Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce forming cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

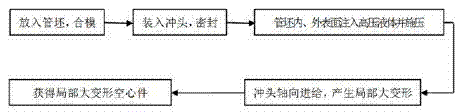

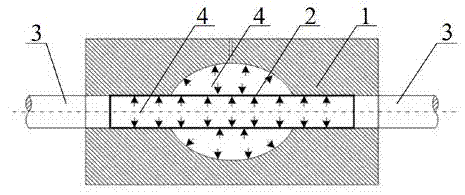

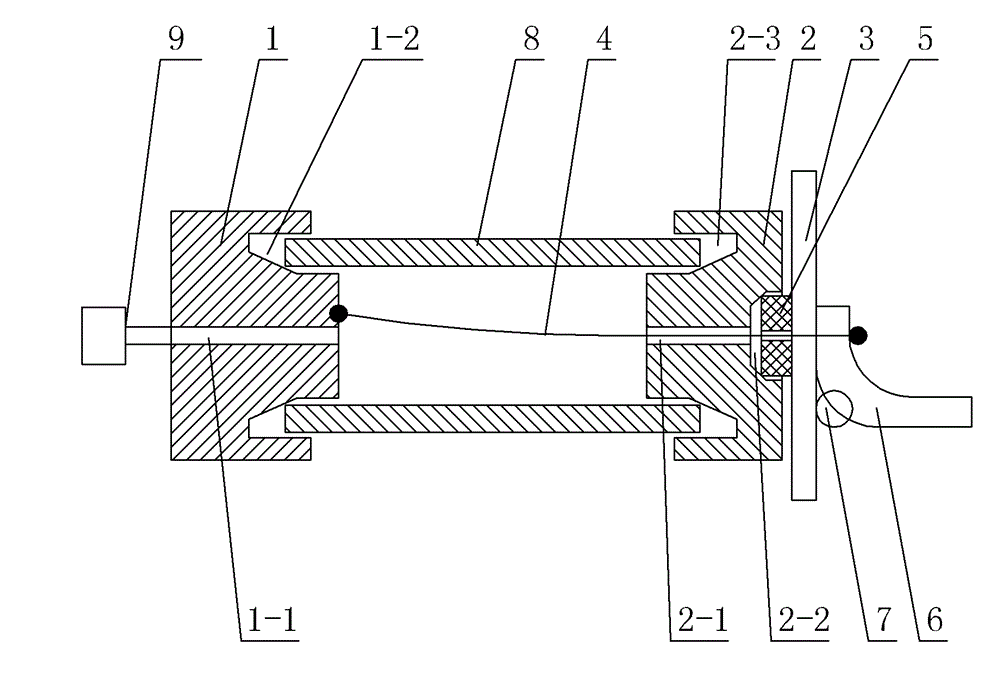

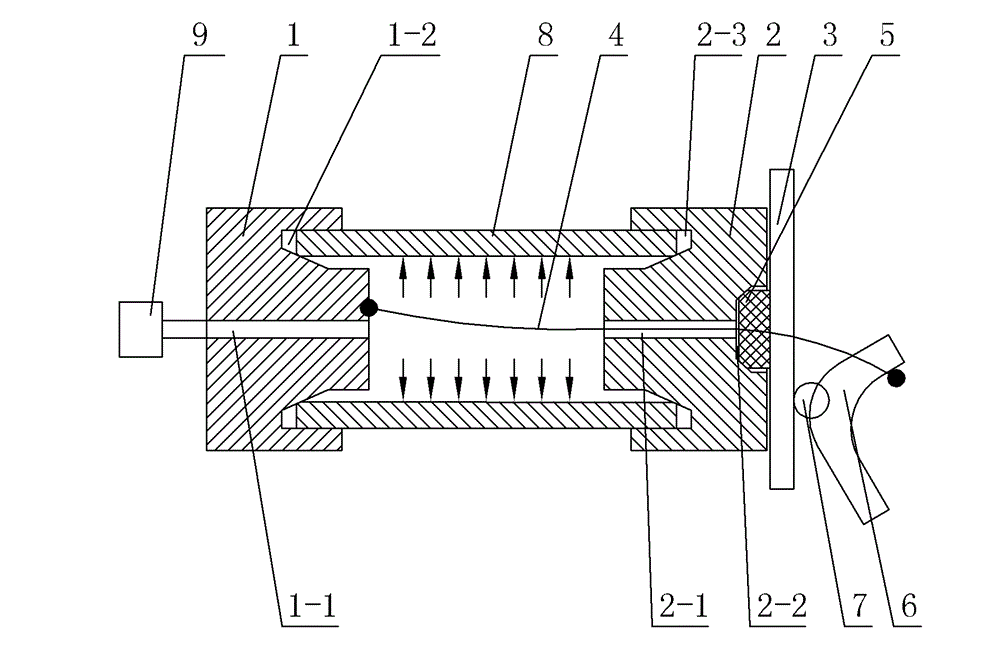

Differential pressure forming method for local large-deformation hollow pieces

InactiveCN103920788AImprove the lubrication effectSimple structureHydraulic cylinderStructural engineering

