Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202 results about "Linear component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear components are component that have a linear correspondence between their governing properties in electronics: Resistor - correspondence between voltage to current (V=R*I).

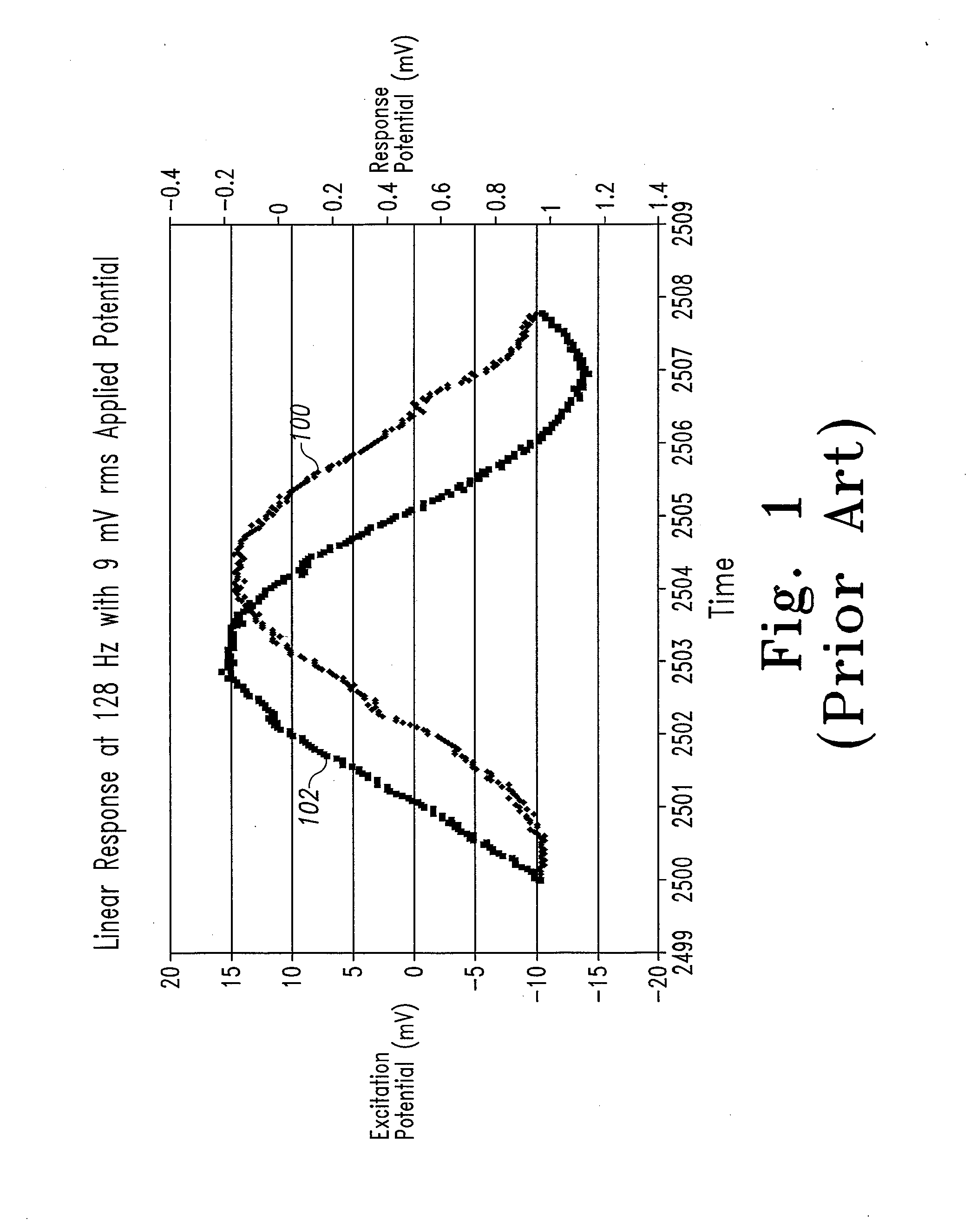

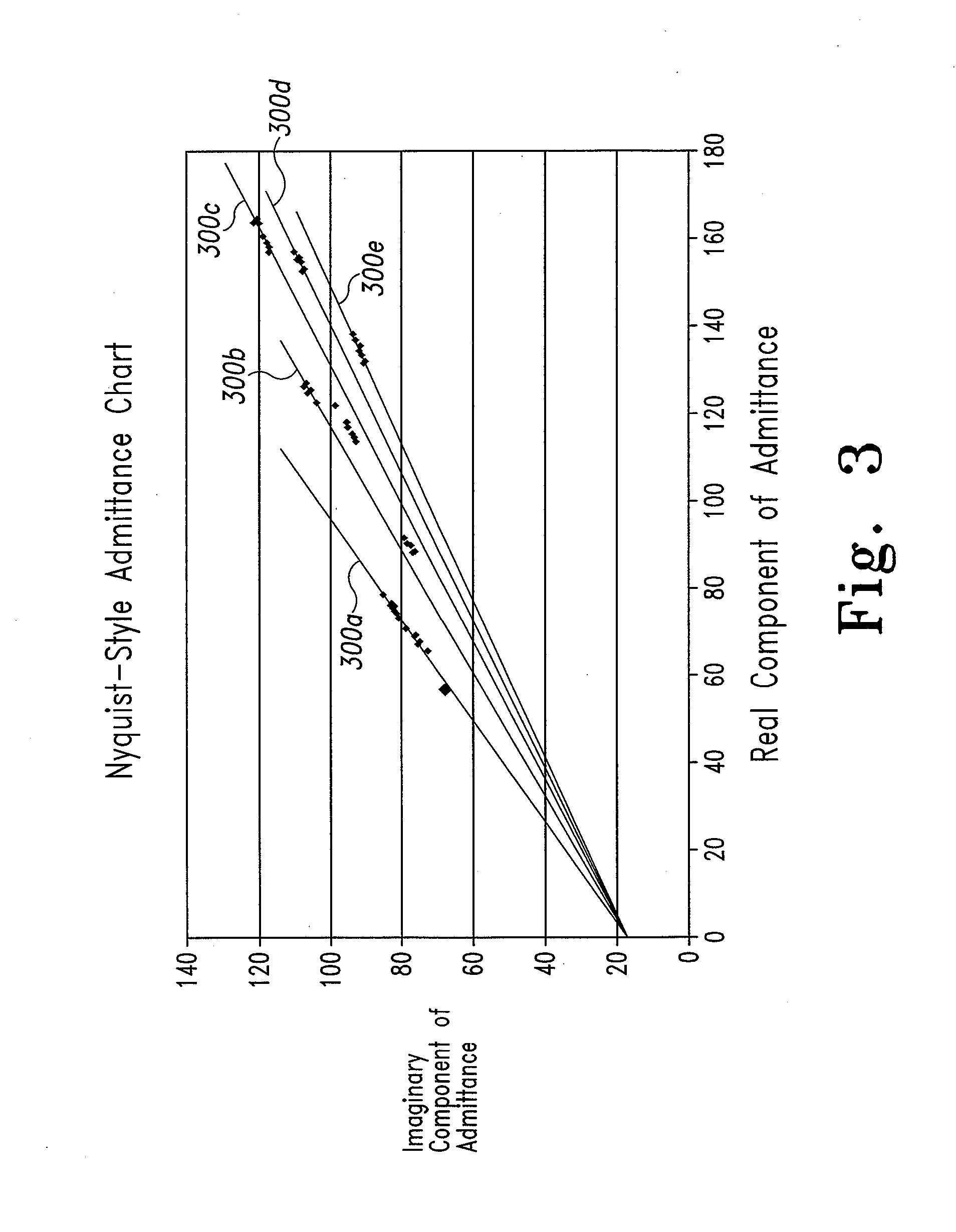

System and method for analyte measurement using a nonlinear sample response

InactiveUS20070264721A1Microbiological testing/measurementBiological testingLinear componentApplied potential

The systems and methods of the present invention utilize a linear component of a non-linear, faradaic current response generated by a biological fluid sample when an AC excitation potential sufficient to produce such a faradaic current response is applied to the sample, in order to calculate the concentration of a medically significant component in the biological fluid sample. The current response is created by the excitation of electrochemical processes within the sample by the applied potential. Typically, the linear component of the current response to an applied AC potential contains phase angle and / or admittance information that may be correlated to the concentration of the medically significant component. Also typically, the fundamental linear component of the current response is utilized in the disclosed systems and methods. Harmonics of the fundamental linear component may also be used. Other methods and devices are disclosed.

Owner:ROCHE DIABETES CARE INC

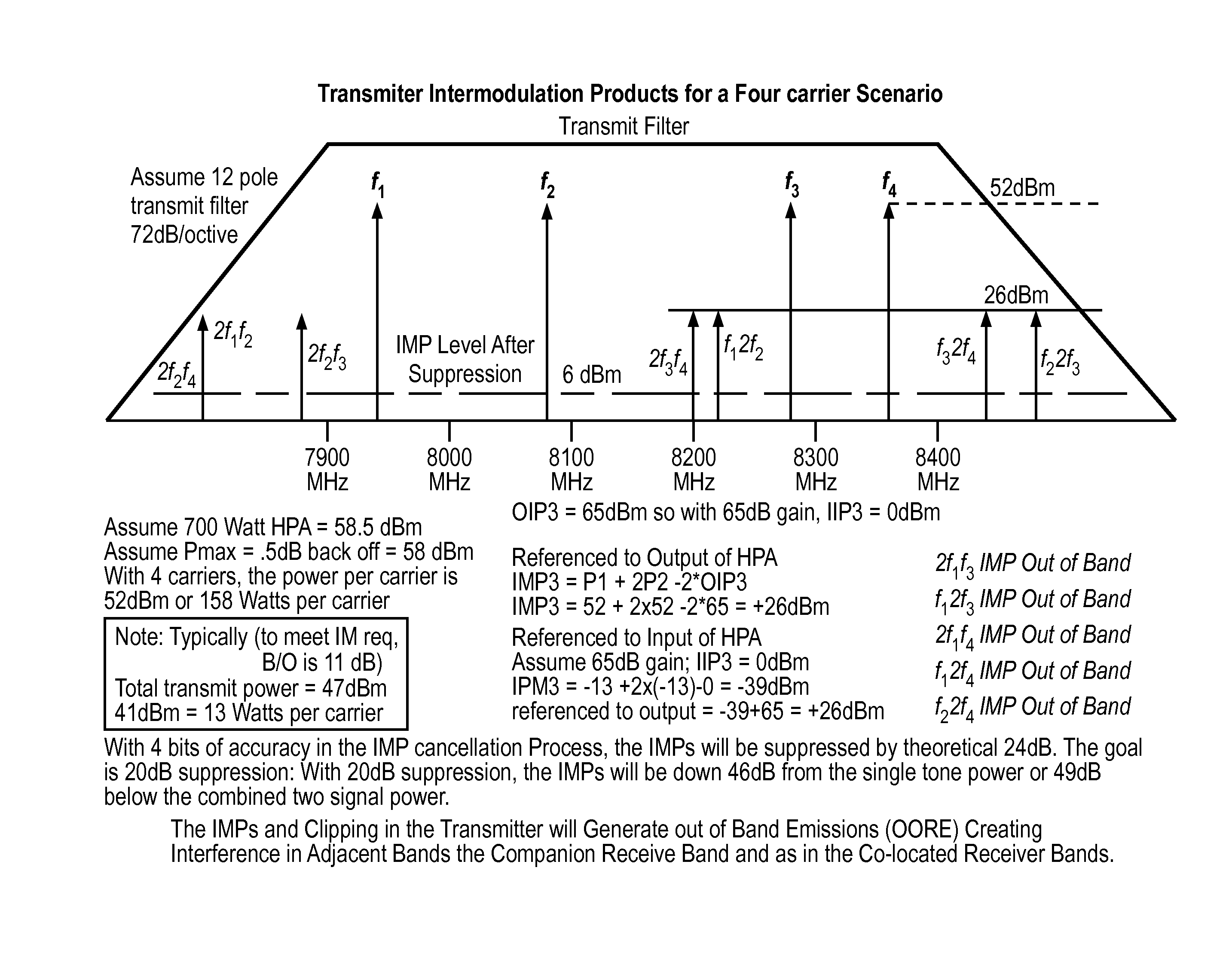

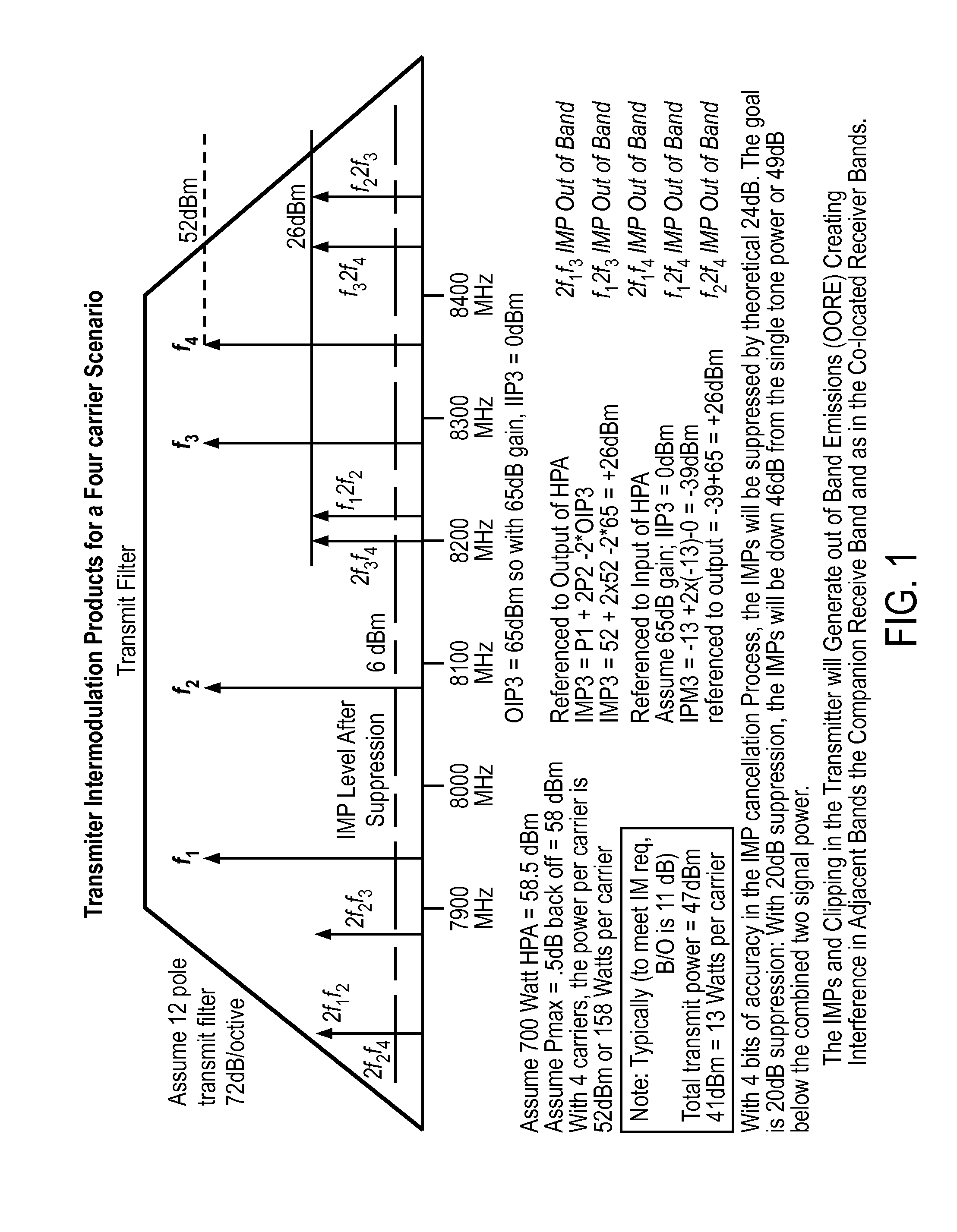

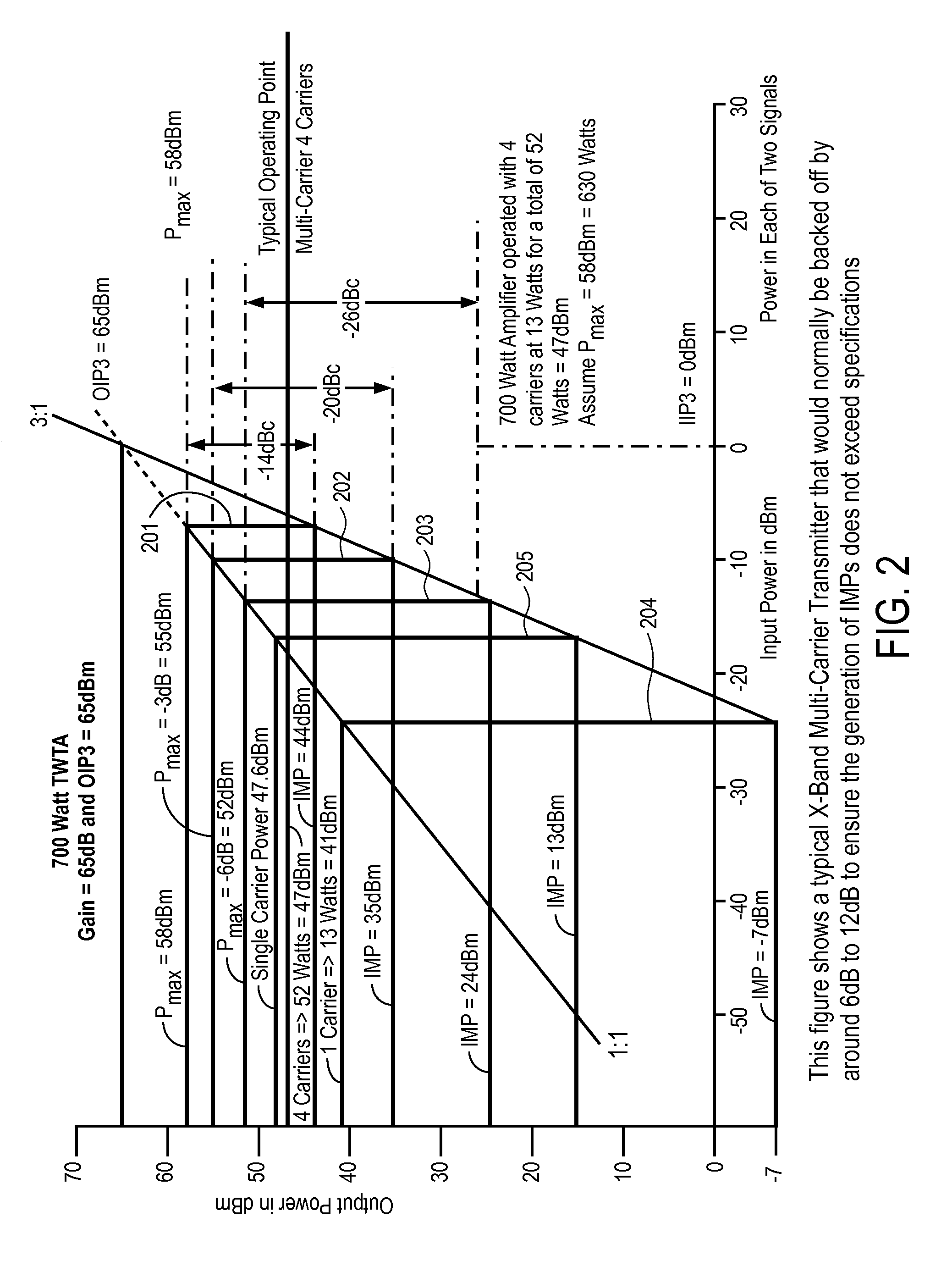

Mitigation of transmitter passive and active intermodulation products in real and continuous time in the transmitter and co-located receiver

ActiveUS20110075754A1Secret communicationTransmitter/receiver shaping networksLinear componentEngineering

A transmitter channel interference mitigation processing method for cancellation of intermodulation products are described. In one embodiment, a method comprising generating continuous and real time IMP cancellation signals (ICS) in the baseband digital signal set of the transmitter based on a transmitter signal set, combining digital IMP cancellation signals with a digital baseband transmitter signal set such that the digital cancellation signals, when converted to analog signals and transmitted as part of an analog transmitter signal set, are cancelled by and so cancel the IMPs generated by the non-linear components in the analog transmitter hardware, including digitally generating the IMP cancellation signals using a process based on a power series description of a non-linear process generating the IMPs, generating 3rd order IMP cancellation signals by digitally multiplying two or three signals of the transmitter signal set to create 3rd order IMP cancellation signals, generating 5th order IMP cancellation signals by digitally multiplying two or three or five signals of the transmitter signal set to create 5th order IMP cancellation signals, generating 7th order IMP cancellation signals by digitally multiplying two or three or five or seven signals of the transmitter signal set to create 7th order IMP cancellation signal, generating odd order IMP cancellation signals (ICS) by digitally multiplying an odd number of digital signals and combining multiplied digital signals with the transmitter baseband digital signals, creating IMP cancellation signals in the receiver, and cancelling one or both of active and passive IMPs generated in a transmitter path that fall within a receiver passband.

