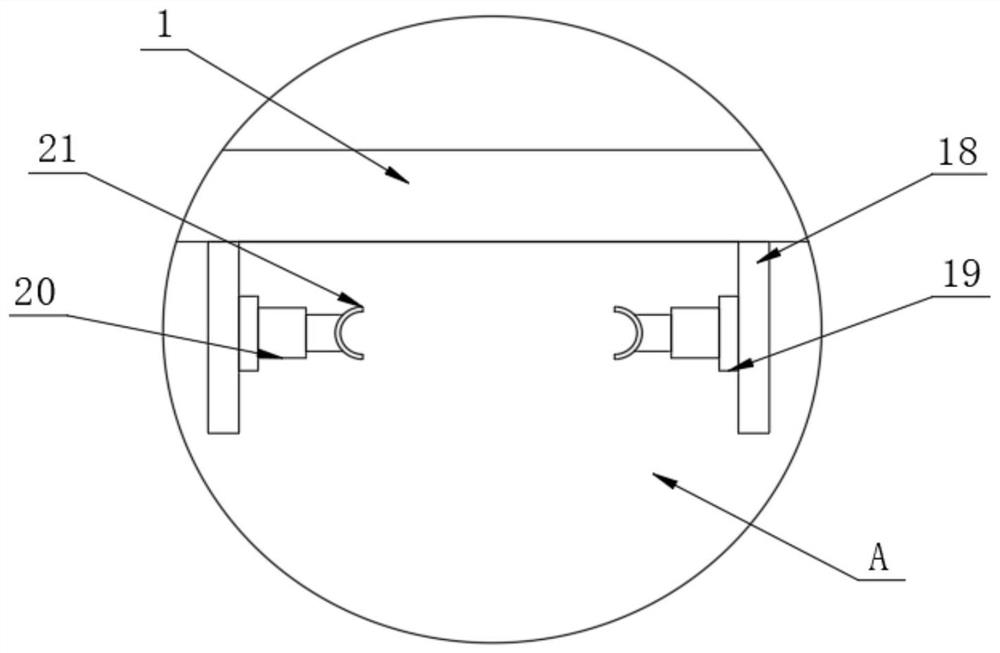

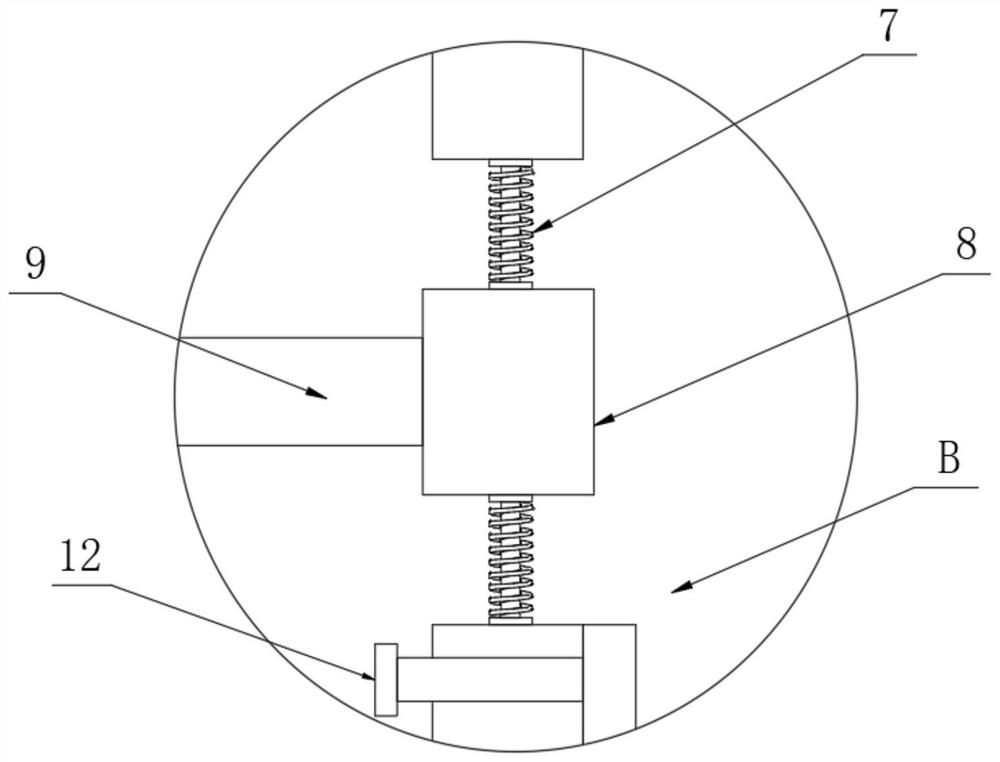

The invention discloses a cooked-corn threshing device. The cooked-corn threshing device comprises a base, a cavity is formed in the base, a tail base is arranged at one end of the base, a limiting ejector rod capable of moving left and right is installed on the tail base, a machine head is arranged at the other end of the base, a fork-rod gear and a threaded-rod gear which are mutually engaged are arranged in the machine head, a fork rod is rotationally arranged at the upper portion of the machine head through a sliding sleeve, a rotatable handle is arranged at the other end of the fork rod,the fork-rod gear is fixedly installed on the fork rod, a vertical rod is fixedly installed on the upper end face of a feeding sleeve, the end, upwards extending out of a strip-type groove, of the vertical rod is connected with a threshing cutter, the threshing cutter comprises a pair of clamping bodies movably hinged together through a hinging shaft, and centers of an ejector cone, a clamping head and the fork rod are arranged on a same horizontal center line. The invention also provides an application method for the cooked-corn threshing device, the hands are not required to be in direct contact with cooked corn in the peeling process, the application method is clean and sanitary and high in threshing efficiency, and the threshing strength is reduced.

Owner:刘昭昌

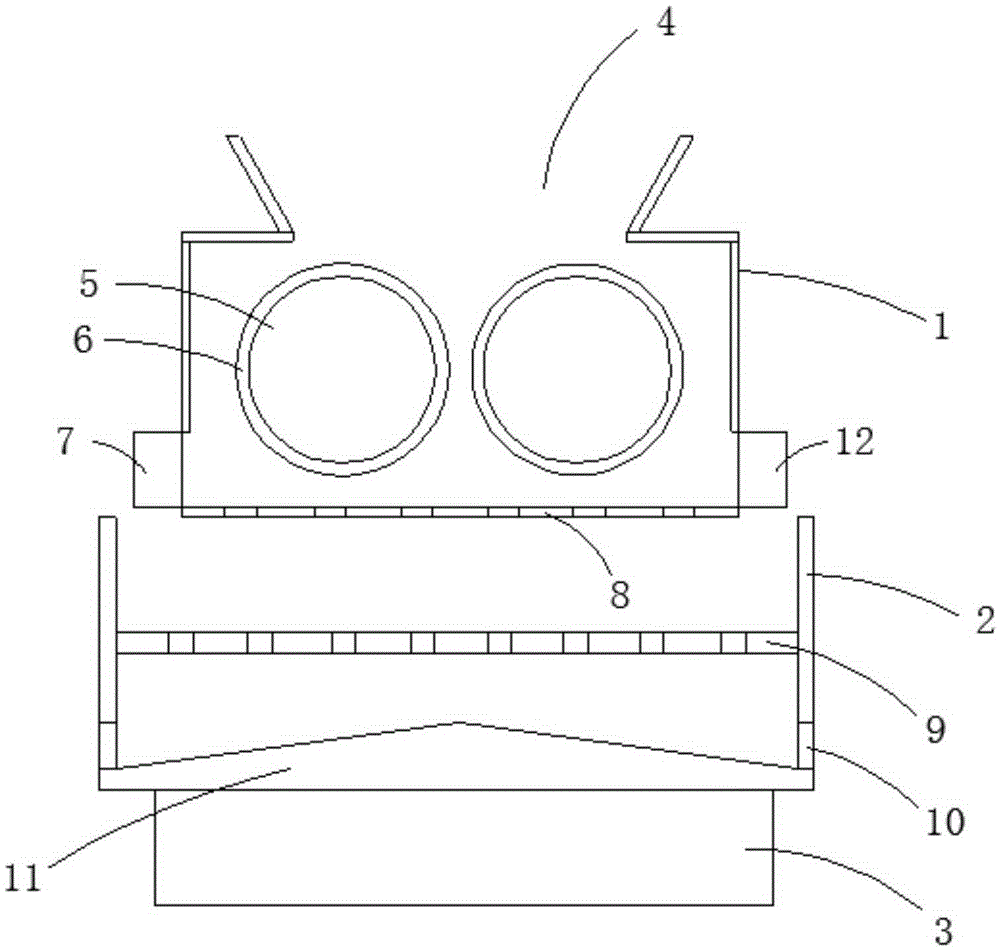

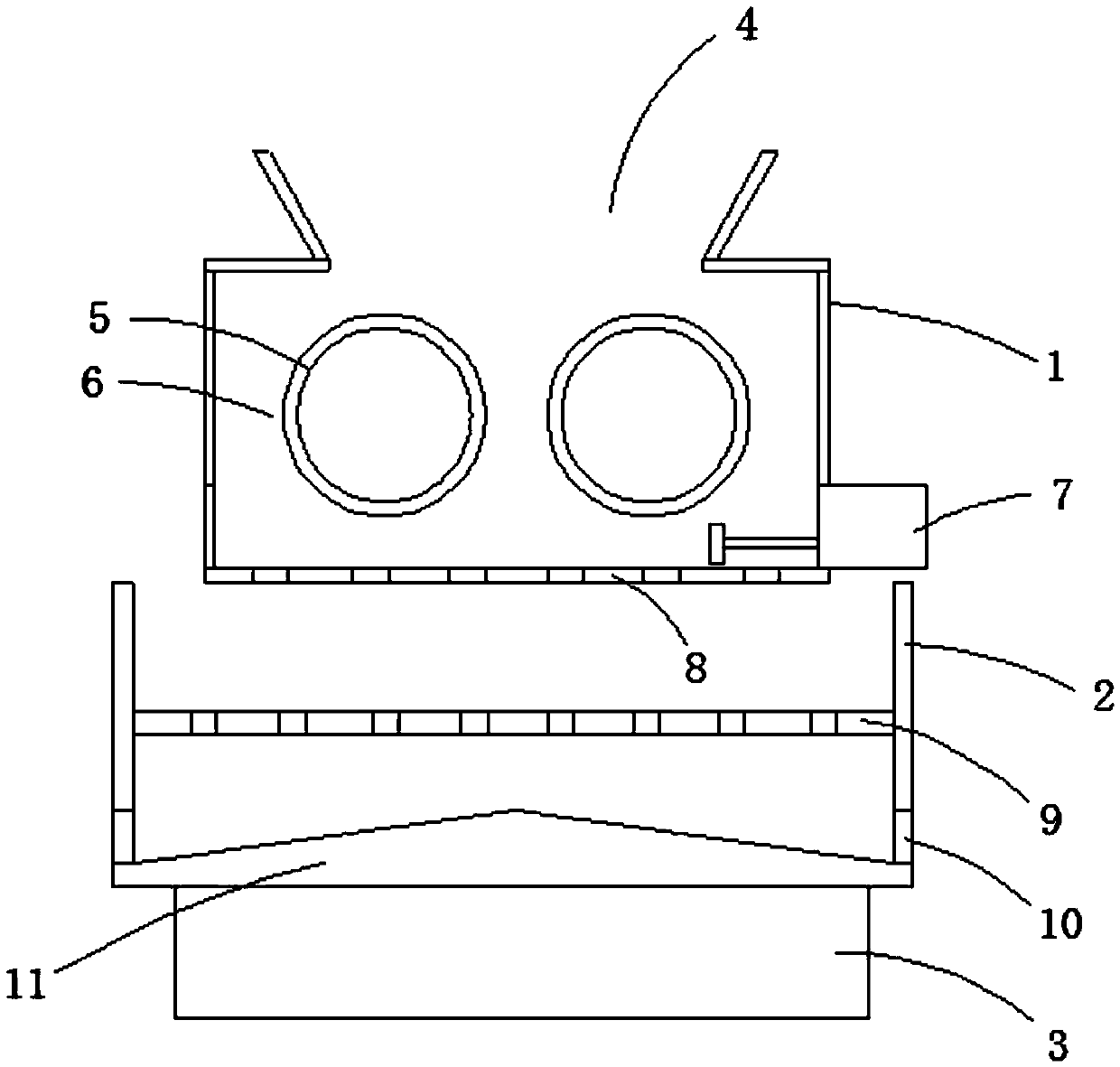

Dry grain thresher

The present invention relates to a dry grain thresher. The thresher comprises a threshing cylinder, a grain collector and a vibrator. The threshing cylinder is disposed above the grain collector; the vibrator is disposed at the lower end of the grain collector; the upper end of the threshing cylinder is fixedly provided with a grain placing port; two rollers are arranged in the threshing cylinder and are located below the grain placing port in parallel; spiral blades for threshing are arranged on the two rollers; the bottom of the threshing cylinder is a screen; and a blower capable of blowing out hot air is arranged on one side of the threshing cylinder and an induced draft pump is arranged on the other side of the threshing cylinder. Compared with the prior art, the dry grain thresher disclosed by the present invention has the features that the threshing speed is high; grains can be dried by hot air; grain waste is avoided; and the grains are clean.

