Ridge and platform subsoiling and stubble formation ridge soil preparation machine

A technology of soil preparation machine and ridge platform, which is applied to agricultural machinery and implements, agriculture, shovels, etc., can solve the problems of increased failure rate of machinery and implements, decreased operation quality and efficiency, and increased walking resistance of the unit, and achieves remarkable technical effects. The effect of reducing walking resistance and eliminating blockage failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

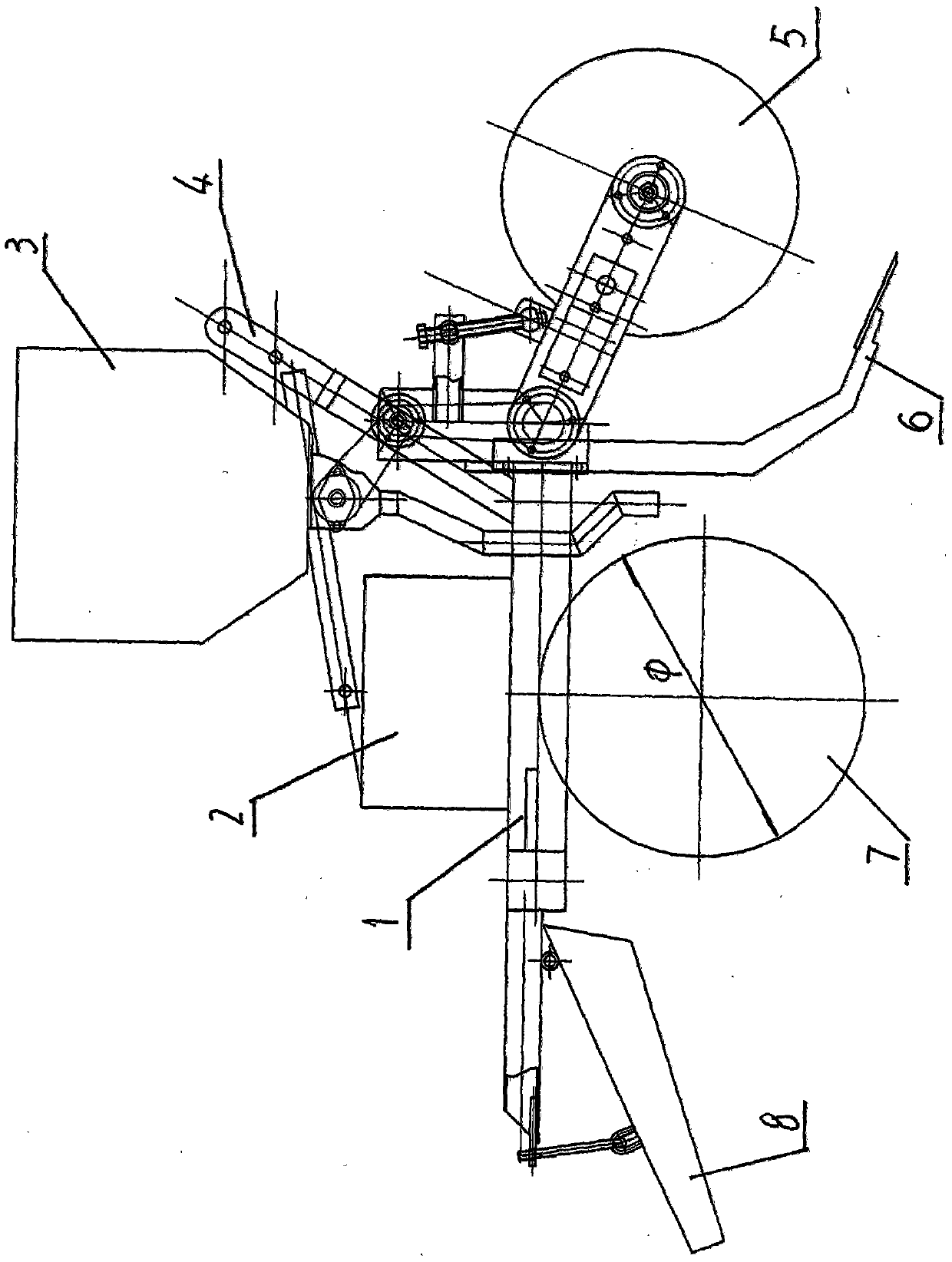

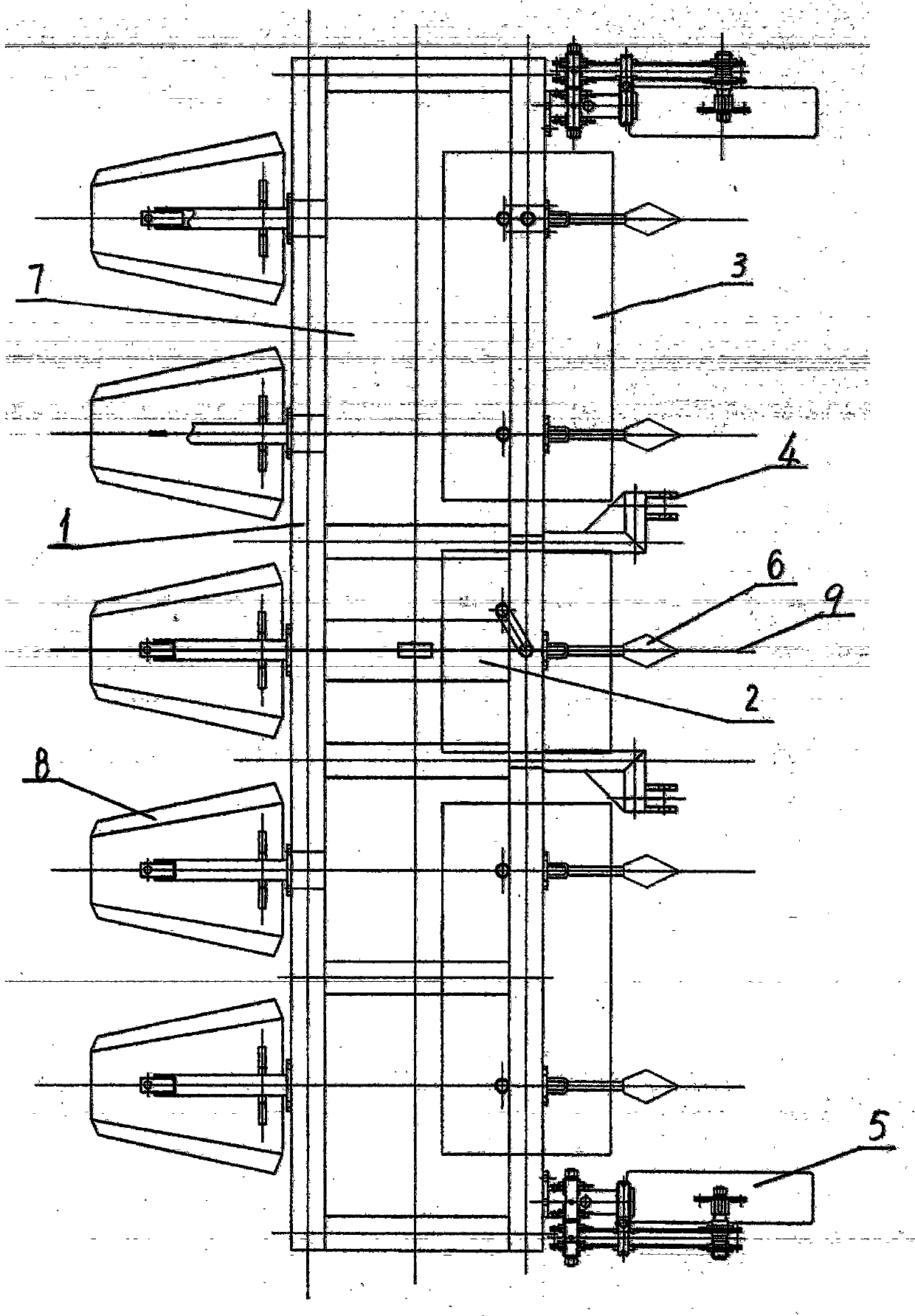

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A ridge platform deep loosening and stubble removal machine for ridge formation and soil preparation includes a frame assembly 1 and a variable speed transmission box 2 mounted on the frame assembly 1, a fertilizer box 3, a three-point suspension frame assembly 4, ground wheels 5, and a The recommended cutter shaft assembly 7 and the ridge forming soil collector 8, the speed change transmission box 2 is connected with the recommended cutter shaft assembly 7, and is located in front of the stubble cutter shaft assembly 7 on the front end of the frame assembly 1 The side part is equipped with a ridge platform subsoiling shovel assembly 6, the longitudinal centerline of the ridge platform subsoiling shovel assembly 6 coincides with the corresponding ridge platform longitudinal centerline 9, and the outer edge of the ridge platform subsoiling shovel assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com