Feed hopper of novel corn thresher

A thresher and feeding hopper technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of batch feeding, low threshing efficiency, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

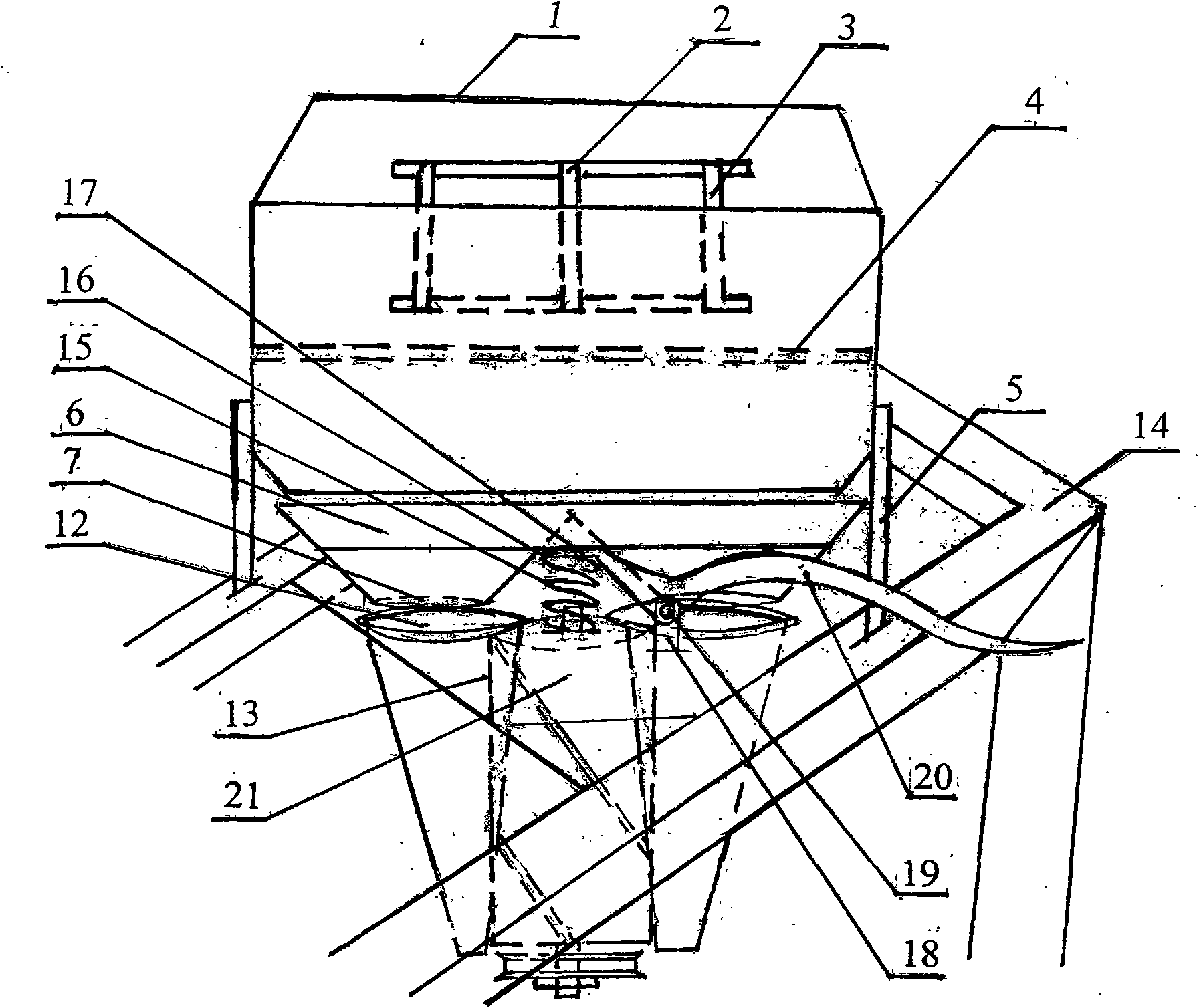

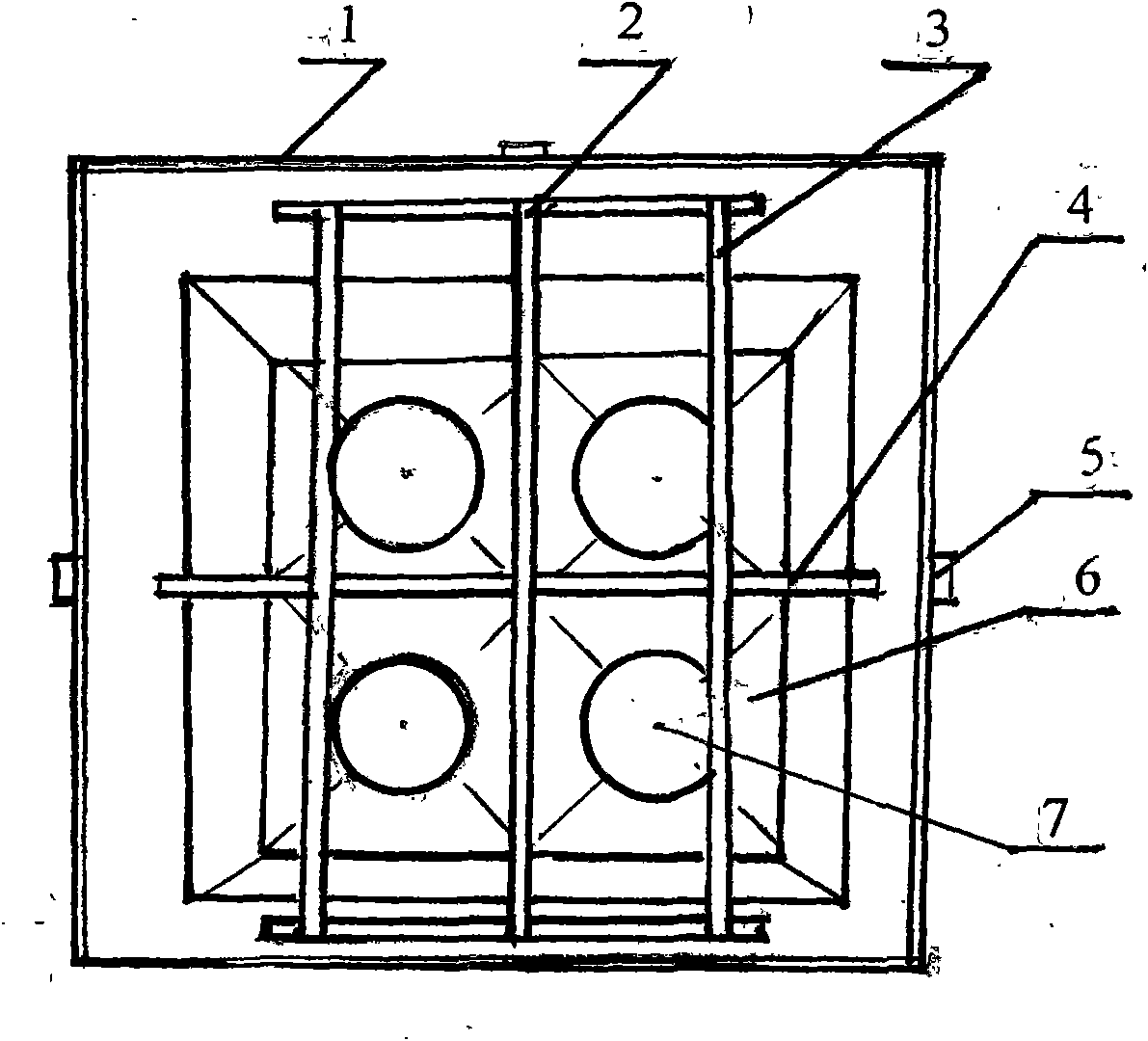

[0014] Feeding hopper of vertical corn thresher

[0015] Barrier screens 2 are arranged on the upper layer in the feed bucket frame 1, and there is a certain distance between each barrier bar 3 of the barrier screens 2. The middle layer in the feed bucket frame 1 is arranged with a crossbar 4, and the crossbar 4 is placed in the middle, and crosses with the upper fence sieve bar 3 in the shape of a "cross" when viewed from above. On the lower floor of the feed hopper frame 1, set up the corn cob outlet, namely the discharge hopper 6. The discharge hopper 6 is the number of the threshing pipes 12 of the corn threshing unit, and separates one or more threshing pipes from the corn threshing unit with a partition plate. 12 corresponding funnel-shaped outlets. There is crank 20 below the discharge hopper 6, and spring 15 is arranged below the front end of crank 20. Spring 15 and crank support block 18 are fixed on the frame plate 21. The handle 20 is movably connected with the cr...