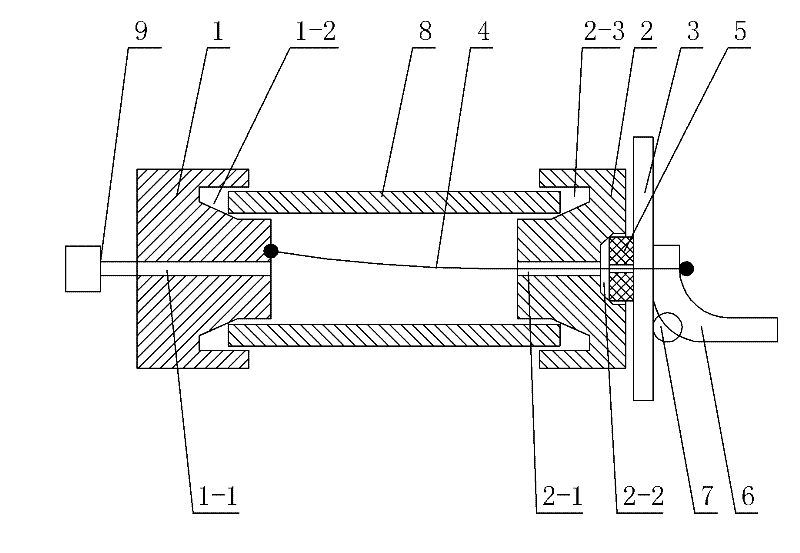

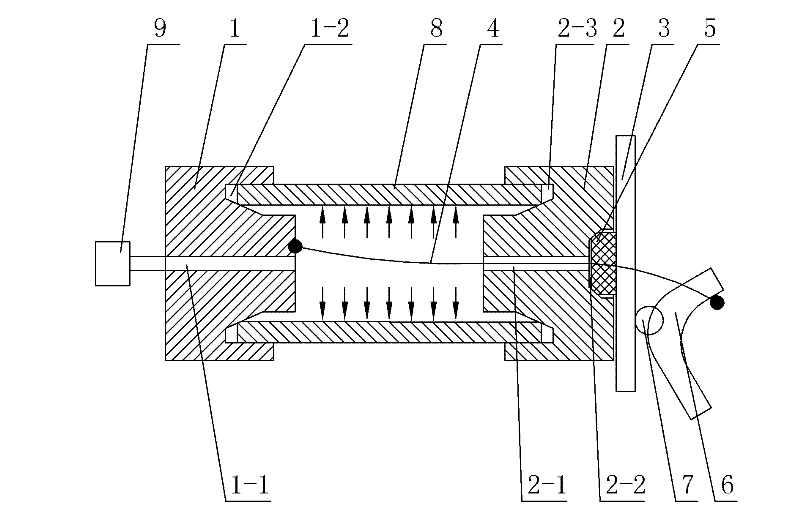

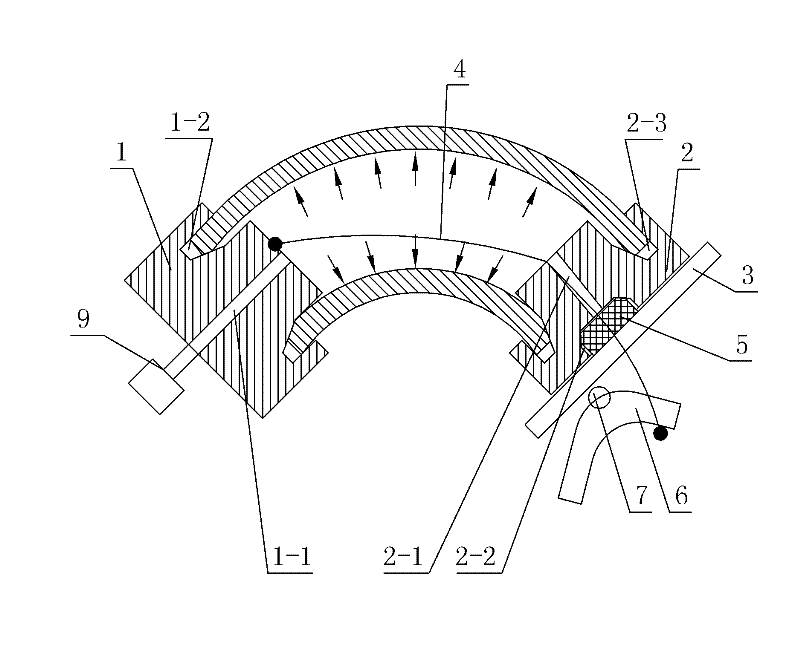

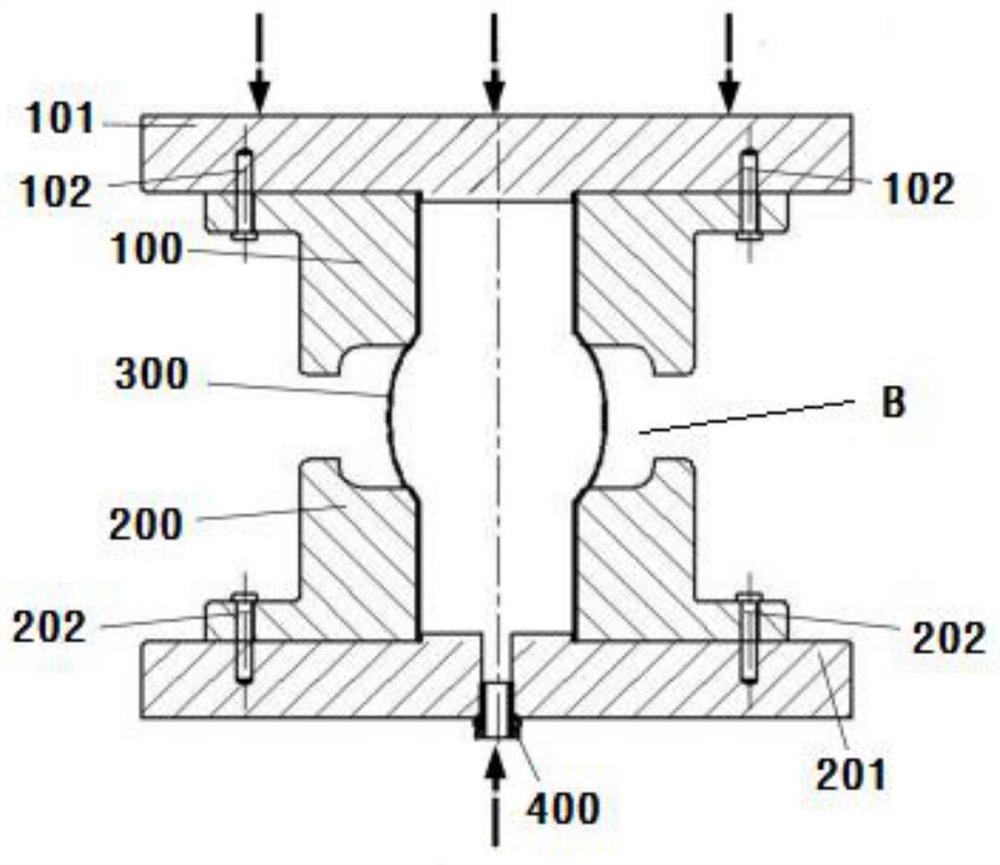

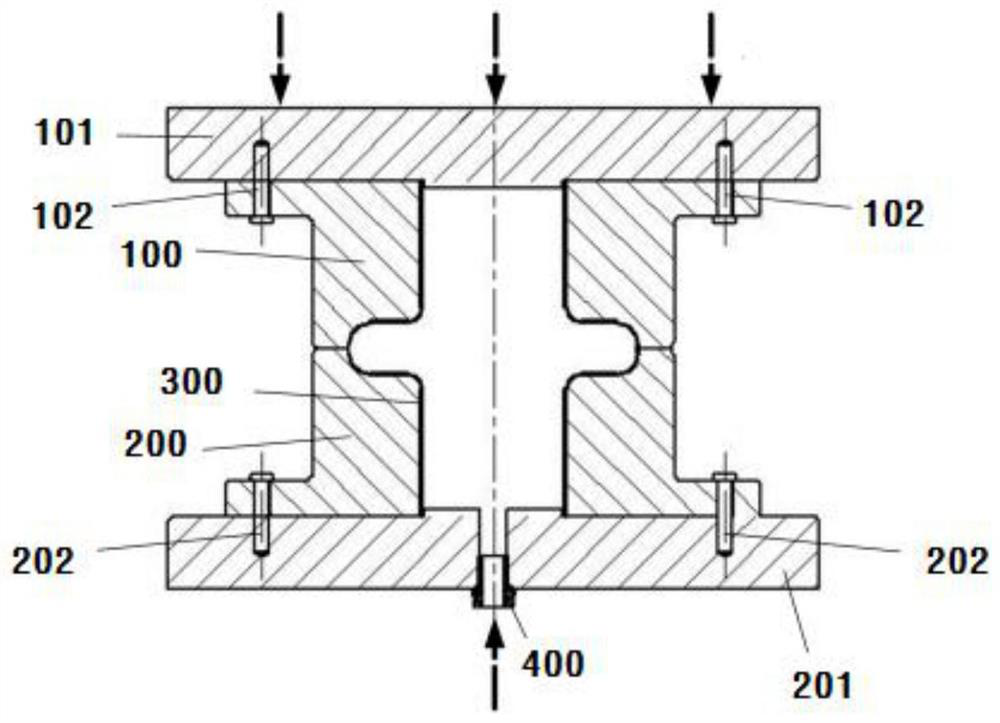

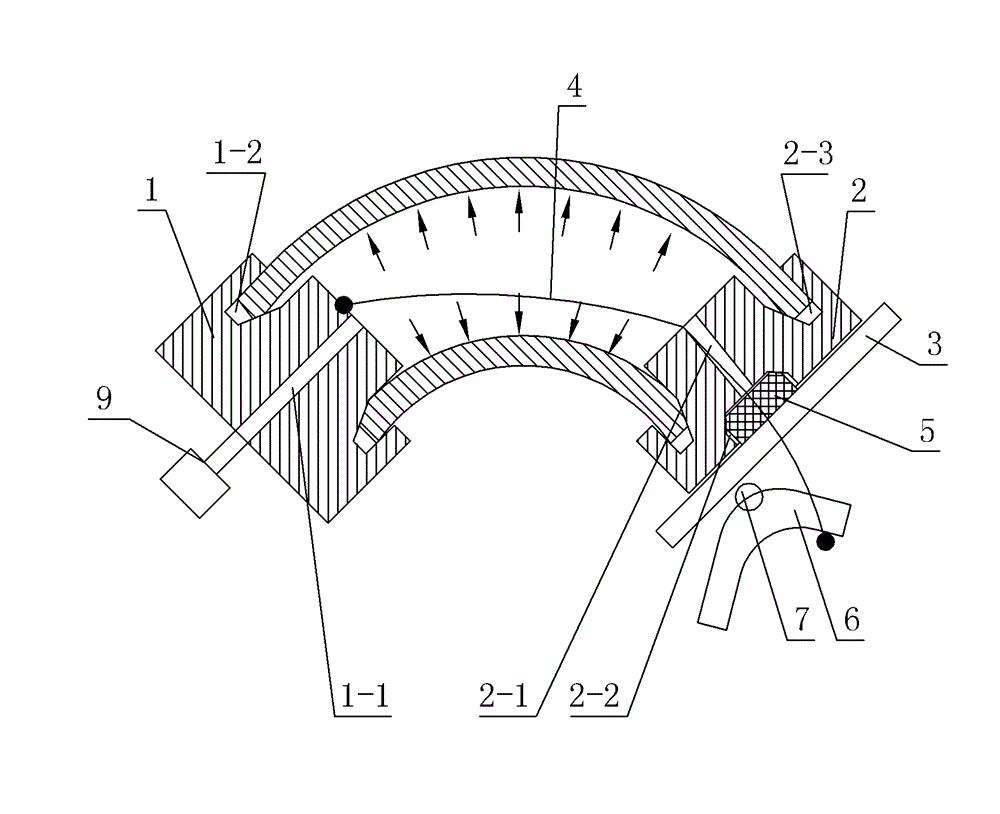

The invention discloses a differential pressure forming method for local large-deformation hollow pieces and belongs to the technical field of manufacturing of metal hollow members. The differential pressure forming method includes steps of firstly placing a pipe billet into a rear die, loading a punch into the pipe billet and sealing; injecting high-pressure liquid to the inner and outer surfaces of the pipe billet at the same time, keeping pressure in the pipe billet larger than the pressure of the outer surface of the pipe billet and forming controllable pressure difference; pushing the punch to axially feed to realize material supplement by the aid of a hydraulic cylinder, and enabling the pipe billet to generate local large deformation under the action of inside and outside hydraulic differential pressure; finally, discharging the high-pressure liquid and obtaining a local large-deformation hollow piece. By controlling inside and outside pressure difference of the pipe billet, stress state during local expansion of the pipe billet can be improved, expansion can be sufficiently realized and expansion limit is increased. Hydraulic oil is injected onto the outer surface of the pipe billet, lubricating between the outer surface of the pipe billet and a form cavity of the die is evidently improved, friction is reduced, and axial supplement and final forming are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

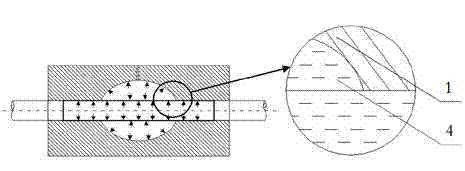

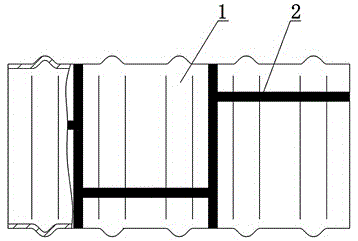

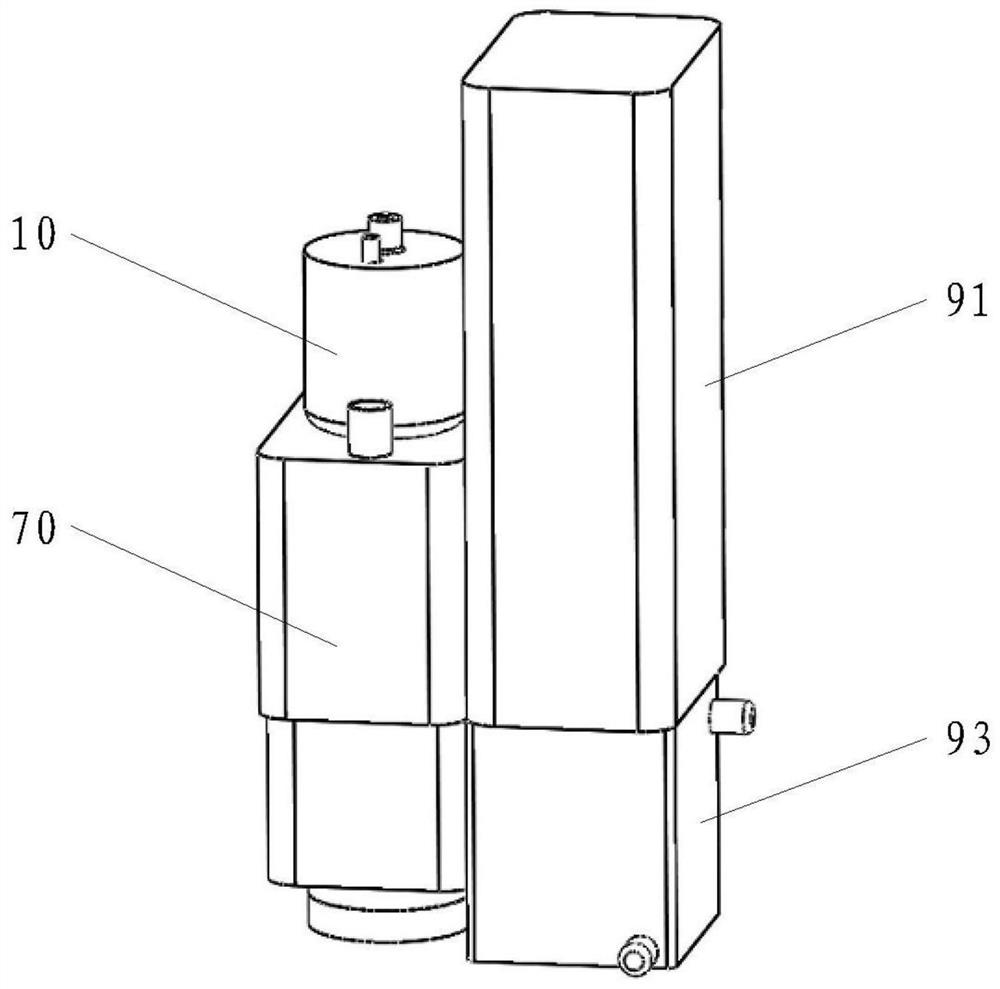

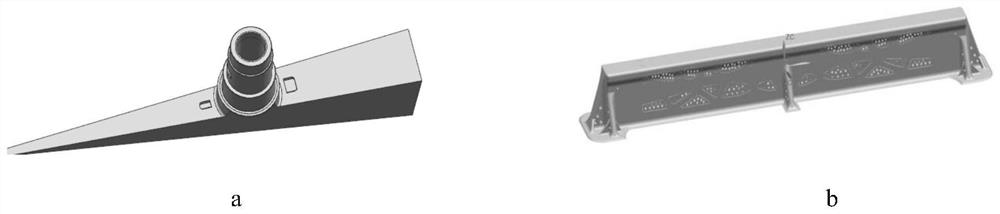

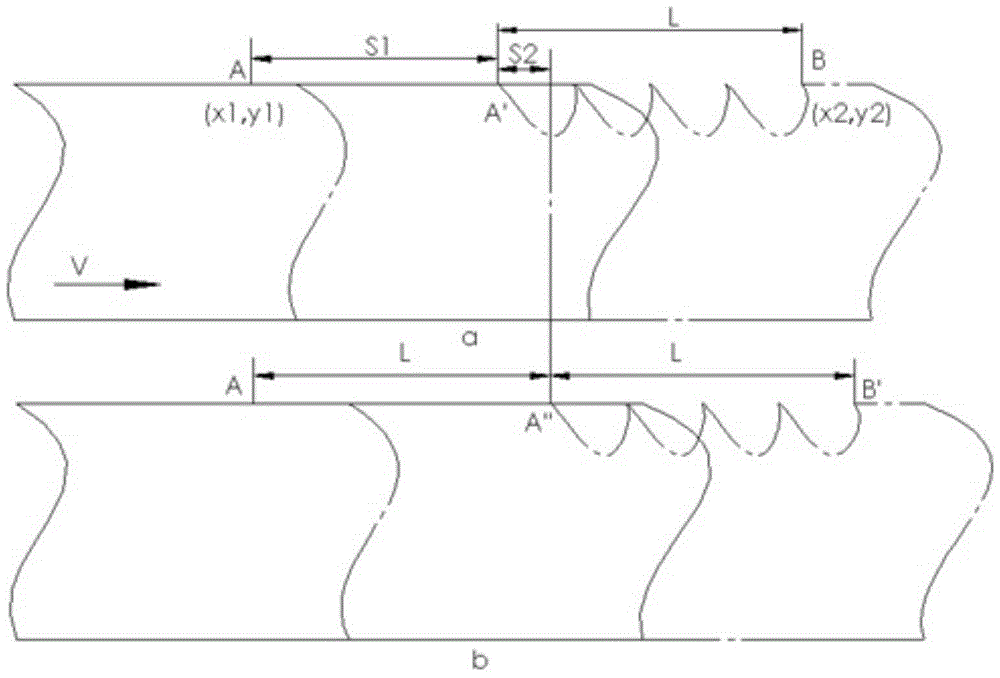

Internal spinning forming method for corrugated tube

ActiveCN105537345AImprove product qualityReduced circumferential weldsEngineeringMechanical engineering