Owner:FINESSE WIRELESS LLC

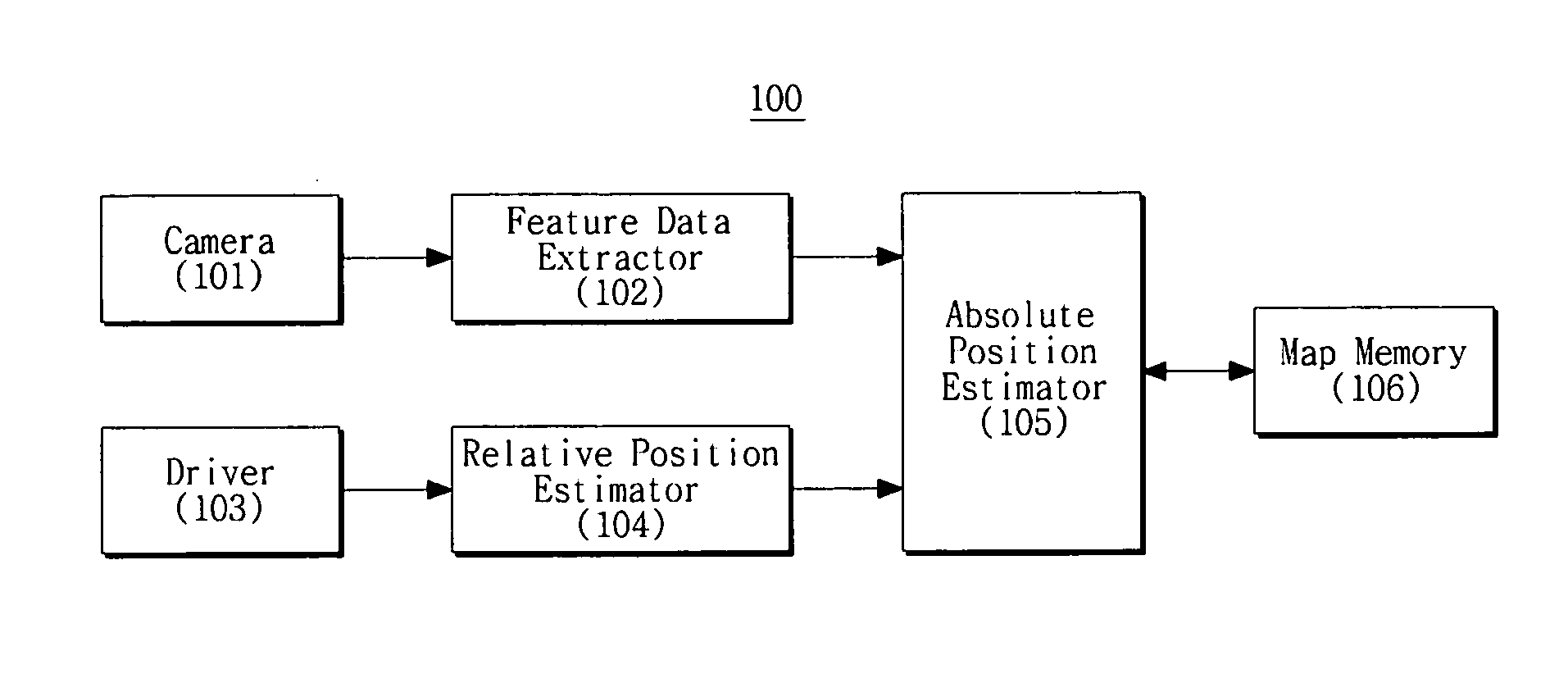

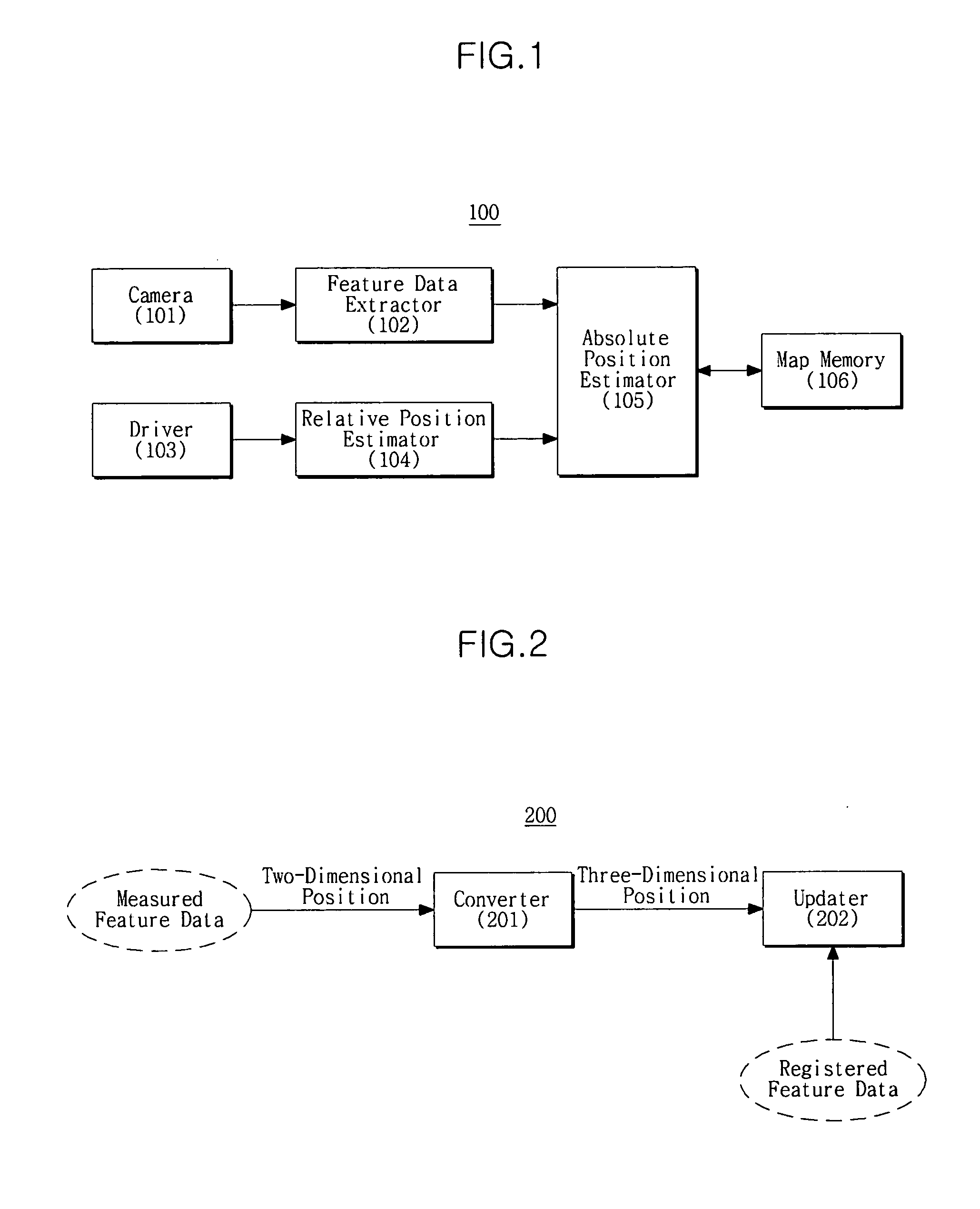

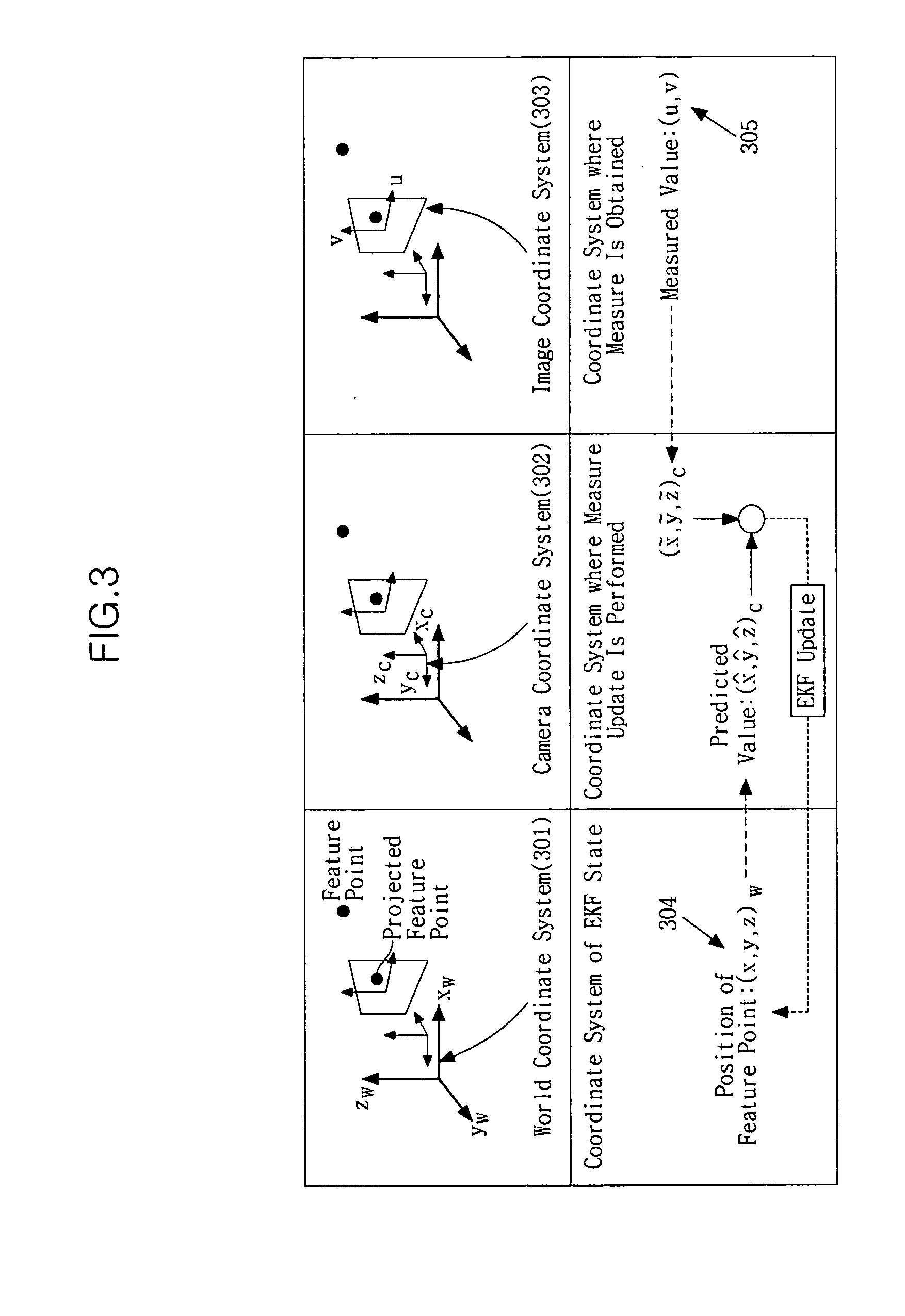

Method and apparatus for simultaneous localization and mapping of robot

A SLAM of a robot is provided. The position of a robot and the position of feature data may be estimated by acquiring an image of the robot's surroundings, extracting feature data from the image, and matching the extracted feature data with registered feature data. Furthermore, measurement update is performed in a camera coordinate system and an appropriate assumption is added upon coordinate conversion, thereby reducing non-linear components and thus improving the SLAM performance.

Owner:SAMSUNG ELECTRONICS CO LTD

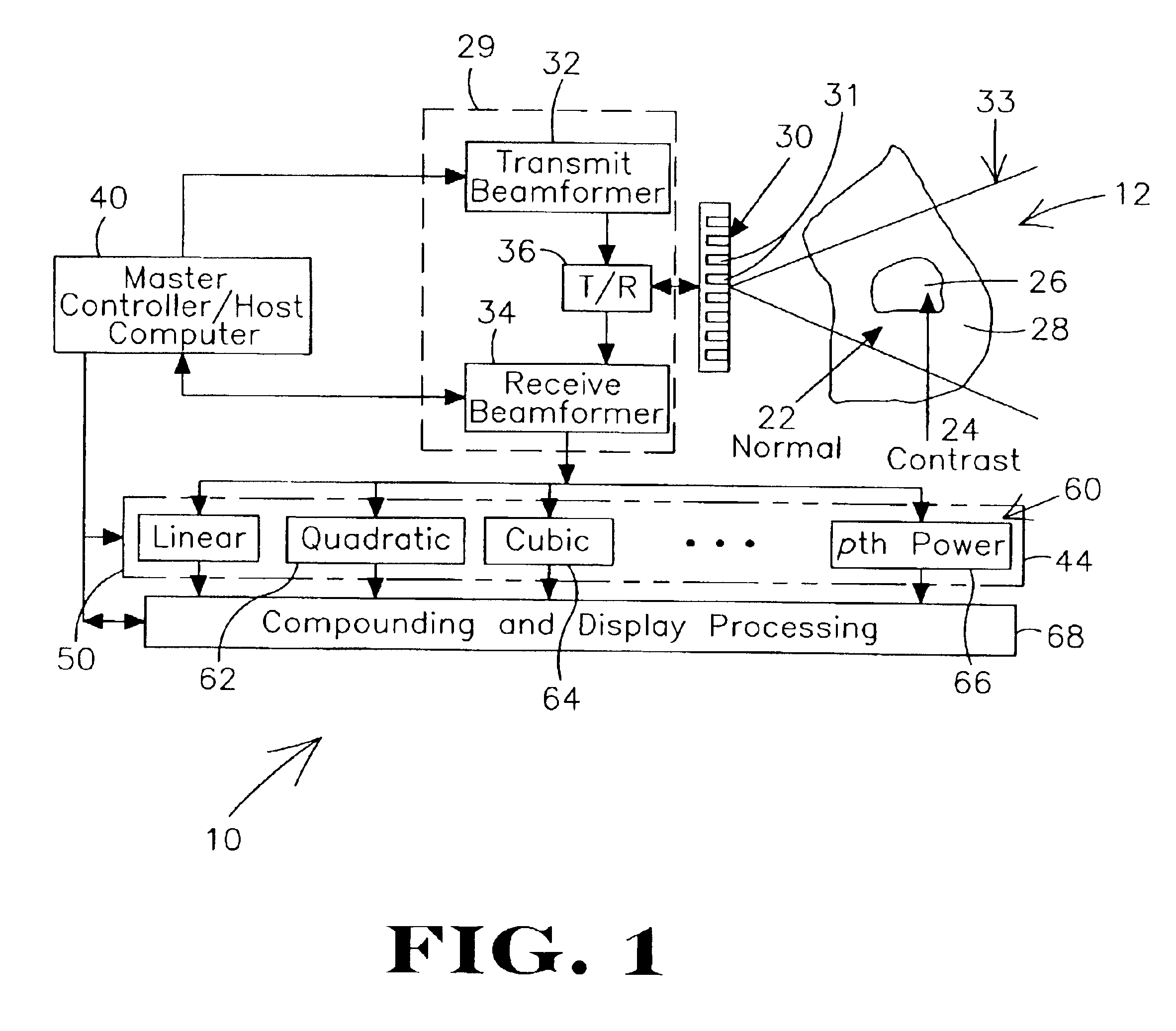

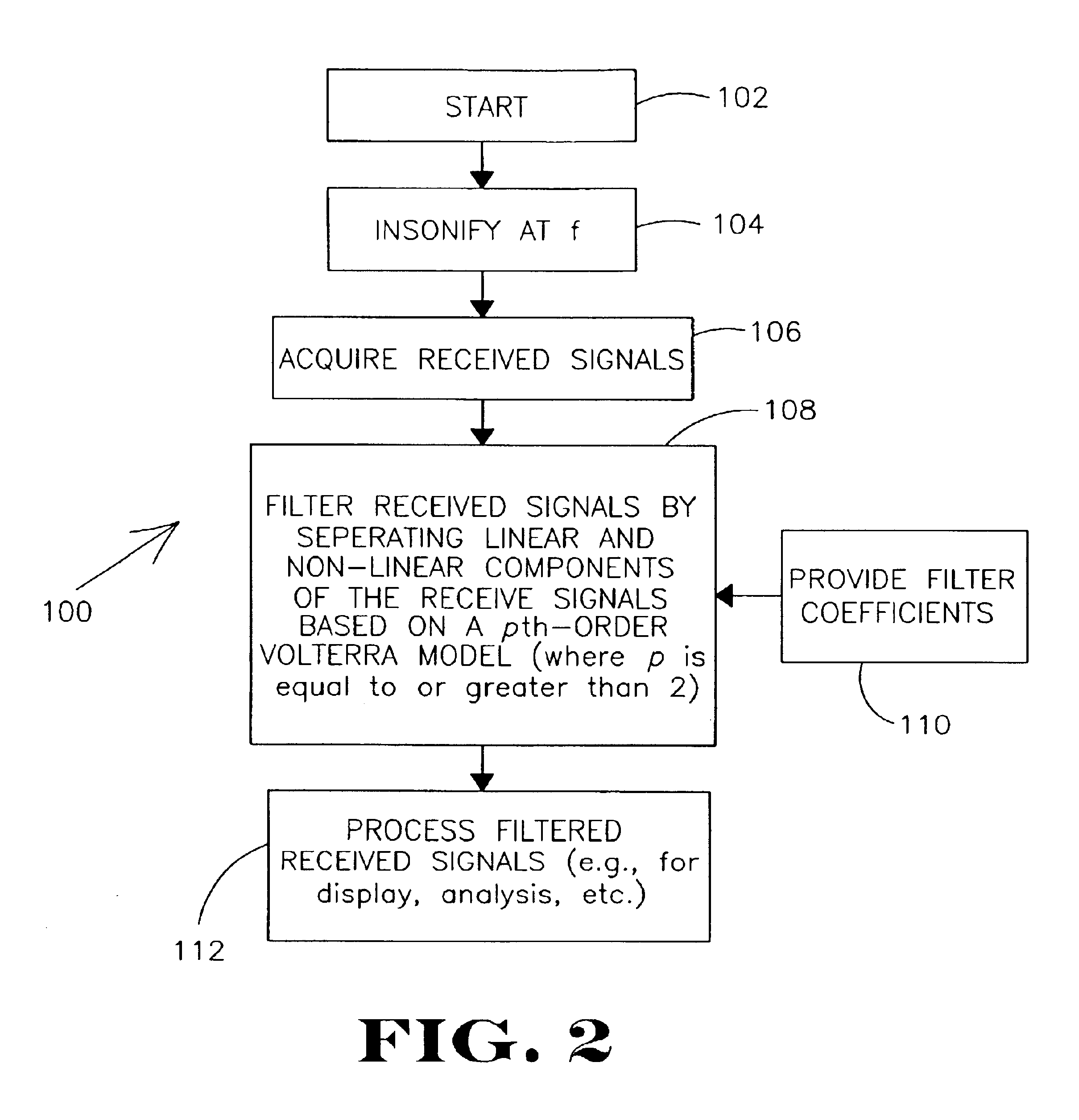

Ultrasound imaging system and method using non-linear post-beamforming filter

InactiveUS6951540B2Ultrasonic/sonic/infrasonic diagnosticsWave based measurement systemsLinear componentUltrasound imaging

Systems and / or methods provide for ultrasound imaging through the use of a dynamic non-linear post-beamforming filter (e.g., based on a pth-order Volterra model) capable of separating the linear and non-linear components of image data. A coefficient identification algorithm for deriving coefficients for filter is also provided.

Owner:RGT UNIV OF MINNESOTA

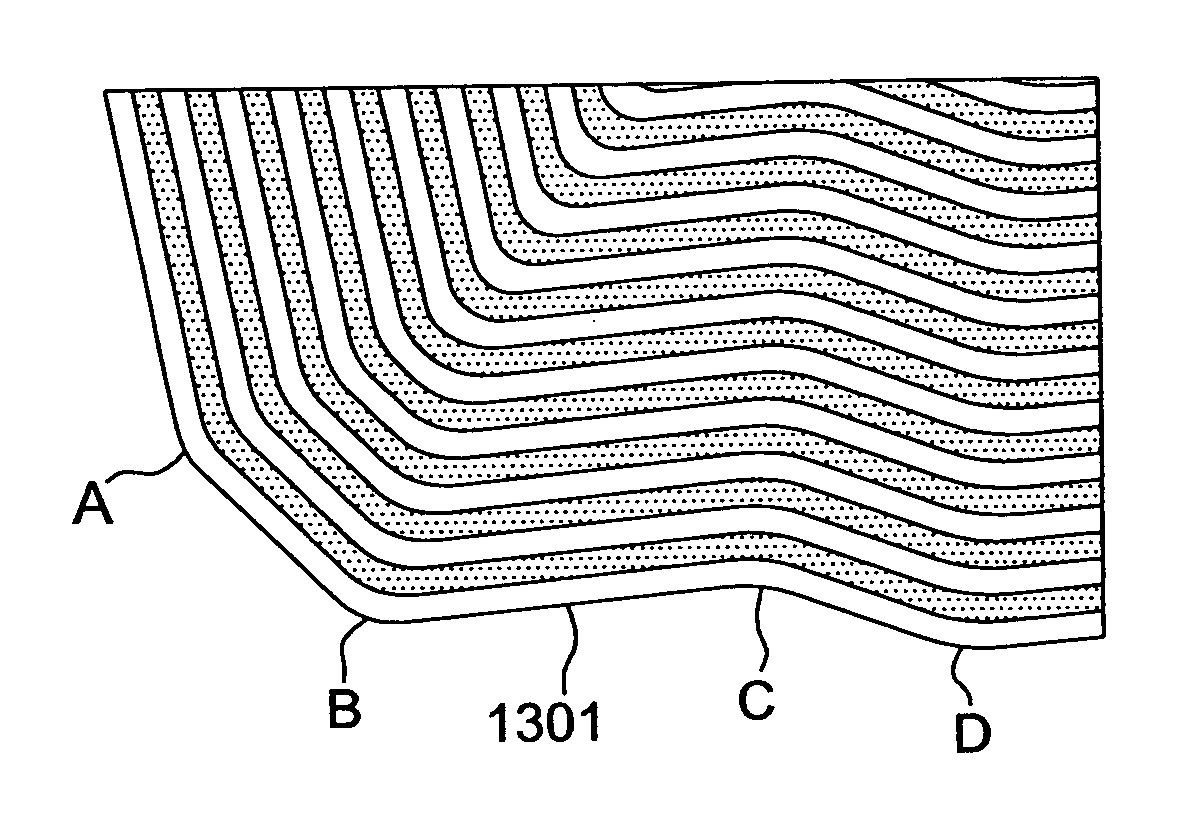

Path planner and method for planning a contour path of a vehicle

InactiveUS7216033B2Instruments for road network navigationRoad vehicles traffic controlLinear componentComputer graphics (images)

In accordance with one embodiment of the invention, a path planner and method for planning a path of a vehicle defines a reference row having a reference contour in a work area. A representation of the defined reference row is established. The defined reference row comprises a curved component, a generally linear component, or both. A generator generates one or more contour rows with a tracking contour that tracks or mirrors the reference contour based on a vehicular width and a radius difference parameter associated with the curved component. The contour rows are generated by a translation technique for the generally linear component and a radius modification technique for the curved component.