Owner:GUILIN UNIV OF AEROSPACE TECH

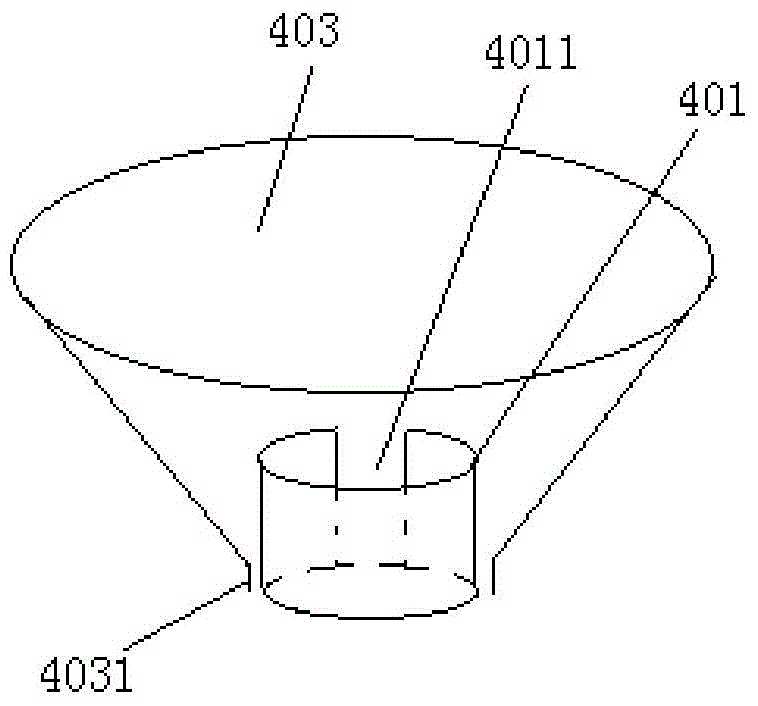

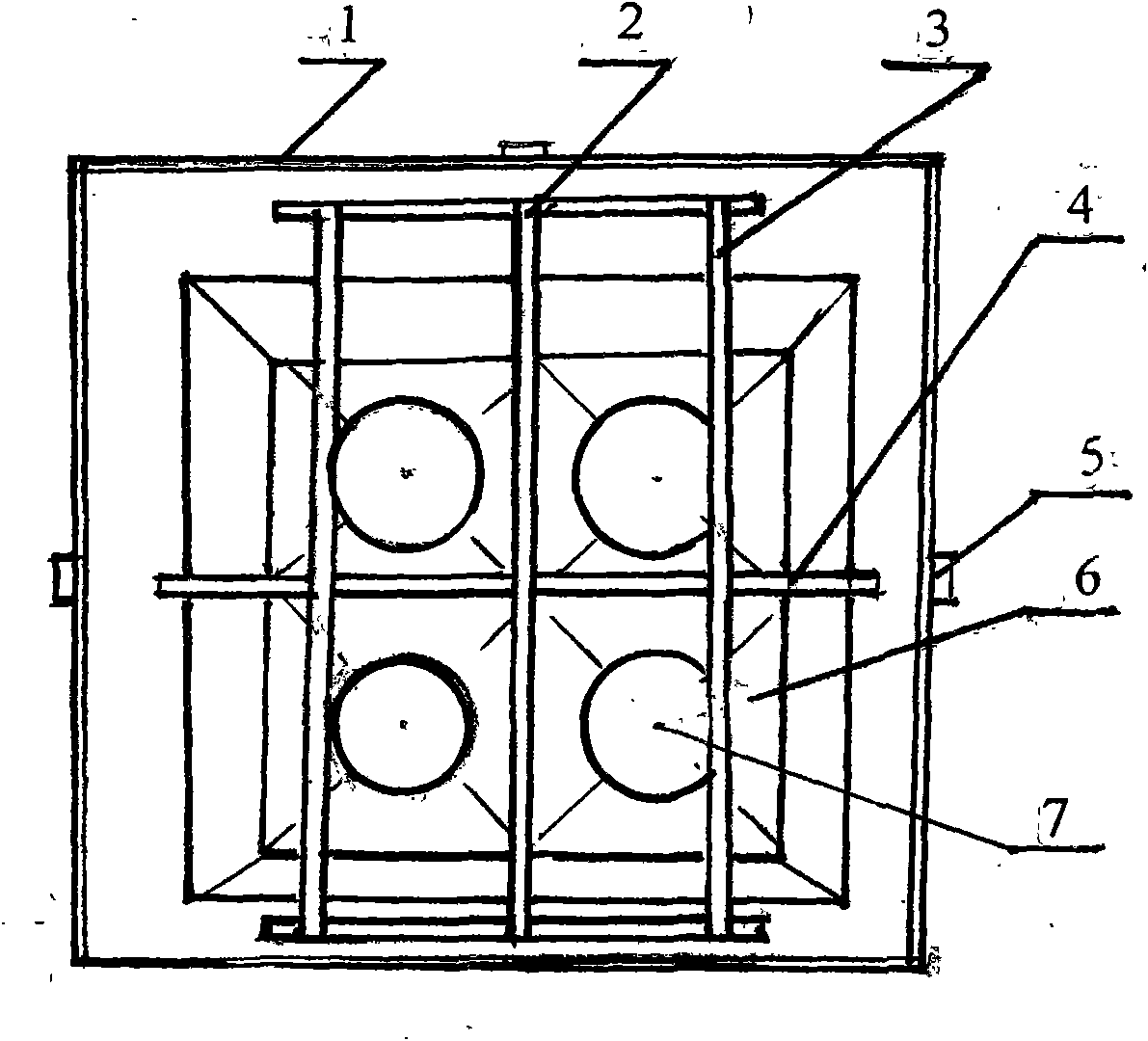

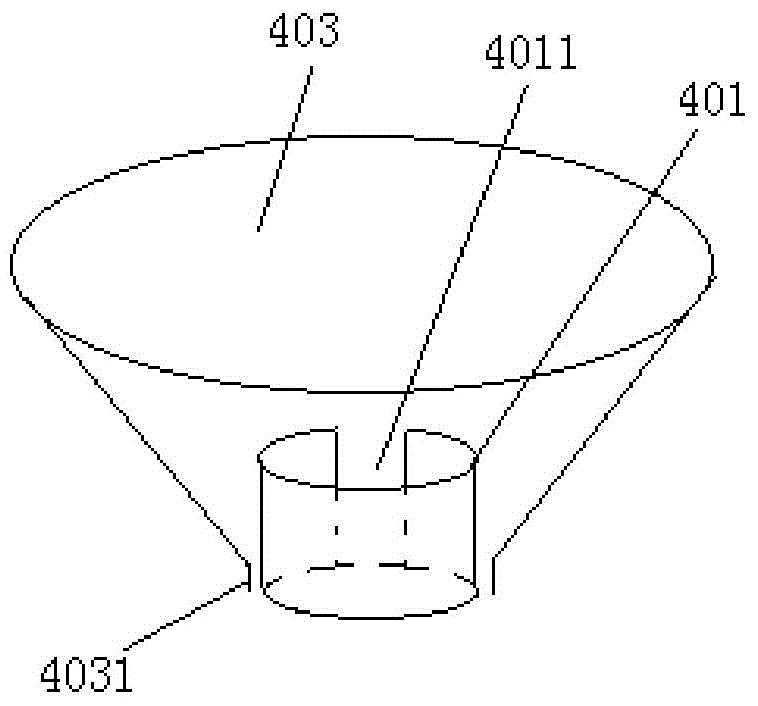

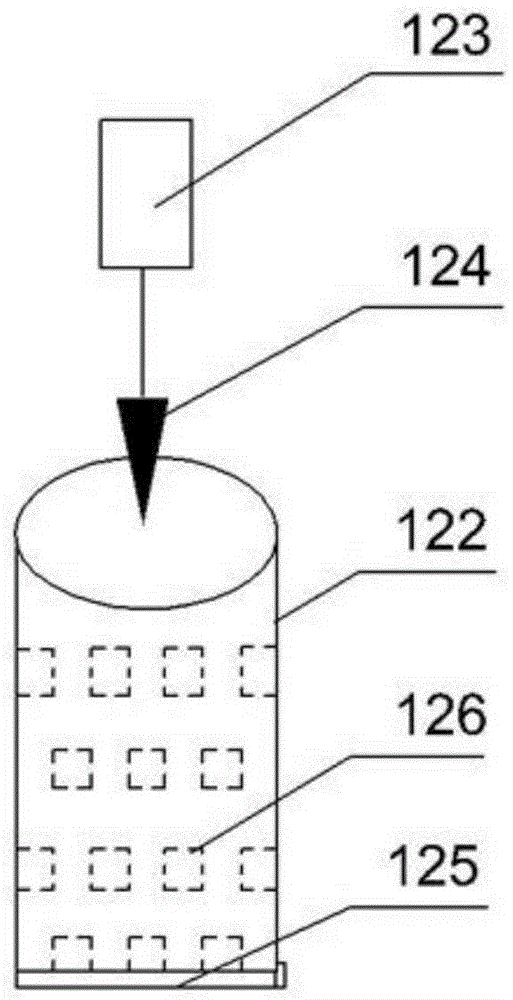

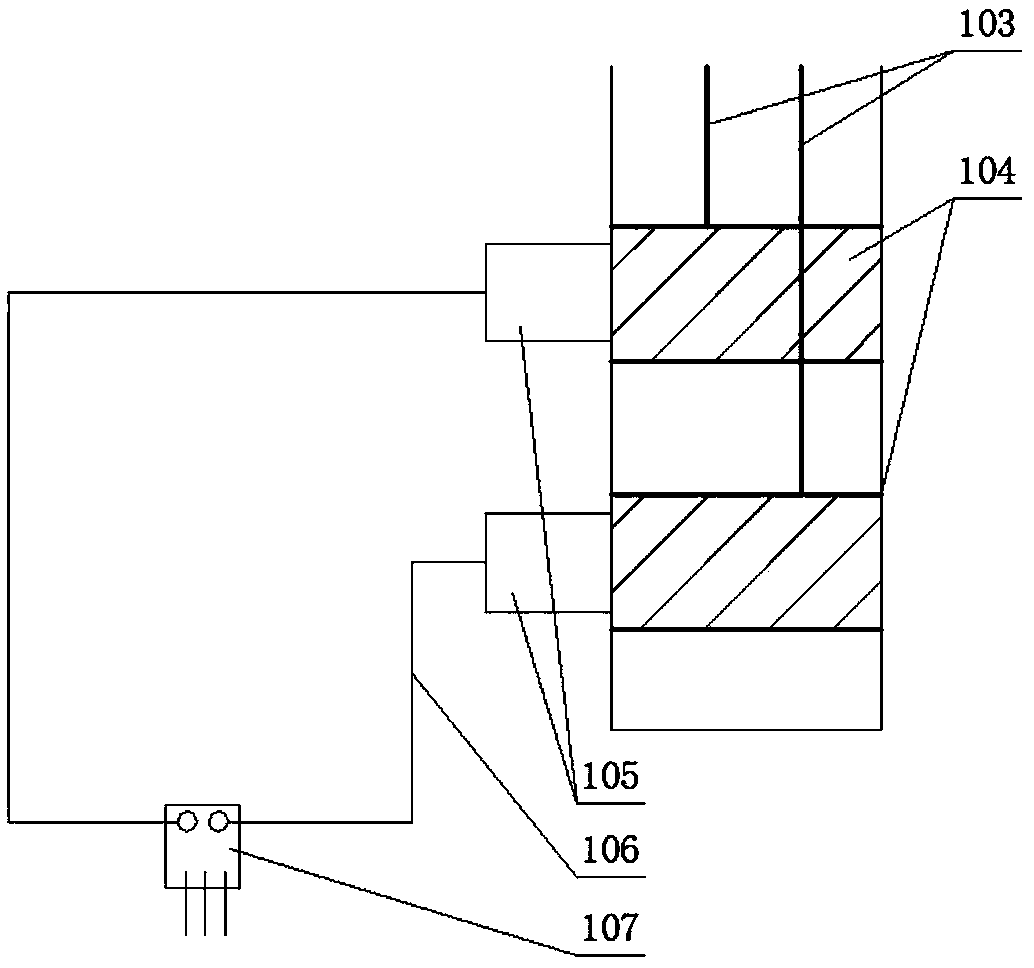

Feed hopper of novel corn thresher

The invention discloses a feed hopper of a novel corn thresher, which is arranged according to the threshing and feeding requirements of a tubular corn thresher and the shape and the size of a corn cob and used for the mass feed of a vertical type corn thresher and a horizontal type corn thresher. The feed hopper is divided into an upper layer, a middle layer and a lower layer, wherein the upper layer is provided with a fence sieve, and the lower layer is provided with a corn cob outlet; the middle layer of the feed hopper suitable for the vertical type corn thresher is provided with a horizontal rod, and the middle layer of the feed hopper suitable for the horizontal type corn thresher is provided with a flat hopper. The corn cobs with different sizes in disorder are fed into the feed hopper in batch during working, and the corn cobs fed in batch can sequentially fall one by one to enter a threshing pipe of the corn thresher to thresh under the actions of mutual impact and manual pullthrough the automatic adjustment of the fence sieve and a horizontal rod or the flat hopper; the problem of power and time waste of single manual feed of a small corn thresher is solved, and the batch feed speed and the threshing efficiency are both high.

Owner:唐满江

Corn threshing device for agricultural harvesting machinery

InactiveCN111802087AReduce the difficulty of collectionDecrease productivityThreshersAgricultural scienceAgricultural engineering

The invention discloses a corn threshing device for agricultural harvesting machinery, and particularly relates to the field of agricultural machinery. The corn threshing device comprises a threshingbox, wherein a feeding hopper is detachably mounted at the top end of the threshing box; a threshing device body is detachably mounted on one side of the inside of the threshing box; a supporting plate is detachably mounted on one side of the threshing box; and a vibrating motor is detachably mounted on the surface of the top end of the supporting plate. By cooperation of a screen and the vibrating motor, the effect of low particle collecting difficulty is achieved, the problems that when an existing corn threshing device for agricultural harvesting machinery works, corn cobs are not removed after being threshed, the particle collecting difficulty can be increased once the corn cobs and corn particles are mixed, then the working efficiency of the device is reduced, moreover, the device canbe damaged if the corn cobs remain in the machine, certain economic loss is caused to a user, and development is not facilitated are solved, and the practicality of the device is improved.