The invention discloses an internal spinning forming method for a corrugated tube. The internal spinning forming method for the corrugated tube comprises the following steps that a tube billet is installed on a main shaft of a spinning machine, and a length thin tube is driven by the main shaft to rotate; the interior and the exterior of the tube billet are respectively provided with an inner spinning roller and an outer spinning roller for forming corrugations; the inner spinning roller and the outer spinning roller synchronously work; a feed rate of the inner spinning roller is paused until a gap between a convex molded surface of the inner spinning roller and a concave molded surface of the outer spinning roller is 1.1 to 1.3 times of the thickness of the tube billet, and the gap is kept for forming for 3 to 5 seconds until one position machining is finished; the inner spinning roller and the outer spinning roller synchronously move for one pitch of waves along the axial direction of the tube billet, and the steps are repeated until the corrugated tube of a required length is formed. The internal spinning forming method disclosed by the invention is higher in forming precision and low in forming cost; moreover, a metallographic structure is even and compact due to grain refinement and spinning deformation of the corrugated tube during a spinning process; meanwhile, grains are squashed and stretched to form a fibrous tissue in a spinning direction; product quality is high, and the service life is greatly prolonged.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

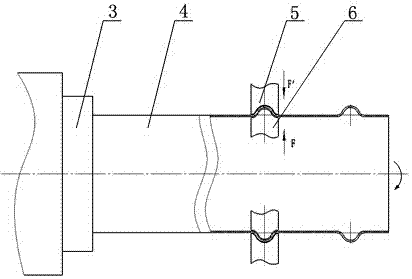

Device and method for bending pipe with sealed end by using tension rope or plug

The invention discloses a device and a method for bending a pipe with a sealed end by using a tension rope or plug, which relate to a pipe bending device and a pipe bending method. The invention solves the problems of unreliable sealing and low forming efficiency in a pipe internal pressure bending forming process. In the device, plugs are arranged at the two ends of a pipe, the plugs and the pipes are sealed by the annular grooves with slant walls on the inner sides of the plugs, a tension rope sealing ring is arranged in a counter bore, the outer end face of the tension rope sealing ring isprovided with a pressure plate, one end of the tension rope is connected with the inner end face of the first plug, the other end of the tension rope passes through a tension rope central hole, the tension rope sealing ring and the pressure plate to be connected with a tensioning wrench, and the tensioning wrench is arranged on the pressure plate through a rotating shaft. The method comprises: assembling the bending device, and tensioning the rope by using the tensioning wrench; filling high-pressure medium under the pressure of 0.5 to 100MPa into the pipe by using a pressurizing cylinder, and bending the pipe; and discharging the high-pressure medium, taking the tensioning rope and plugs, and accomplishing the bending forming of the pipe. The device and the method are used for bending forming of pipes.

Owner:HARBIN INST OF TECH

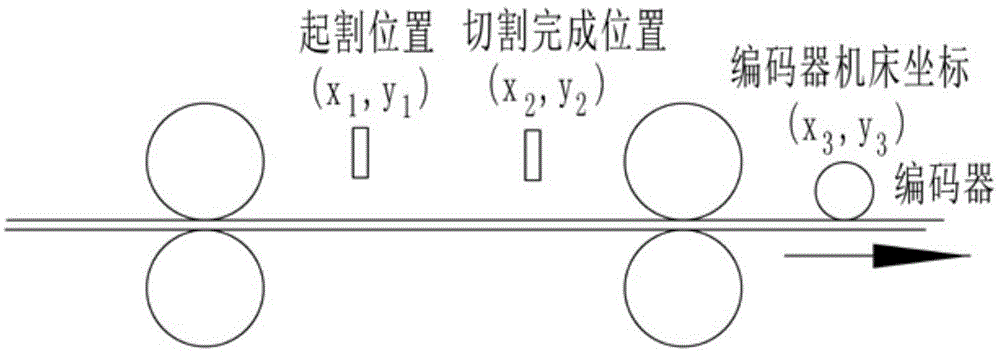

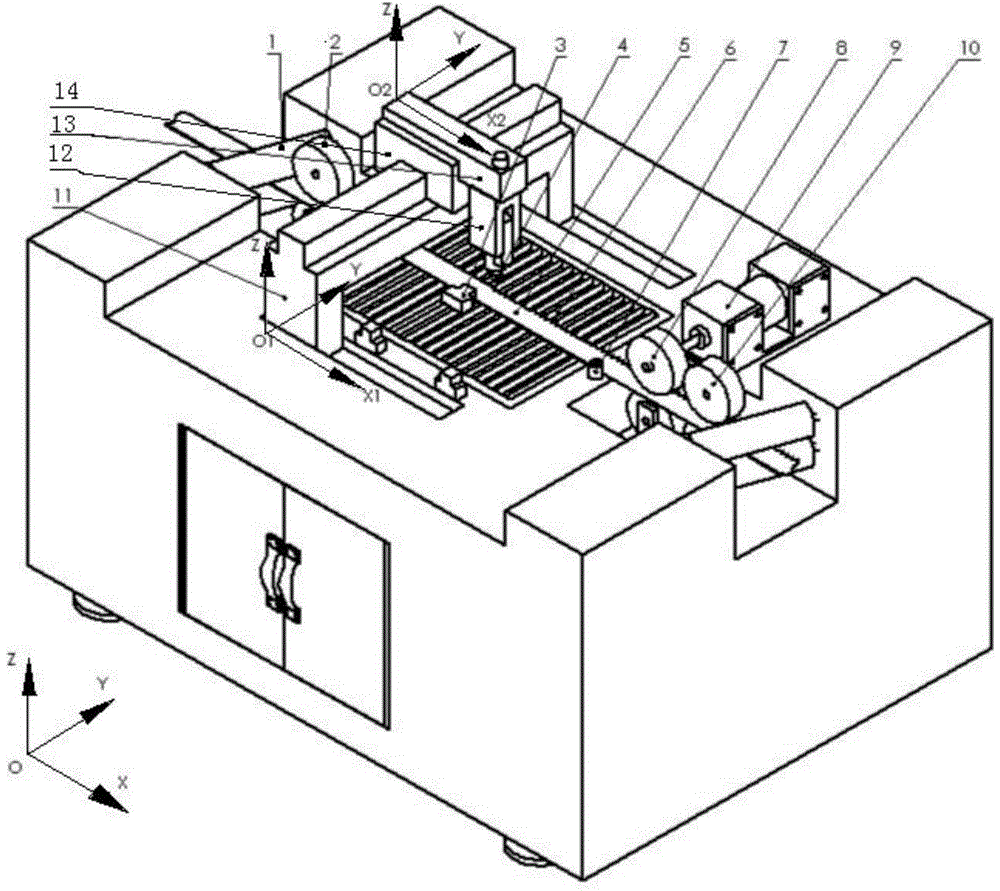

Laser continuous cutting device used for cutting saw belt and cutting method

ActiveCN104014938ANo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusMilling cutterLaser cutting

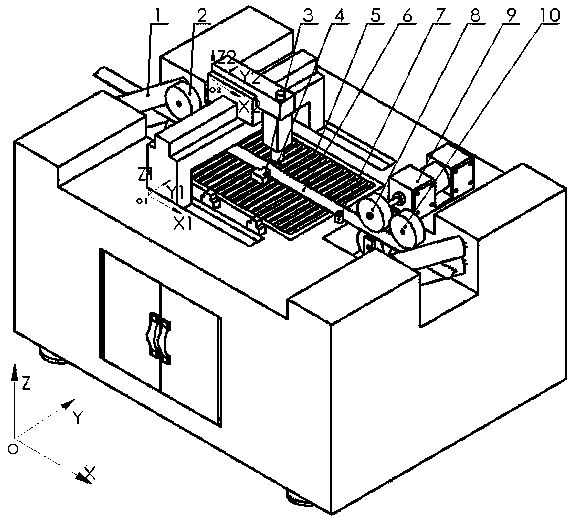

The invention discloses a laser continuous cutting device used for cutting a saw belt and a cutting method. The laser continuous cutting device aims to solve the problems that continuous cutting and forming of sawteeth can not be achieved, tool auxiliary time accounts for a high percentage, and cutting efficiency is low in the prior art. The laser continuous cutting device comprises a base which is sequentially provided with a driving friction roller used for regulating feeding speed of the saw belt, a pressing wheel set used for pressing the saw belt, a work platform and a driving wheel set driven by a driving device; a laser head which is arranged on a Z shaft for cutting the saw belt is arranged above the work platform; the work platform is provided with a feeler block and a transverse locating mechanism used for locating the saw belt; during cutting work, the speed of a sliding platform X1 is the same as the feeding speed of the saw belt. The laser cutting sawtooth continuous forming technique does not need a milling cutter, and the sawteeth in any two-dimensional shapes can be correspondingly manufactured very rapidly.