Owner:DEERE & CO

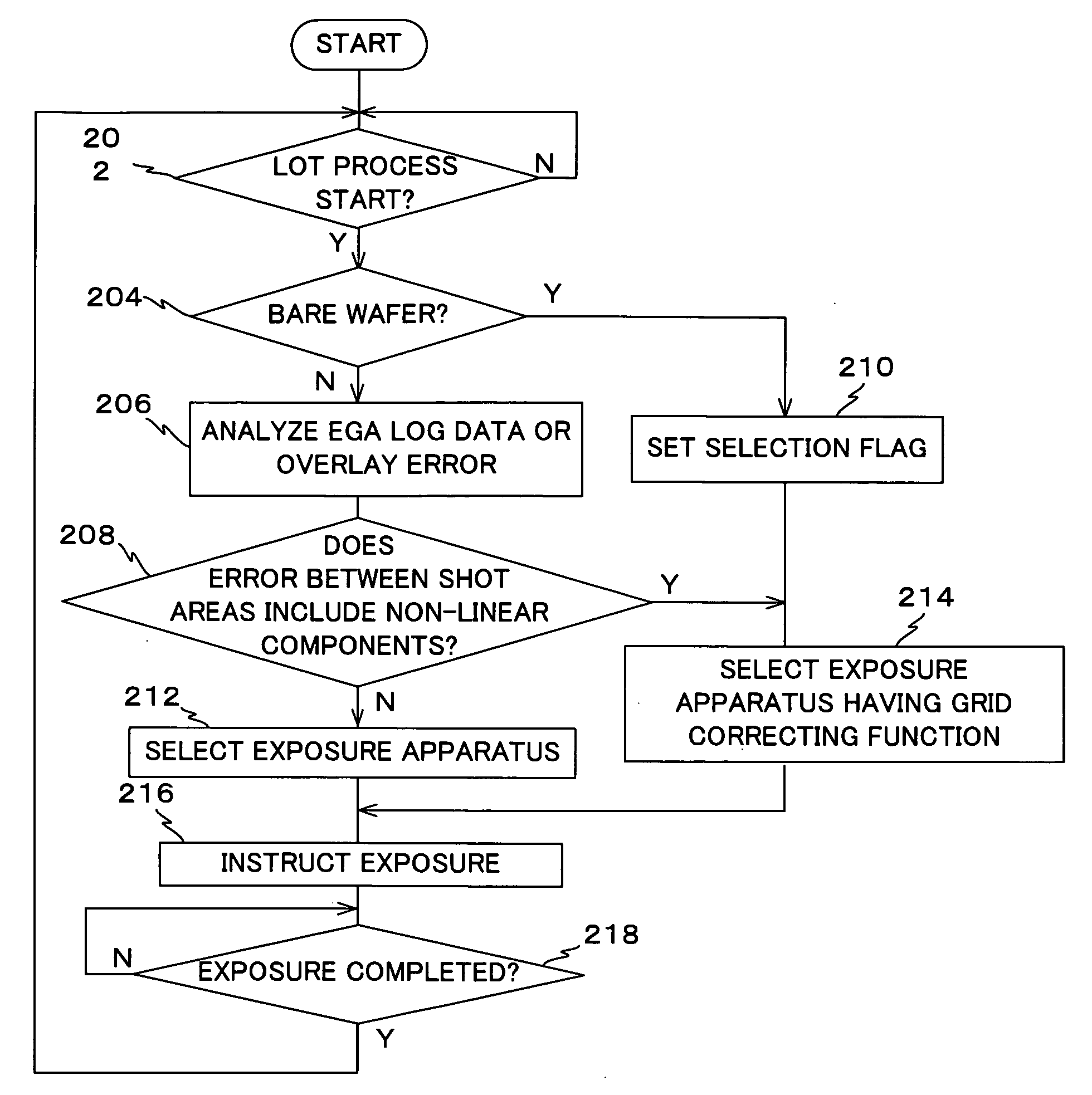

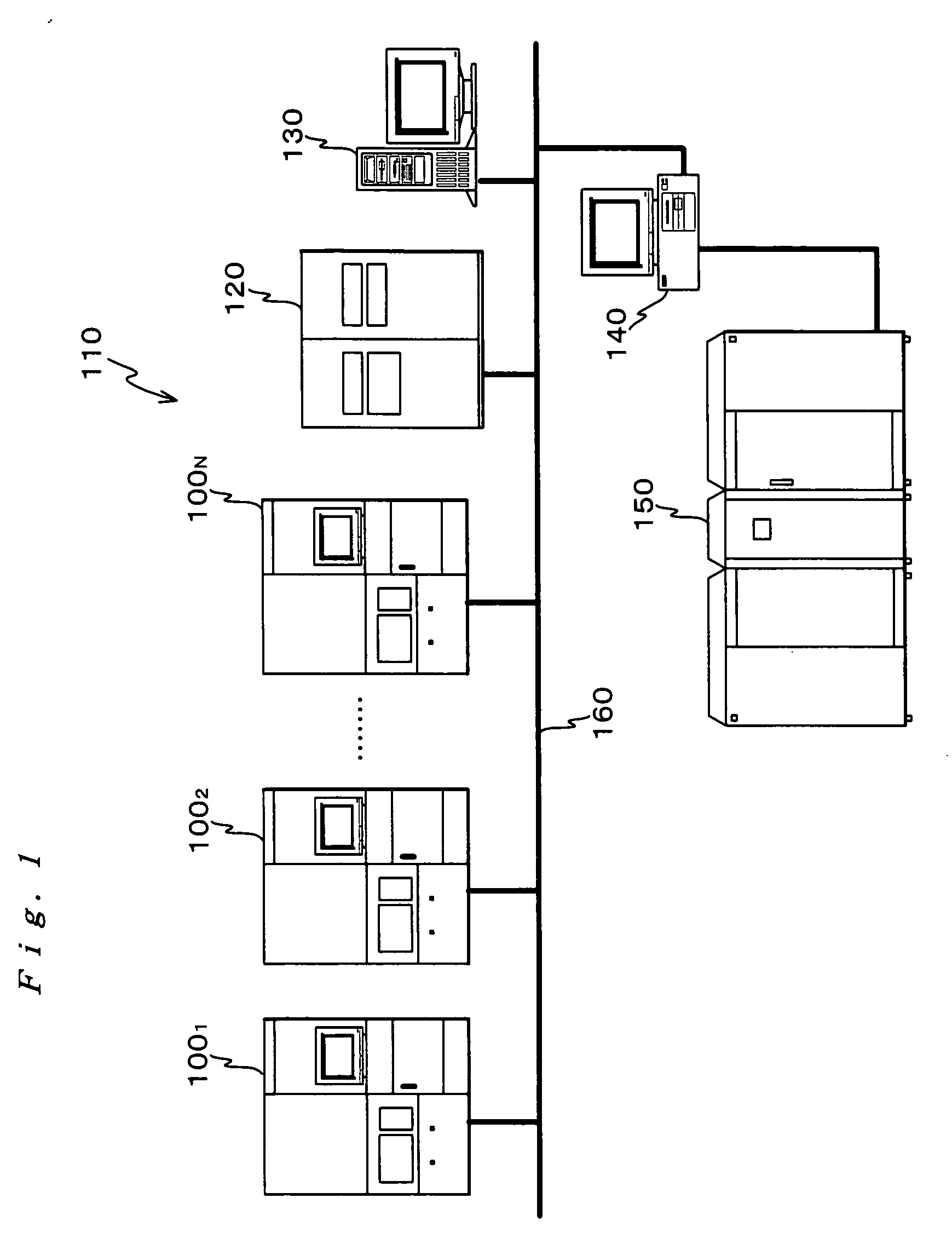

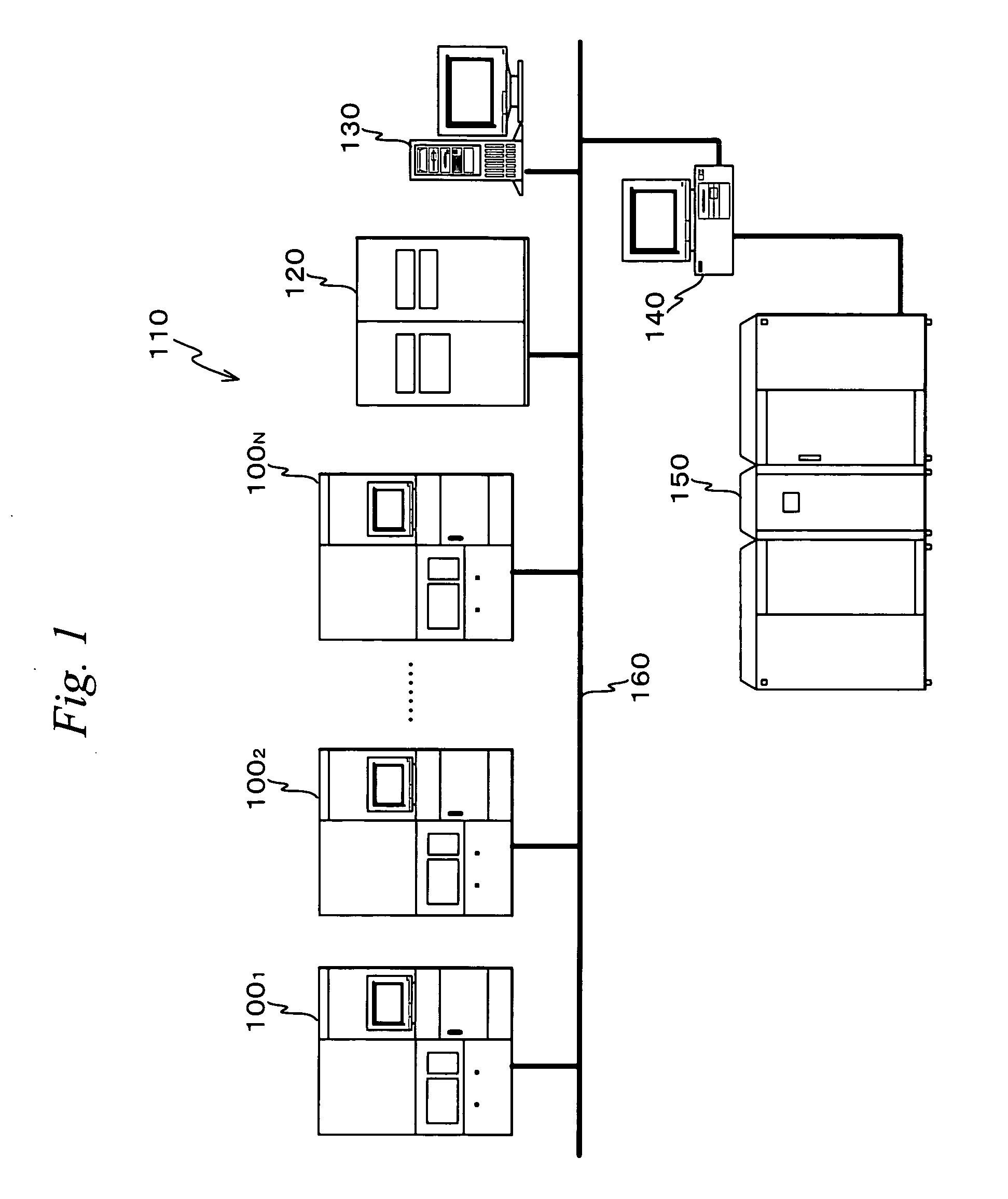

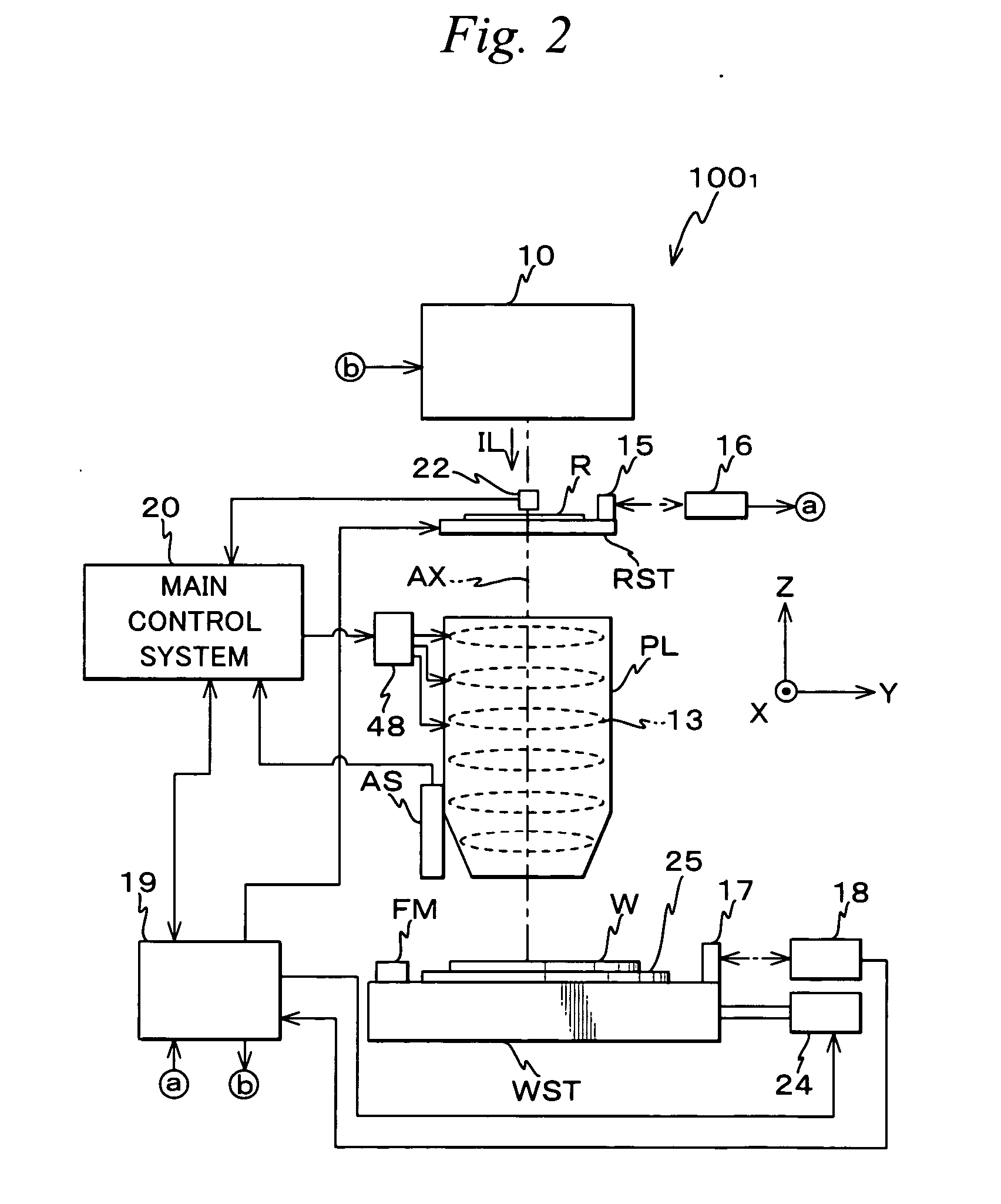

Correction method and exposure apparatus

ActiveUS20090153817A1Short timePrecise functionPhotomechanical apparatusUsing optical meansLinear componentCorrection method

At Step 602, the grid of a wafer loaded into an exposure apparatus is approximated by a mathematical function fitting up to, for example, a cubic function, and at Step 612, the magnitude of a residual error between the position of a sample shot area obtained by the function and an actually measured position is compared with a predetermined threshold value. GCM measurement is performed in a mathematical function mode in a subroutine 616, or it is performed in a map mode in a subroutine 616, on the basis of the result of the comparison. In addition, it is determined whether to extract non-linear components from the wafer in each lot on the basis of a variation in the temperature of the wafer (Step 622) and a variation in random error between the wafers (Step 624).

Owner:NIKON CORP

Path planner and method for planning a contour path of a vehicle

ActiveUS20050197766A1Instruments for road network navigationRoad vehicles traffic controlLinear componentArtificial intelligence

In accordance with one embodiment of the invention, a path planner and method for planning a path of a vehicle defines a reference row having a reference contour in a work area. A representation of the defined reference row is established. The defined reference row comprises a curved component, a generally linear component, or both. A generator generates one or more contour rows with a tracking contour that tracks or mirrors the reference contour based on a vehicular width and a radius difference parameter associated with the curved component. The contour rows are generated by a translation technique for the generally linear component and a radius modification technique for the curved component.

Owner:DEERE & CO

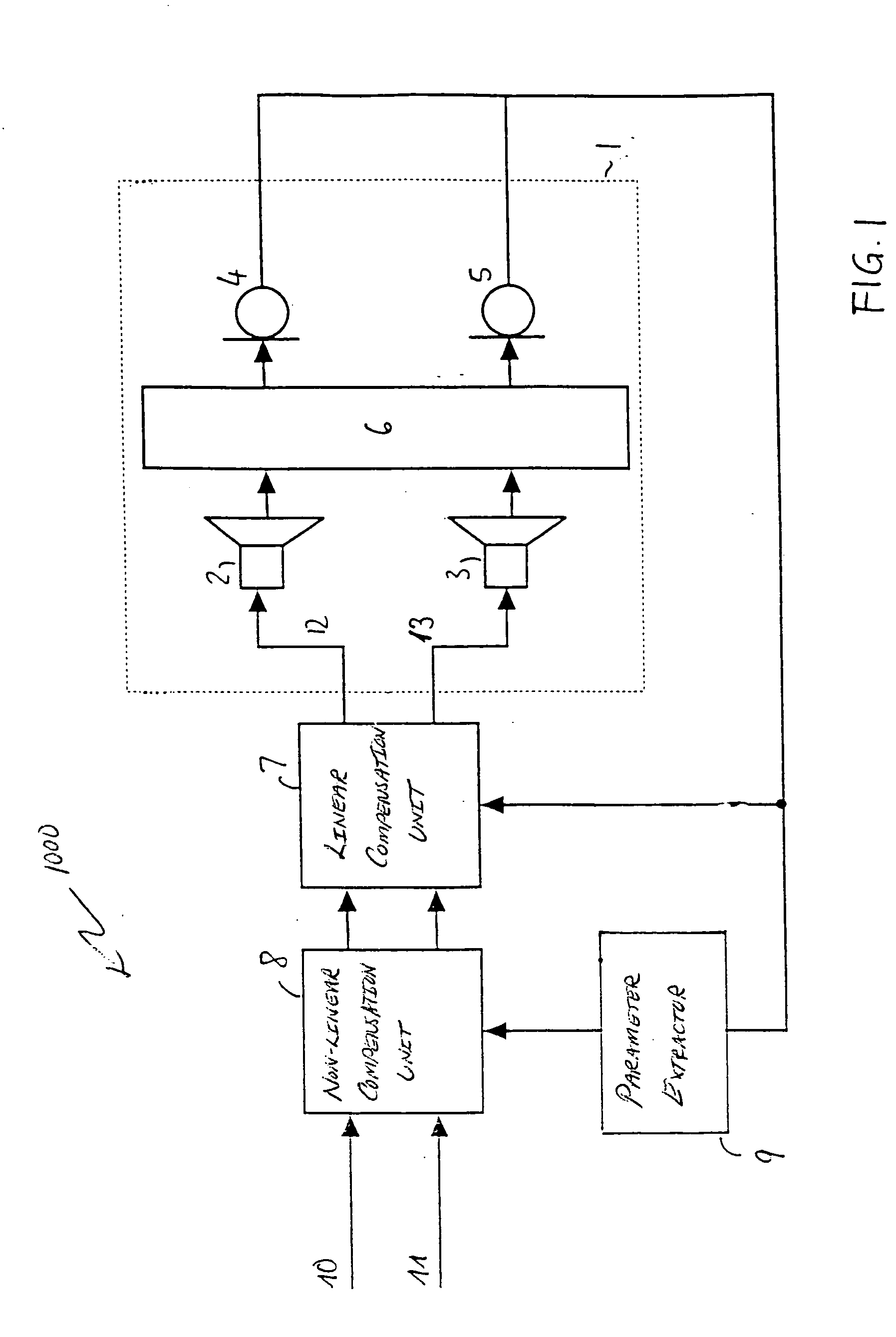

Stereo audio-signal processing system

ActiveUS20050008170A1Reduce the amplitudePublic address systemsTransmission noise suppressionLinear componentEngineering

An audio processing system is provided for controlling the acoustics of a loudspeaker-room system. The loudspeaker-room system having a listening room and loudspeakers located in said listening room, and transfer functions with linear and non-linear components. The audio processing system comprises a compensator with a transfer function for obtaining at least two compensated signals from the input signals. The transfer functions of the compensator may include linear and non-linear components and are inverse to the transfer functions of the loudspeaker-room system to the extent that a desired overall transfer function is established.

Owner:HARMAN BECKER AUTOMOTIVE SYST

Direct conversion receiver with reduced even order distortion

InactiveUS6021323AReduce distortion problemsReduces even order distortionModulation transference balanced arrangementsRadio/inductive link selection arrangementsPhase currentsLinear component

A mixer for use in a direct conversion receiver includes a compensating differential amplifier which injects equal amplitude opposite phase currents with respect to even order distortion currents. The compensating differential amplifier utilizes an ideal current source. The mixer is an active mixer which utilizes four switching transistors. The even order distortion is introduced by non-linear components which demonstrate strong off-channel signals.

