Deep processing mechanical device

A mechanical device and deep processing technology, applied in the field of deep processing machinery and deep processing machinery, to achieve the effect of convenient promotion, improved efficiency, practical and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

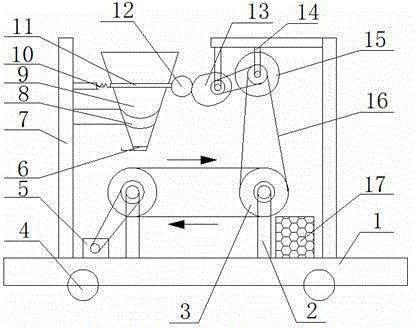

[0019] Embodiment 1: The motor 5 is rolled and connected to the left transmission wheel 3 , the right transmission wheel 3 , the transmission wheel 15 , and the eccentric wheel 13 through the conveyor belt 16 , and the power transmission source is transmitted through the conveyor belt 16 .

Embodiment 2

[0020] Embodiment 2: The transmission ball 12 is in contact with the eccentric wheel 13 on the right side of the feed box 9, and the eccentric wheel 13 is in an irregular shape and hits the transmission ball 12 when rotating.

Embodiment 3

[0021] Embodiment 3: The motor 5 is arranged on the top surface of the base 1 on the left side of the transmission wheel 3, and the receiving box 17 is arranged on the top surface of the base 1 on the right side of the transmission wheel 3. The power comes from the motor 5, and the crops pass through the transmission wheel. The tray 3 is delivered to the receiving box 17 for packaging and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com