Owner:湖南泰嘉智能科技有限公司

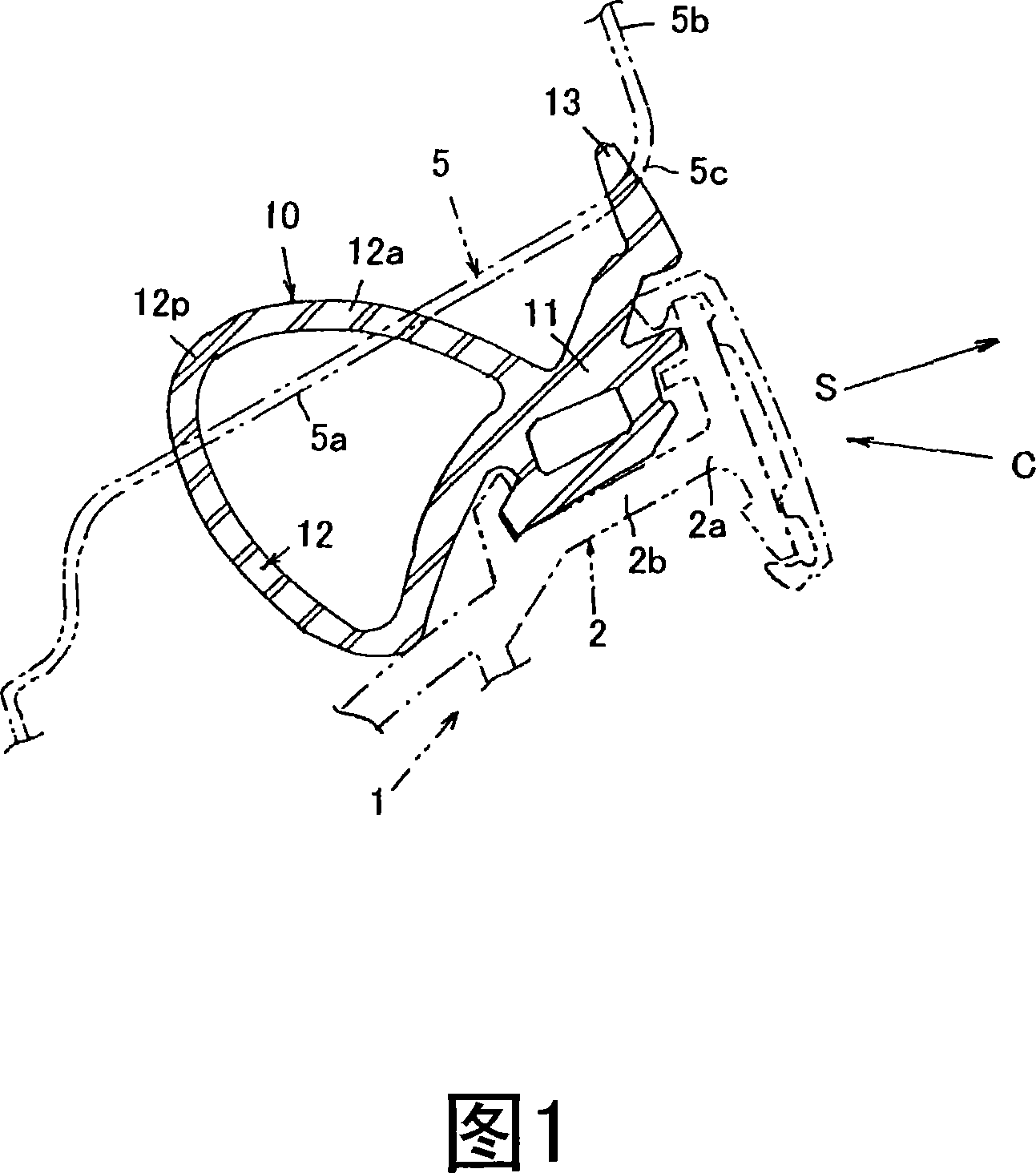

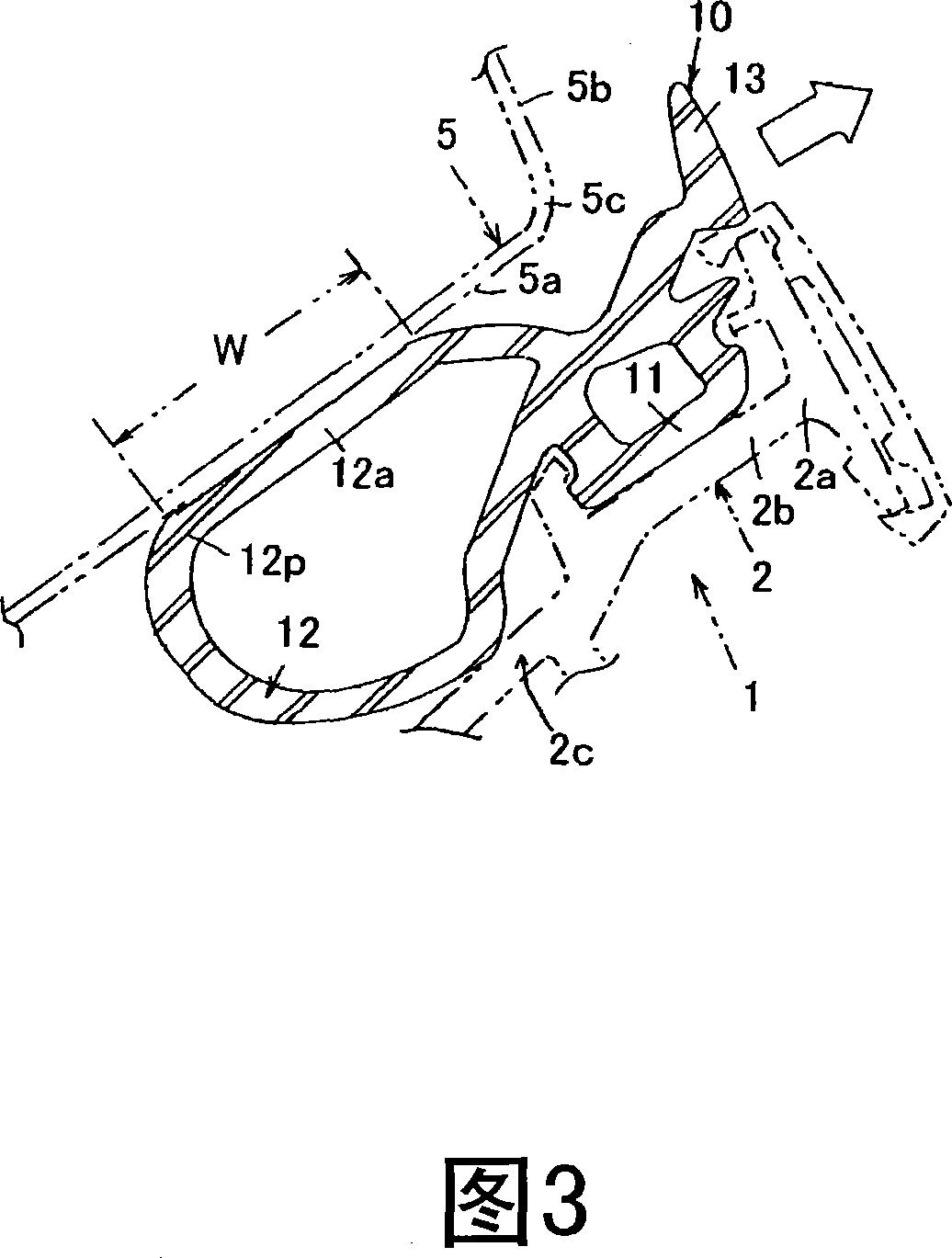

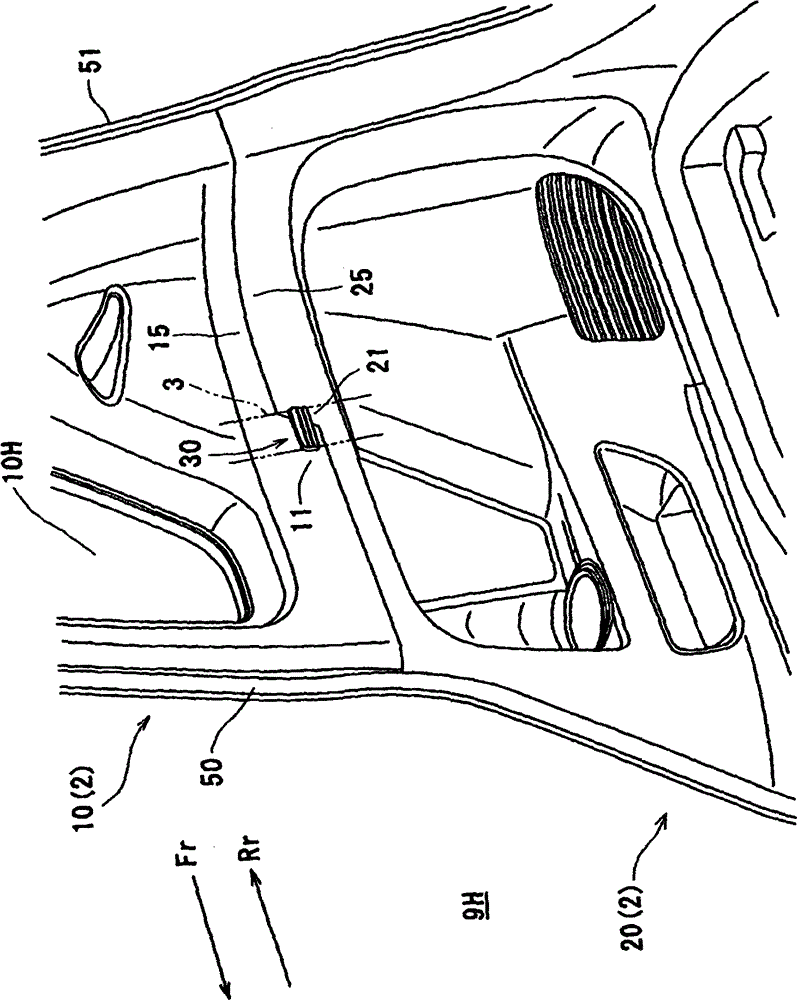

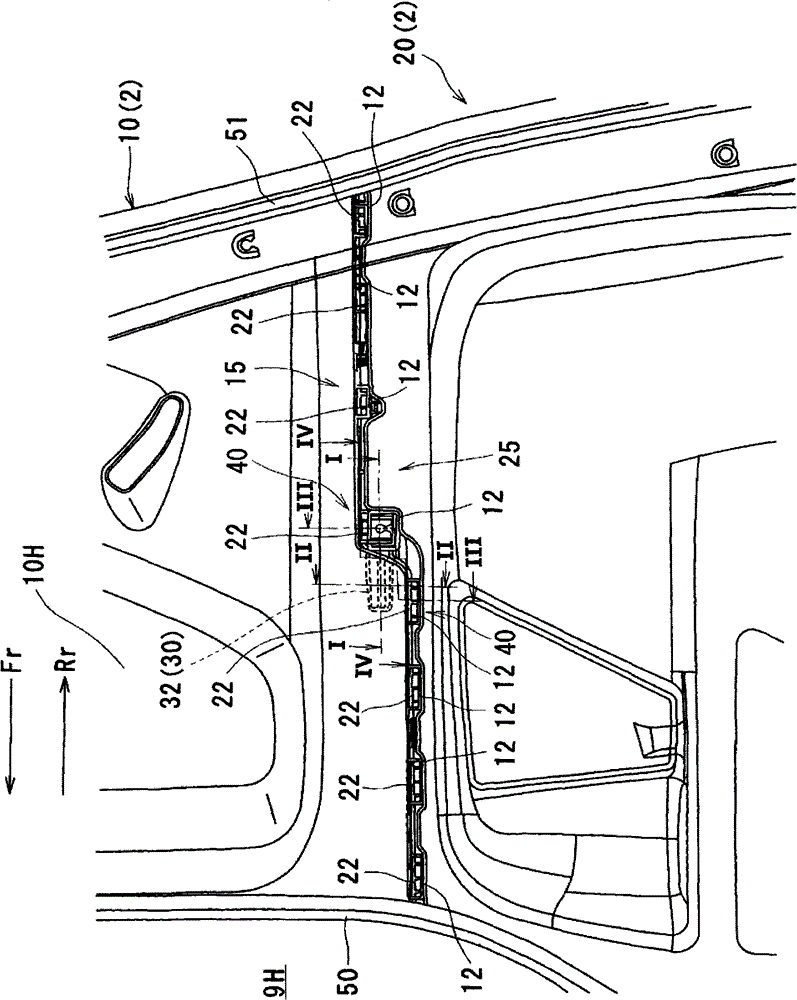

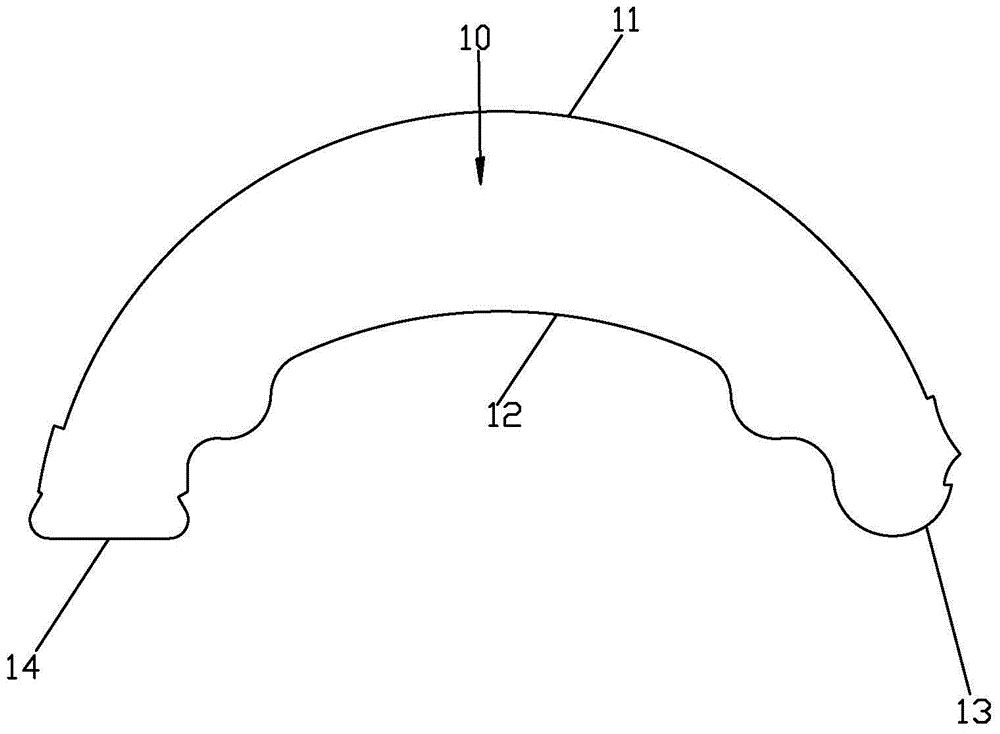

Attachment structure of door weather strip for vehicle

InactiveCN101062653AImprove sealingClosed retentionEngine sealsVehicle sealing arrangementsTravel modeEngineering

The invention provides a car door weather strip mounting structure capable of maintaining the high sealability even when a door is sucked outside a car when the car is traveling while maintaining the good door closability. The door weather strip 10 has a mounting base part 11 mounted on a retainer part 2a of a door sash 2, and a hollow seal part 12 which is integrated with the mounting base part 11 and elastically brought into contact with a body panel 5 when the door is closed. A part of the body panel 5 with the hollow seal part 12 elastically brought into contact therewith forms a flat parallel seal face 5a which is formed parallel or substantially parallel to the sucking direction S of a door 1 in a traveling mode.