Owner:TELEDYNE SCI & IMAGING

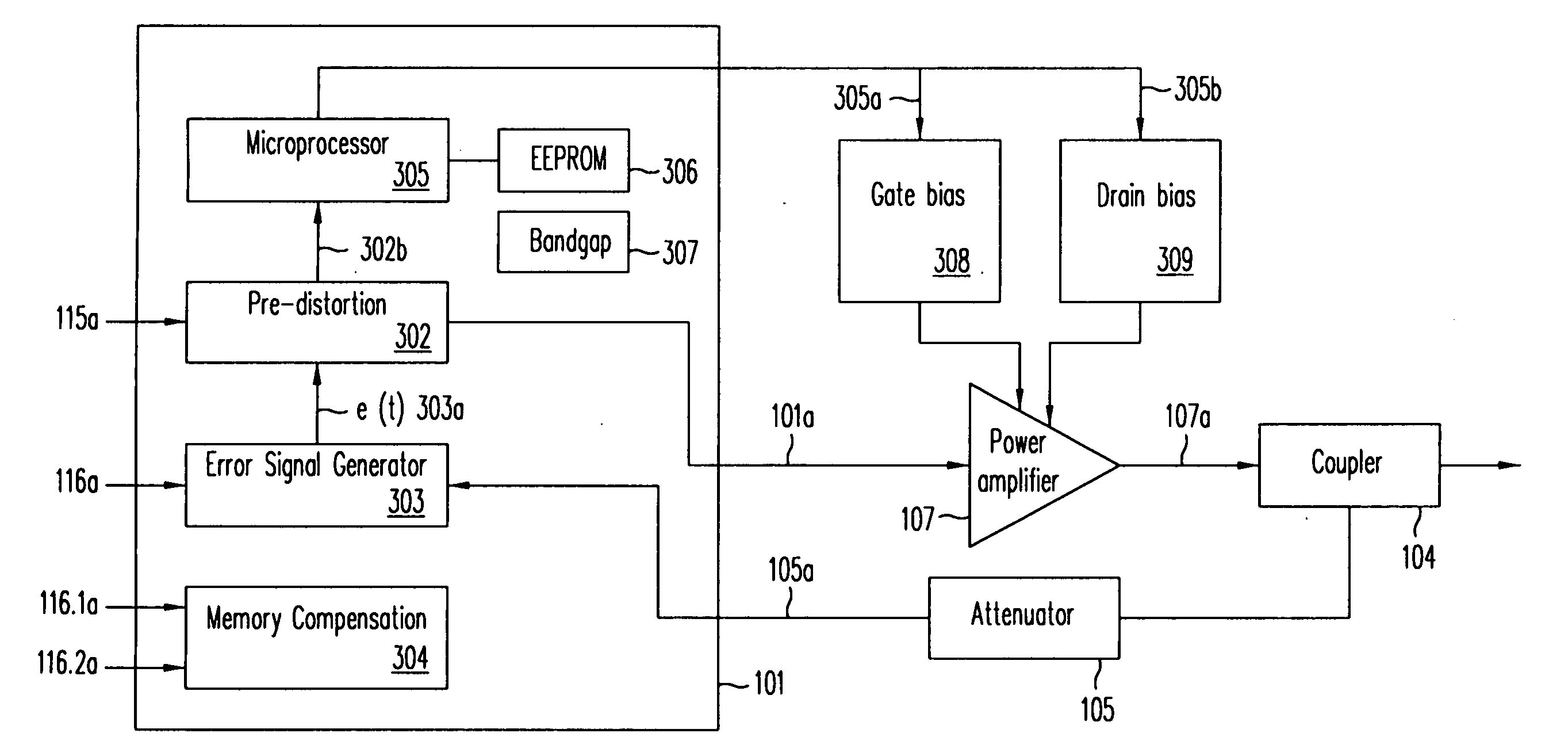

Pre-distortion apparatus

InactiveUS20080008263A1Modulated-carrier systemsAmplifier with semiconductor-devices/discharge-tubesCorrelation coefficientLinear component

Pre-distortion apparatuses and methods for a non-linear component are provided. The apparatus comprises an adaptive block for generating a plurality of correlation coefficients, which are used to weight a plurality of synthesis work functions to pre-distort a given signal. The adaptive block can be driven by an error signal generated from a feedback signal from the non-linear component output signal and a delayed version of the input signal. The apparatus is capable of being operated directly at radio frequency. Also provided are apparatuses and methods for generation of quadrature signals, transconductance amplification employing negative resistance, variable-gain amplification, and envelope detection.

Owner:SCINTERA NETWORKS

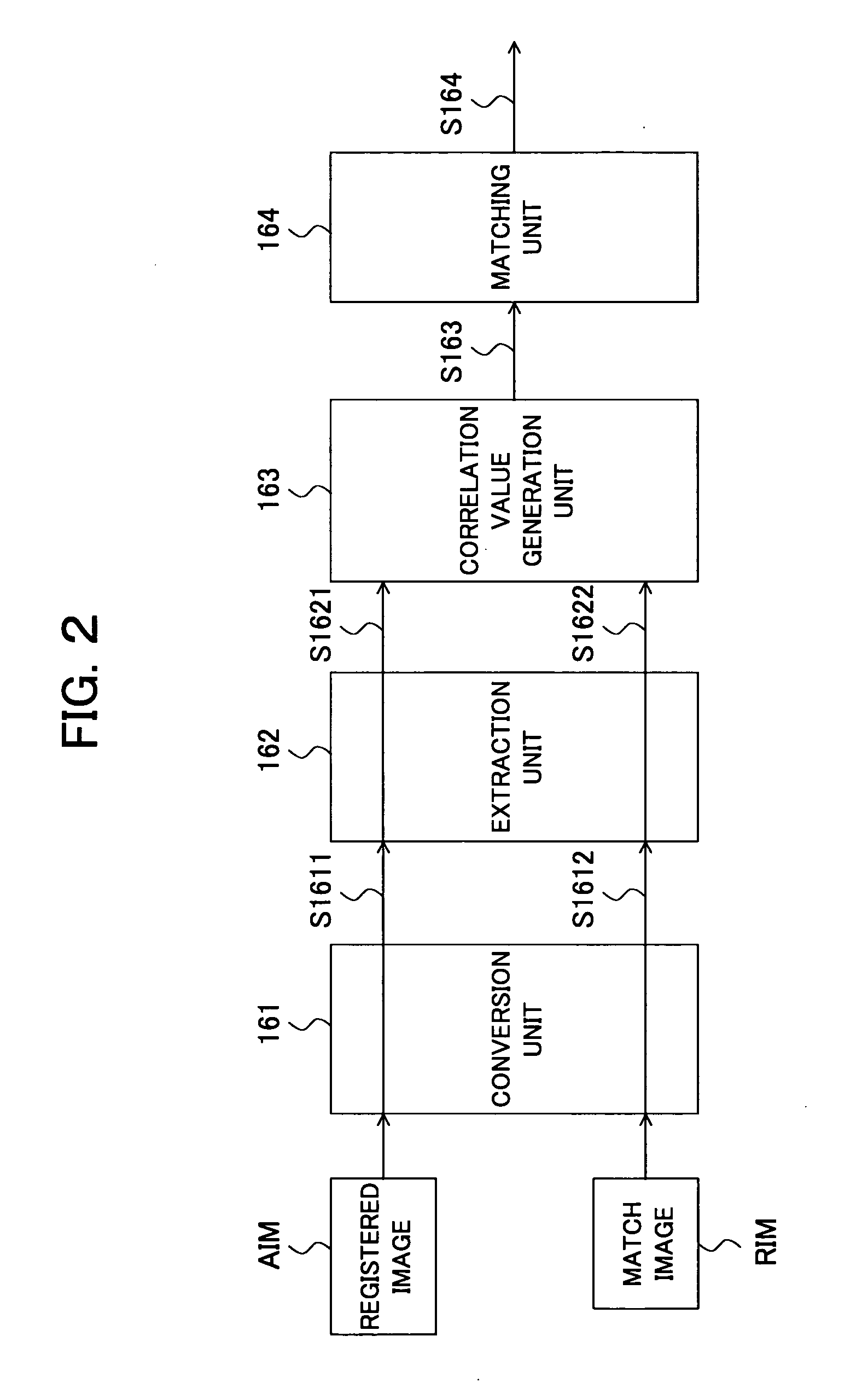

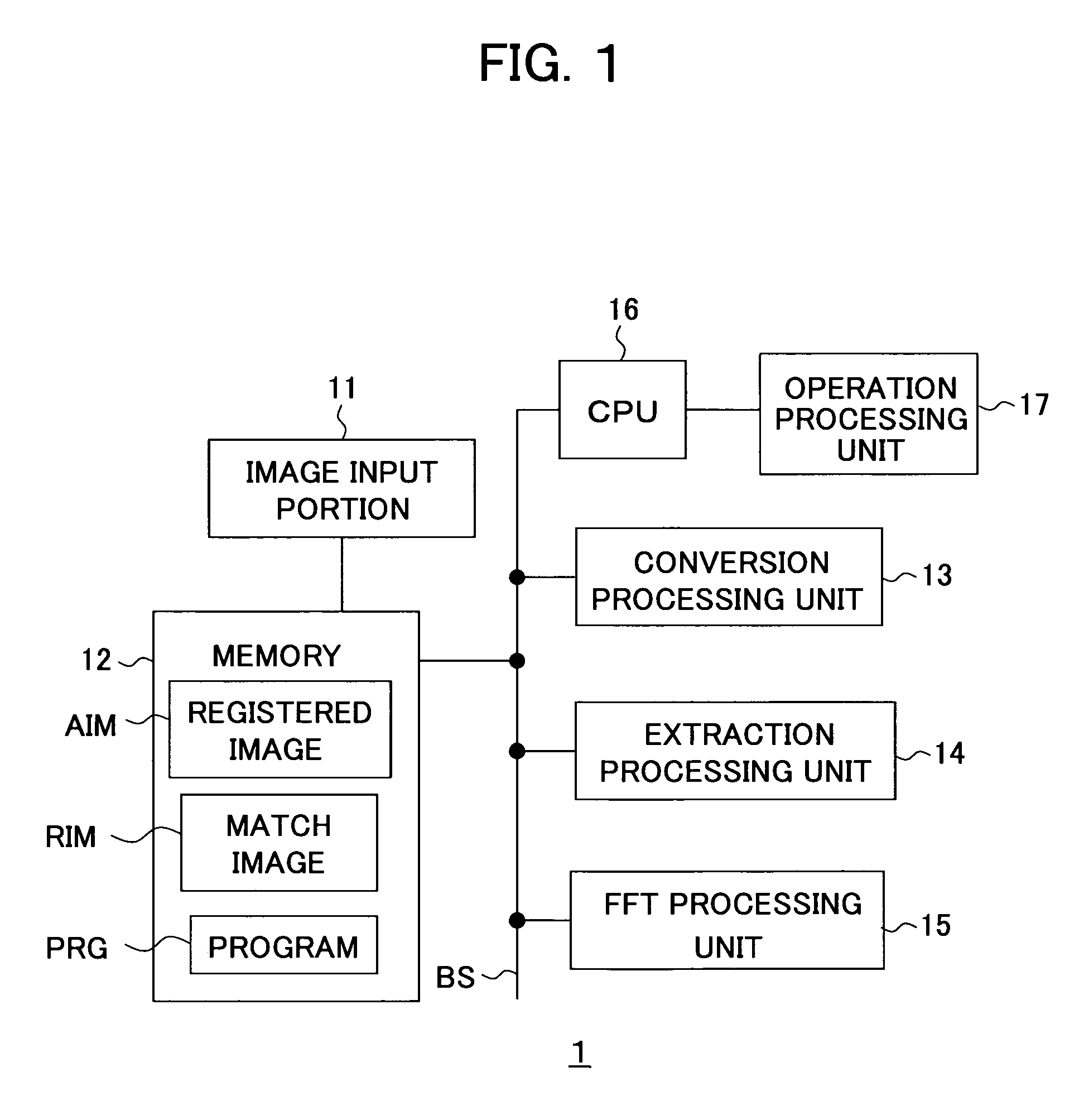

Image matching method, program, and image matching system

InactiveUS20050111738A1Improve accuracyImage analysisGeometric image transformationLinear componentPerformed Imaging

Owner:SONY CORP

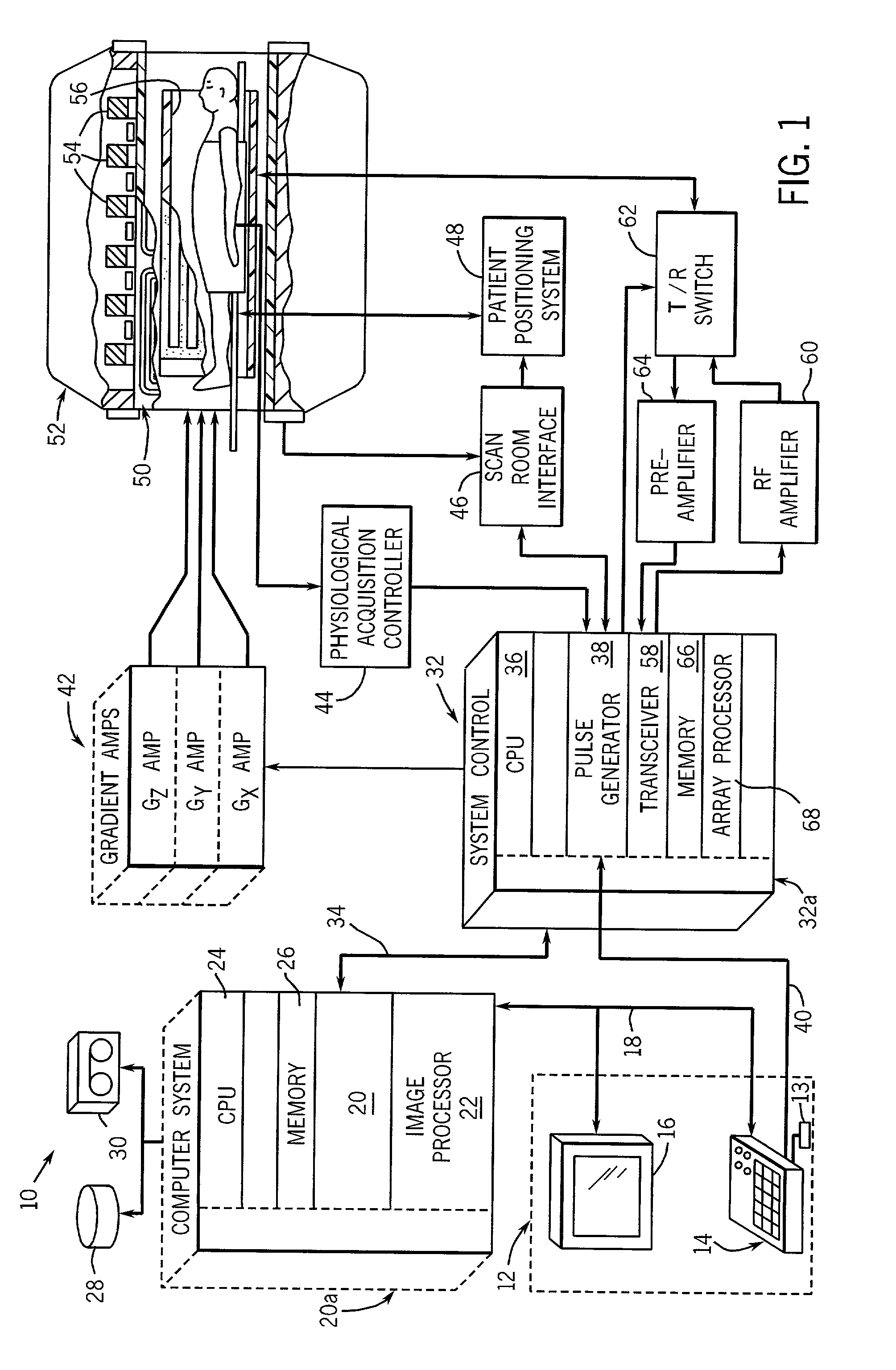

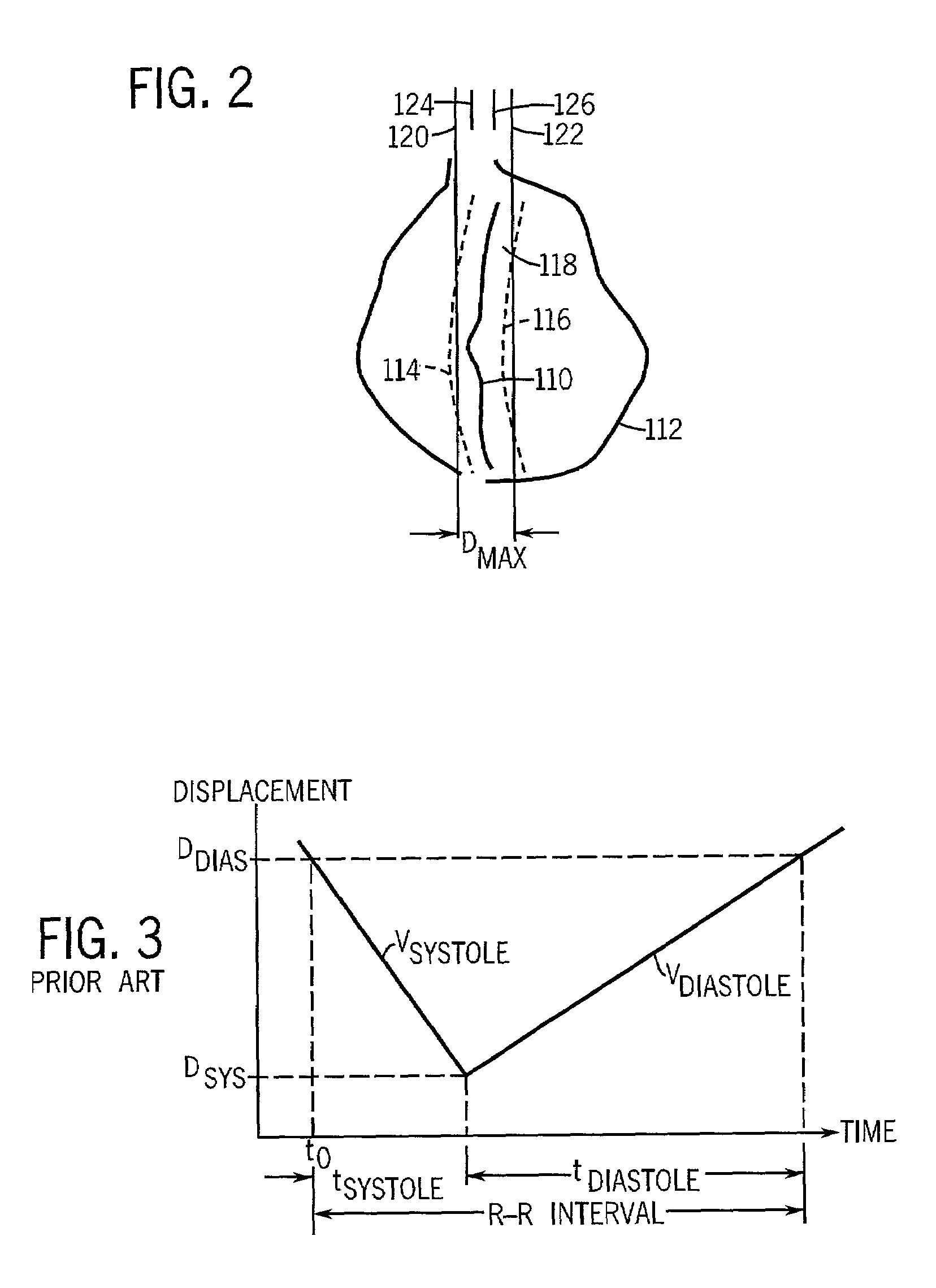

Method and apparatus for automated tracking of non-linear vessel movement using MR imaging

ActiveUS7209777B2Improve efficiencyEnhance the imageDiagnostic recording/measuringSensorsLinear componentLinear motion

A system and method is disclosed for tracking a moving object using magnetic resonance imaging. The technique includes acquiring a scout image scan having a number of image frames and extracting non-linear motion parameters from the number of image frames of the scout image scan. The technique includes prospectively shifting slice location using the non-linear motion parameters between slice locations while acquiring a series of MR images. The system and method are particularly useful in tracking coronary artery movement during the cardiac cycle to acquire the non-linear components of coronary artery movement during a diastolic portion of the R—R interval.