Owner:蒋尧威

A kind of corn thresher

The invention discloses a corn threshing machine comprising a housing, a threshing unit arranged in the housing, and a kernel and core separation device arranged in the housing. The kernel and core separation device is arranged below the threshing unit. A sound insulation layer is arranged in a shell layer of the housing; and the thickness of the sound insulation layer is the half of the thickness of the shell layer. The corn threshing machine also includes a corncob feeding device arranged at the top of the housing. The corncob feeding device contains a feeding cylinder and a rotation cylinder. The feeding cylinder connected with the inner cavity of the housing is fixed at the top of the housing and is protruded outwardly; and the rotation cylinder connected with the feeding cylinder in a rotation mode is in transmission connection with a first power unit. Multiple corncob that are going to be processed by threshing are laid on the inner wall of the rotation cylinder in a loop mode. According to the invention, on the basis of improvement of the existing corncob feeding device, the corn threshing machine has the automatic feeding function; and with the sound insulation layer at the housing, noises caused during the equipment running processing can be effectively reduced.

Owner:秦朝东

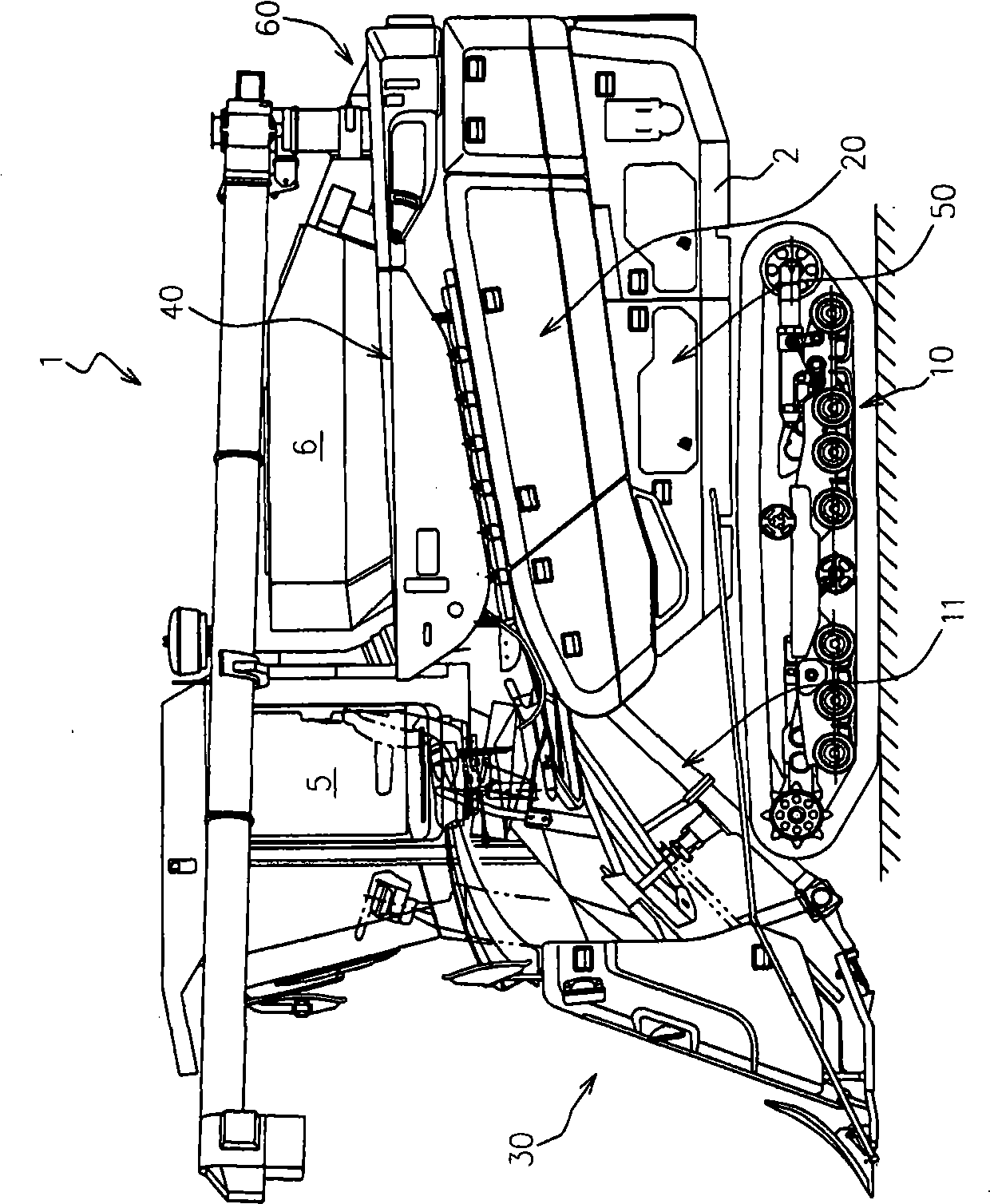

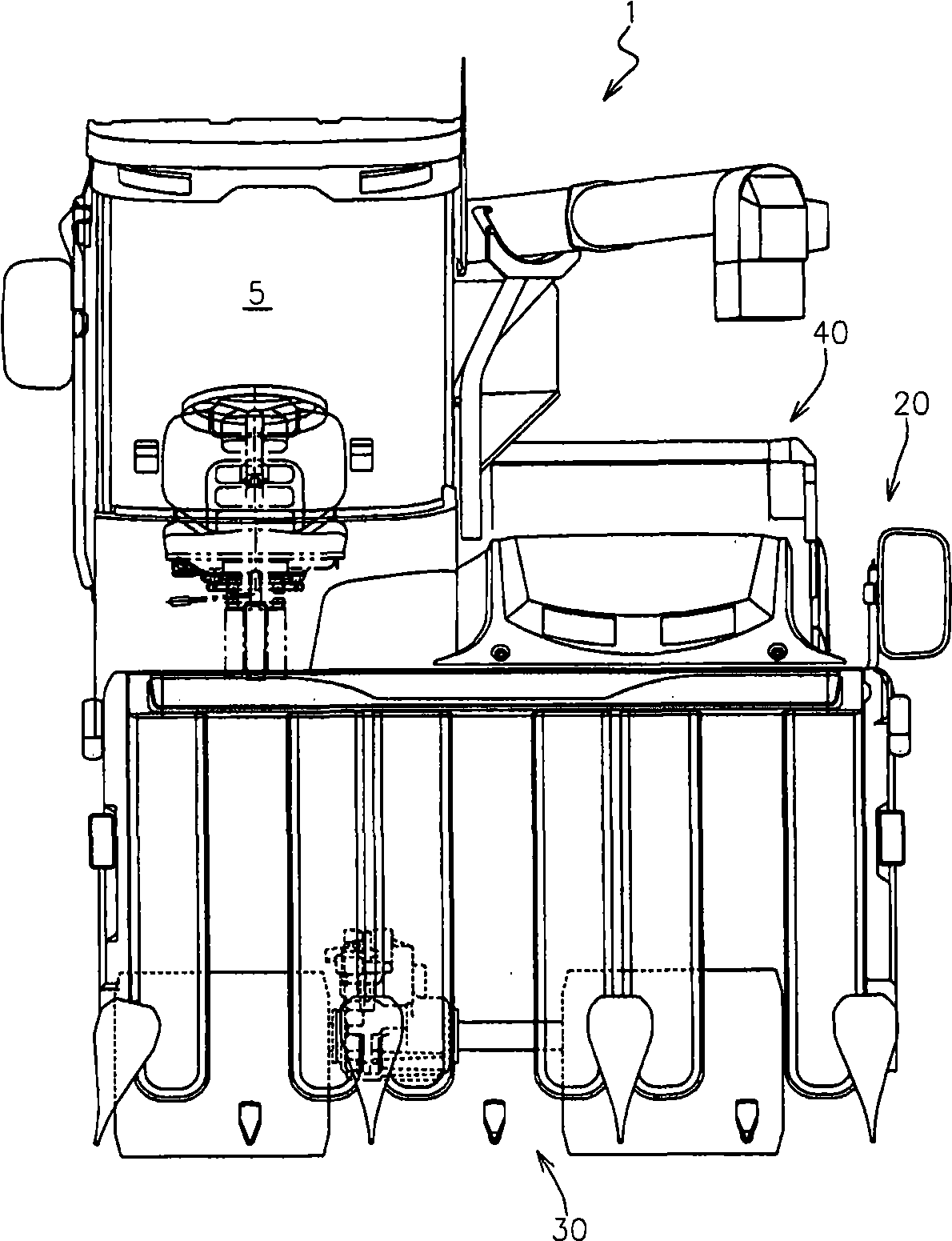

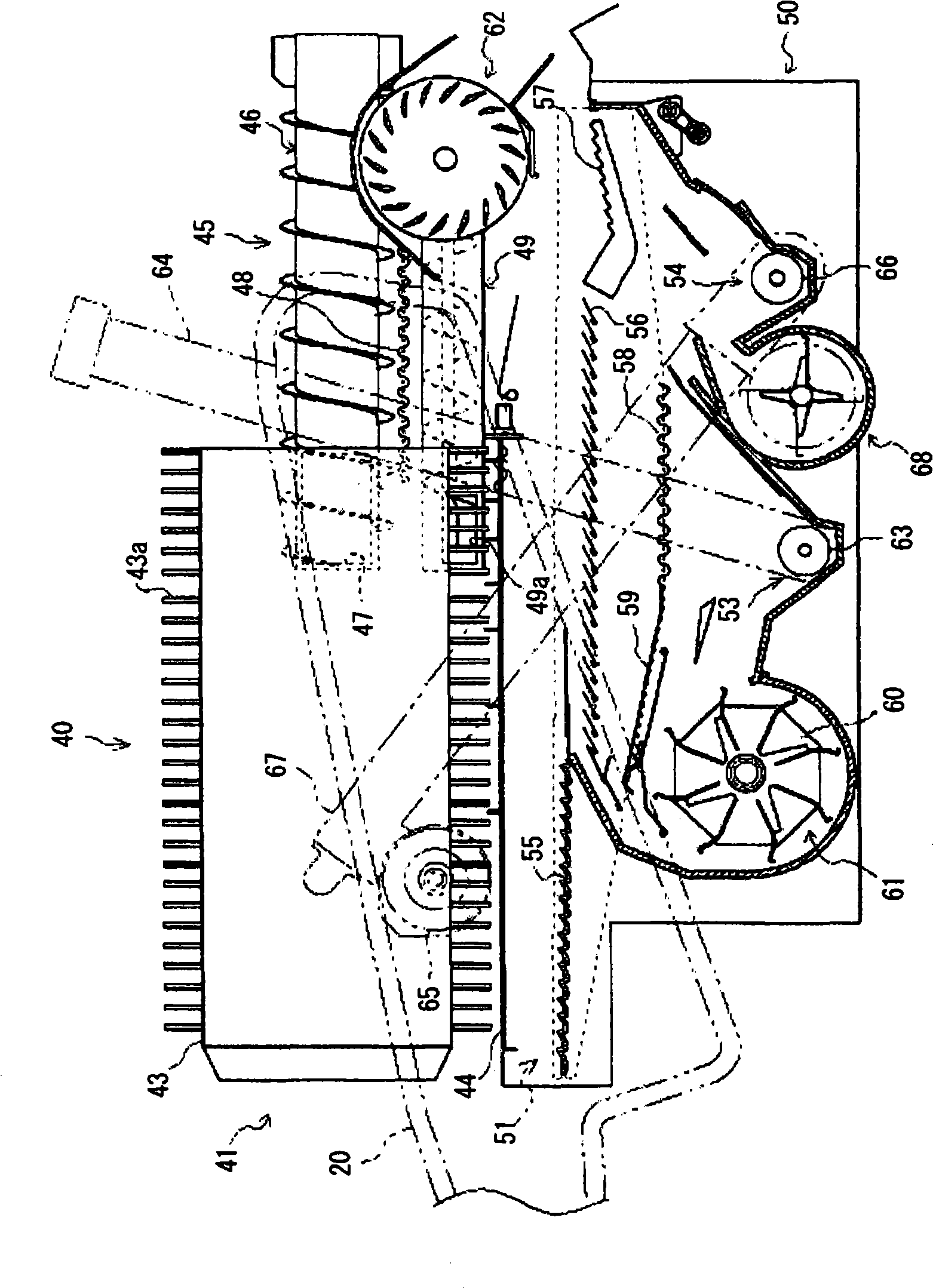

Threshing apparatus

ActiveCN101530037AImprove the effect of removing strawImprove threshing efficiencyThreshersLinear componentEngineering

The present invention discloses a threshing apparatus, which is provided with a receiving network under a threshing roller; one rear side of a roller room that collects the threshing roller communicates with a front side of a processing room that collects a dust sending port processing roller through the dust sending port, which is capable of enhancing threshing efficiency of the threshing roller, and is capable of transporting substance unprocessed by the threshing roller from the roller room to the processing room in high efficiency. In a first receiving network (71) of a receiving network (44) that located on one front side of the dust sending port (47), a plurality of longitudinal panel components (73) with plate surface facing front and back along the threshing roller (43). A plurality of linear components (74) seen from a cross section view are in circular shape roughly, in a state of alternating on holes (73a) of the longitudinal panel components (73) along axial direction of the threshing roller (43), and are arranged along circumferential direction of the threshing roller (43).

Owner:YANMAR POWER TECHNOLOGY CO LTD

Millet threshing device

The invention provides a millet threshing device aiming at the problem that in the prior art, a grain threshing device is short in threshing distance, and consequently threshing is not thorough. The millet threshing device comprises a shell, a driving shaft rotationally arranged on the opposite side faces of the shell, a conical front end assembly arranged on the driving shaft and used for pushing grain ears, a rotary threshing assembly connected with the large diameter end of the conical front end assembly, driven by the driving shaft and used for threshing, and a shake separating assembly driven by the driving shaft and used for separating millet grains from impurities. The rotary threshing assembly and a grid concave plate I cooperate for threshing, the rotary threshing assembly is composed of a plurality of threshing rolls which are evenly distributed on the outer side of the driving shaft and are parallel to the axis of the driving shaft, and the threshing rolls all can rotate around the axes of themselves. The millet threshing device is simple in structure, the threshing rolls rotate around own axes, the rubbing distance can be increased, and the threshing efficiency can be improved.