Owner:NISHIKAWA RUBBER +1

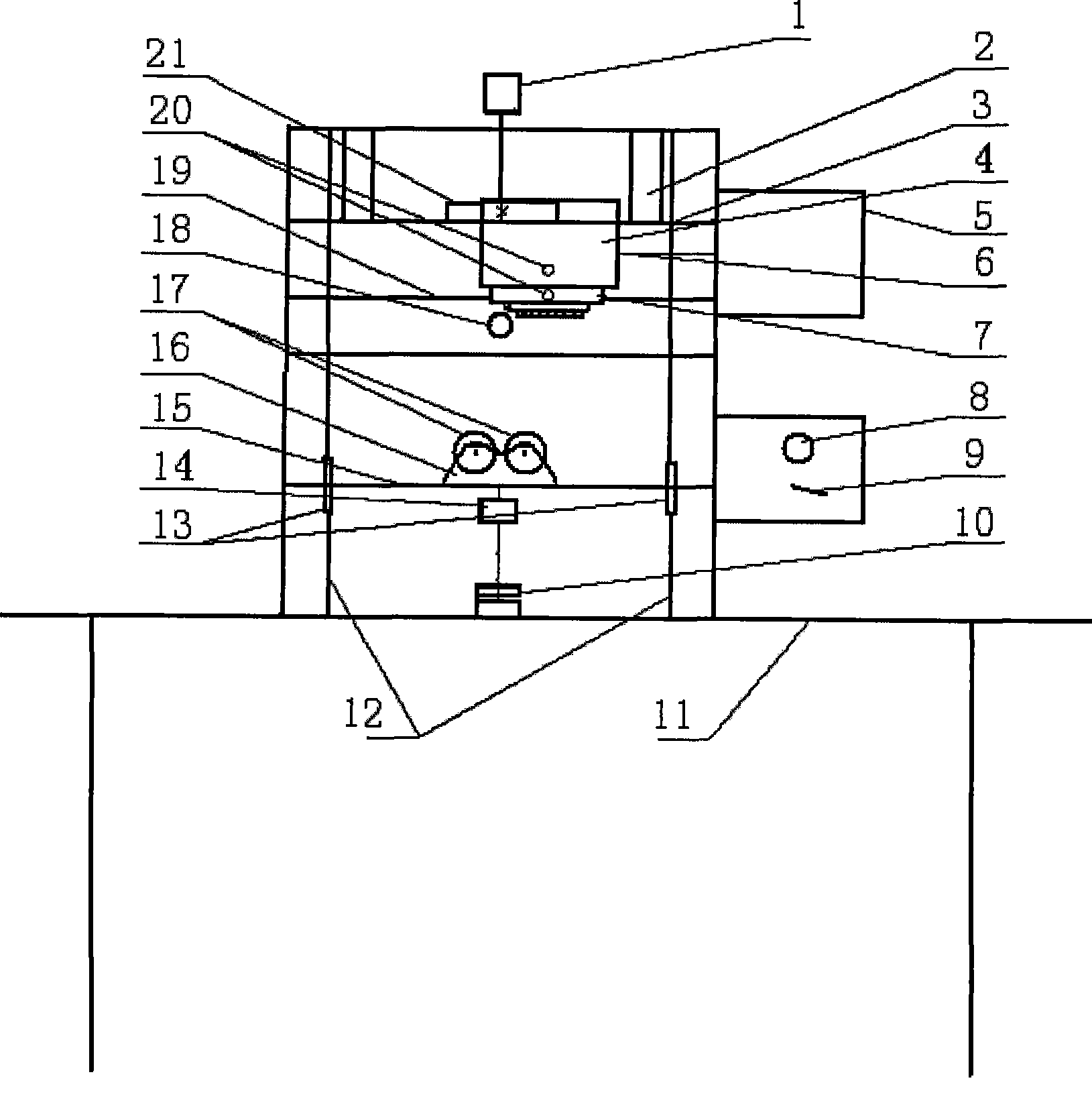

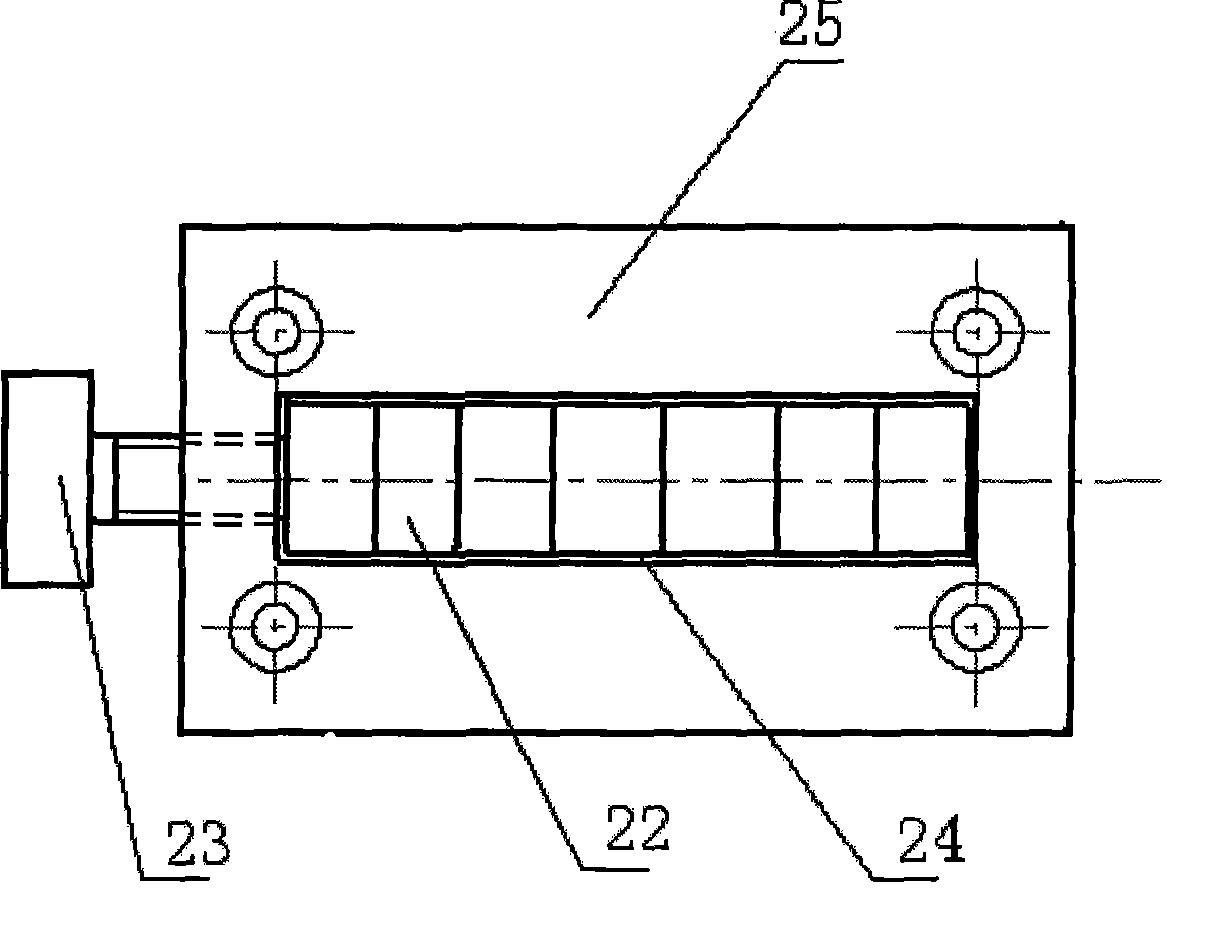

Fixture for forming characters or designs on surface of circular column workpiece

The invention discloses a surface character or pattern forming frock for cylindrical workpieces, which comprises a machine frame, a horizontally reciprocating pneumatic slider mechanism, a quick change typehead mechanism which is connected to the lower part of the pneumatic slider mechanism and a vertically lifting support plate mechanism, wherein the support plate mechanism is positioned on the lower part of the pneumatic slider mechanism; and the upper part of the support plate mechanism is provided with two adjacent bearings for placing the cylindrical workpieces. The surface character or pattern forming frock for the cylindrical workpieces adopts the structure and can be suitable for character or pattern printing on cylindrical surfaces of the cylindrical workpieces with different diameters; the cylindrical workpieces only need to be simply and quickly placed on the bearings and the typing depth, the typeface and the end height distance are adjustable; and the surface character or pattern forming frock for the cylindrical workpieces can quickly change the printing typehead, is driven by air pressure, has low energy consumption and low requirements on the skills of operators, reduces the labor intensity, is sanitary and environment-friendly, and can reduce the mark forming cost, improve the mark forming efficiency and guarantee the mark quality of the cylindrical workpieces.