Owner:GENERAL ELECTRIC CO

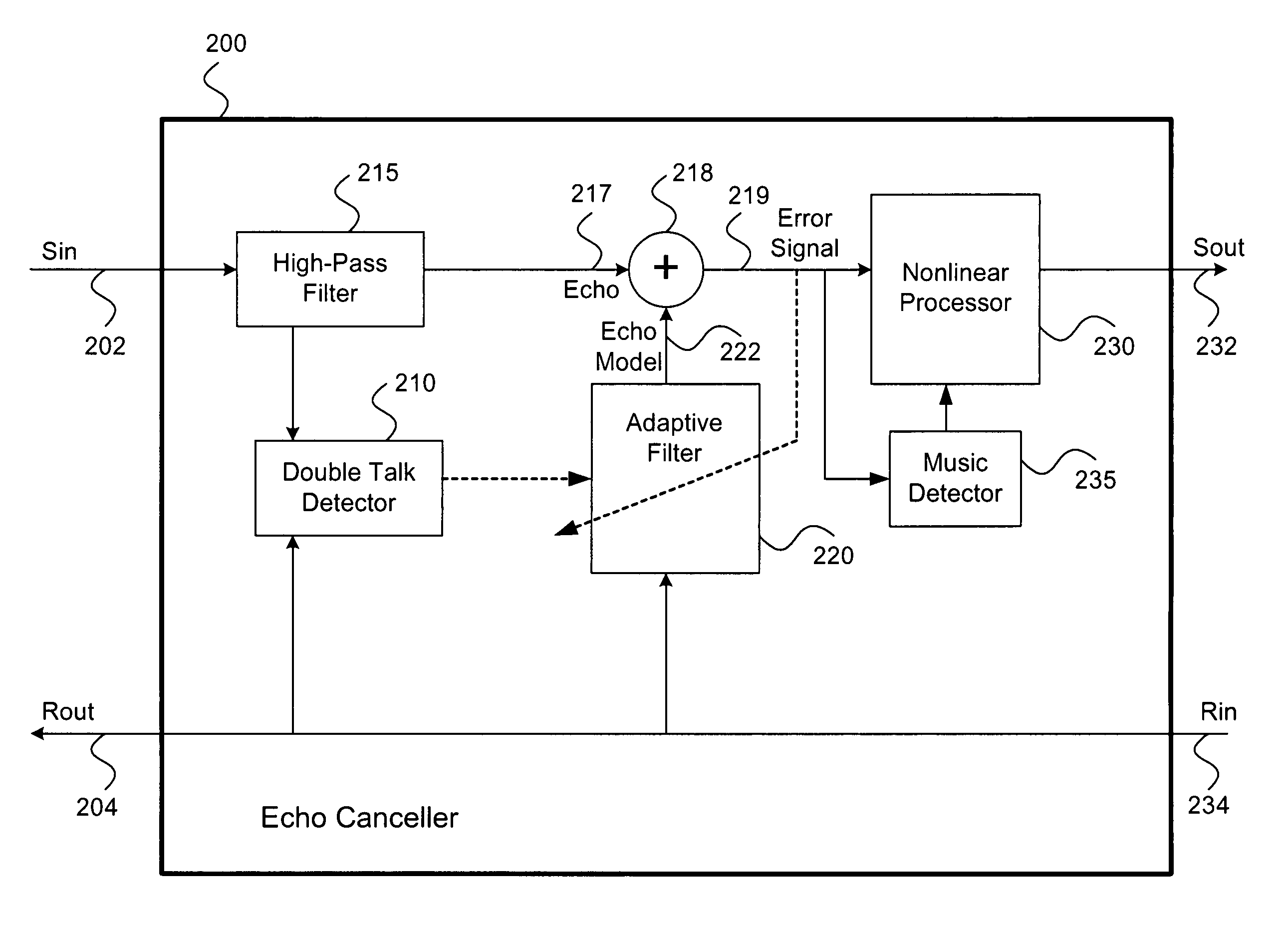

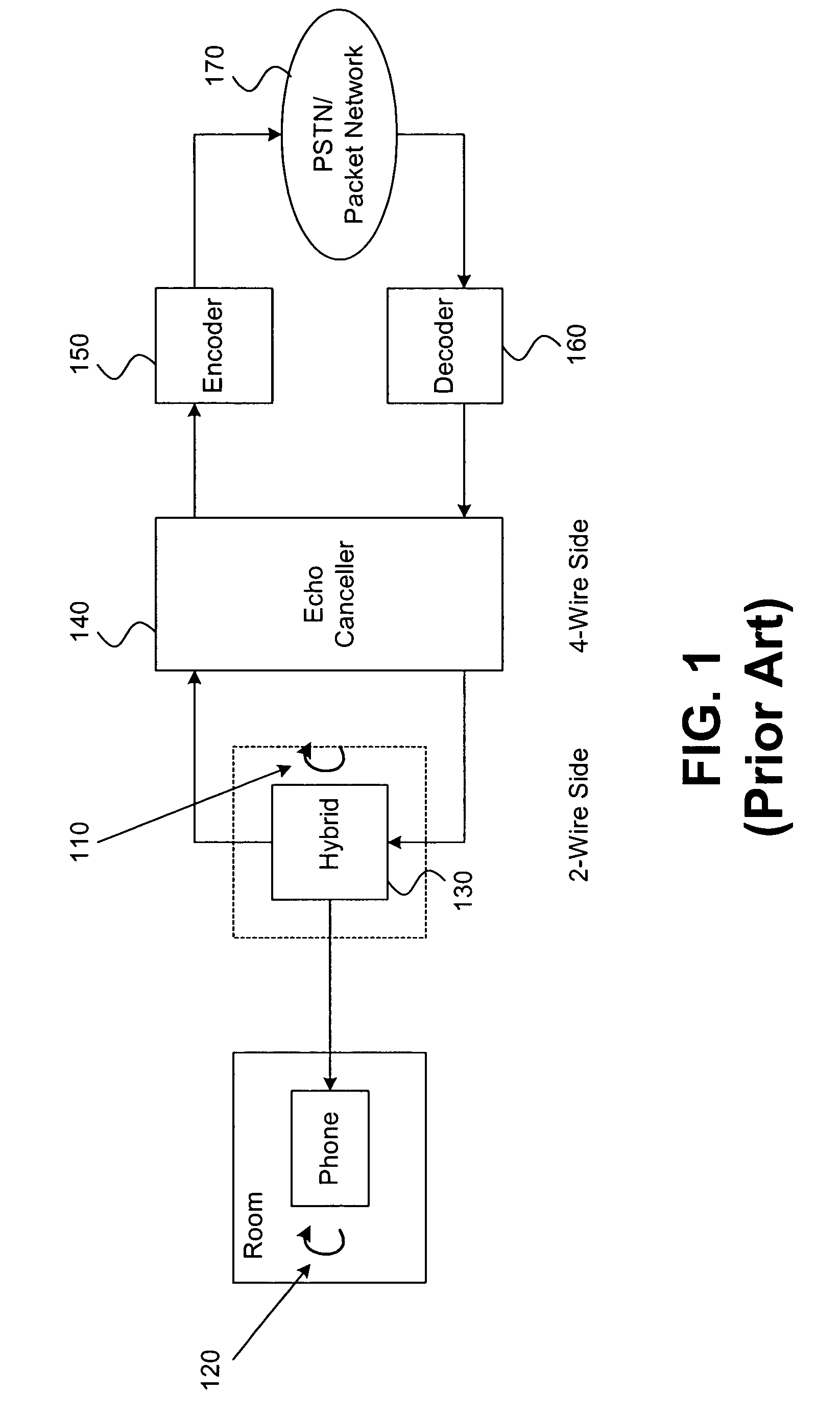

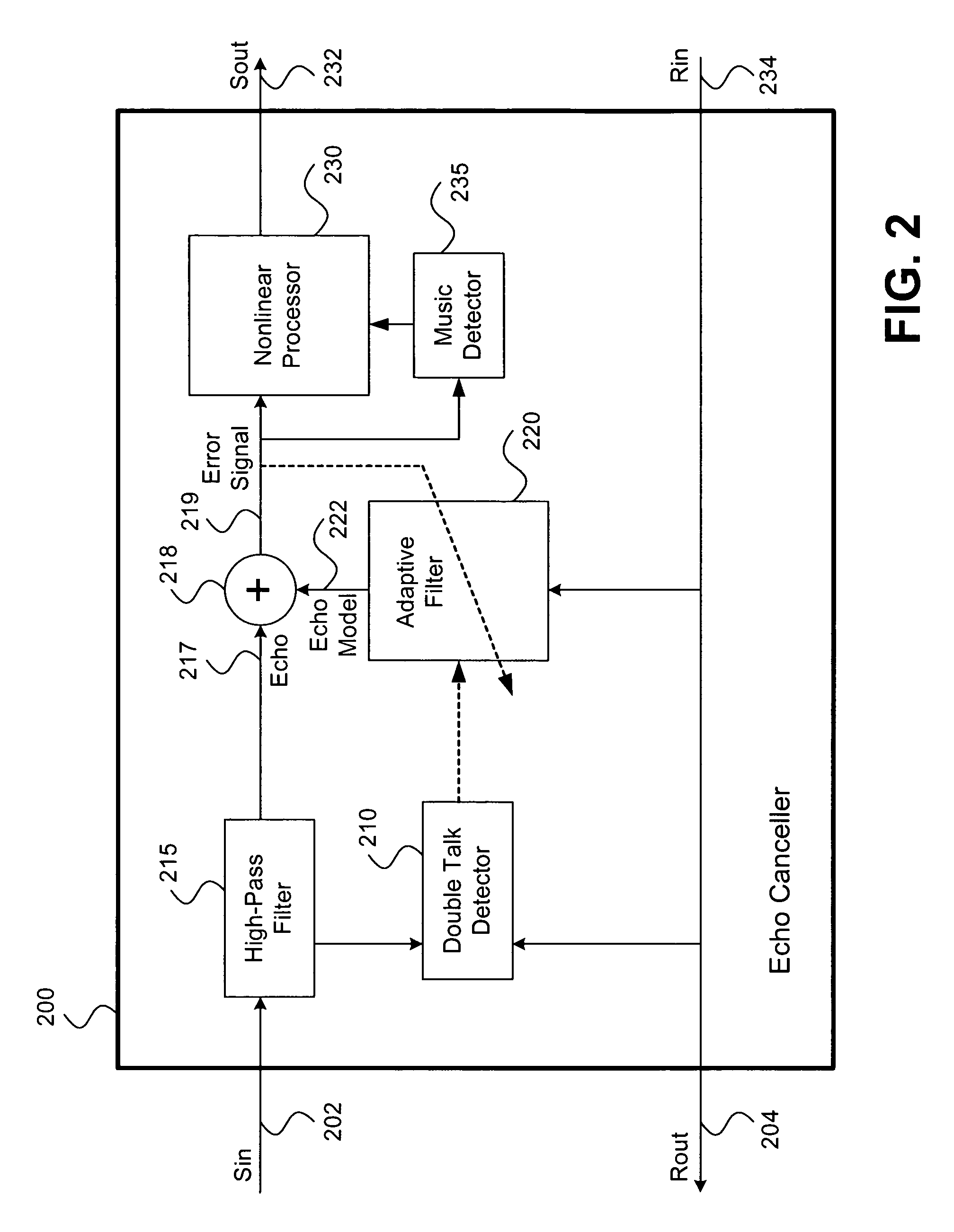

Music detection for enhancing echo cancellation and speech coding

ActiveUS7558729B1Easy to operateLessen noise gainTwo-way loud-speaking telephone systemsSpeech recognitionLinear componentAdaptive filter

A method of using music detection to enhance an operation of an echo canceller is provided, wherein the echo canceller includes an adaptive filter and a nonlinear processor. The method comprises receiving an input signal including an echo signal by the echo canceller from a near end device, filtering the input signal using the adaptive filter to eliminate linear components of the echo signal in the input signal and generate an error signal, analyzing the error signal using a music detector to determine existence of a music signal in the error signal, bypassing the nonlinear processor if the analyzing determines the music signal exists in the error signal, and eliminating nonlinear components of the echo signal from the error signal using the nonlinear processor if the analyzing determines the music signal does not exist in the error signal.

Owner:NYTELL SOFTWARE LLC

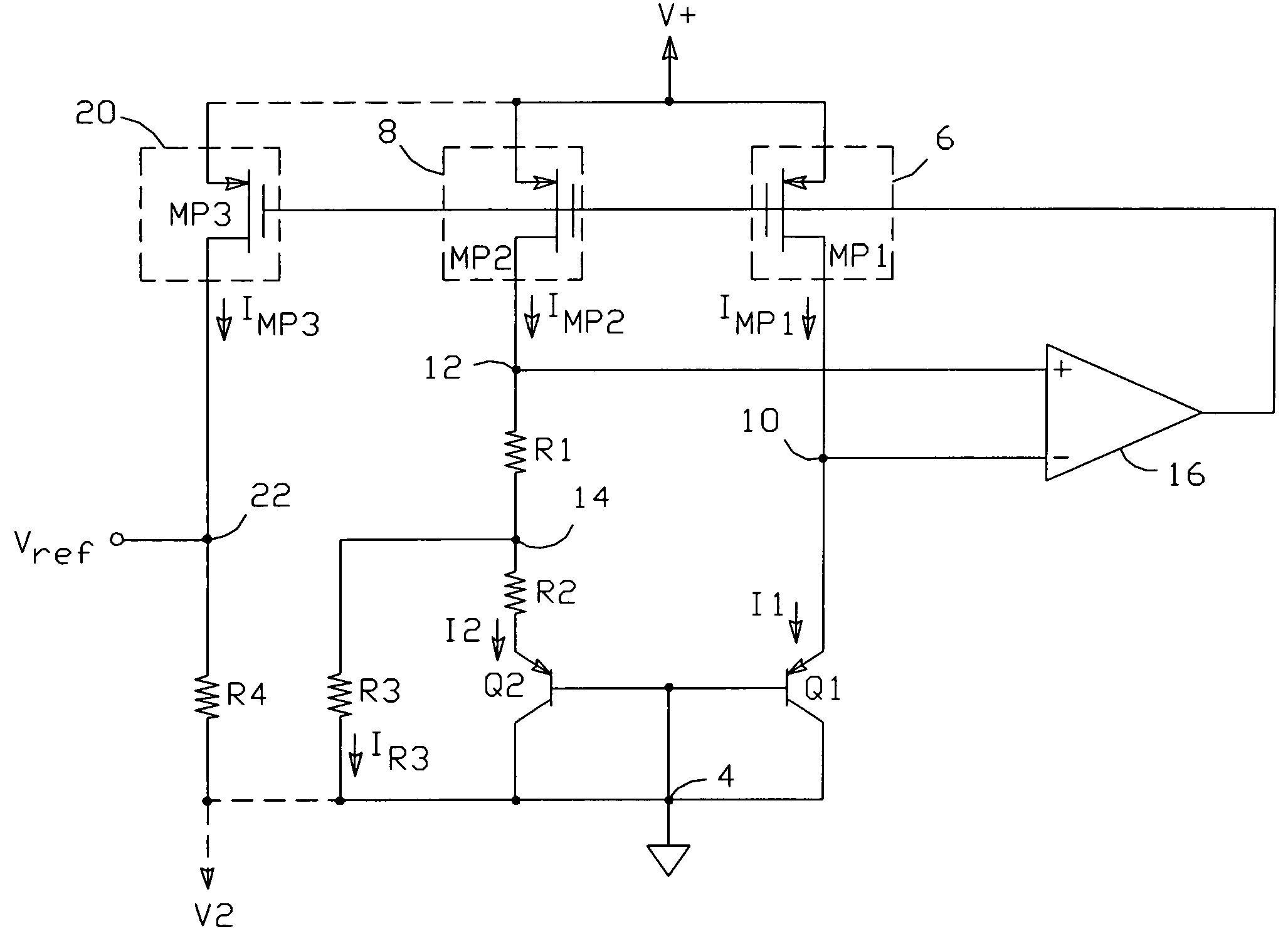

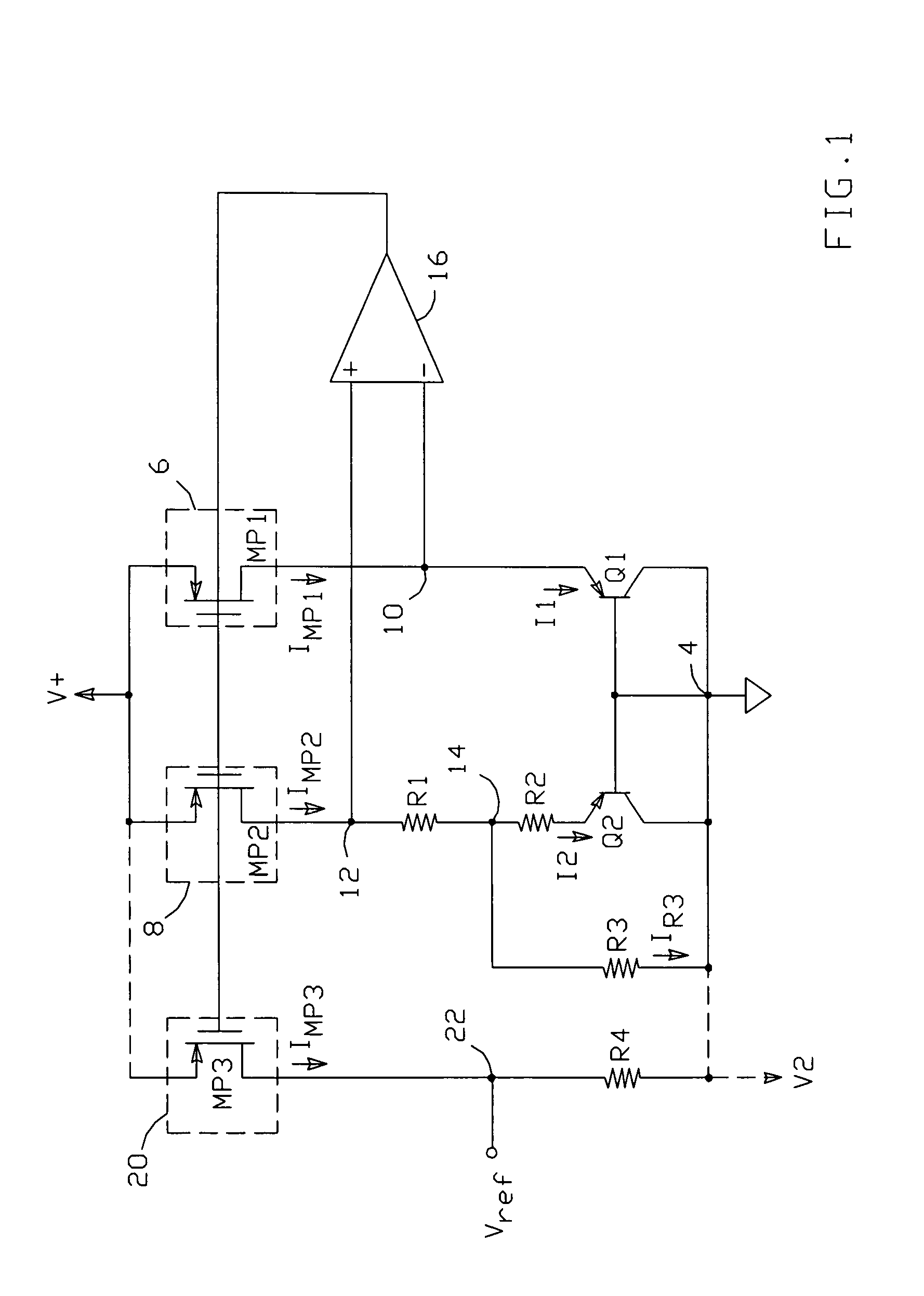

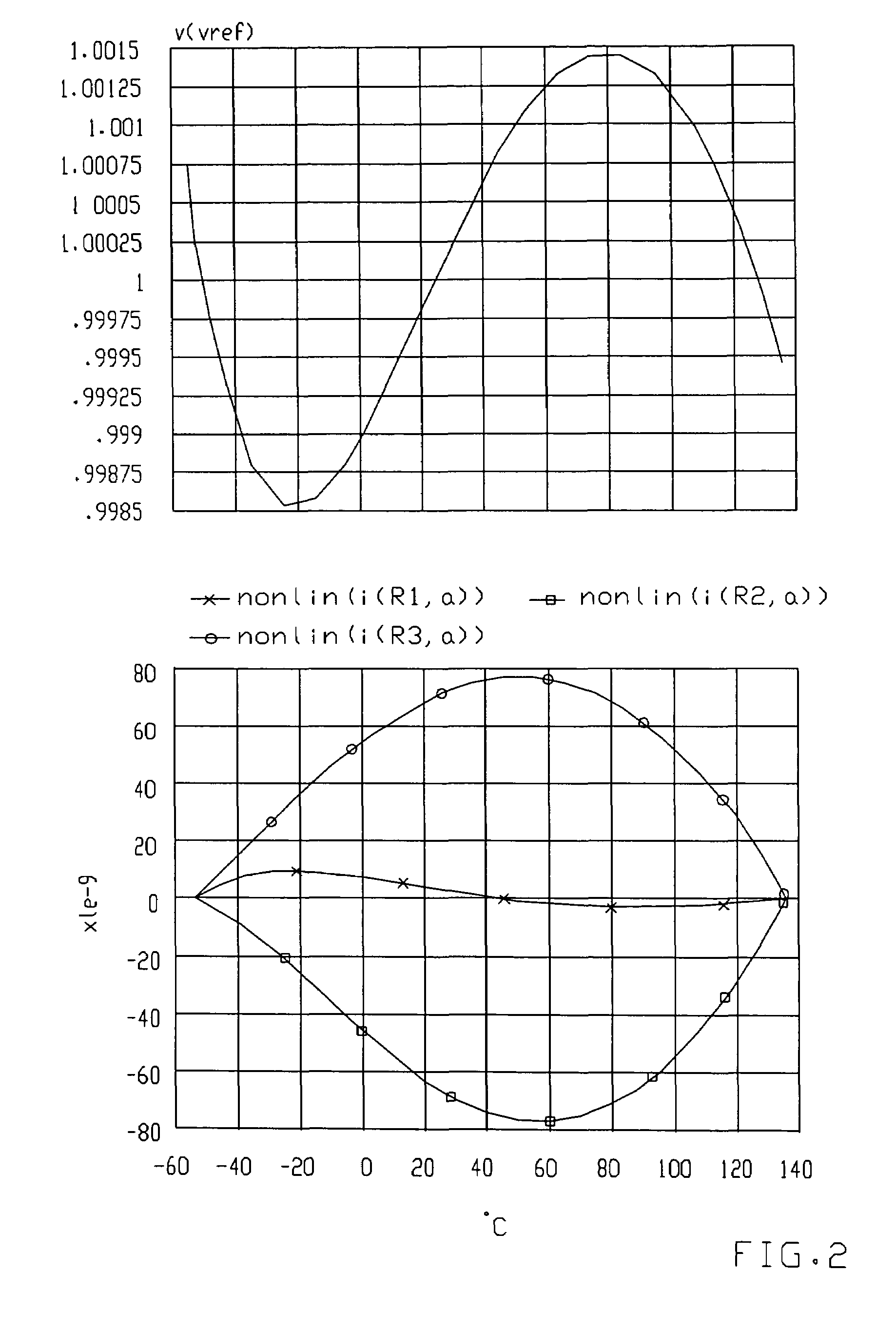

Curvature corrected bandgap reference circuit and method

A curvature corrected bandgap reference circuit comprises a first bipolar transistor having a base-emitter voltage Vbe1 and operated such that it has a constant operating current, and a second bipolar transistor having a base-emitter voltage Vbe2 and operated such that it has an operating current consisting of an approximately temperature proportional component and a non-linear component. The circuit is arranged such that the ratio of the current densities in the two transistors varies with temperature, such that the difference voltage (ΔVbe=Vbe1−Vbe2) includes a residual component which approximately compensates bandgap curvature error.