Owner:HENAN UNIV OF SCI & TECH

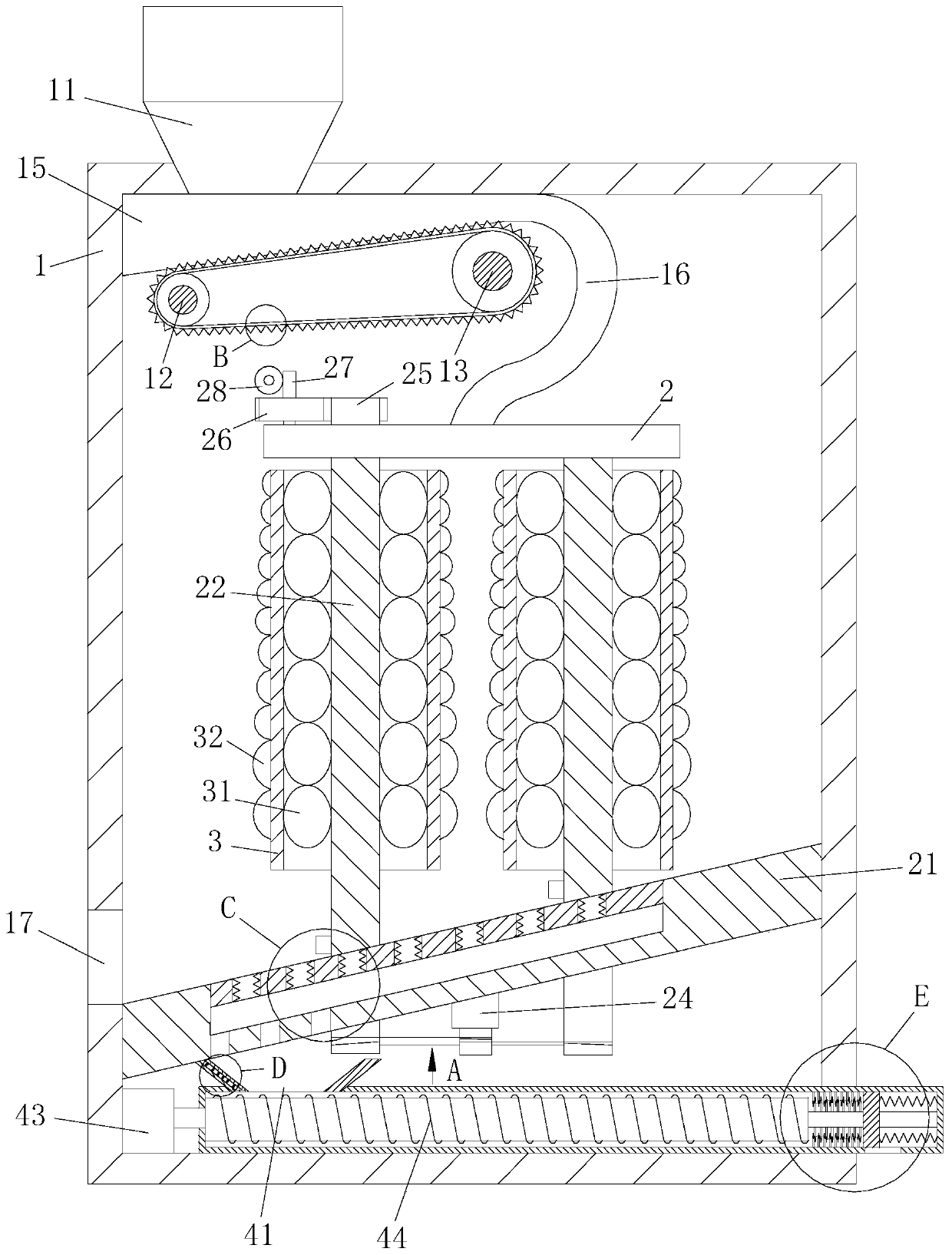

Threshing and deslagging integrated device for corn

ActiveCN105409462AGuaranteed smoothnessImprove threshing efficiencyThreshersEngineeringConveyor belt

The invention discloses a threshing and deslagging integrated device for corn. The device comprises a threshing part, a separating part and a deslagging part, wherein the threshing part comprises a horizontally arranged box body and a first threshing mechanism and a second threshing mechanism; the first threshing mechanism comprises a plurality of pressing assemblies, a supporting plate and a plurality of rotor drums; each of the pressing assemblies comprises an air cylinder and a needle head; a bottom plate is hinged to the bottoms of the rotor drums; a sensor is arranged on the bottom plate; the air cylinder, the rotor drums, the bottom plate and the sensor are connected with a controller; the second threshing mechanism comprises a roll shaft assembly and a conveyor belt; the separating part comprises a barrel body, wherein a space where corn kernel roll is formed between the barrel body and the box body; the deslagging part comprises a serpentine pipeline, an exhaust fan and a dust box. By threshing the cobs in two sections, corn kernels and cobs are separated; the cobs are deslagged in two sections, so that the corn kernels are separated from small particle slag body impurities and cob impurities; the device has the advantages of being sanitary, energy-saving, convenient, high in threshing efficiency, good in corn kernel quality and the like.

