Multi-tube corn thresher

A thresher, corn technology, applied in the direction of threshing equipment, agricultural machinery and implements, applications, etc., to achieve the effect of improving threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

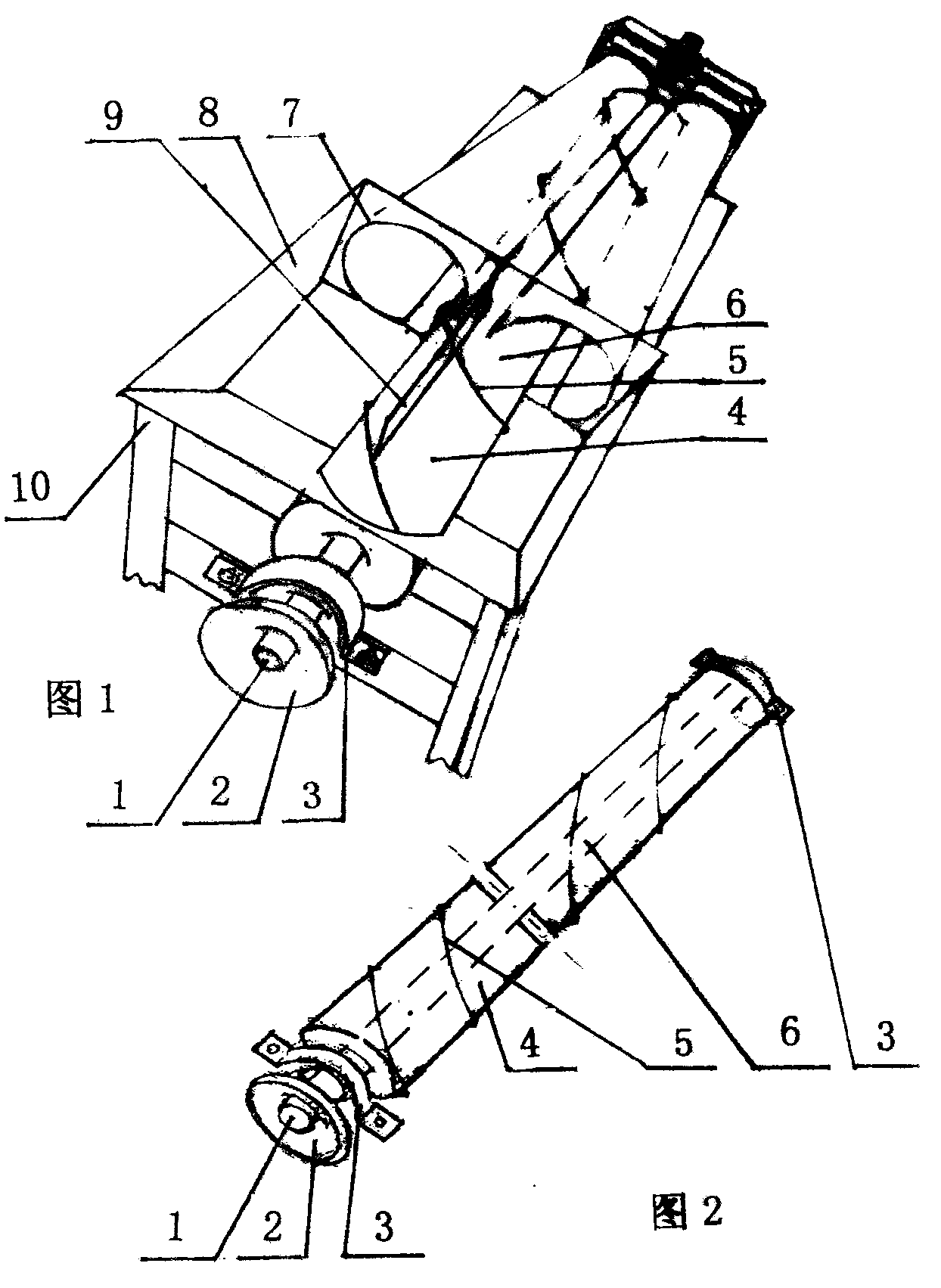

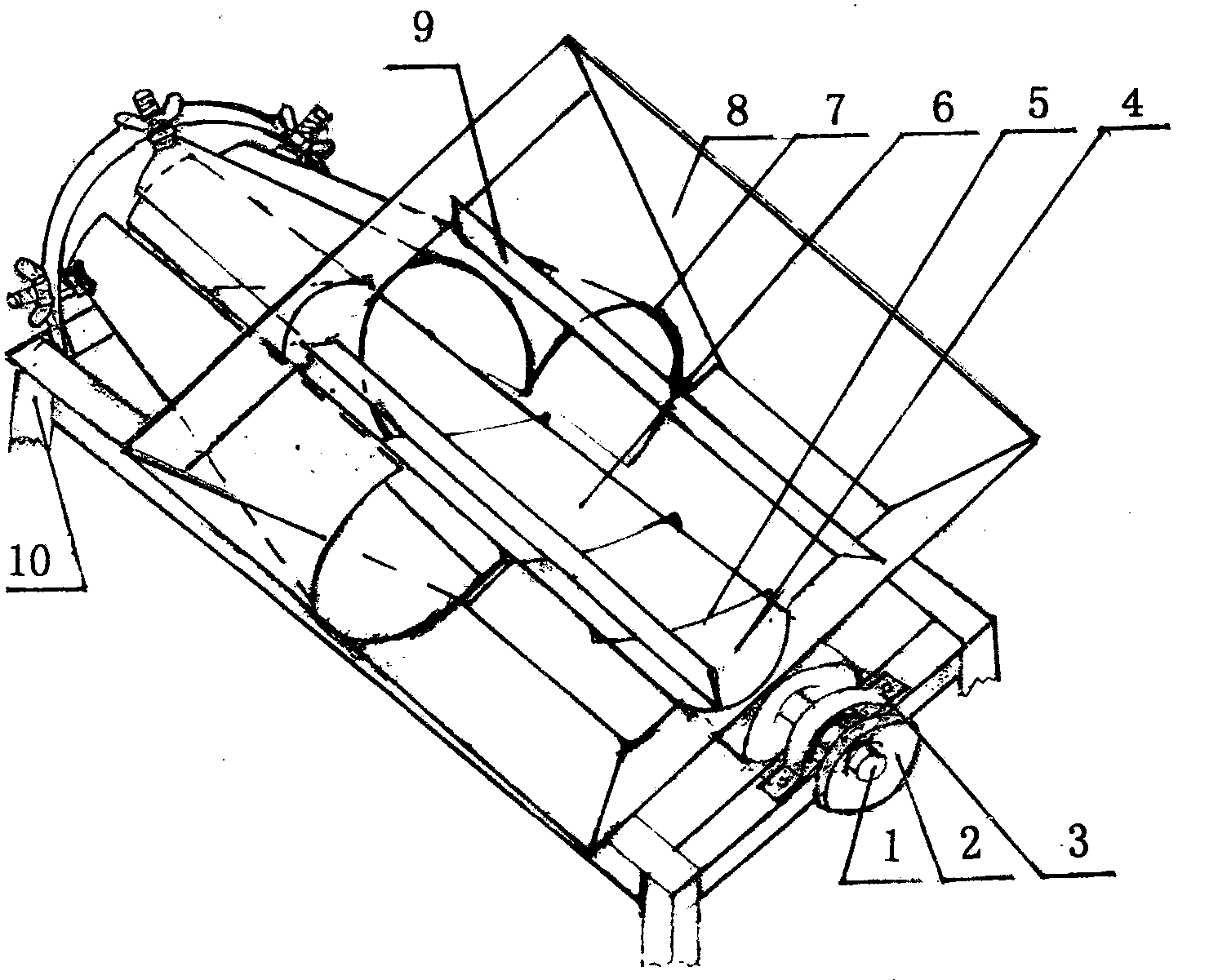

[0018] Horizontal multi-tube corn thresher

[0019] Such as Figure 1-5 As shown, the main shaft (1) is divided into two sections, the advancing device (4) is fixed on the front section of the main shaft (1), the threshing cylinder (6) is fixed on the rear section of the main shaft (1), and the advancing device (4) is A cylinder, the surface of the advancing device (4) and the threshing cylinder (6) are fixed with spiral ribs (5), the main shaft (1) passes through the advancing device (4), and the two ends of the main shaft (1) pass through the bearing seat (3) Installed on the frame (10), the pulley pulley (2) is installed at the front end of the main shaft (1), and the feeding hopper (8) is installed on the top of the advancing device (4), and the feeding hopper (8) and The position that the threshing concave plate (7) inlet is connected, the fixed partition plate (9) between each threshing concave plate (7) inlet, and the top of the threshing cylinder (6) is equipped with ...