Owner:ANALOG DEVICES INC

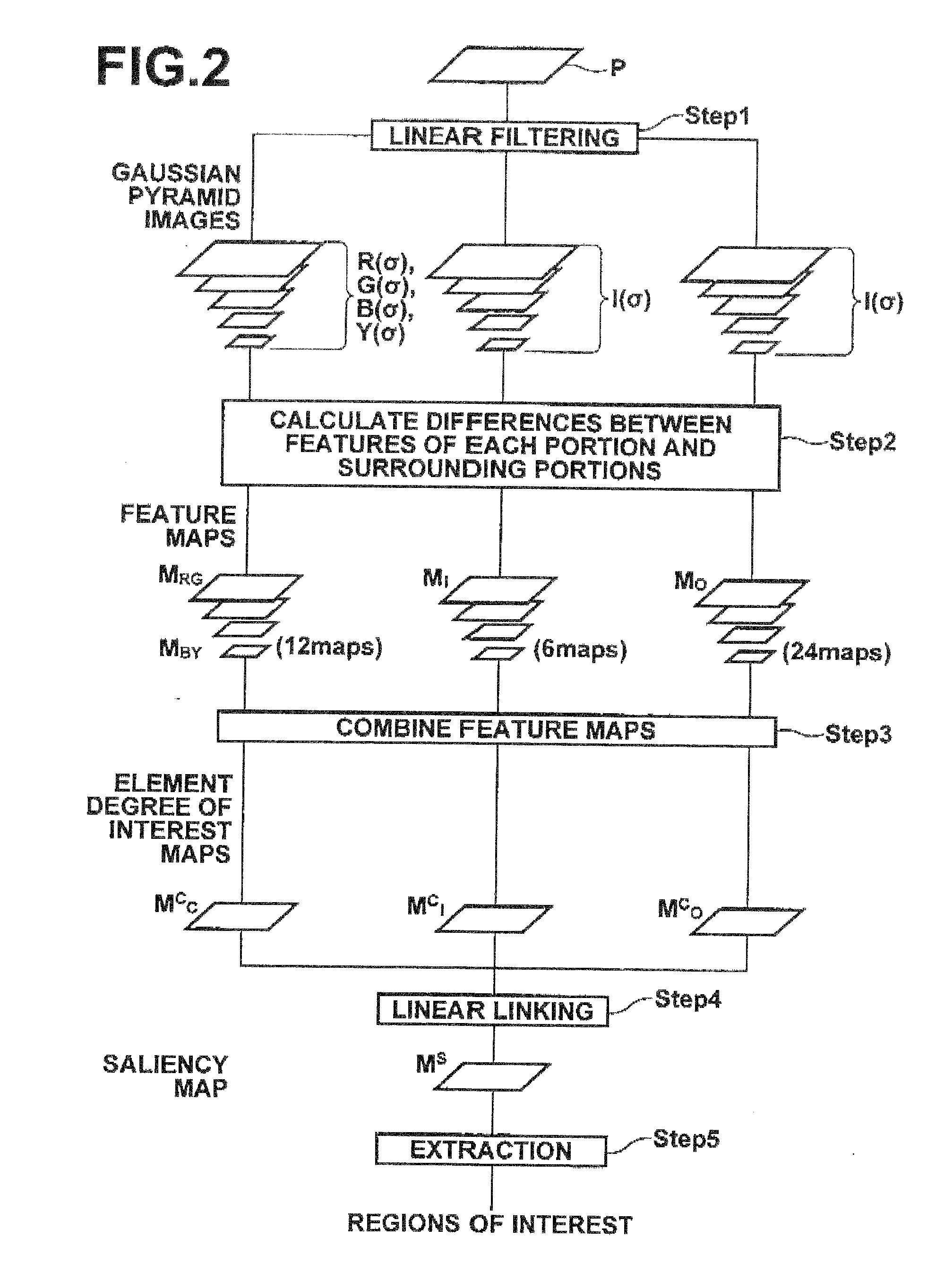

Image processing method, image processing apparatus, and image processing program

A region of interest extracting section automatically extracts regions of interest from within original images by obtaining the degree by which the features of portions within the original images differ from the features of surrounding portions, based on the colors of the original images, brightnesses of the original images, and the orientations of linear components that appear in the original images. A partial image generating section generates partial images by cutting out images of predetermined sizes that include the regions of interest, which are extracted by the region of interest extracting section, from the original images. The generated partial images are displayed.

Owner:FUJIFILM CORP

Micromechanical pressure sensor device and corresponding measurement system

InactiveUS20040079159A1Fluid pressure measurement using ohmic-resistance variationPressure difference measurement between multiple valvesLinear componentSemiconductor materials

A micromechanical pressure sensor device, particularly for measuring low absolute pressures and / or small differential pressures. The device includes a frame that is formed at least partially by a semiconductor material, a membrane retained by the frame, at least one measuring resistor that is disposed at a first location in or on the membrane and whose resistance value is a function of pressure-induced mechanical stresses in the membrane, and at least one compensating resistor that is disposed at a second location in or on the membrane and whose resistance value is a function of pressure-induced mechanical stresses in the membrane. The resistance value changes at the first location with a first linear component and a first quadratic component as a function of the pressure, and the resistance value changes at the second location approximately without a linear component and with a second quadratic component, which is proportional to the first quadratic component, as a function of the pressure.

Owner:ROBERT BOSCH GMBH

Exposure method and device manufacturing method, exposure apparatus, and program

ActiveUS20070109524A1Good precisionImprove throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLinear componentEngineering

Positional information (an estimate value in which a linear component of positional deviation amount is corrected) of each shot on a wafer is calculated by a statistical computation using actual measurement values of positional information of a plurality of sample shots on the wafer (step 488). And, a variation amount of a non-linear component of positional deviation amount is calculated at predetermined intervals with respect to each of a plurality of measurement shots including the sample shots (step 496), and judgment is made about the necessity of update of correction information based on magnitude of the calculated variation amount of a non-linear component of each measurement shot area (step 498). Therefore, comparing with the case when actual values of positional information of all shots on the wafer are obtained at least once in each lot in order to update a correction value, the number of shots subject to positional information measurement and the measurement time can be reduced without fail.

Owner:NIKON CORP

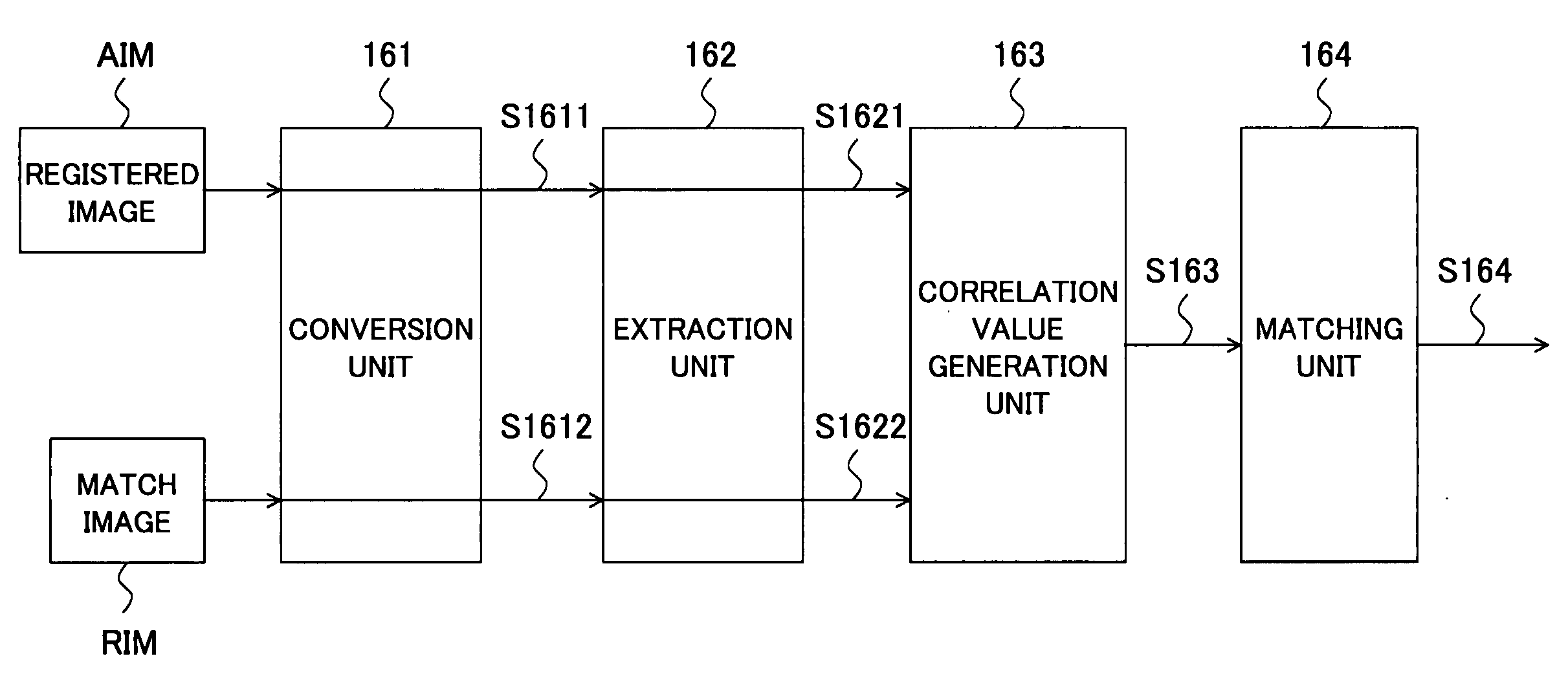

Image matching method, program, and image matching system

InactiveUS7720307B2Improve accuracyImage analysisGeometric image transformationClosest pointLinear component

An image matching method capable of matching images with a high precision and a program and an image matching system for the same, providing a conversion unit for performing image processing based on a registered image and a match image for converting points in each image to patterns of curves based on a distance from a reference position to the closest point on a straight line passing through each point in the image from the reference position and an angle formed by a straight line passing through the reference position and the closest point and an x-axis as a reference axis including the reference position, converting linear components in the images to patterns of a plurality of overlapped curves, and generating converted images, a correlation value generation unit for performing correlation processing based on the converted images and generating a correlation value, and a matching unit for performing the matching based on a signal indicating the correlation value generated by the correlation value generation unit.

Owner:SONY CORP

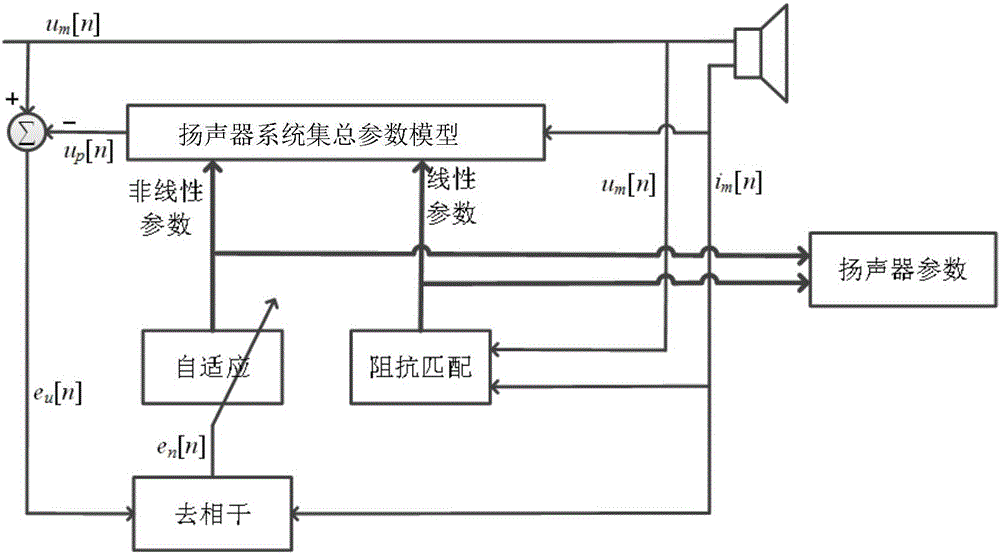

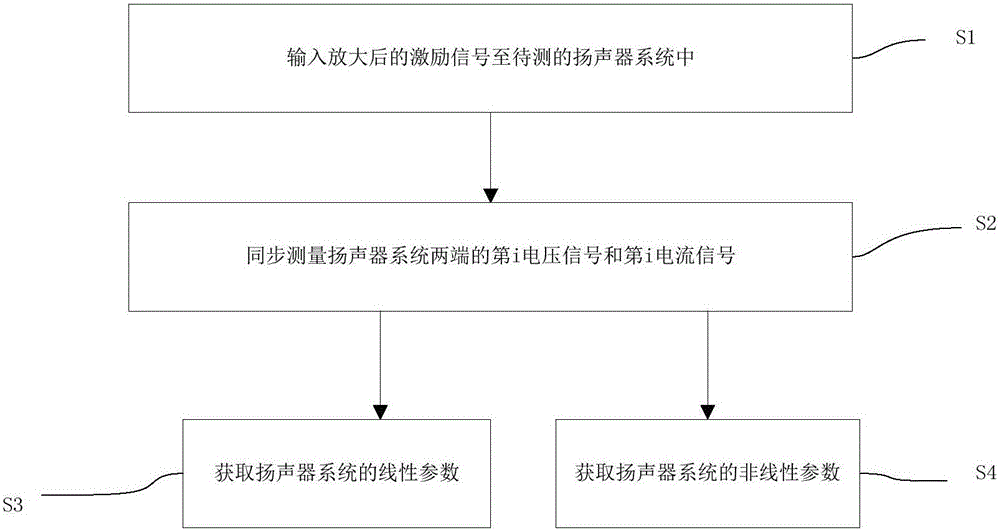

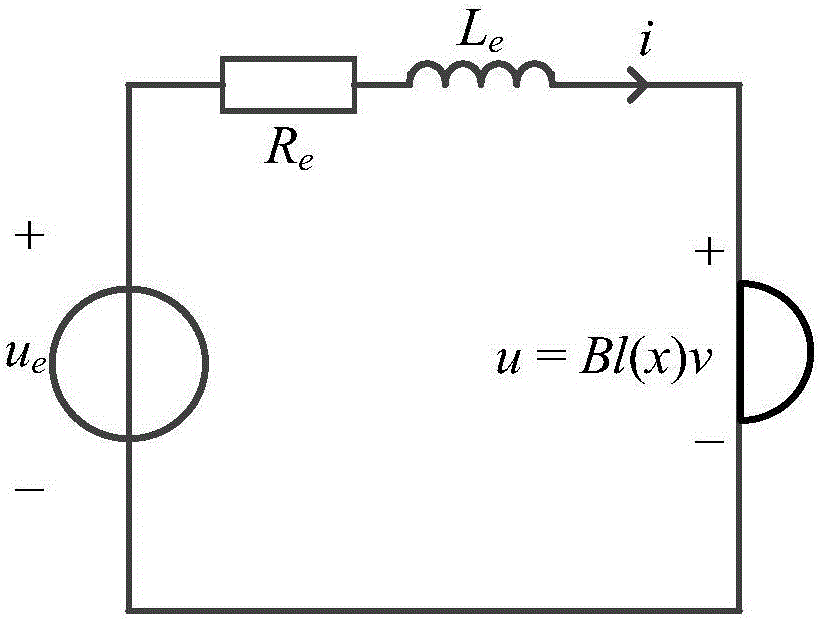

Loudspeaker nonlinear system identification method

ActiveCN106068007AImprove accuracyIncrease flexibilitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansLinear componentSignal on

The invention provides a loudspeaker nonlinear system identification method comprising the steps of providing an amplified excitation signal for a loudspeaker system to be tested; synchronizing a voltage signal and current signal on both ends of the loudspeaker system; acquiring a linear parameter of the loudspeaker system: according to the measured voltage signal and the measured current signal, computing the impedance curve of the loudspeaker system on a large signal condition, and matching the impedance curve by using a least square method so as to obtain the linear parameter of the loudspeaker system; acquiring the nonlinear parameter of the loudspeaker system: inputting the measured current signal into the lumped parameter model of the loudspeaker system to compute an estimated voltage signal; comparing the estimated voltage signal with the measured voltage signal and computing a voltage error signal between the estimated voltage signal with the measured voltage signal; de-correlating the voltage error signal in order remove the linear component in the voltage error signal, and acquiring the nonlinear parameter by an adaptive iteration algorithm according to the de-correlated voltage error signal.

Owner:AAC TECH PTE LTD

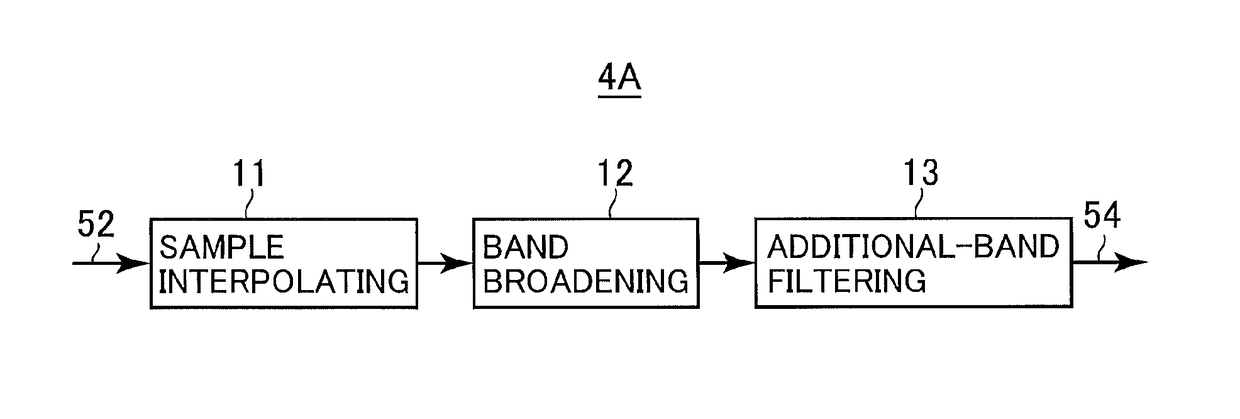

Voice decoding apparatus of adding component having complicated relationship with or component unrelated with encoding information to decoded voice signal

ActiveUS9734835B2Reduce cloggingImproved in nose clogging feelingSpeech analysisLinear componentSpeech sound

A voice decoding apparatus includes an MBE-type decoder, a sampling convertor, a non-linear components generator and an adder. The decoder decodes digital voice-encoded information to generate a first decoded voice signal. The convertor converts the first decoded voice signal to a second decoded voice signal with a higher sampling frequency. The generator performs a non-linear process to the first or second decoded voice signal to generate an additional voice signal with the same sampling frequency as the second decoded voice signal. The additional voice signal has components in a frequency band in which the first decoded voice signal has no component and continuing to another frequency band of the first decoded voice signal. The adder adds the second decoded voice signal to the additional voice signal.

Owner:OKI ELECTRIC IND CO LTD

Current reference source circuit and method for generating current reference source

ActiveCN102122191AReduce sensitivityImprove stabilityElectric variable regulationLinear componentNegative temperature

The invention relates to an integrated circuit and discloses a current reference source circuit and a method for generating a current reference source. The method comprises the following steps of: generating a linear positive temperature coefficient current, a nonlinear negative temperature coefficient current and a nonlinear positive temperature coefficient current through three circuits respectively; superimposing the three currents; and taking the superimposed output currents as the current reference source. The linear positive temperature coefficient current is used for effectively offsetting linear components in the nonlinear negative temperature coefficient current, and the nonlinear positive temperature coefficient current is used for compensating residual nonlinear negative temperature coefficients, so that the sensitivity of the acquired currents to temperature changes is further reduced, and the current reference source which approximates to a zero temperature coefficient can be realized.