Owner:唐山鑫盛源农产品加工有限公司

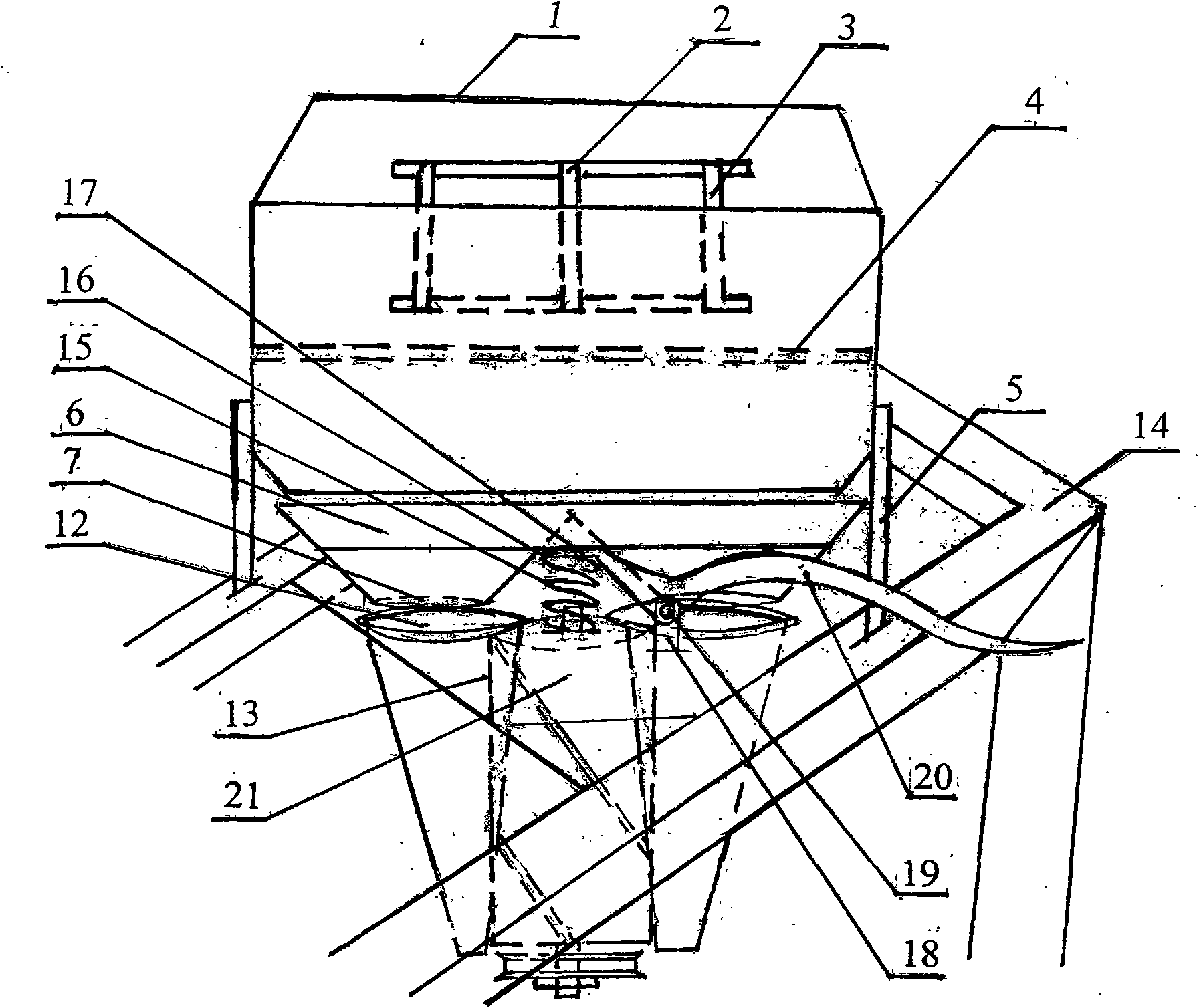

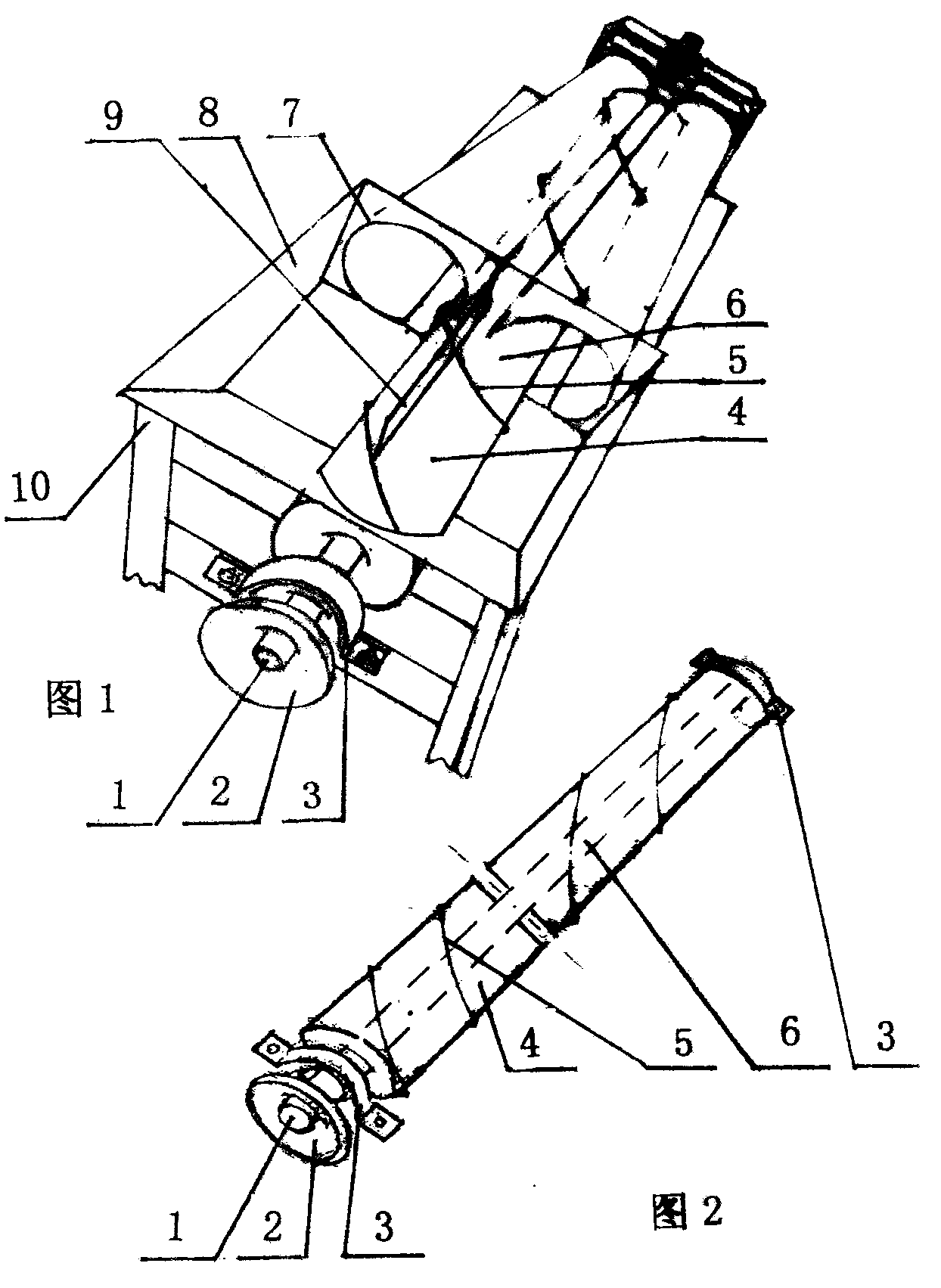

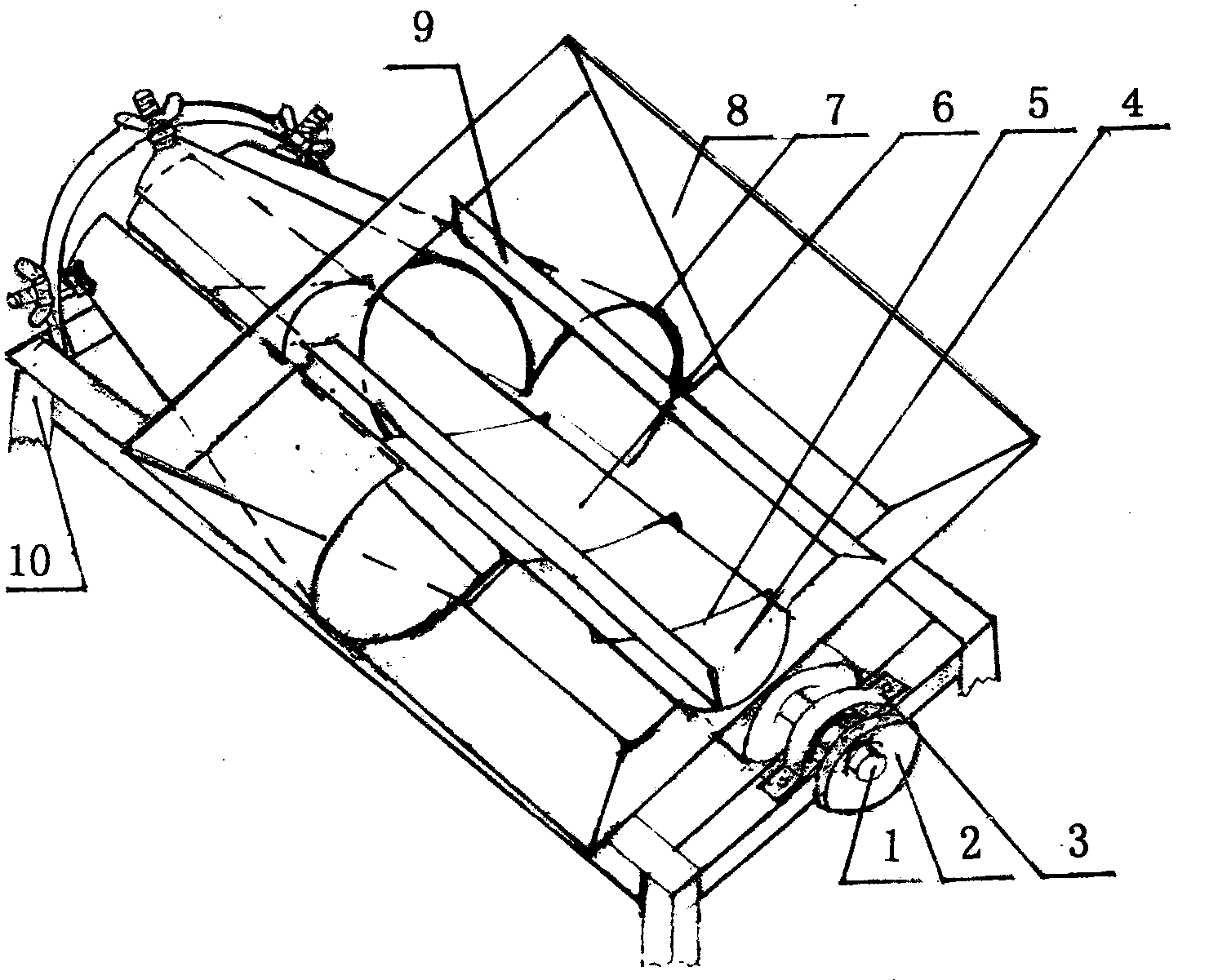

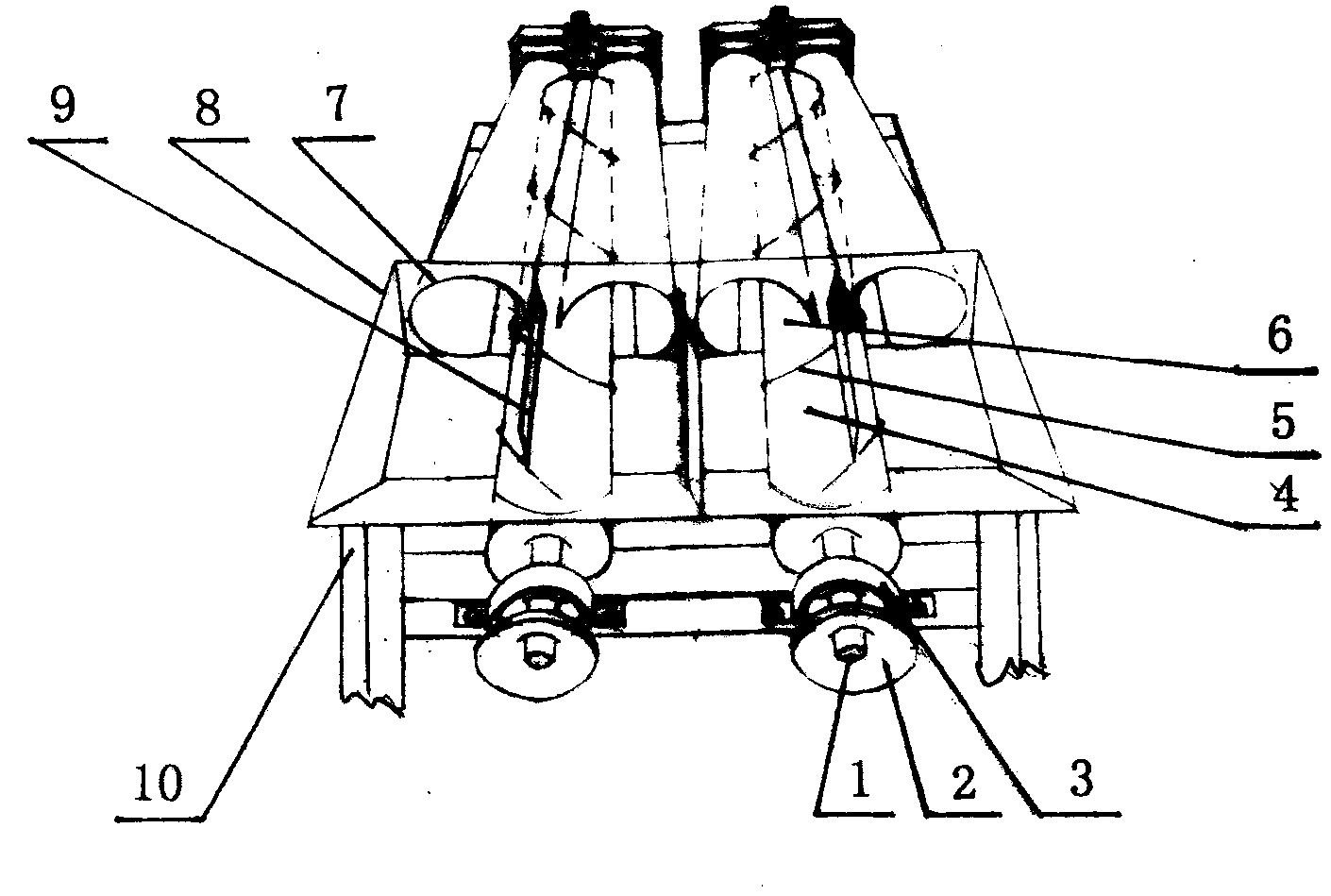

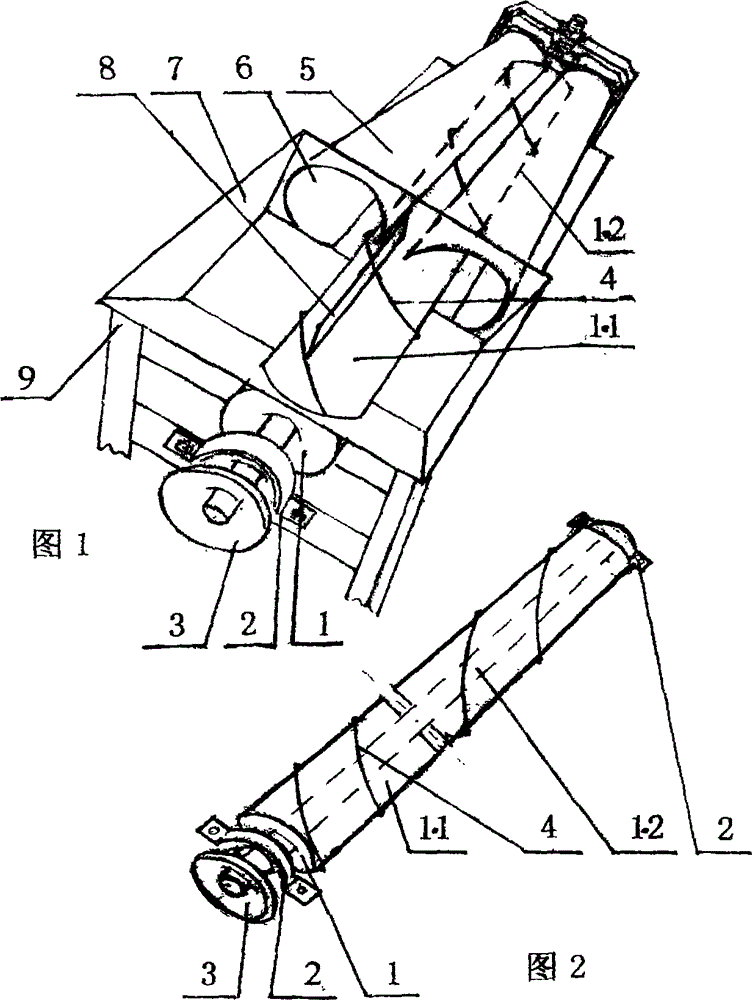

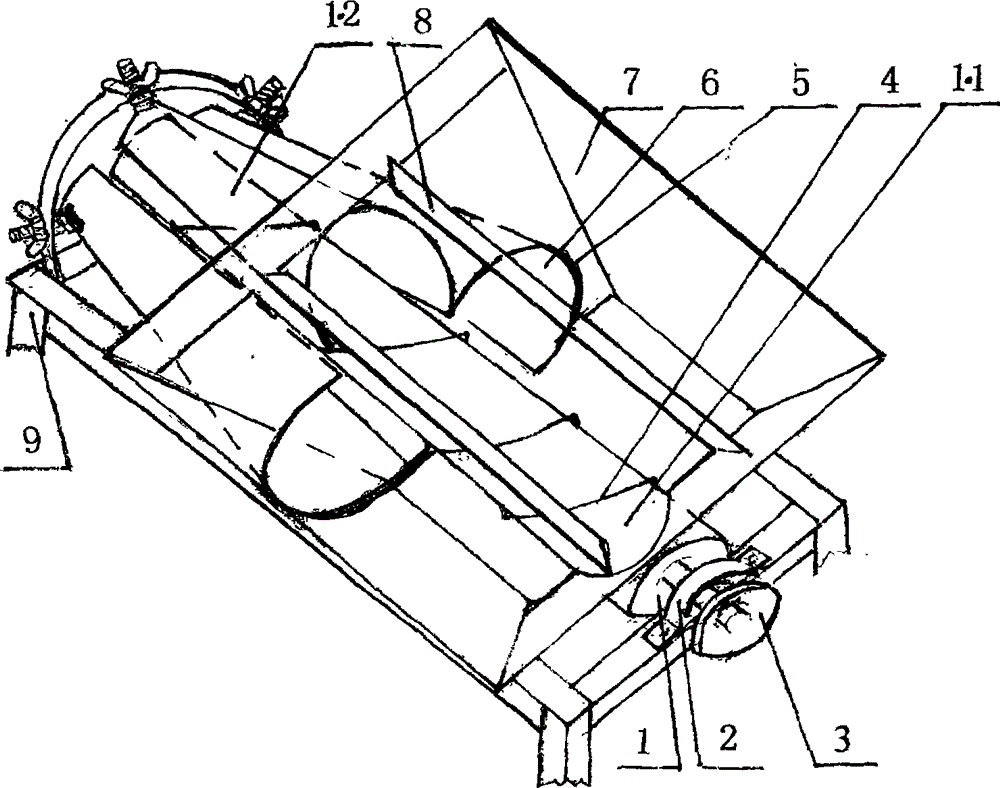

Multi-tube corn thresher

InactiveCN103931357AKeep threshing without heartbreakImprove threshing efficiencyThreshersEngineeringSingle tube

A multi-tube corn thresher is composed of a main shaft, a roller belt pulley, a bearing pedestal, a boosting device, a spiral rib, a threshing roller, threshing concave boards, a feed hopper, partition boards and a thresher frame. The boosting device and the threshing roller are fixed to the same main shaft. The main shaft is installed on the thresher frame through the bearing pedestal. The boosting device is a cylinder. The spiral rib is fixed to the surface of the boosting device. The feed hopper is installed at the upper portion of the boosting device. The partition boards are fixed to the portion where the feed hopper and the threshing concave boards are connected and located between the threshing concave boards. The threshing concave boards are installed around the threshing roller, and the vertical or horizontal multi-tube corn thresher can be formed. The vertical or horizontal multi-tube corn thresher not only keeps the advantages that corn cobs are not damaged and sorting is not needed when a single-tube corn thresher is used for threshing, but also achieves batched feeding, is free of blocking and can thresh a lot of corns rapidly and simultaneously, the threshing efficiency is improved largely, and as the structure of the thresher is simplified, the production cost of the multi-tube corn thresher is lowered, the weight of the multi-tube corn thresher is reduced, and kinetic energy consumption is reduced.

