Grain threshing separation device

A technology for threshing and separating grains, which is applied in threshing equipment, applications, agricultural machinery and implements, etc. It can solve problems such as excessive grain threshing, loss of grass discharge entrainment, poor effect of grain combing and brushing, etc., to reduce frictional resistance and increase threshing speed , The effect of small entrainment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

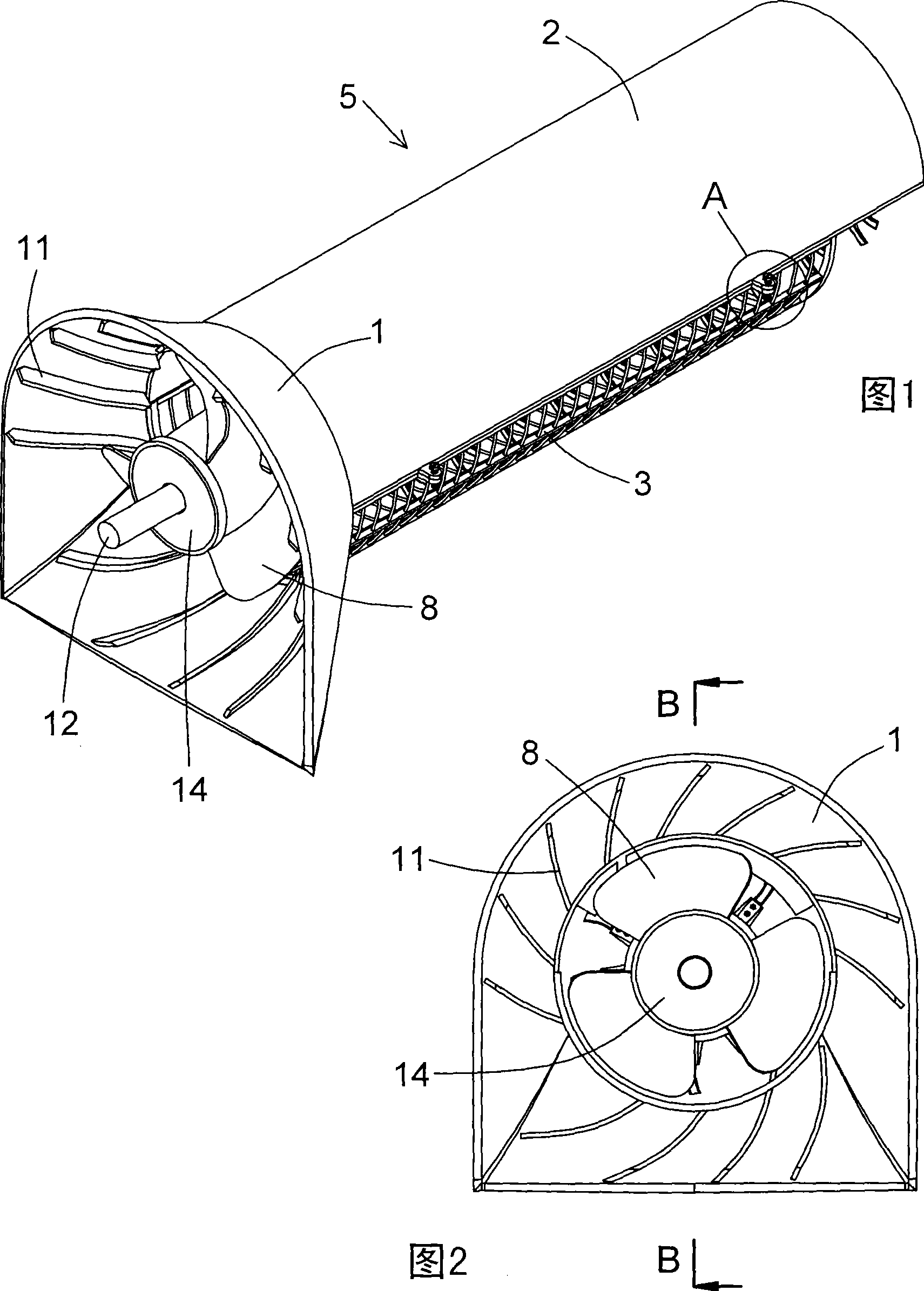