Owner:HI TREND TECH SHANGHAI

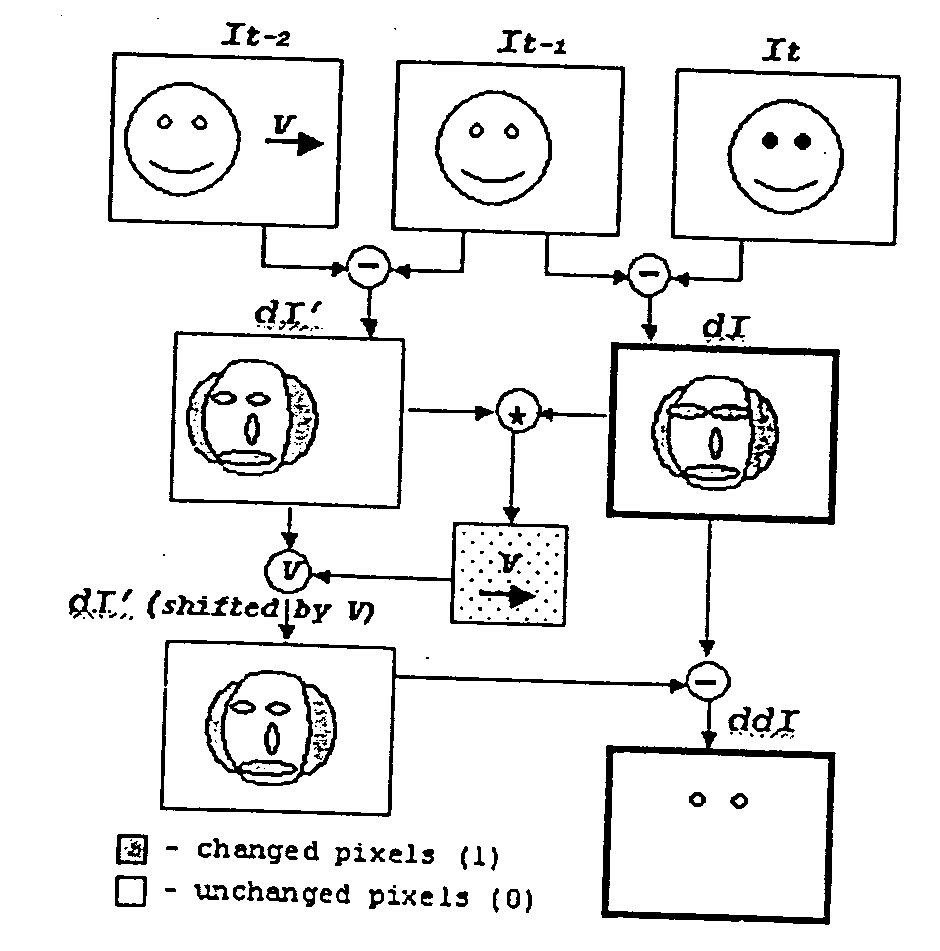

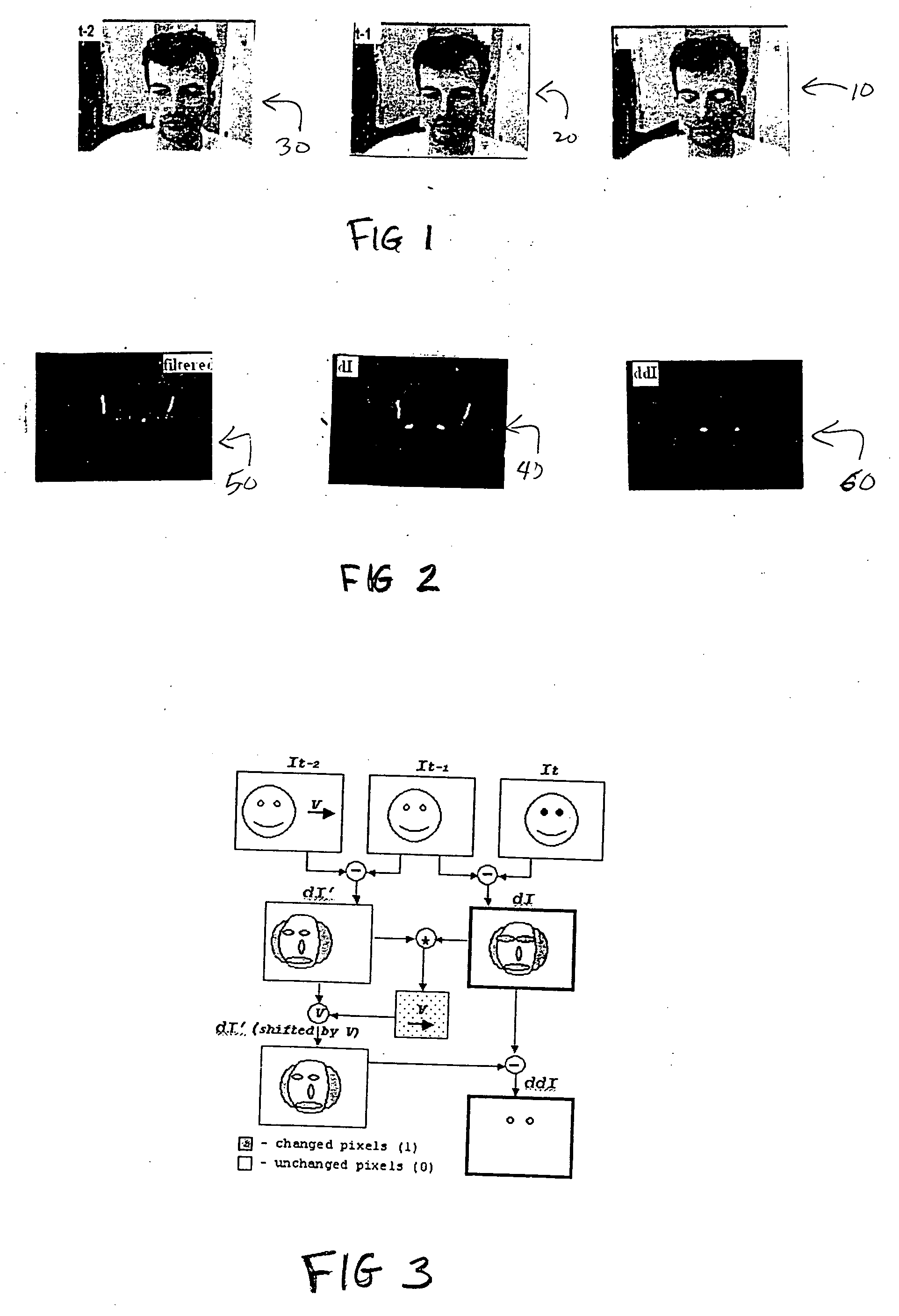

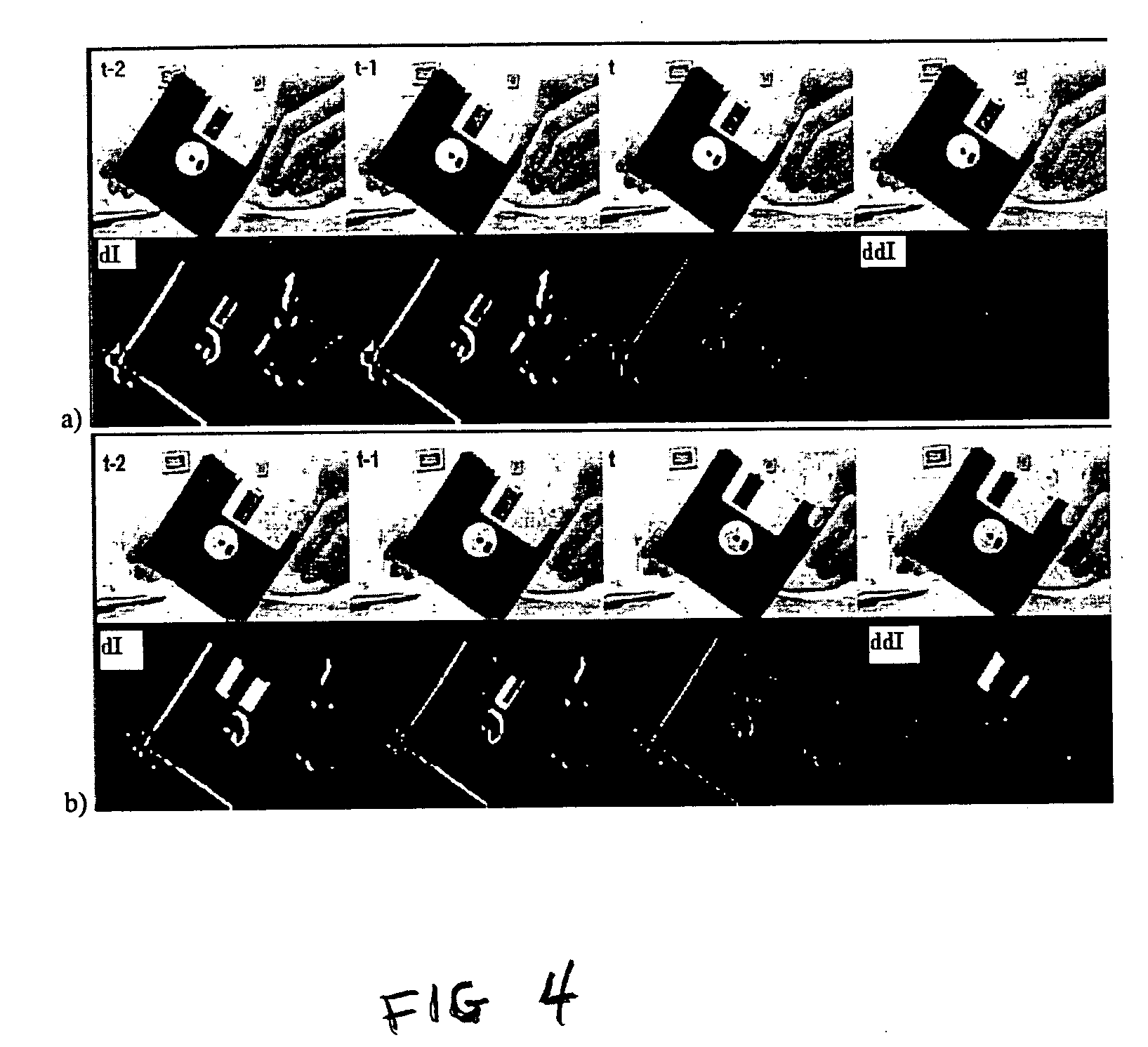

Second order change detection in video

InactiveUS20050047662A1Number of pixel which matchMaximizing numberInput/output for user-computer interactionImage analysisLinear componentIntermediate image

Methods and devices for processing captured video frames to detect specific changes observable in video using three consecutive video frames. The images in the first video frame are compared with the second frame and the images of the second frame are compared with the third frame to produce two intermediate images which show the first order change observable in video. These interim images are then analyzed. A geometric transformation is found such that when the transformation is applied to one of these intermediate images, the number of pixels which match between the interim is maximized. This geometric transformation, which may include a linear as well as a rotational component, is then applied to one of the intermediate images to result in a transformed image. The transformed image is then subtracted from the other intermediate image to arrive at an end image which shows the second order change or the change in a change observable in video. The second order change image will show only those specific pixels which have changed in the images between the three original video frames. The invention may be used to detect changes in the state of a subject's eyes. A subject's blinking can thus be used for sending binary commands to a computer remotely. In particular, a double blink, i.e.. two consecutive blinks, of a person can be used as a hand-free substitute to a clicking of a mouse.

Owner:NAT RES COUNCIL OF CANADA

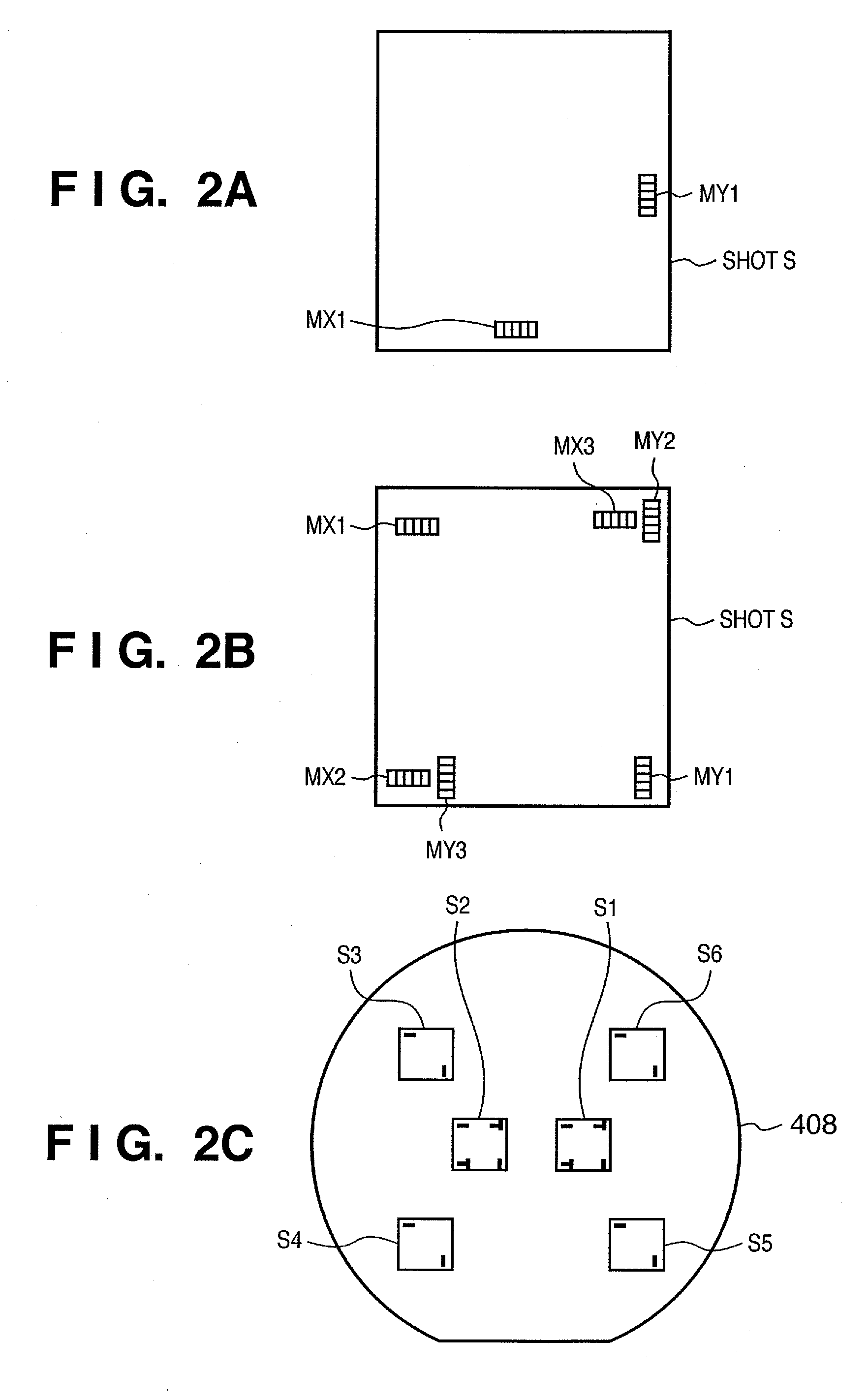

Apparatus and method for measuring at least one of arrangement and shape of shots on substrate, exposure apparatus, and device manufacturing method

InactiveUS20070133864A1Improve accuracyImprove throughputImage enhancementImage analysisLinear componentMultiple criteria

Owner:CANON KK

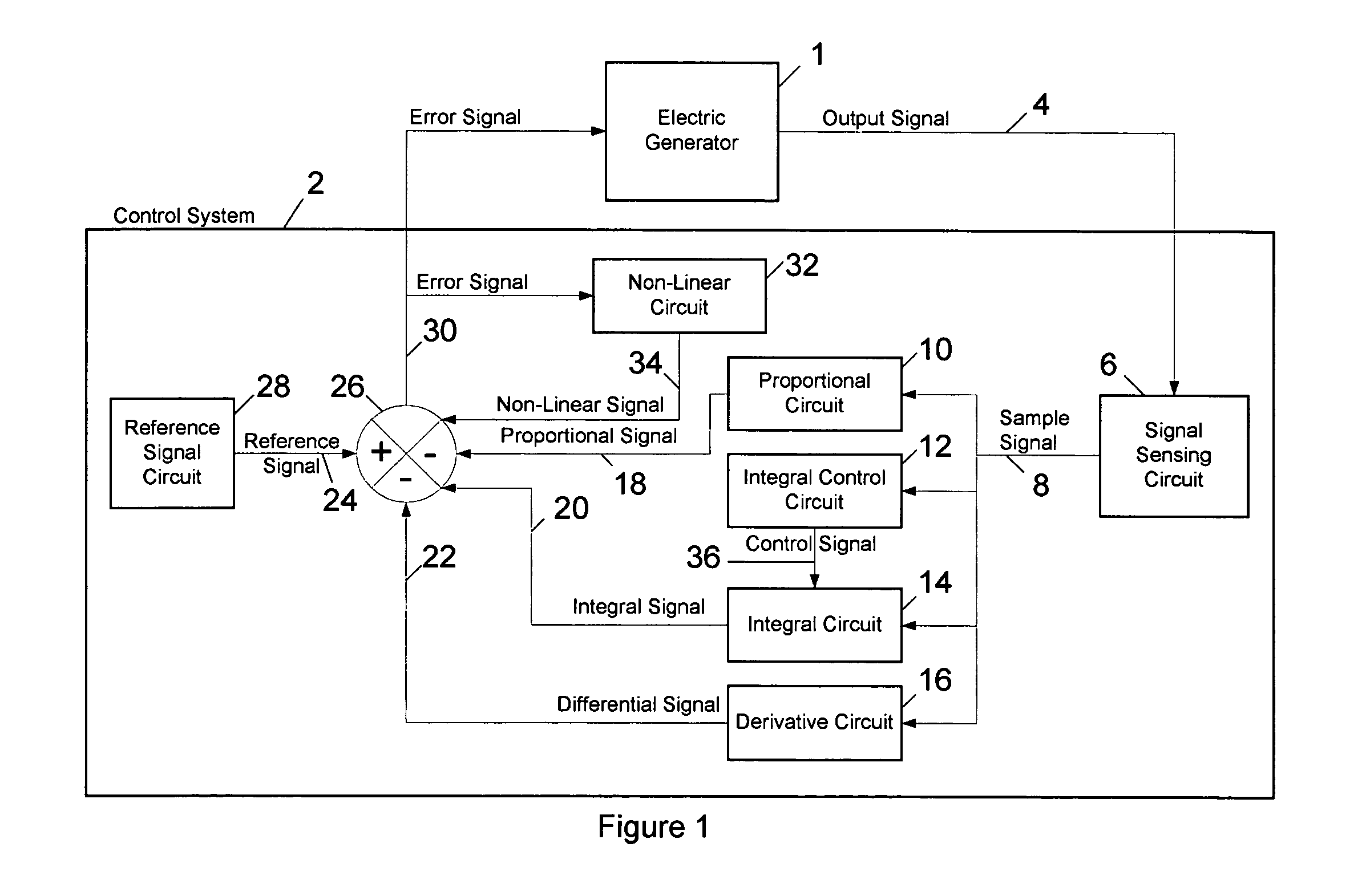

Control system for an electric machine

ActiveUS20060012344A1Conversion with intermediate conversion to dcEmergency protective circuit arrangementsLinear componentDifferential signaling

There is provided an adjustable integral component in a feedback loop of a closed loop control system. The closed loop control system controls an output signal of an electric generator. The adjustable integral component provides an integral signal. The integral signal is proportional to the output signal in a first operational mode. The integral signal is proportional to a time integral of an output signal in a second operational mode. According to another aspect of the invention there is provided a non-linear component in a feedback loop of a closed loop control system. The closed loop control system controls an output signal of an electric generator. The electric generator having non-linear characteristics. The feedback loop has an error signal, of which the output signal is responsive to. The non-linear component receives a load signal and provides a non-linear signal related to the non-linear characteristics of the electric generator. The error signal is responsive to the non-linear signal. According to another aspect of the invention, there is provided a method of controlling a system variable in a control system for an electric generator. The output signal of the electric generator is sensed and a sample signal is provided thereof. The sample signal is compared to be below a threshold value, and accordingly an adjustable impedance is adjusted to be substantially resistive. A proportional signal and integral signal that are proportional to the sample signal are provided. A time derivative is taken of the sample signal to provide a differential signal. An error signal is generated by providing a difference between a reference signal and a sum of the proportional signal, the integral signal and the differential signal. The output signal is then adjusted based on the error signal, by driving the output signal towards the set-point value. The sample signal is then compared to be above the threshold value, and accordingly the adjustable impedance is adjusted to be substantially capacitive. The integral signal now being representative of a time integral of the sample signal.

Owner:CARRIER CORP

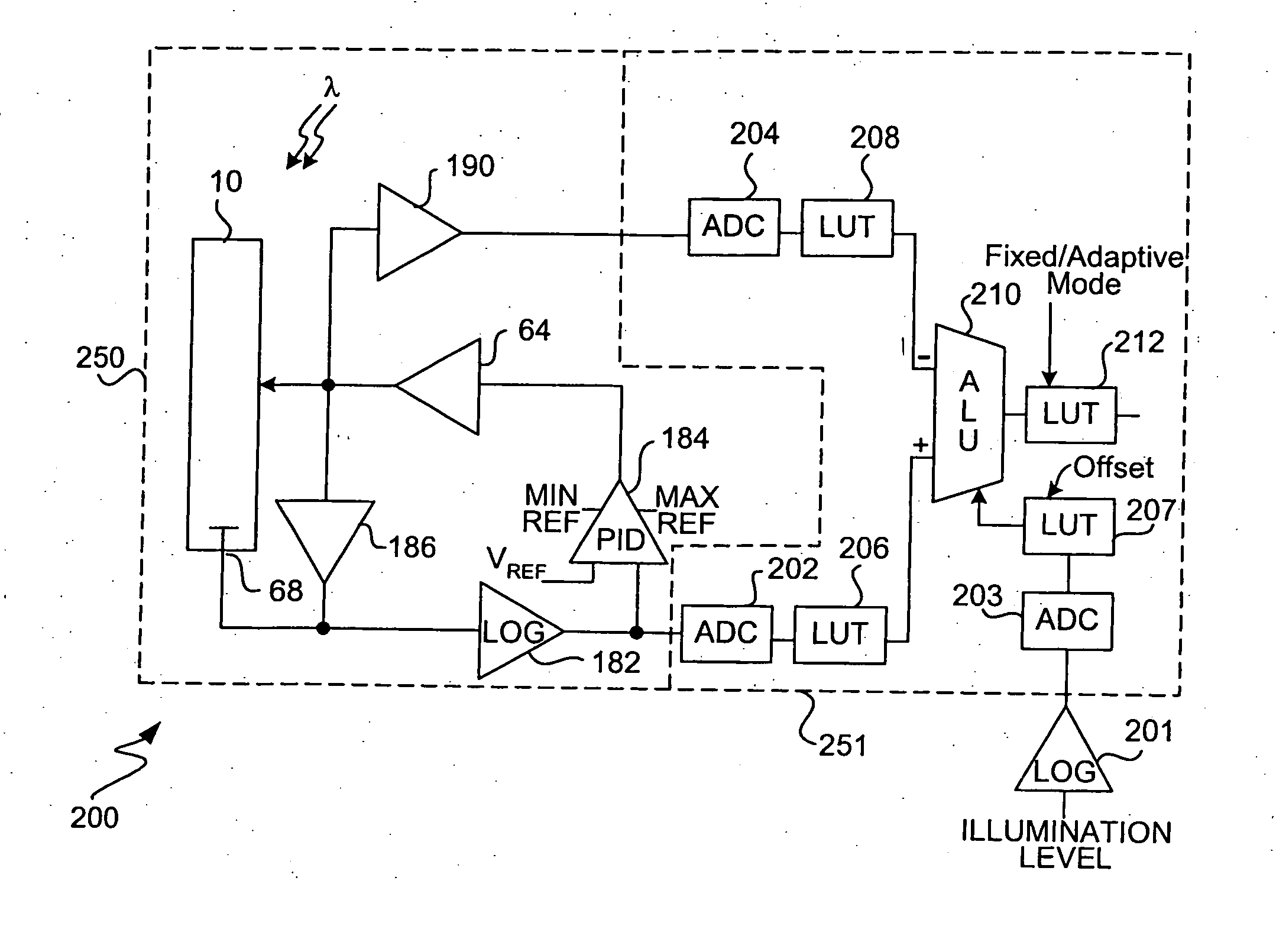

Apparatus and methods for optically inspecting a sample for anomalies

InactiveUS20050092899A1Avoid rounding errorSensor gain is not alteredScattering properties measurementsPhotoelectric discharge tubesLinear componentA d converter

Disclosed are methods and apparatus for detecting a relatively wide dynamic range of intensity values from a beam (e.g., scattered light, reflected light, or secondary electrons) originating from a sample, such as a semiconductor wafer. In other words, the inspection system provides detected output signals having wide dynamic ranges. The detected output signals may then be analyzed to determine whether defects are present on the sample. For example, the intensity values from a target die are compared to the intensity values from a corresponding portion of a reference die, where a significant intensity difference may be defined as a defect. In a specific embodiment, an inspection system for detecting defects on a sample is disclosed. The system includes a beam generator for directing an incident beam towards a sample surface and a detector positioned to detect a detected beam originating from the sample surface in response to the incident beam. The detector has a sensor for detecting the detected beam and generating a detected signal based on the detected beam and a non-linear component coupled to the sensor. The non-linear component is arranged to generate a non-linear detected signal based on the detected signal. The detector further includes a first analog-to-digital converter (ADC) coupled to the non-linear component. The first ADC is arranged to digitize the non-linear detected signal into a digitized detected signal.

Owner:KLA TENCOR TECH CORP

Radical basis function neural network predistortion method for adaptive power amplifier

InactiveCN101072220AReduce complexityImprove linearityAmplifier modifications to reduce non-linear distortionMultiple carrier systemsFrequency changerLinear component

The method includes following steps: (1) through simulated down converter, broadband multicarrier input signal forms intermediate frequency signal; (2) through simulated up converter, predistortion component is sent to power amplifier to counteract non-linear component generated by power amplifier; the said predistortion signal is controlled based on offset of error between envelope signal and digital feedback signal of reflecting linearity of transmission channel. Using scheme of self-adaptive radio nonlinear digital predistortion based on radial basic neural network, the invention reduces implementing complexity greatly, possesses features of higher linearity, and easy of implementation.