Owner:SUNWAY HYDRAULIC IND WUHU CO LTD

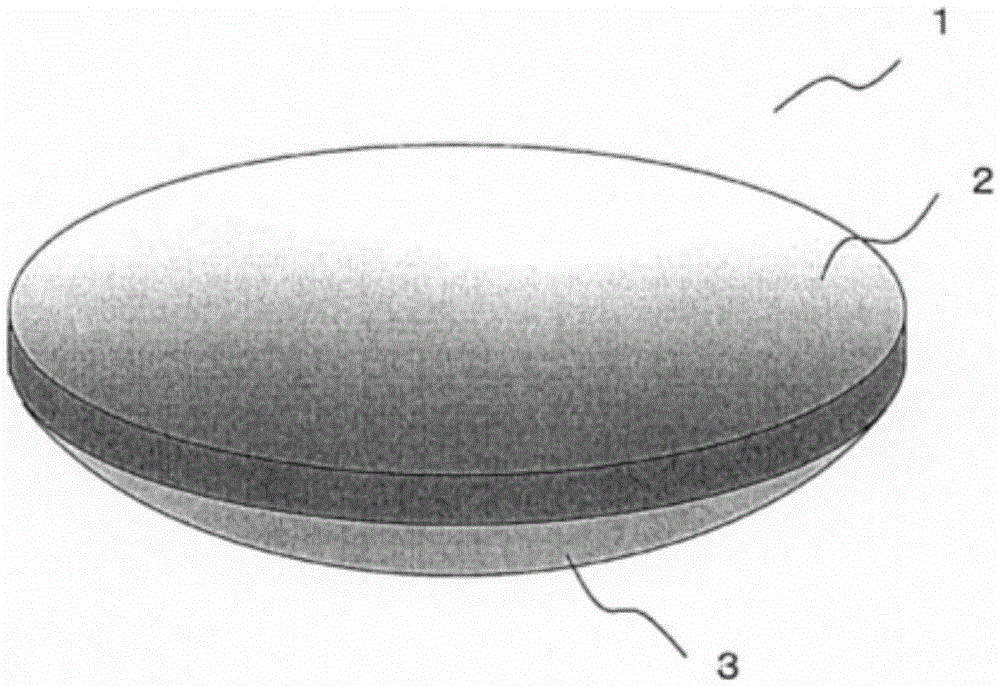

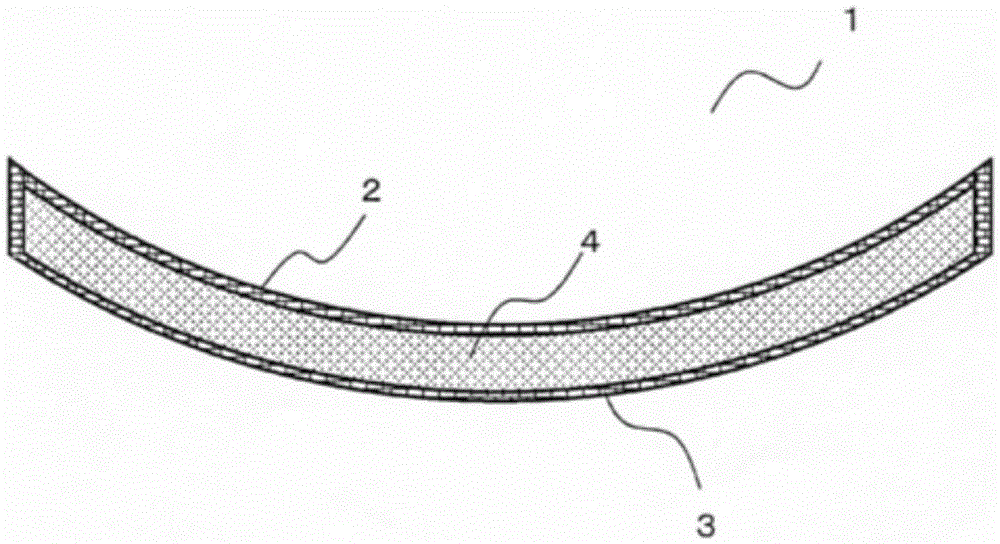

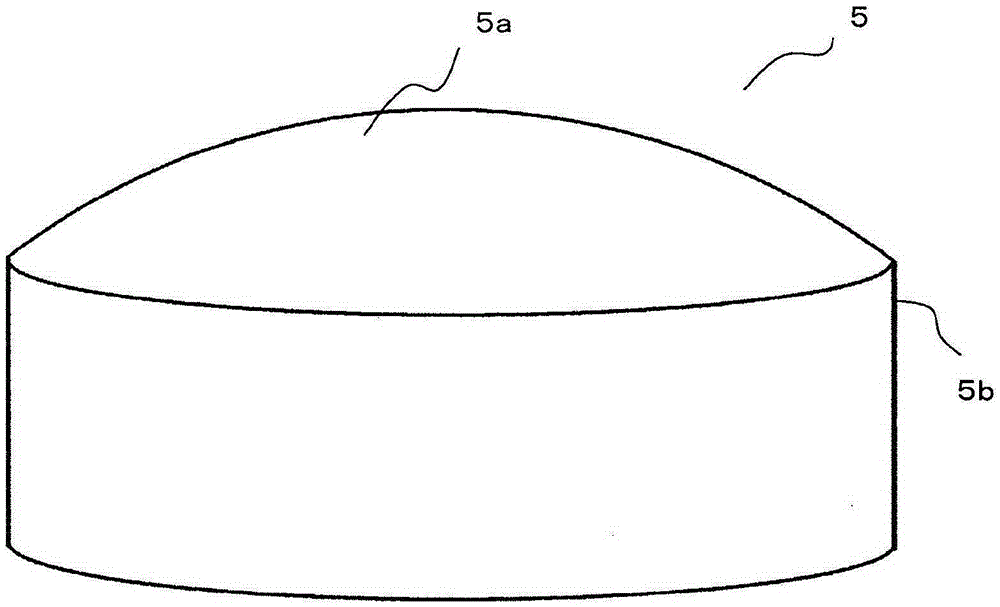

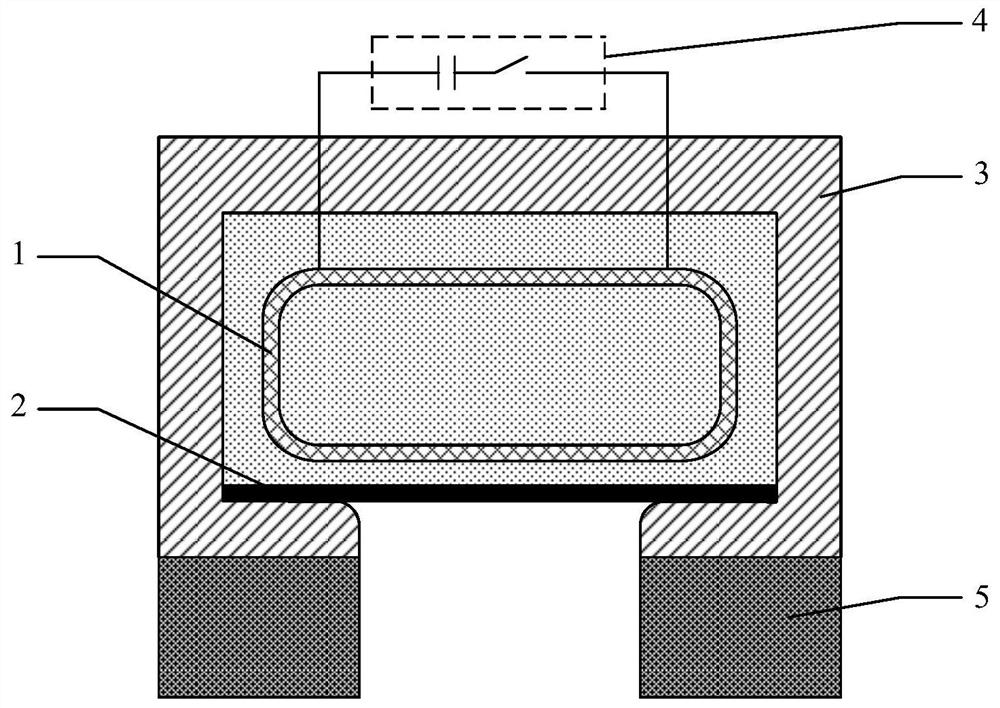

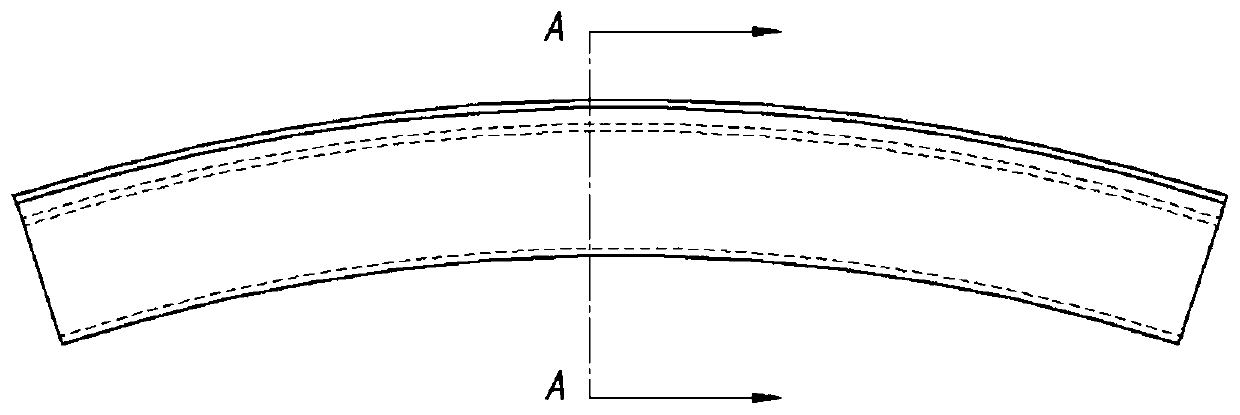

Manufacturing method of curved-surface-shaped sandwich structure and curved-surface-shaped sandwich structure

The invention provides a curved-surface-shaped sandwich structure and a manufacturing method thereof. A prospective mirror surface precision is obtained, and the forming cost of the curved-surface-shaped sandwich structure is lowered. The manufacturing method comprises: a first surface skin material shaping step in which a convex shaping die (5) with a convex curved surface part (5a) and a side surface part (5b) having the prospective mirror surface precision is utilized to form a first surface skin material (2) with a first curved surface skin part (2a) and a first edge part (2b); a core materla bonding step in which a foaming core material (4) which is processed in advance and has the surface precision is bonded to the first curved surface skin part; a second surface skin material shaping step in which a second surface skin material (3) with a second curved surface skin part (3a) and a second edge part (3b) is formed to cover the laminated the first surface skin material and foamng core material on the convex shaping die; and a projection part removing step in which the first edge part and the second edge part are laminated and the parts protruding towards the lower part of the first surface skin material are removed.

Owner:MITSUBISHI ELECTRIC CORP

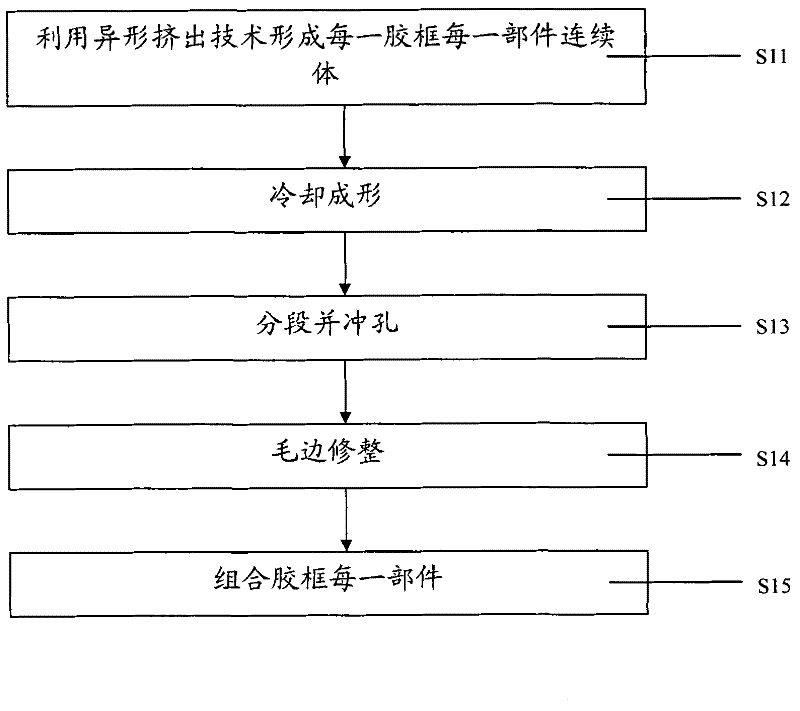

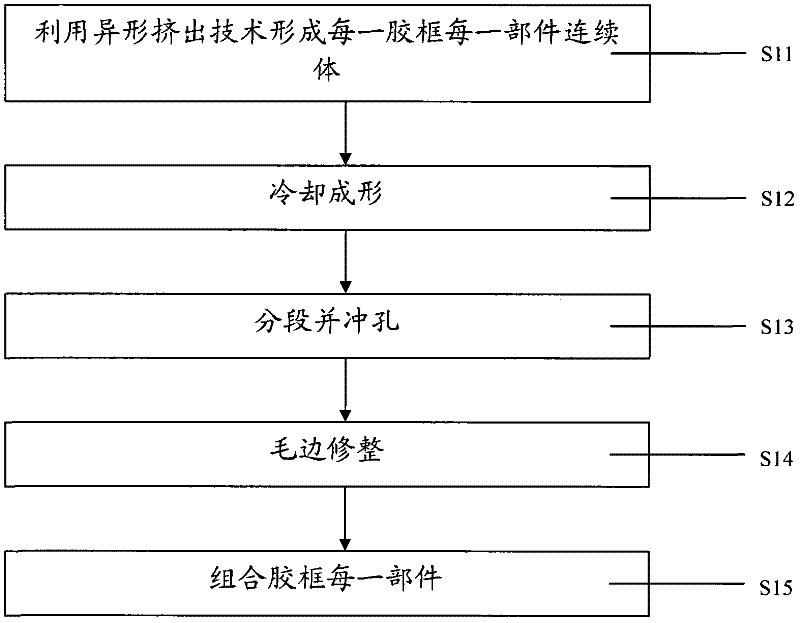

Adhesive frame making method

InactiveCN102243391AReduce production costsReduce forming costNon-linear opticsAbnormal shapedLiquid-crystal display

The invention provides an adhesive frame making method which is applied to adhesive frames of LCD (Liquid Crystal Display) backlight sources and comprises the steps of: forming a continuum of each part of each adhesive frame by using an irregular extrusion technology; cooling each continuum; segmenting each continuum and punching system locking and attaching holes to form each part of each adhesive frame; and assembling all the parts into the corresponding adhesive frame. By adopting the adhesive frame making method provided by the invention, the mould production cost can be reduced greatly so as to reduce forming cost, a long and thin member can be formed, and a fastener type design is beneficial to reduction of the using amount of screws, so that the cost can be reduced by 20%.