Embodiment 2

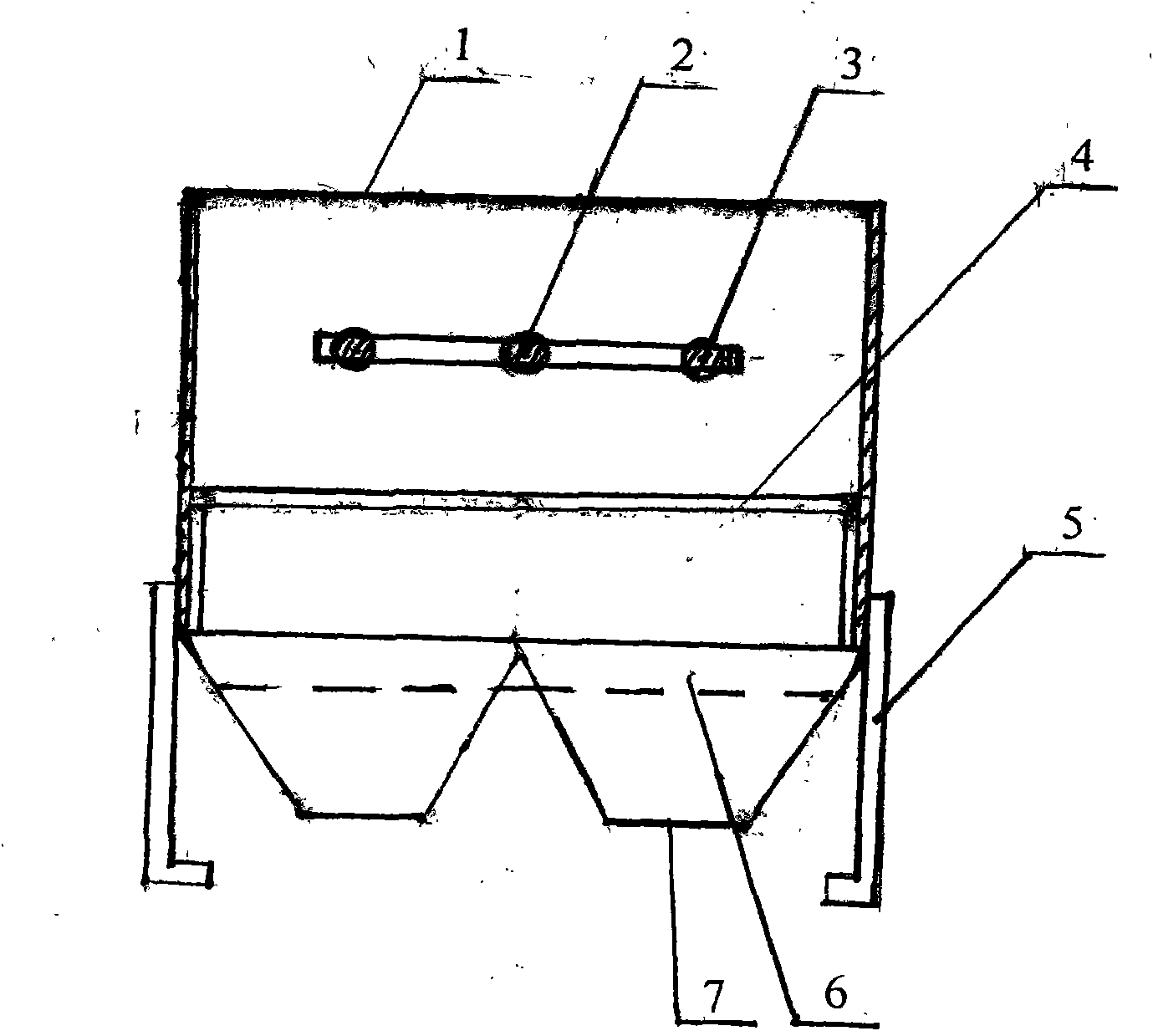

[0017] Feed hopper of horizontal corn thresher

[0018] The feed hopper of the horizontal corn thresher is different from the feed hopper of the vertical corn thresher in that the cross bar 4 in the middle layer of the feed hopper of the vertical corn thresher is replaced with a flat funnel 8, and one side of the flat funnel has an elbow 9. There is a discharge trough 10 set up corresponding to the threshing pipe of the corn thresher under the flat funnel 8 . The bottom floor 11 of the discharge chute 10 has a certain inclination. After the corn cobs are put into the feed hopper frame 1, they fall through the fence screen 2 in the feed hopper frame 1, and then enter the flat funnel 8, the flat funnel elbow 9 blocks the corn cobs falling from the top and cannot fall vertically into the discharge chute 10. Do not allow a large amount of corn cobs to fall directly into the discharge chute 10 to prevent the discharge chute 10 from being blocked, so as to ensure that the corn cobs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com