Owner:ZTE CORP

Control system for an electric machine

ActiveUS7154248B2Conversion with intermediate conversion to dcEmergency protective circuit arrangementsLinear componentDifferential signaling

There is provided an adjustable integral component in a feedback loop of a closed loop control system. The closed loop control system controls an output signal of an electric generator. The adjustable integral component provides an integral signal. The integral signal is proportional to the output signal in a first operational mode. The integral signal is proportional to a time integral of an output signal in a second operational mode. According to another aspect of the invention there is provided a non-linear component in a feedback loop of a closed loop control system. The closed loop control system controls an output signal of an electric generator. The electric generator having non-linear characteristics. The feedback loop has an error signal, of which the output signal is responsive to. The non-linear component receives a load signal and provides a non-linear signal related to the non-linear characteristics of the electric generator. The error signal is responsive to the non-linear signal. According to another aspect of the invention, there is provided a method of controlling a system variable in a control system for an electric generator. The output signal of the electric generator is sensed and a sample signal is provided thereof. The sample signal is compared to be below a threshold value, and accordingly an adjustable impedance is adjusted to be substantially resistive. A proportional signal and integral signal that are proportional to the sample signal are provided. A time derivative is taken of the sample signal to provide a differential signal. An error signal is generated by providing a difference between a reference signal and a sum of the proportional signal, the integral signal and the differential signal. The output signal is then adjusted based on the error signal, by driving the output signal towards the set-point value. The sample signal is then compared to be above the threshold value, and accordingly the adjustable impedance is adjusted to be substantially capacitive. The integral signal now being representative of a time integral of the sample signal.

Owner:CARRIER CORP

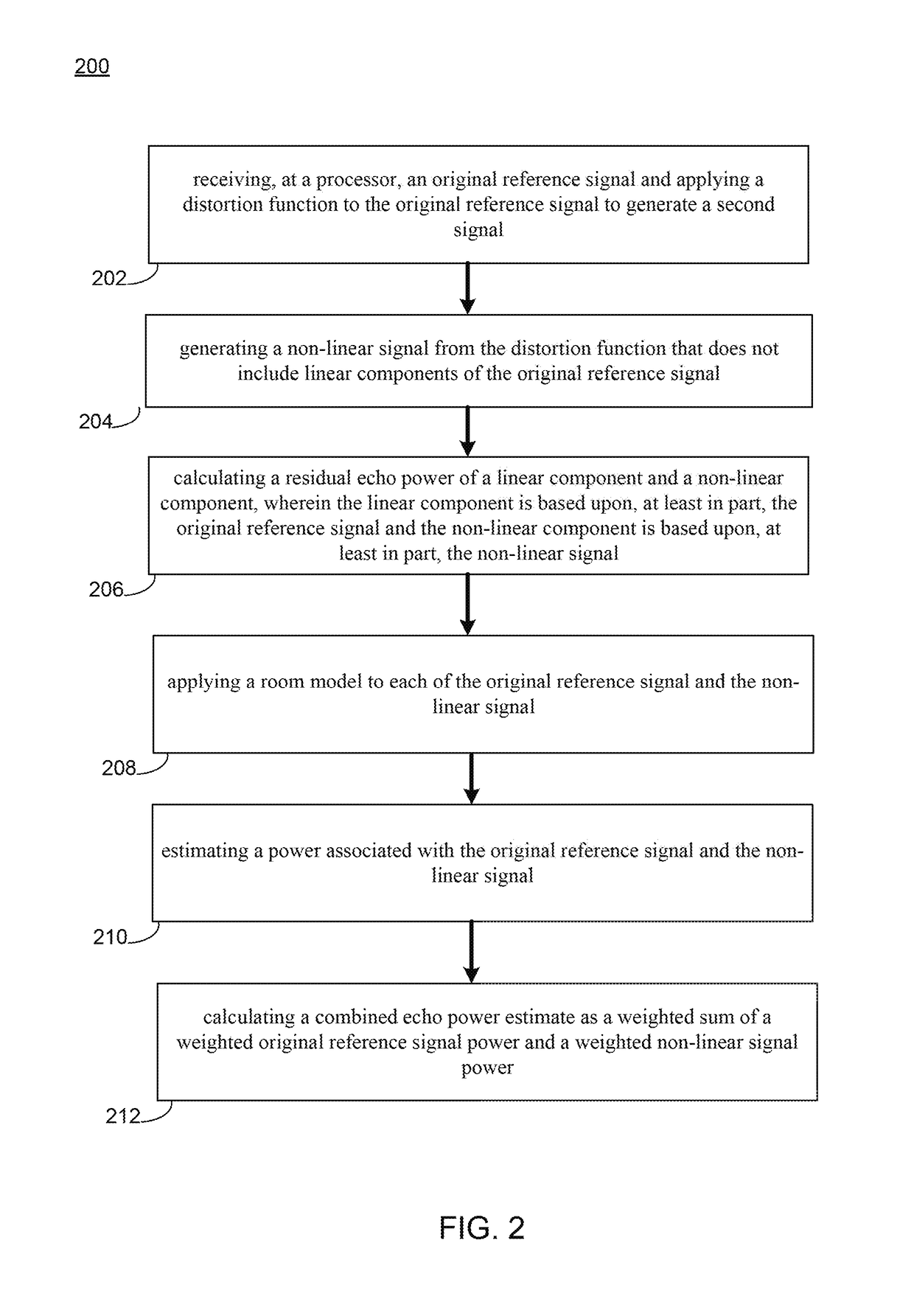

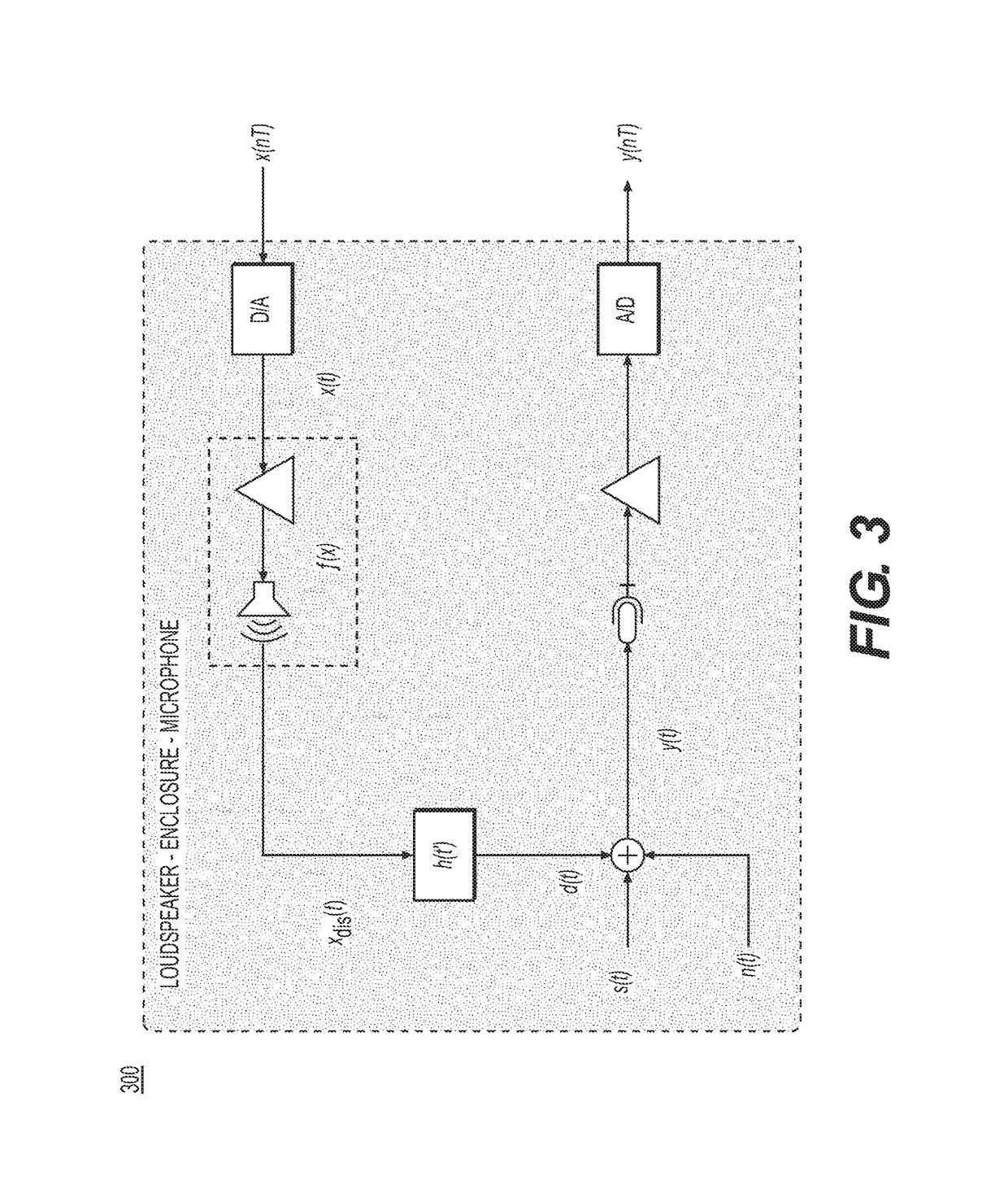

System and method for suppression of non-linear acoustic echoes

ActiveUS20180367674A1Two-way loud-speaking telephone systemsSpeech analysisLinear componentDistortion function

A method for residual echo suppression is provided. Embodiments may include receiving an original reference signal and applying a distortion function to the original reference signal to generate a second signal. Embodiments may include generating a non-linear signal from the distortion function that does not include linear components of the original reference signal. Embodiments may also include calculating a residual echo power of a linear component and a non-linear component, wherein the linear component is based upon the original reference signal and the non-linear component is based upon the non-linear signal. Embodiments may further include applying a room model to each of the original reference signal and the non-linear signal and estimating a power associated with the original reference signal and the non-linear signal. Embodiments may include calculating a combined echo power estimate as a weighted sum of a weighted original reference signal power and a weighted non-linear signal power.

Owner:CERENCE OPERATING CO

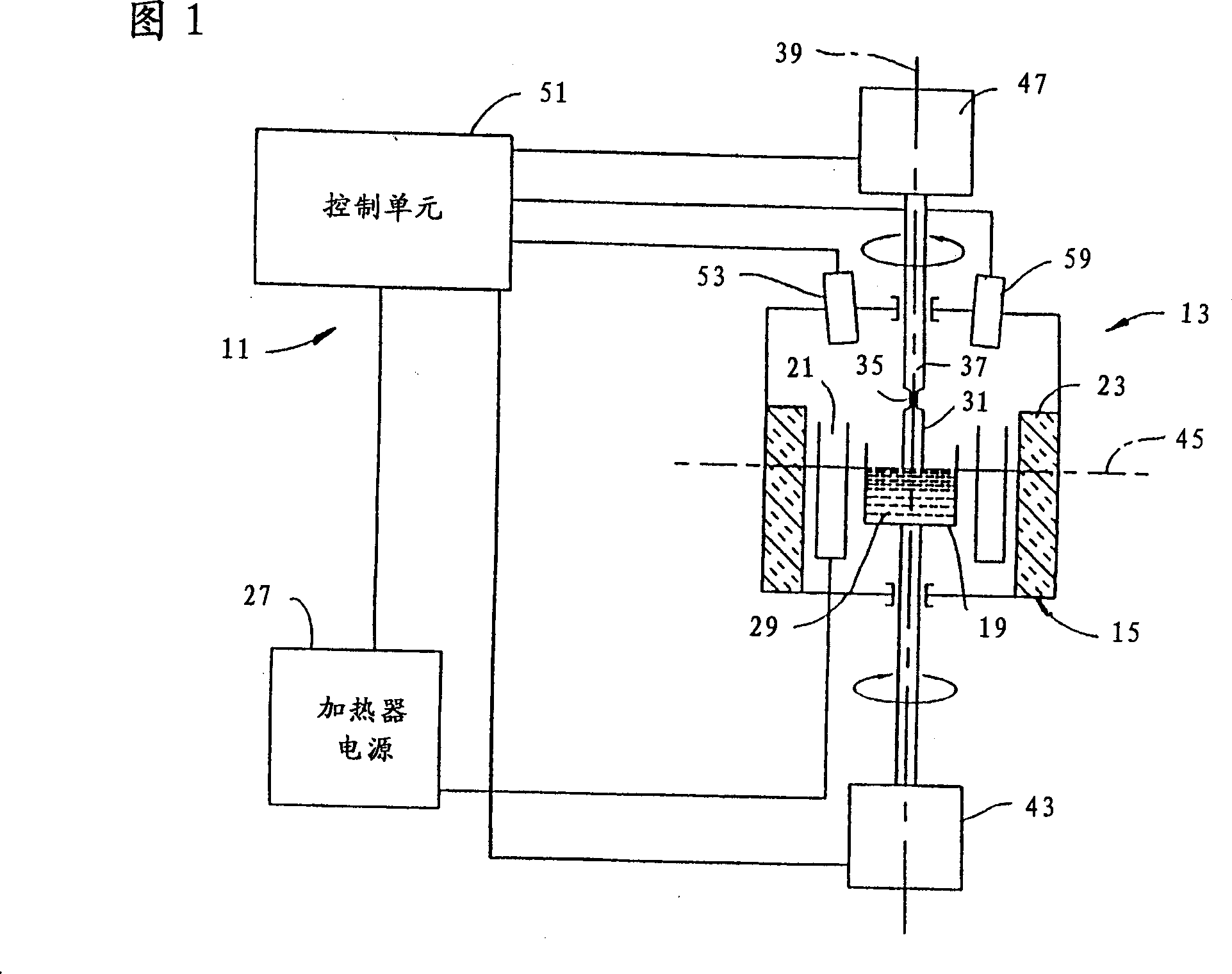

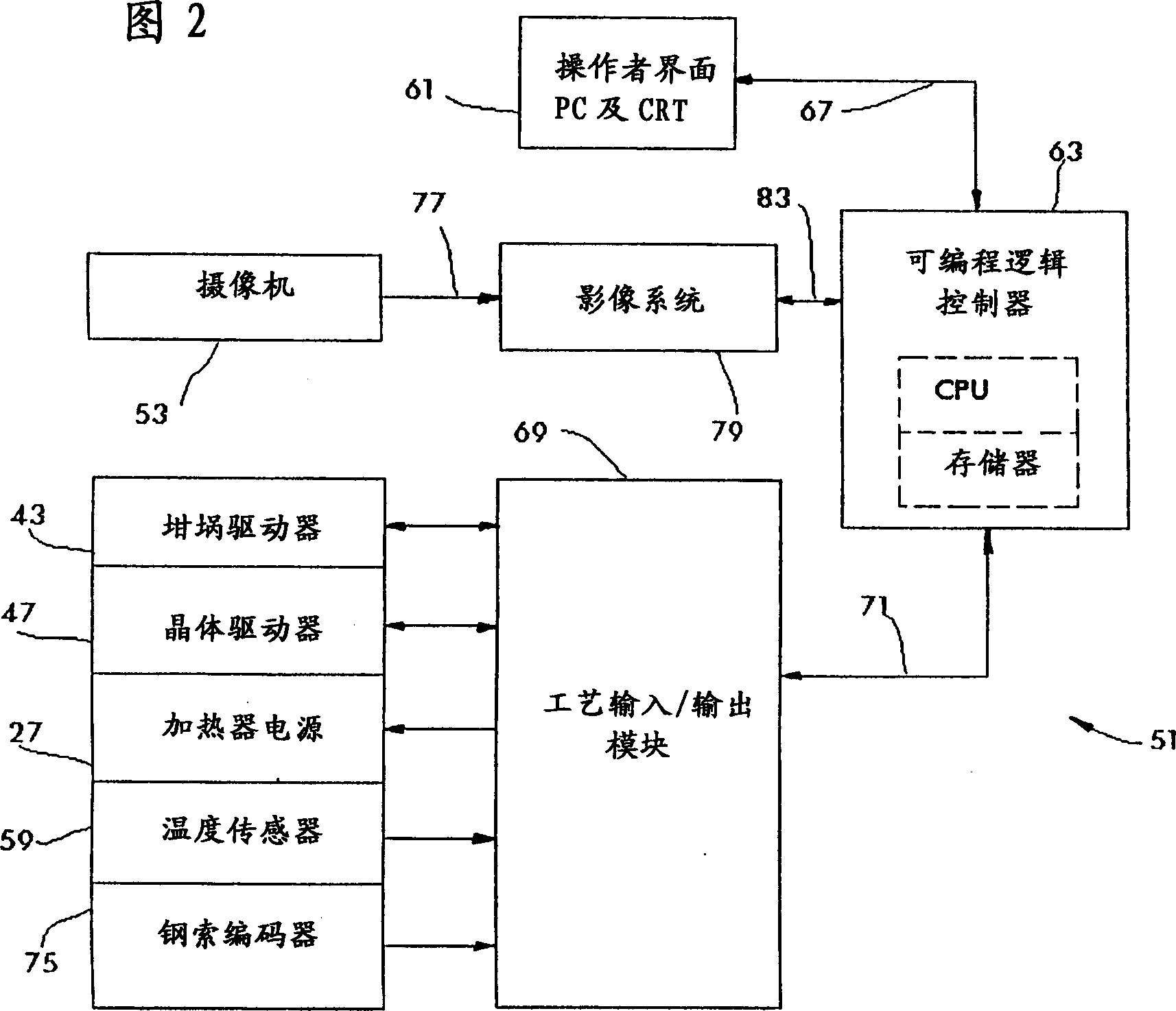

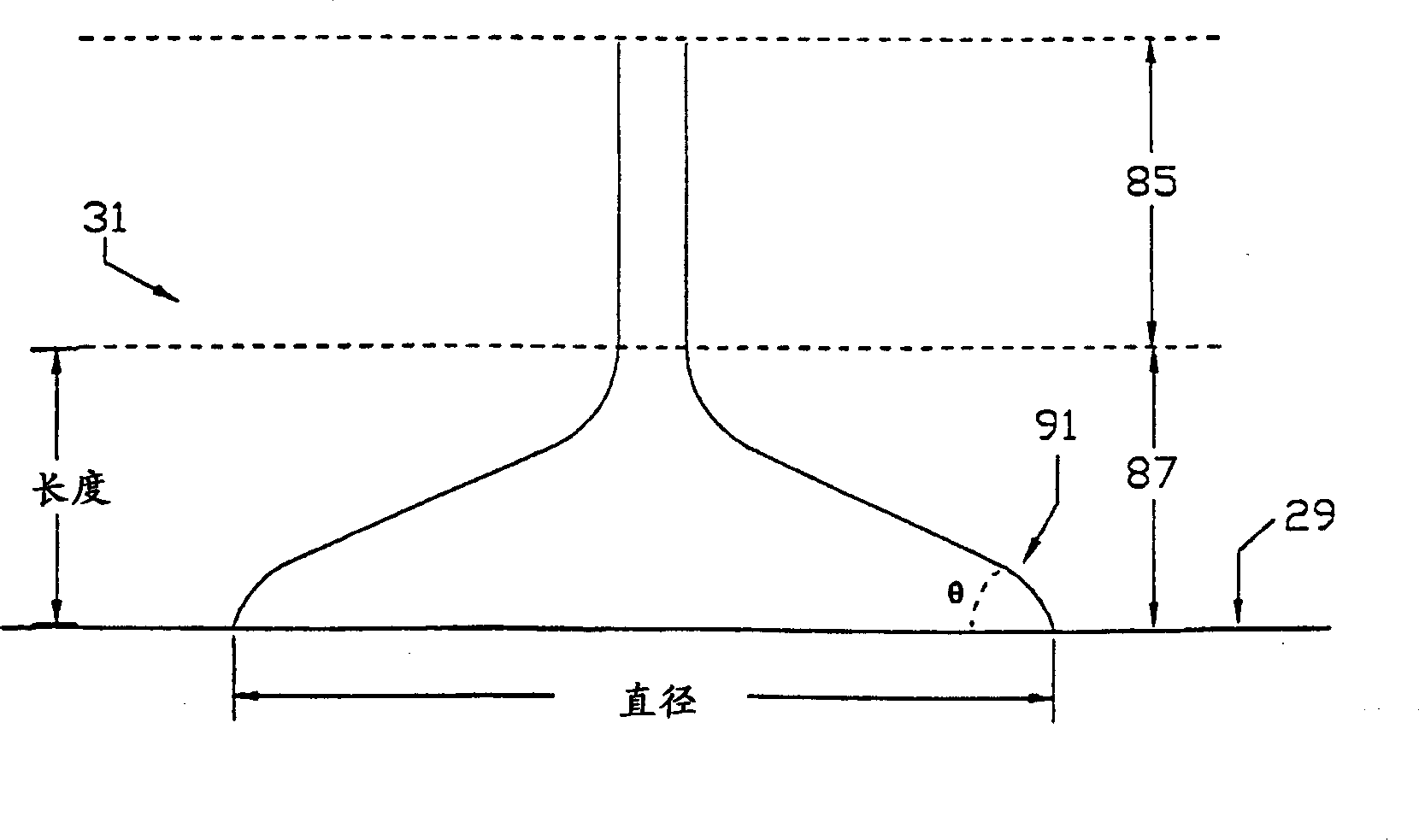

Method and system of controlling taper growth in a semiconductor crystal growth process

A method and system for controlling growth of a taper portion of a semiconductor single crystal based on the slope of the taper. A crystal drive unit pulls the growing crystal from a melt at a target pull rate that substantially follows an initial velocity profile for growing the taper. A controller calculates a taper slope measurement as a function of a change in crystal diameter relative to a change in crystal length. The controller then generates an error signal as a function of the difference between the taper slope measurement and a target taper slope and provides a pull rate correction to the crystal drive unit as a function of the error signal. In turn, the crystal drive unit adjusts the pull rate according to the pull rate correction to reduce the difference between the taper slope measurement and the target taper slope. The target taper slope is defined by a function having a generally exponential component and a generally linear component.

Owner:MEMC ELECTONIC MATERIALS INC

Methods and devices for position determination using regional minimal residual estimation

ActiveUS20130244692A1Improve performanceEfficient solutionPosition fixationLocation information based serviceLinear componentAlgorithm

A computer-implemented method and device for determining a user position, implemented in a user handheld computing device programmed to perform the method. The method includes solving for the position of a user based on ranges, which are computed by estimating power loss between a user and a number of Wi-Fi Access Points. Embodiments of the present invention includes a method that is designed to accommodate the non-linear nature of solving a position solution using power estimates. This method includes solving a two-dimensional solution grid of position residuals, or magnitudes of error between true and computed ranges, using signal strength measurements from multiple Wi-Fi access points in order to determine local minima of the position residuals indicating a user position. Standard approaches in the area such as a Least Squares Solution overly simplify the non-linear components resulting in poor performance.

Owner:INPIXON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com