Owner:唐满江

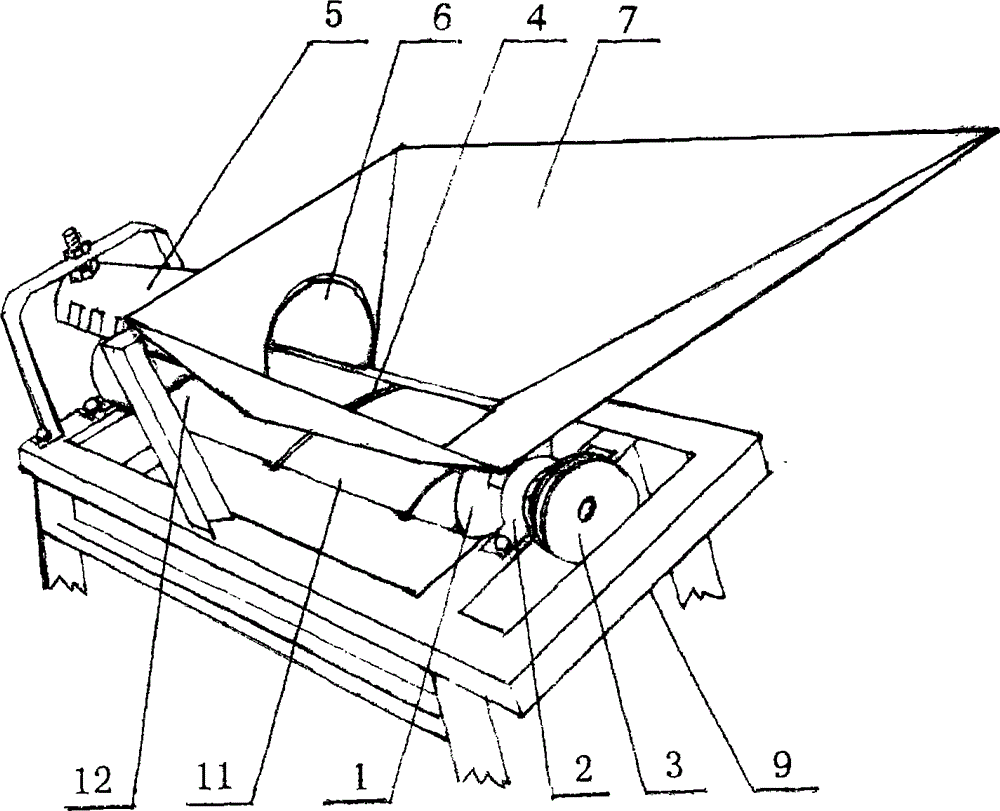

Multi-tube corn thresher

A multi-tube corn thresher is composed of a roller, bearing blocks, a roller belt pulley, a spiral fillet, threshing concave boards, a feed hopper, partition plates and a thresher frame. Shafts at the two ends of the roller are installed on the thresher frame through the bearing blocks, the spiral fillet is fixed to the surface of the roller, the roller is divided into a conveying section and a threshing section, the feed hopper is installed at the upper portion of the conveying section, the conveying section is the bottom of the feed hopper so that a conveying device can be formed, the threshing concave boards are installed on the periphery of the threshing section of the roller so that a threshing device can be formed, and the partition plates are fixed to the side, connected with an inlet of each threshing concave board, of the feed hopper and fixed between the threshing concave boards respectively. The multi-tube or single-tube corn thresher can be in a horizontal type or vertical type, the advantages that a small type single-tube corn thresher is free of threshing core rot and cleaning are kept, batched feeding is achieved, and blocking is avoided; meanwhile, multiple corn cobs are threshed rapidly at the same time, so that threshing efficiency is largely improved; as the structure of a thresher body is simplified, the weight of the thresher body is reduced and the production cost is lowered.

Owner:广西合浦县惠来宝机械制造有限公司

Deep processing mechanical device

The invention discloses a deep processing mechanical device comprising a feeding box, a pedestal and sprocket racks. Stands, a motor, the sprocket racks and a material receiving box are arranged on the top surface of the pedestal. Conveying sprockets are movably connected to the tops of the sprocket racks. A transmission sprocket is movably connected on the right side of the conveying sprockets through a conveyor belt. The motor is movably connected on the left side of the conveying sprockets through a conveyor belt. The transmission sprocket and an eccentric wheel are movably connected on the lower ends of two sprocket fixing racks. The conveying sprockets are movably connected with the transmission sprocket through the conveyor belt. The transmission sprocket is movably connected with the eccentric wheel through a conveyor belt. A fixing device is arranged on the periphery of the feeding box body. The fixing device is fixed on the stand. The feeding box is arranged on the stand through a fixing belt. According to the novel device, the eccentric wheel stimulates a movable blanking plate to perform reciprocative movements, such that threshing according to crop particle sizes is realized. Therefore, efficiency is greatly improved. The device is convenient to move, and is convenient to use.

Owner:天津天成昇科技有限公司

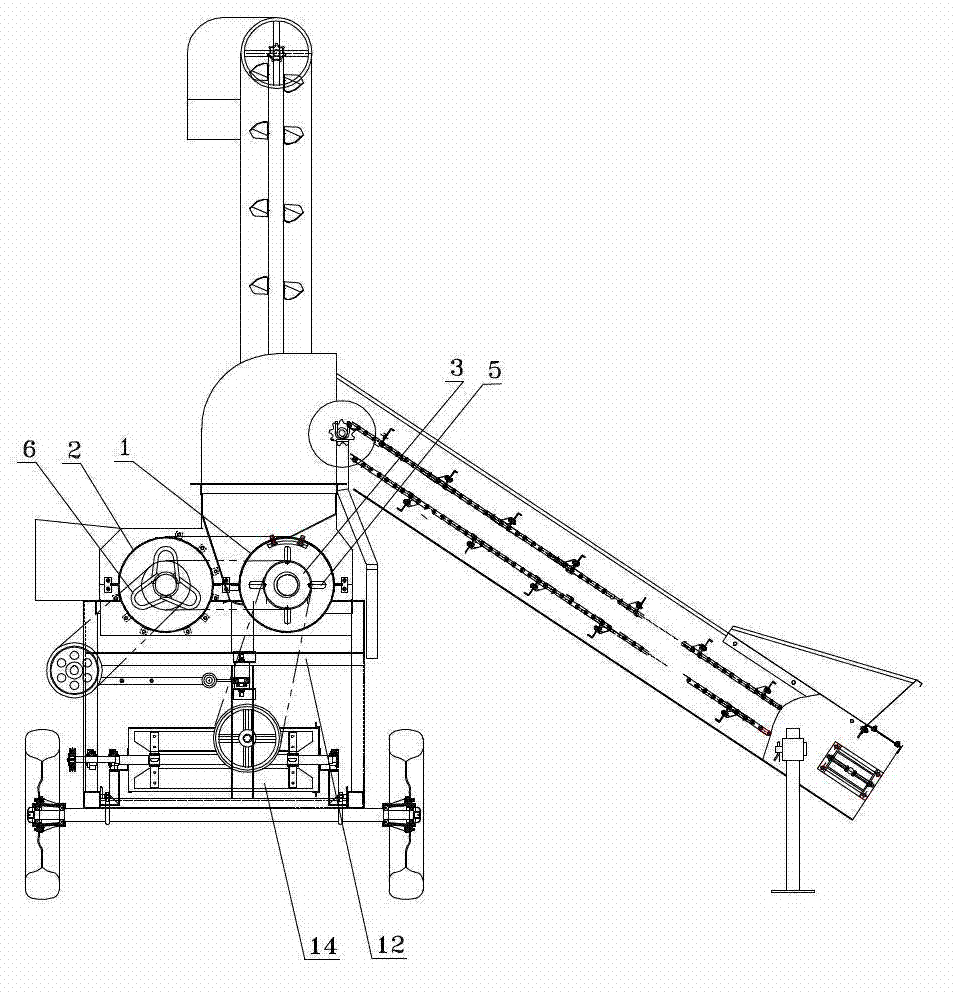

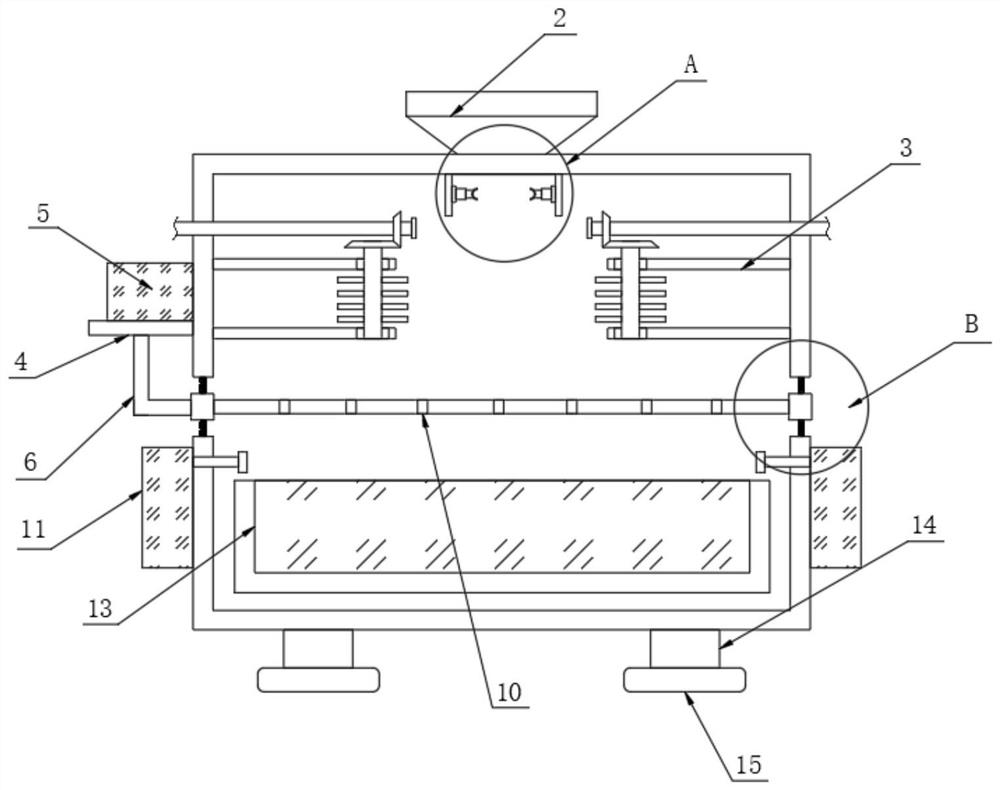

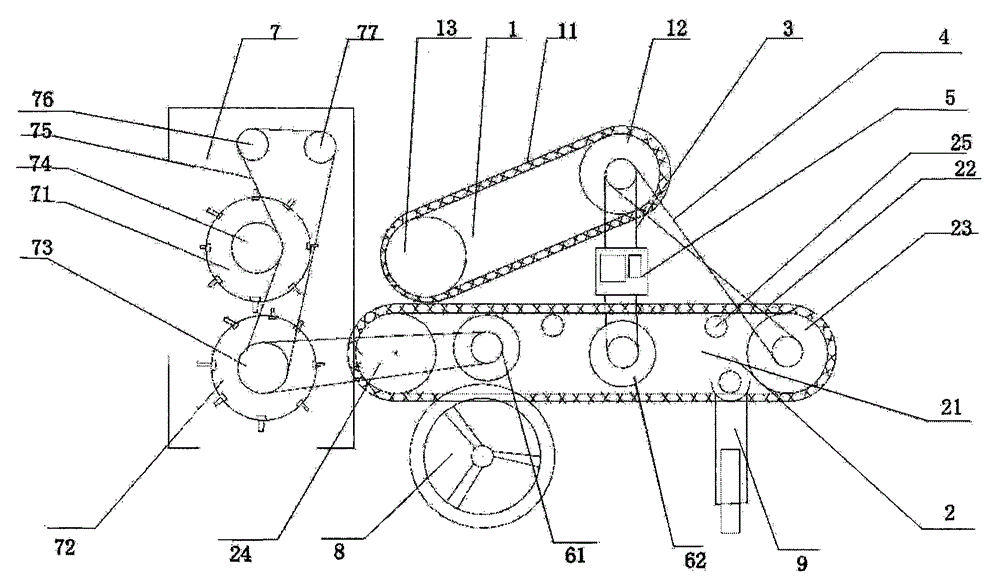

Movable double-belt crop threshing machine capable of performing synchronous pressing and conveying

The invention provides a movable double-belt crop threshing machine capable of performing synchronous pressing and conveying and relates to the technical field of crop threshing machines. The movable double-belt crop threshing machine capable of performing synchronous pressing and conveying is characterized by comprising an upper conveyor, a lower conveyor, a lathe support, a hinge support, a C-shaped triangular crossed belt, a variable-frequency electric box, a threshing gear-hobbing motor, a conveyor motor, a threshing machine case, wheels, a movable trailer handle and supporting legs. The lower conveyor is fixed to the lathe support. The upper conveyor is fixed to the lathe support through the hinge support, and the threshing gear-hobbing motor is fixed to the lathe support. The conveyor motor is fixed to the lathe support. A threshing device is fixed to one end of the lather support.

