Cooked-corn threshing device and application method thereof

A corn thresher and tailstock technology, applied in metal processing, etc., can solve problems affecting threshing quality, low shaving efficiency, easy to dirty hands and clothes, etc., to reduce walking resistance, reduce threshing intensity, and high threshing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

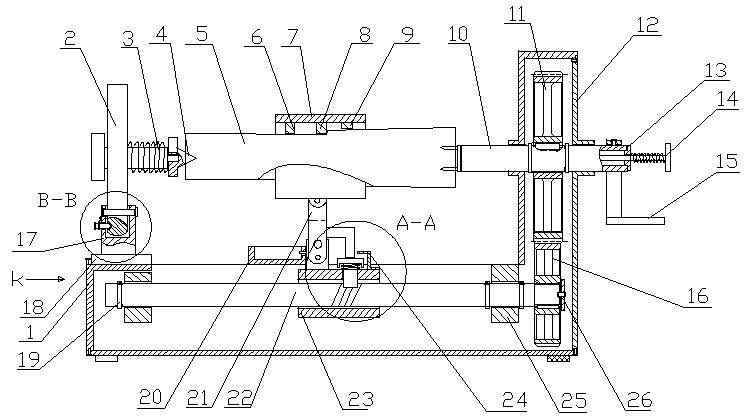

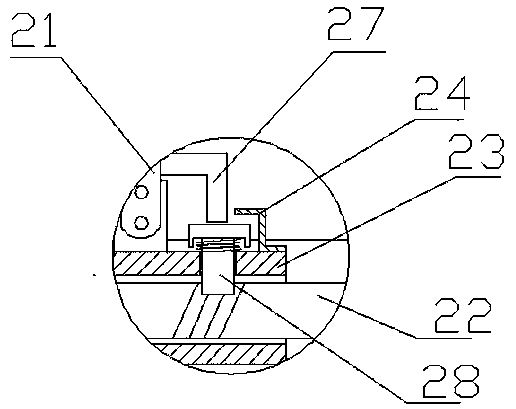

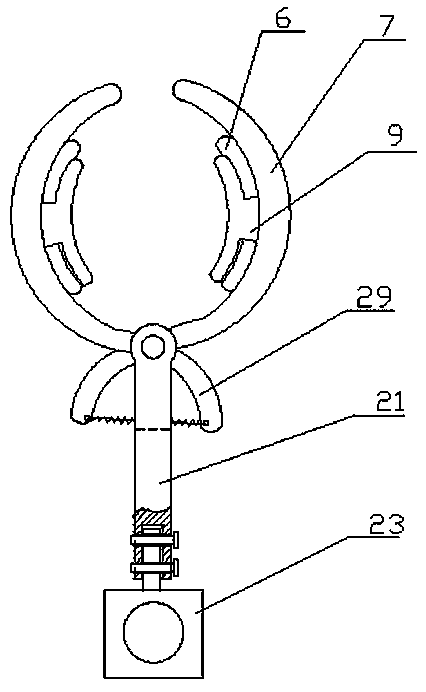

[0033] refer to Figure 1-11, a cooked corn thresher, comprising a base 1, the base 1 is provided with a cavity, the upper surface of the base 1 is provided with a bar-shaped groove 37 connected with the cavity of the base, and one end of the base 1 is provided with a tailstock 2, The tailstock 2 is equipped with a limit push rod 3 that can move left and right, and a rotatable top cone 4 is inserted into the front end of the limit push rod 3. The other end of the base 1 is provided with a machine head 12, and the machine head is provided with intermeshing Fork lever gear 11 and screw gear 16, the top of machine head 12 is rotated through sliding sleeve and is provided with a fork lever 10, and the end of described fork lever 10 stretching out machine head 12 is provided with front fork 35, and the other end of fork lever is provided with rotating handle 15. The fork gear 11 is fixedly mounted on the fork rod 10. A propulsion screw 22 is arranged horizontally in the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com