Owner:AU OPTRONICS CORP

Vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device

PendingCN112776322ASimplify the sintering processPrevent splashAdditive manufacturing apparatusAdditive manufacturing with solidsMolten stateMetallurgy

The invention discloses a vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device. The vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device comprises a forming workbench and an electron beam spray additive device mounted above the workbench, wherein the electron beam spray additive device comprises a cold spraying head, a high-energy electron beam emitter and an electron beam control device. The spraying direction of the cold spraying head can be adjusted, so that sprayed powder particle beams can be scanned on the workbench based on shapes of parts; the electron beam control device is mounted at an emitting opening of the high-energy electron beam emitter and is used for controlling emitting directions of electron beams, so that the electron beams and the powder particle beams sprayed by the cold spraying head are collected at one point, and the surface of a substrate and the powder particles are heated to form a molten state. According to the device, the parts are formed by directionally spraying the powder and heating and sintering in real time; the powder is not needed to be laid layer by layer and sintered; the forming efficiency is greatly improved; the waste of the powder is avoided; the forming cost is reduced; the forming quality consistency is good; the forming quality is improved; the part sintering process is simplified; and the sintering efficiency is improved.

Owner:重庆交通大学绿色航空技术研究院 +1

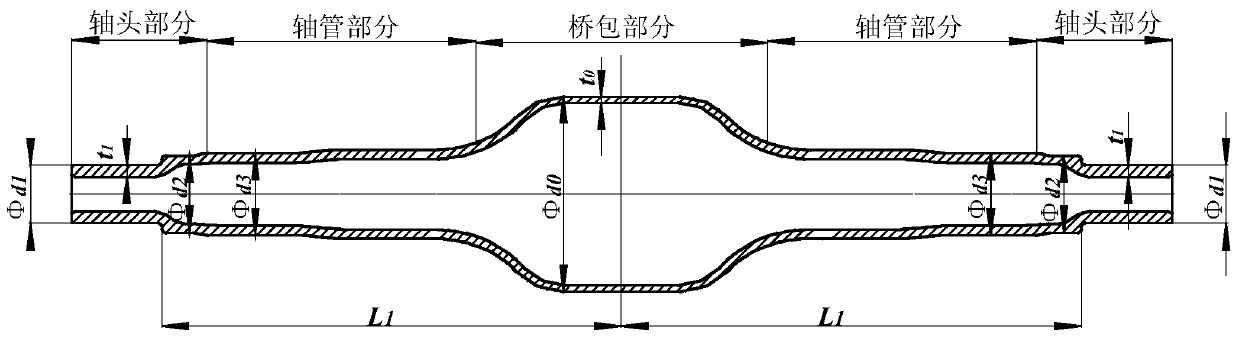

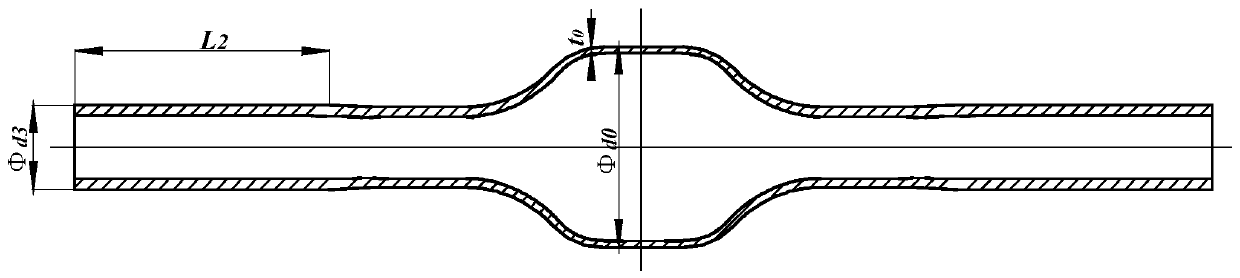

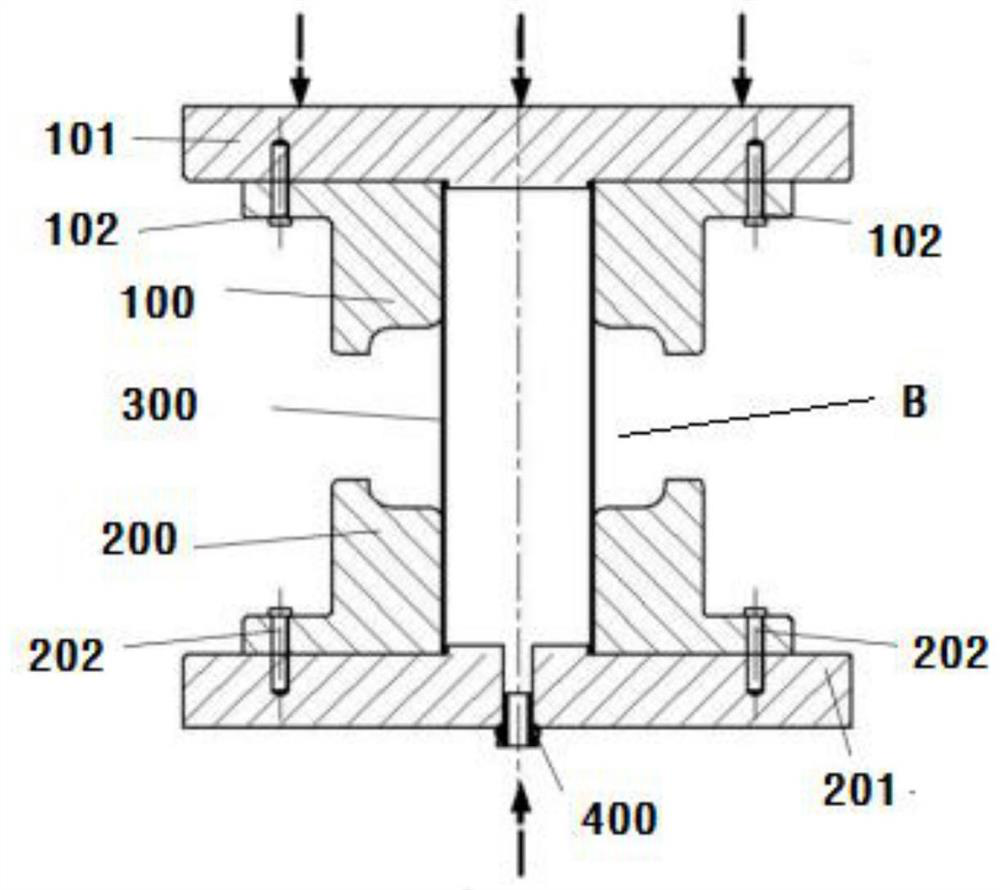

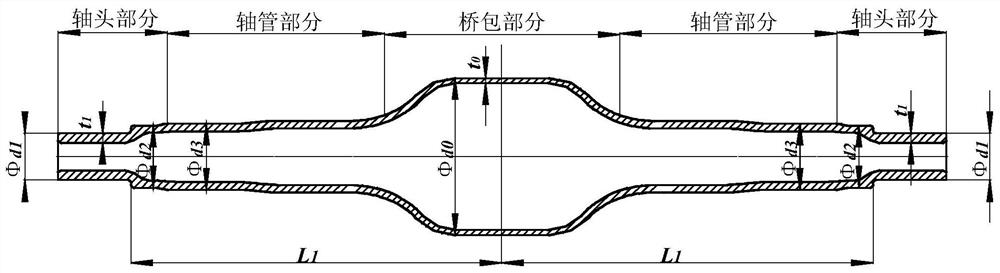

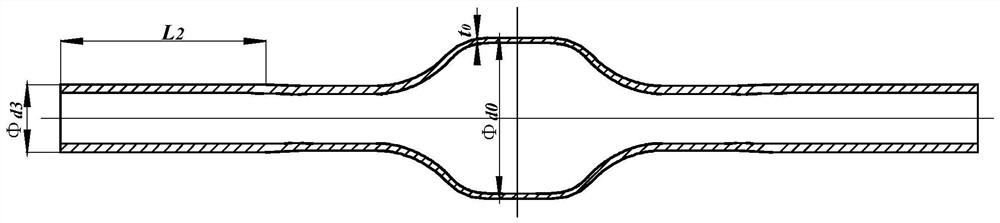

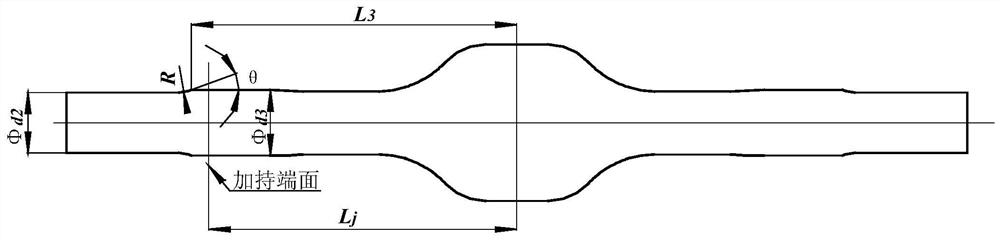

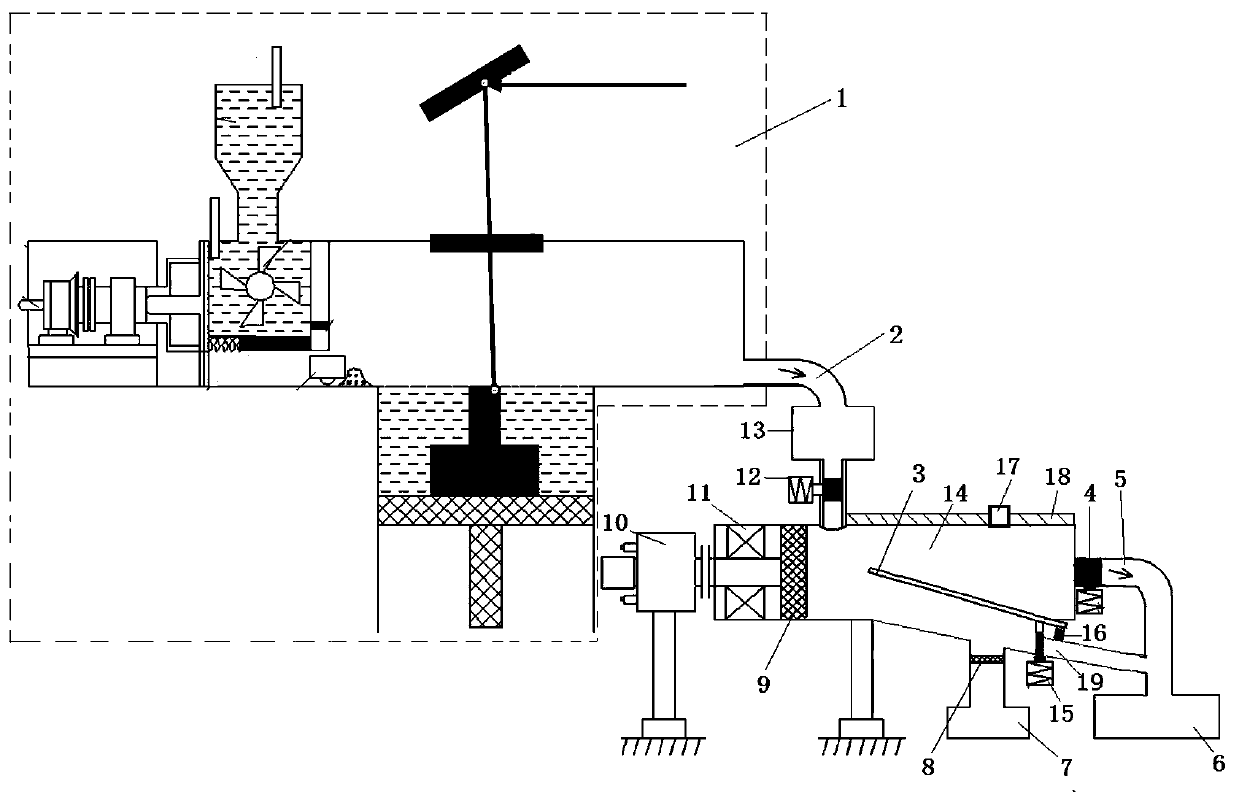

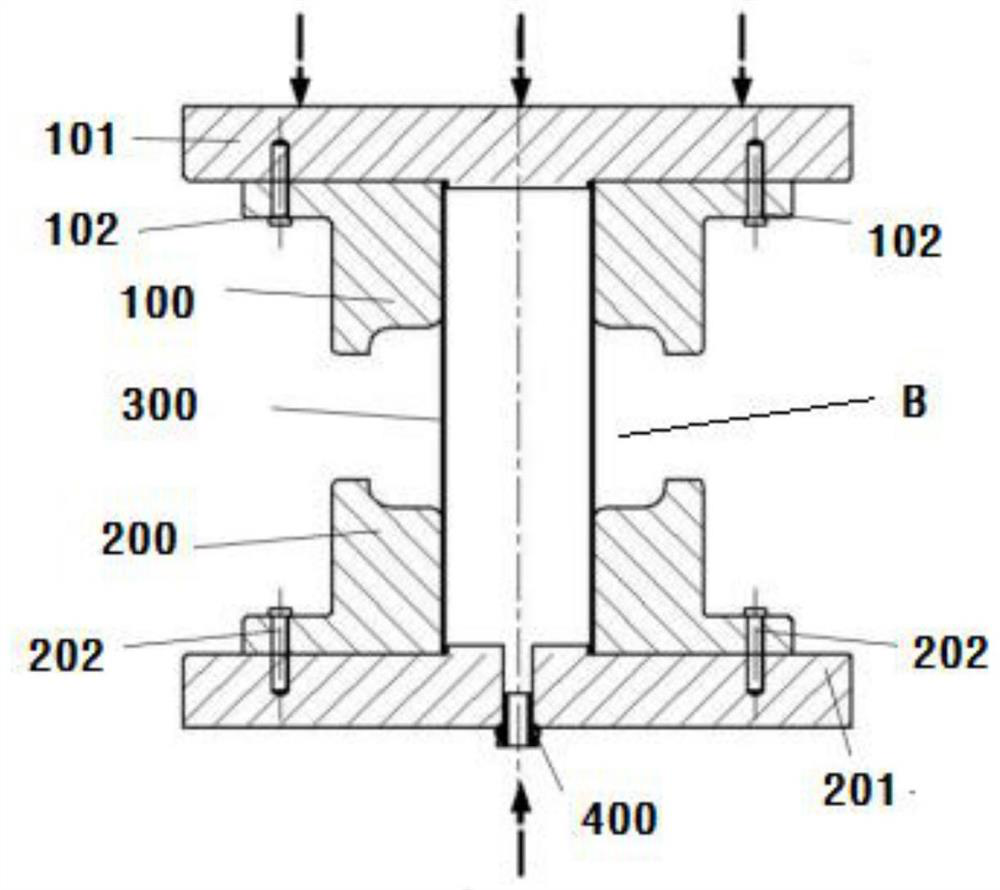

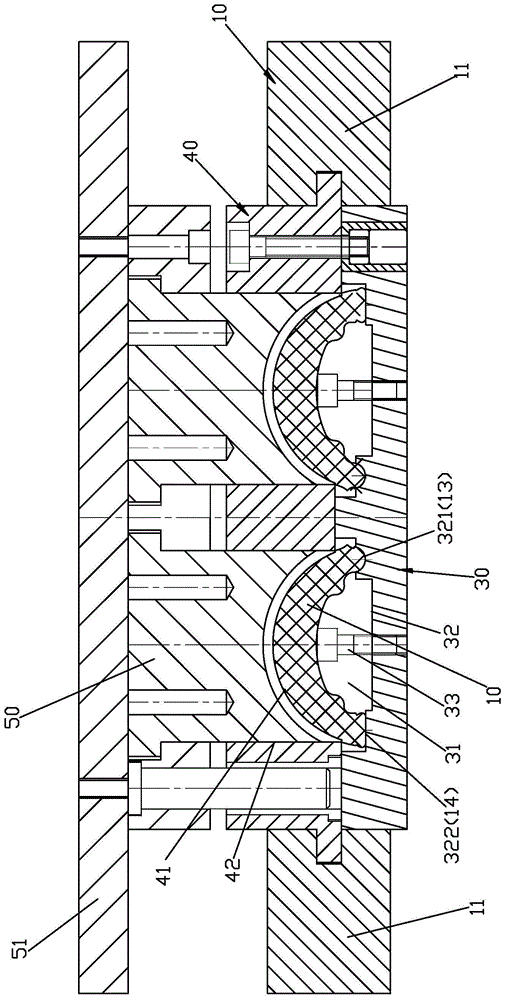

Hydro-bugling drive axle housing axle head forming process and mould

ActiveCN111558665AImprove fatigue strengthReduce quality problemsShaping toolsVehicle componentsPipe fittingEngineering

The invention discloses a hydro-bugling drive axle housing axle head forming process and a mould. The process comprises the steps of carrying out reducing on an axle end for four times and carrying out heat pushing and pressing on the axle end for three times. The mould comprises an upper mould plate, a lower mould plate, a left reducing female die module, a right reducing female die module, a middle part clamping module piece, an end part clamping module piece and the like. The upper mould plate drives a middle-upper clamping die and upper end clamping dies I and II to move downwards; the middle-upper clamping die, the upper end clamping dies I and II, a middle-lower clamping die and lower end clamping dies I and II are used for respectively clamping a middle part and end parts of a pipefitting; by combining with sizing segments of reducing (pushing and pressing) female dies I and II, the pipe fitting is jointly guaranteed to be formed without being creased or losing stability; and the left and right reducing (pushing and pressing) female die modules move face to face, so that reducing or pushing and pressing of the pipe fitting is realized, and an axle head with a conical surface and a perpendicular circular bead is