Embodiment 2

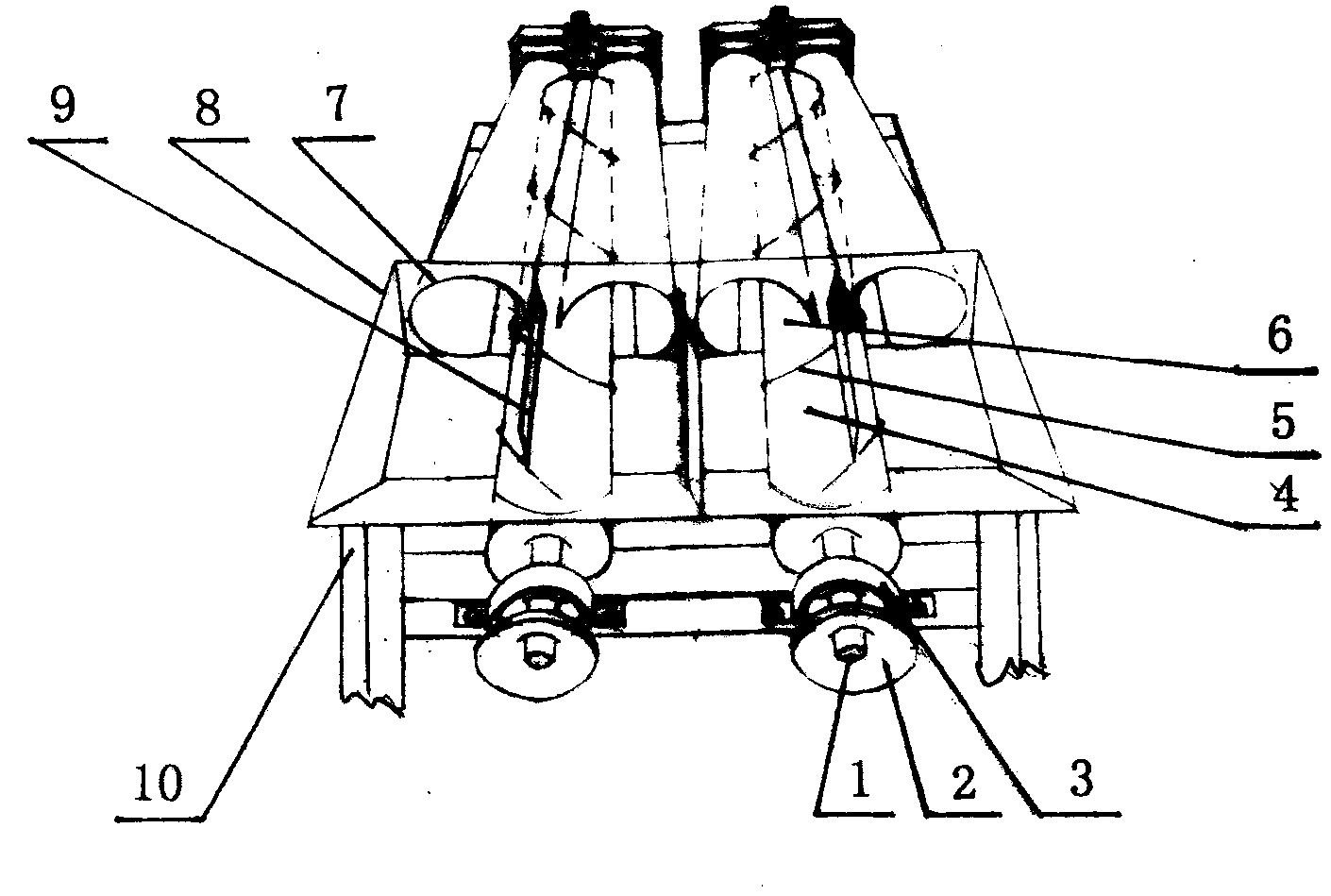

[0021] Vertical multi-tube corn thresher

[0022] Such as Figure 6-8 As shown, the difference from the horizontal multi-tube corn thresher is that the bearing seat (3) used to connect one end of the main shaft (1) of the fixed advancing device (4) and the threshing drum (6) is installed on the advancing device (4) and the threshing drum (6), the main shaft (1) is vertically installed and fixed on the frame (10) through the support of the bearing seat (3), and the drum pulley (2) is installed on the lowermost end of the main shaft (1). Four threshing concave plates (7) are installed around the threshing drum (6) to form a vertical four-pipe corn thresher, which is doubled and combined to make a vertical eight-pipe corn thresher or a vertical multi-pipe corn thresher. Tube corn thresher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com