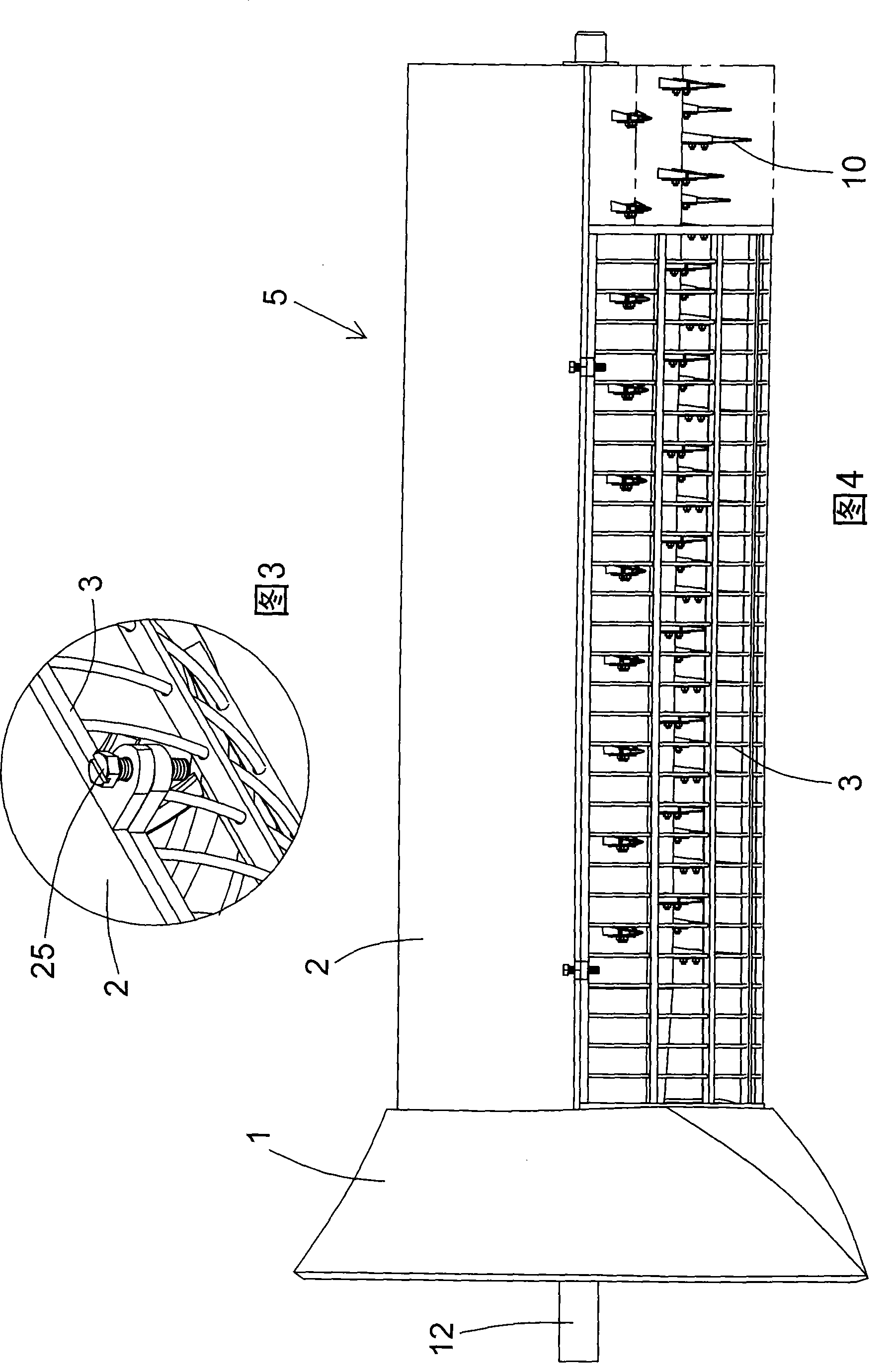

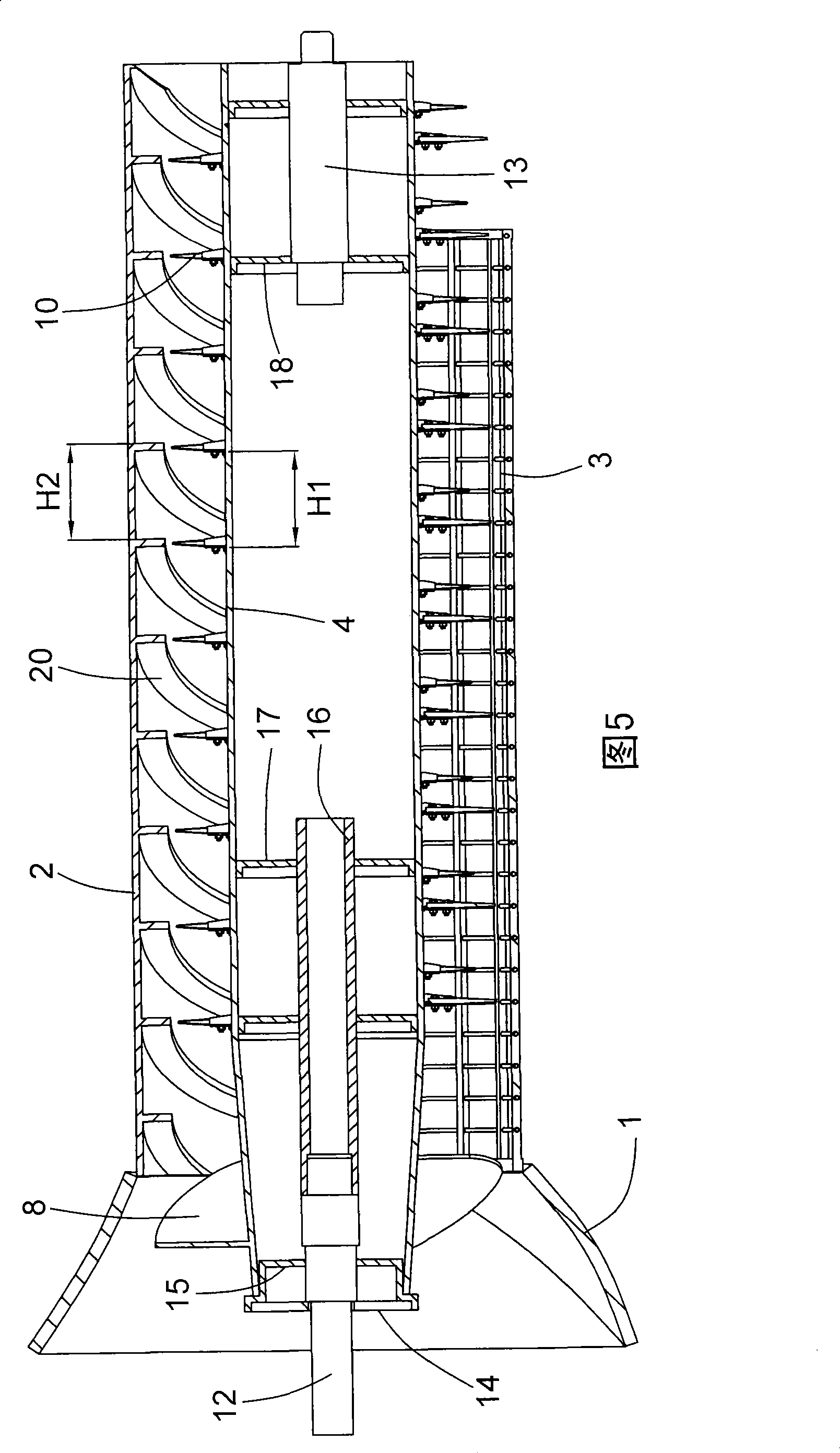

[0030] Label in the figure

[0031] 1 feed port 2 upper cover 3 concave screen 4 drum

[0032] 5 Threshing chamber 6 Front cylinder 7 Rear cylinder 8 Blades

[0033] 9 Threshing tooth seat 10 Threshing tooth 11 Curved material guide plate

[0034] 12 Front-end shaft head 13 Rear-end shaft head 14 Positioning plate 15 Coupling plate

[0035] 16 Bushing 17 Rib 18 Rib 19 Bolt

[0036] 20 Curved deflector 21 Skeleton 22 Steel wire 23 End plate

[0037] 24 Web 25 Adjusting bolt 26 Bolt 27 Nut

[0038] 28 Left half hinge seat 29 Right half hinge seat 30 Pin shaft 31 Conveying channel

[0039] Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7 and Fig. 8, the present invention is a kind of grain threshing and separating device, which is composed of feed port 1, upper cover 2, concave plate sieve 3 , drum 4, the upper cover 2 is semi-cylindrical, the concave screen 3 is an inverted semi-cylindrical, the upper cover 2 and the concave screen 3 are docked to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com