Owner:江定平

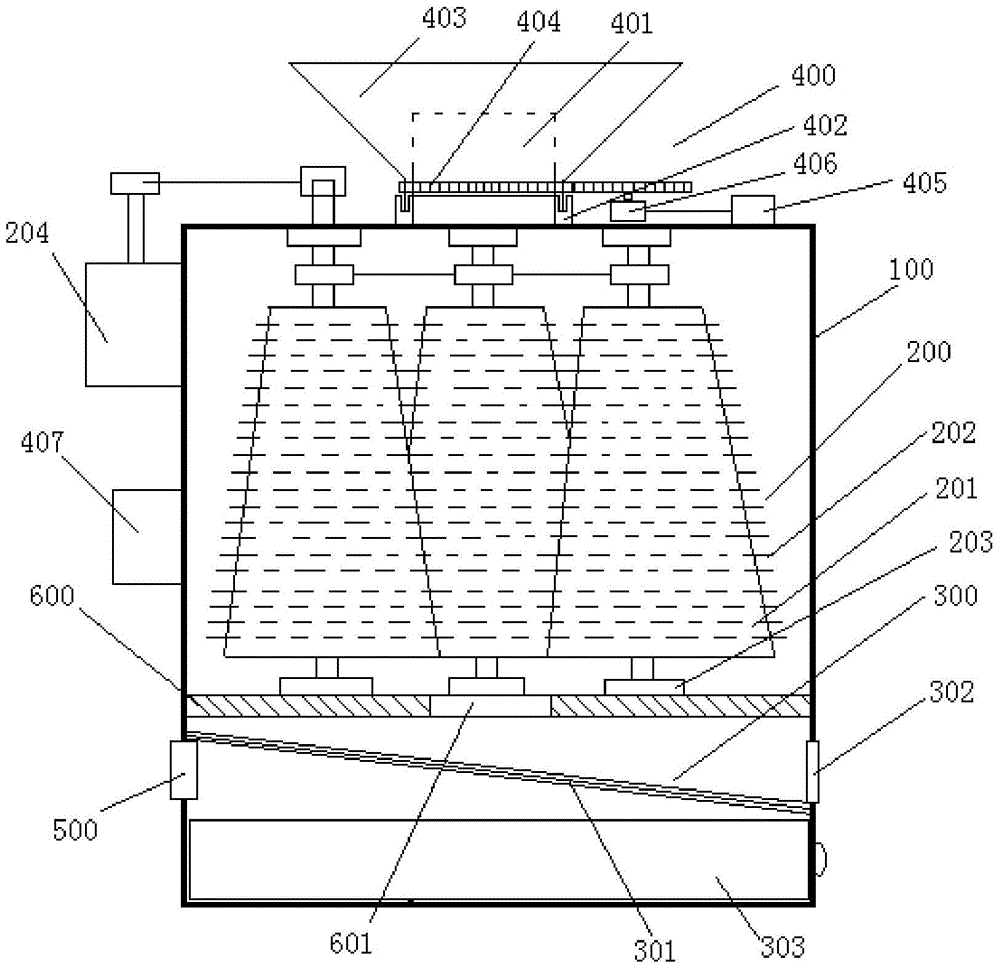

Corn thresher capable of integrating threshing and separate packaging

The invention discloses a corn thresher capable of integrating threshing and separate packaging. The corn thresher comprises a feeding device, a material shaking device and a second clapboard arrangedin a second shell; the feeding device comprises a shelving basket and a feeding cylinder, and the feeding cylinder includes a first shell and a feeding mechanism; the feeding mechanism comprises a first disk, a second disk and a transfer cylinder; the first disk is arranged at an inlet of the first shell and provided with a first circular hole, the second disk is arranged at the rear end of the first shell and provided with a second circular hole, and the second circular hole is internally provided with annular blades; the transfer cylinder is arranged between the first circular hole and thesecond circular hole; the material shaking device is arranged at the rear end of the feeding cylinder and comprises the second shell, a mesh sieve, a first vibrating mechanism and a second vibrating mechanism; the second clapboard partitions the second shell into an upper chamber and a lower chamber, the upper chamber separates corn kernels and corn cobs, and the lower chamber separates the corn kernels and impurities. By means of the corn thresher, automatic threshing can be achieved, the core kernels, the corn cobs and the impurities are separately treated to facilitate later packaging.

Owner:何亮

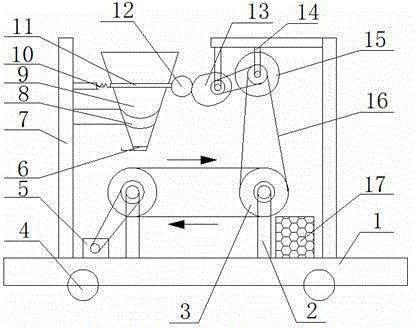

Corn flour food processing production device

InactiveCN109805261AEasy threshingImprove threshing efficiencyThreshersGrain treatmentsCorn flourEngineering

The invention belongs to the technical field of food processing machinery and specifically relates to a corn flour food processing production device which comprises a frame body and a controller, wherein a first rotating shaft and a second rotating shaft are in rotary connection in the frame body, the diameter of the first rotating shaft is smaller than that of the second rotating shaft, a conveying belt is jointly in sleeve connection to the surfaces of the first rotating shaft and the second rotating shaft, a second fixed plate is fixedly connected to an inner wall of the frame body, the second fixed plate is obliquely designed, parts penetrating through the second fixed plate of a third rotating shaft and a fourth rotating shaft are respectively in transmission through hemp ropes, the hemp ropes are wound to the surface of a first motor rotating shaft, the winding directions of the hemp ropes are opposite, a smashing barrel is arranged under the second fixed plate, semicircular second air bags are evenly distributed on the surface of a kneading roller, and the radiuses of the second air bags increase successively from top to bottom. The v corn flour food processing production device disclosed by the invention can effectively thresh the corn cobs under the situation that the corn cobs are not damaged and simultaneously can completely smash corn kernels; furthermore, the purity of smashed corn flour is high.

Owner:陈同翔

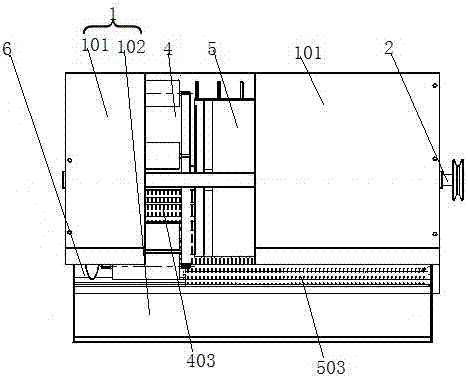

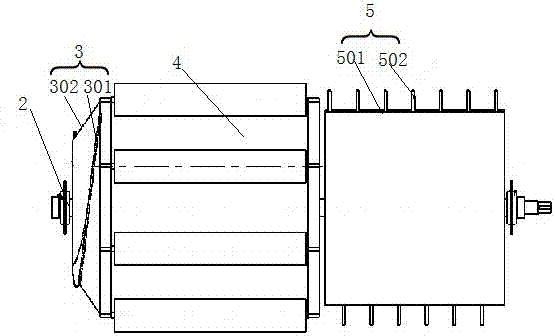

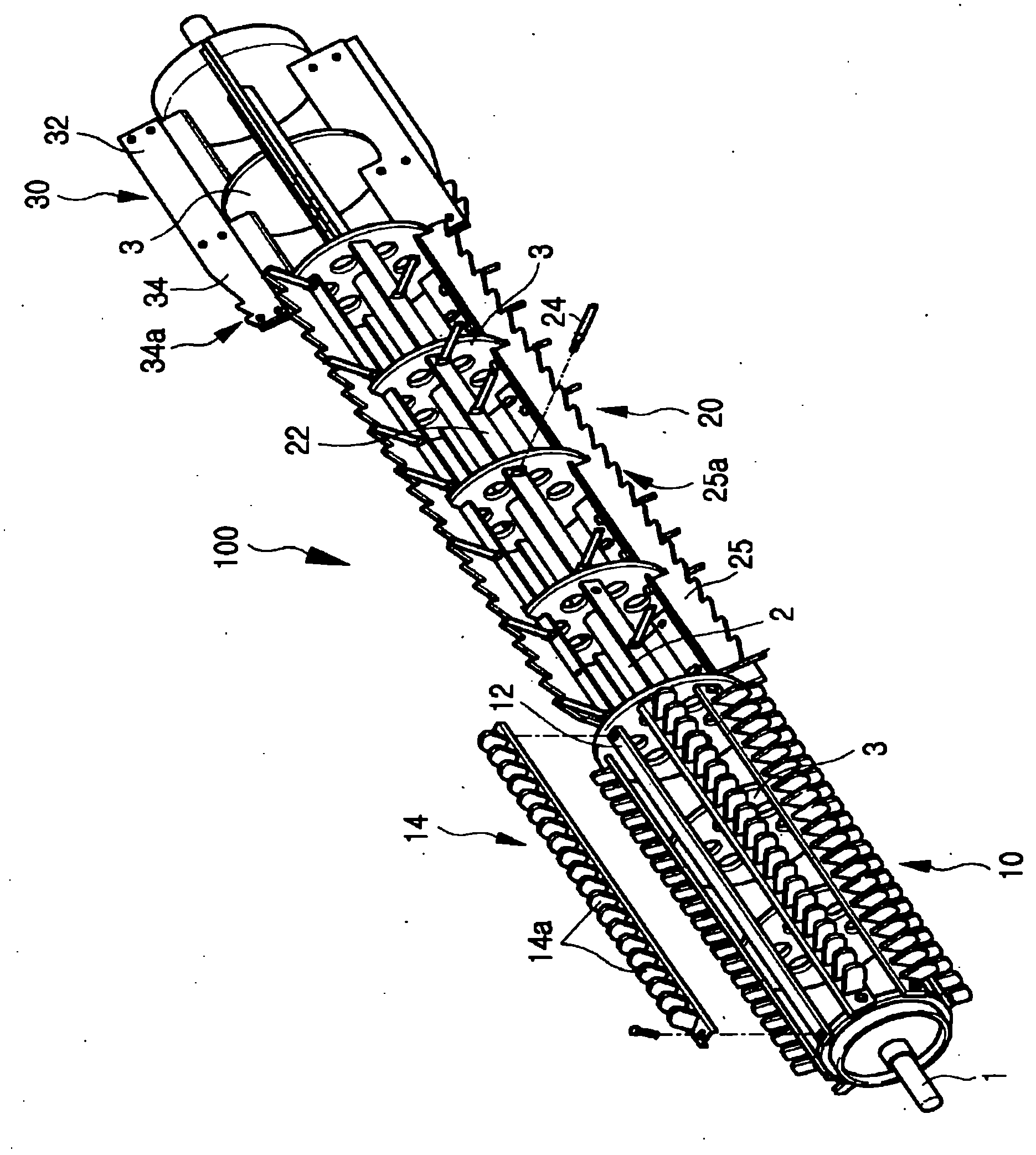

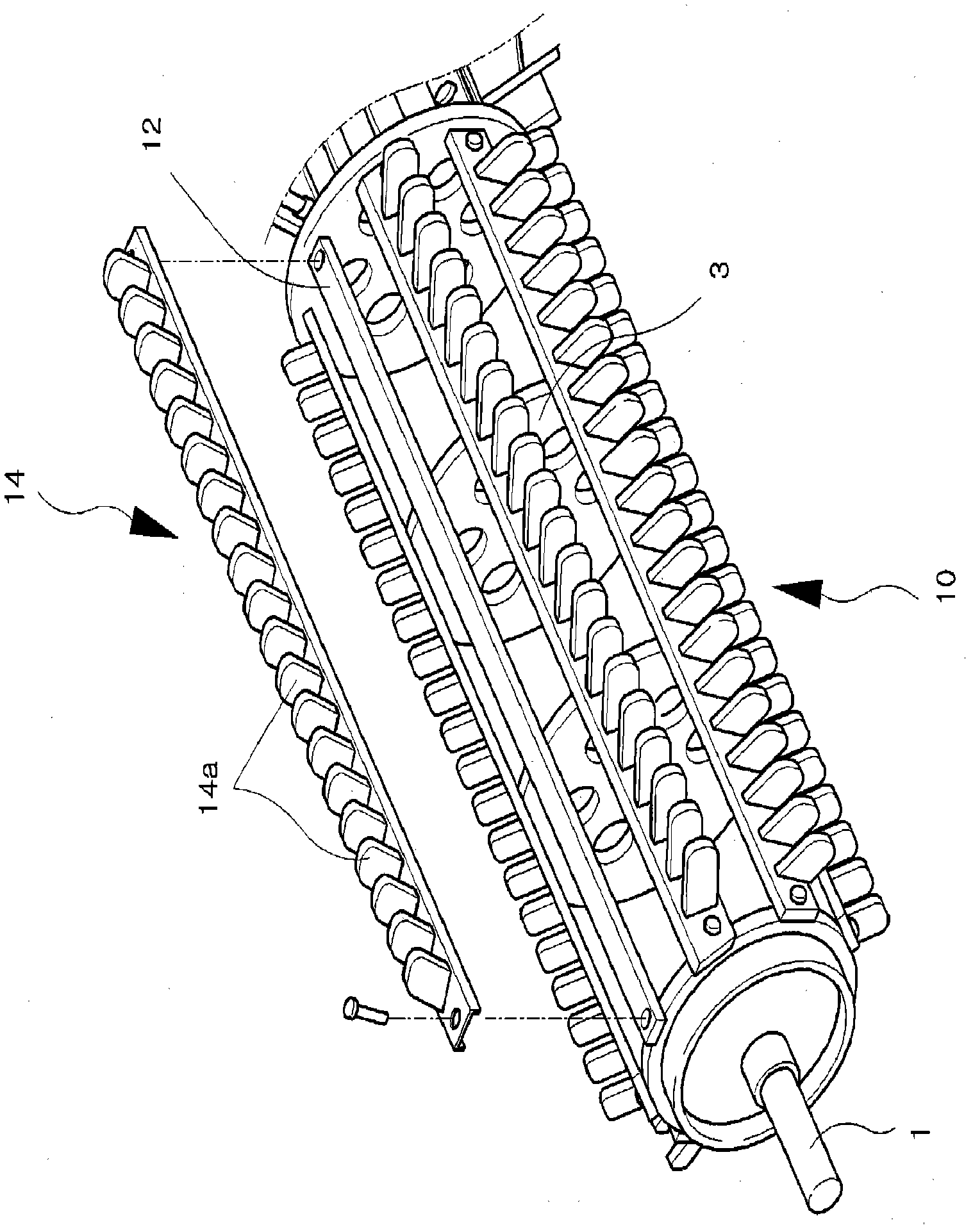

Thrashing drum

The present invention relates to a thrashing drum (100) that can maximize thrashing efficiency while minimizing load occurring when the drum is rotated in a trashing process. The thrashing drum (100) includes a shaft (2) having axle portions formed on its both sides, a plurality of support plates (3) formed on the shaft (2) at specific intervals, a primary thrashing unit configured to primarily separate ears and corns from stems or branches of crops input thereto and that is disposed in the support plates, a secondary thrashing unit configured to secondarily separate by blowing ears and corns that have not been thrashed in the primary thrashing unit and that is disposed in the support plates, and a discharge unit configured to thirdly discharge the stems or branches that have been thrashed and that is disposed in the support plates (3).

Owner:XENITH TRACK

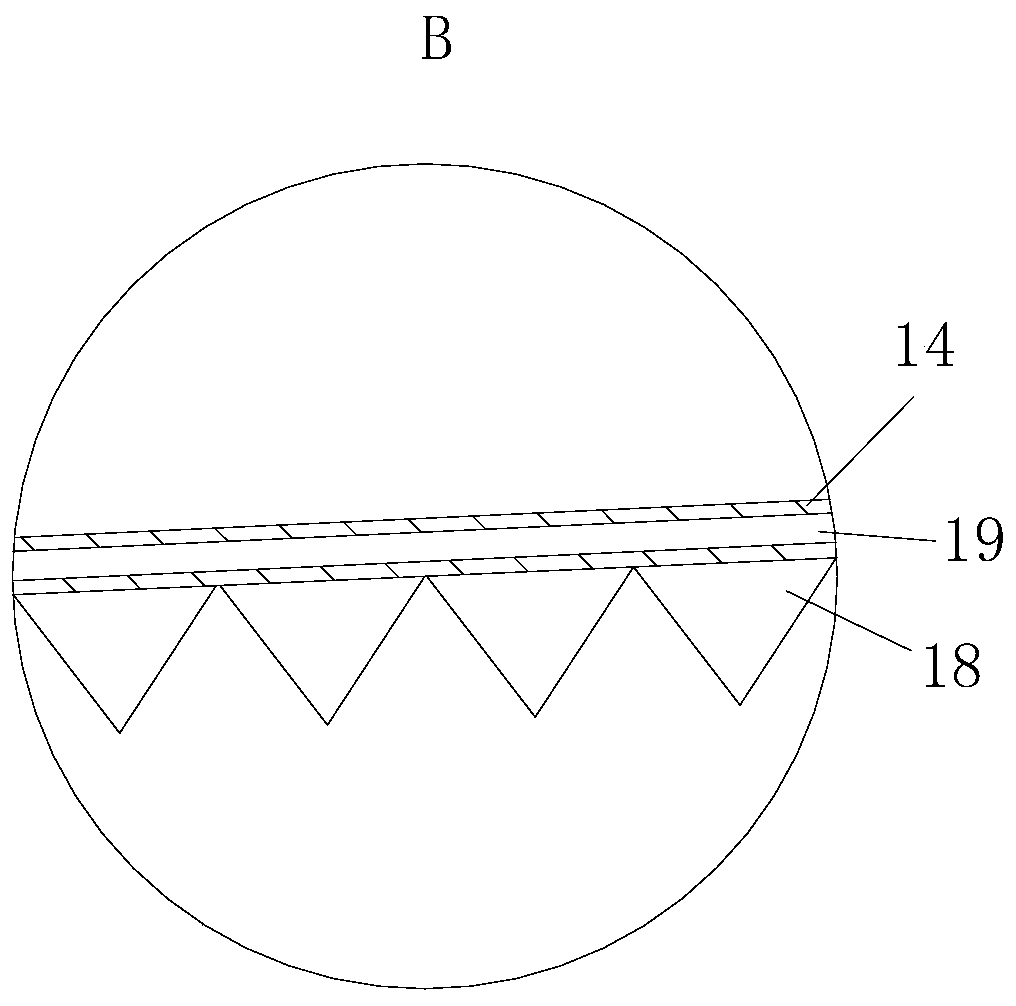

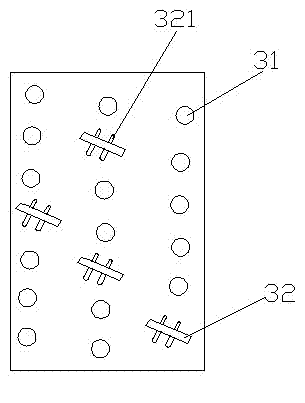

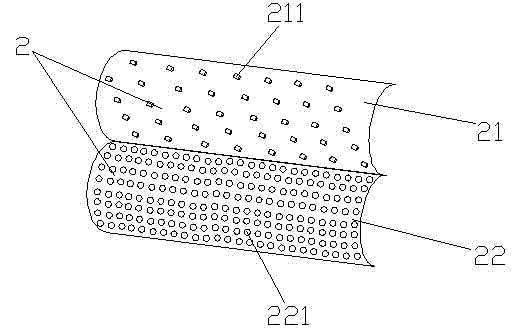

Threshing cylinder of corn thresher

InactiveCN103918416AImprove threshing efficiencyThreshing thoroughlyThreshersAgricultural engineeringStructural engineering

A threshing cylinder of a corn thresher comprises a roller and a screen. The roller is provided with threshing teeth which are distributed from the first to the last in a single helical line manner. The threshing teeth include cylinder teeth and blade teeth, wherein the blade teeth are obliquely arranged along the helical line. The screen is a transversely disposed cylinder, and the upper portion of the screen is a solid plate and the lower portion of the screen is a screening plate. A plurality of first projections are arranged on the inner side of the solid plate. The first projections are arranged on the inner side of the solid plate on the upper portion of the cylindrical screen, threshing efficiency of corn cobs is greatly improved, and threshing of the corn cobs is more thorough. The threshing teeth include blade teeth, and pushing the corn cobs forward is improved, so that the problem that the corn cobs are stuck between the roller and the screen is solved, and threshing capacity is more improved due to the fact that second projections are arranged on the side of the blade teeth.

Owner:ZHANGQIU CITY YONGSHENG VEHICLE FITTINGS

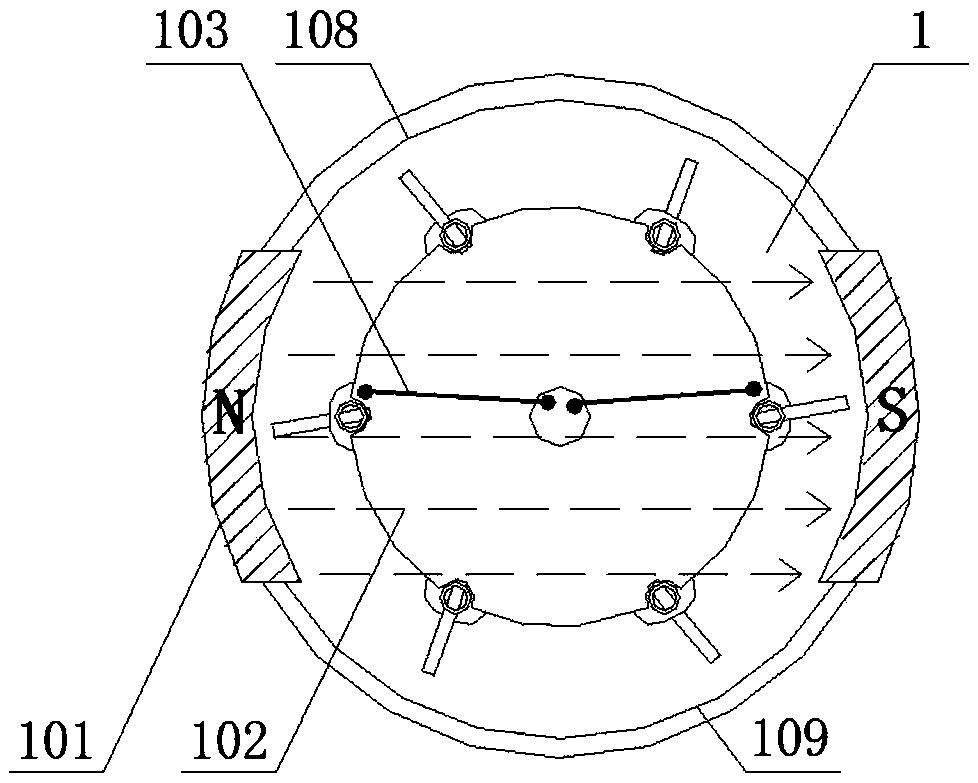

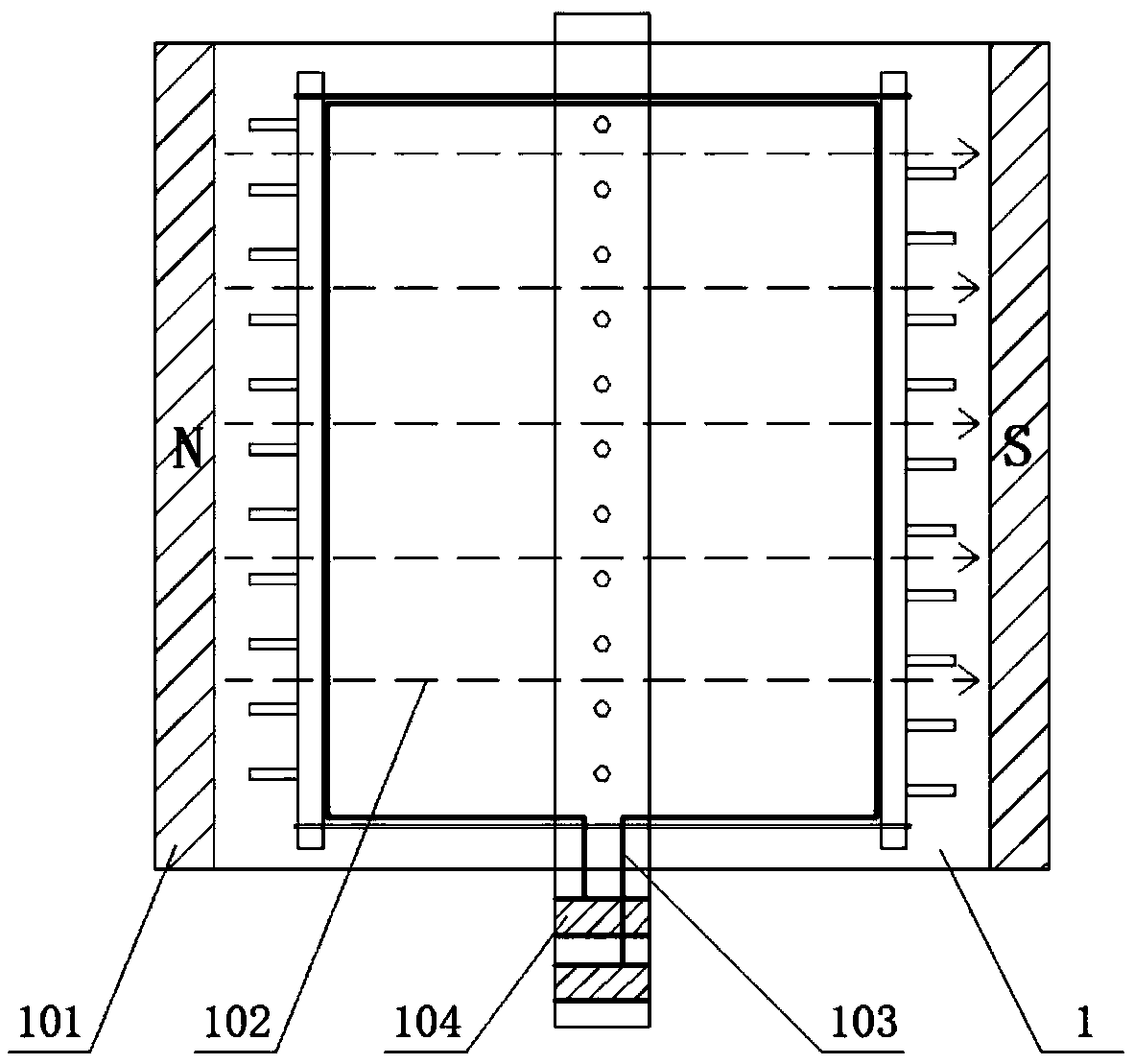

Transmission shaft monitoring device and threshing drum shaft monitoring device

ActiveCN109348876AReduce measurement errorOvercome the disadvantage that only one end of the threshing drum shaft can be monitoredThreshersVoltage amplitudeForce lines

The invention provides a transmission shaft monitoring device. The transmission shaft monitoring device comprises an electromagnetic induction signal generation device and a control system; the electromagnetic induction signal generation device is used for detecting a voltage change signal generated by the rotation of a transmission shaft; the control system is used for analyzing and judging the voltage change signal input by the electromagnetic induction signal generation device. The electromagnetic induction signal generation device comprises a magnetic pole pair, a coil, metal rings, electric brushes and a voltage sensor; the magnetic pole pair is used for generating a magnetic field on a transmission shaft end; the coil is fixed on the end face of the transmission shaft and used for cutting magnetic force lines; the two metal rings are arranged at the shaft ends of the transmission shaft and not in contact with each other; the two ends of the coil are connected with the two metal rings respectively; the two electric brushes are in contact with the two metal rings respectively, and the two electric brushes and the voltage sensor form a closed circuit. The transmission shaft monitoring device can analyze the voltage amplitude and cycle which are output by the voltage sensor and monitor whether or not the state of the transmission shaft meets the design requirement.

Owner:JIANGSU UNIV

Grain threshing machine with stable running

The invention relates to a grain threshing machine with stable running, and the machine comprises a threshing cylinder, a grain collecting device and a vibrator, wherein the threshing cylinder is placed over the grain collecting device; the vibrator is placed on the lower end of the grain collecting device; a grain placement entrance is firmly disposed in the upper end of the threshing cylinder; two rollers are disposed inside the threshing cylinder; the two rollers are located in parallel under the grain placement entrance; spiral blades used for threshing are disposed on both the rollers; the bottom part of the threshing cylinder is a screen; a pushing device is disposed on one side of the lower part of the threshing cylinder; an impurity discharge hole is formed in the other side of the lower part of the threshing cylinder; a push plate is firmly connected on an output shaft of the pushing device; and the push plate can be driven by the output shaft of the pushing device to push impurities on the bottom of the threshing cylinder outwards from the impurity discharge hole. In comparison with the prior art, according to the invention, the threshing becomes quick; the impurities can be pushed out; and the impurities can be disposed timely, so that influences brought by the impurities on threshing efficiency can be avoided and grains become clean.

Owner:GUILIN UNIV OF AEROSPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com