formed. According to the hydro-bugling drive axle housing axle head forming process and the mould provided by the invention, the axle head is formed on the basisof a hydro-bugling drive axle housing body, and no half-axle sleeve tube needs to be welded, so that an axle housing is free of a welded joint, the fatigue strength of the axle housing is improved, and the mass is reduced; and the axle head forming mould is matched with earlier-stage axle housing body forming equipment, so that the forming cost of the axle head is greatly saved.

Owner:YANSHAN UNIV +1

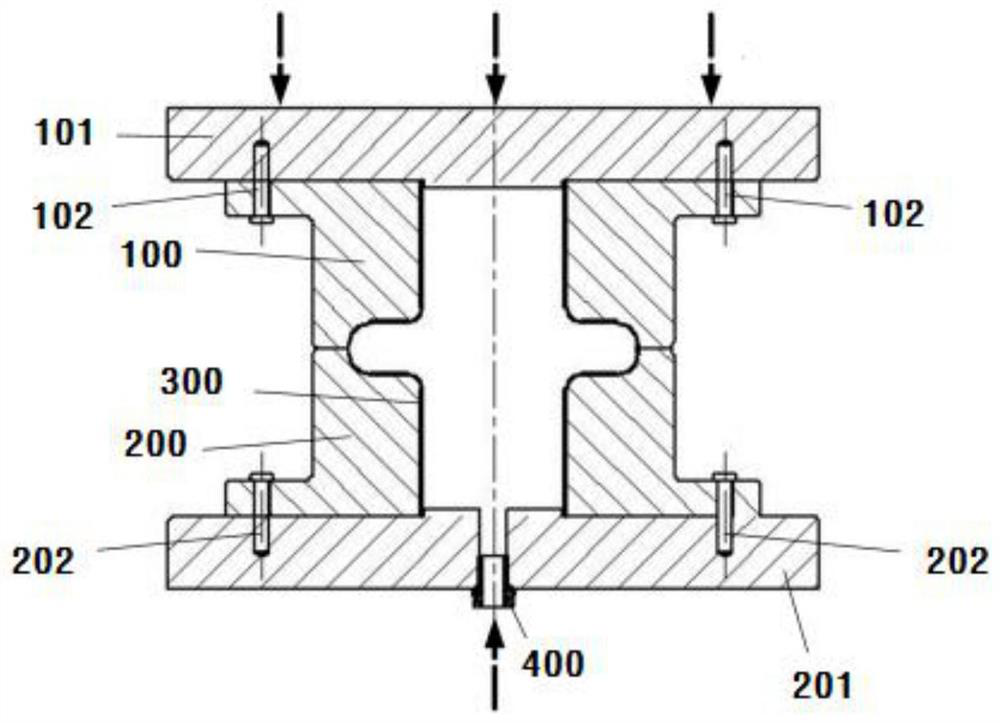

High-temperature alloy fluid medium ultrahigh-pressure forming method and device

The invention relates to a high-temperature alloy fluid medium ultrahigh-pressure forming method and device. The device comprises an upper mold base, a lower mold base, an upper mold, a lower mold and an external flow filling system. The method comprises the steps that high-pressure fluid is injected into a pipe through a high-pressure pipe connector, a certain high-pressure environment is formed in the pipe, meanwhile, the upper mold moves downwards to bend a blank, the descending speed of the upper mold is matched with the internal pressure of the blank, finally, the blank is pressed into the upper mold and the lower mold, the blank is attached to the surfaces of the upper mold and the lower mold, and a final component is obtained. The formed component obtained through the high-temperature alloy fluid medium ultrahigh-pressure forming method is uniform in wall thickness distribution, good in surface quality and high in forming precision. High-precision, high-efficiency and low-cost forming of the high-temperature alloy component is achieved, the application field of fluid filling forming is greatly widened, and extremely wide application prospects are achieved.

Owner:BEIHANG UNIV

Method for mouldless directly manufacture of parts and mould

Owner:武汉昱峰科技产业发展有限公司

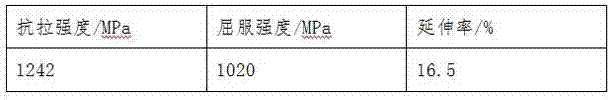

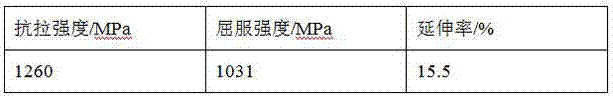

CoCrMo powder hot isostatic pressing forming method based on PREP technique

The invention provides a CoCrMo powder hot isostatic pressing forming method based on a PREP technique. The CoCrMo powder hot isostatic pressing forming method comprises the following steps that 1, CoCrMo alloy powder is prepared through the PREP technique, and grading is conducted to obtain the CoCrMo alloy powder with the diameter being 50-150 [mu]m; 2, a CoCrMo forming piece is prepared througha hot isostatic pressing technology; and 3, an alloy is sampled correspondingly and used for tensile property detection. The CoCrMo alloy prepared by the method has the characteristics that the forming mode is simple, the strength is high, and the plasticity is high, and good isotropic homogeneity is kept.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Forming Technology and Die of Axle Head of Hydraulic Bulging Drive Axle Housing

ActiveCN111558665BImprove fatigue strengthReduce quality problemsShaping toolsVehicle componentsPipe fittingStructural engineering

The invention discloses a hydraulic bulging driving axle head forming process and mold. The process includes four shaft end reductions and three shaft end warm pushes. The mold includes an upper template, a lower template, left and right reducing die assemblies, middle and end clamping mold assemblies, etc. The upper template drives the middle and upper clamping molds and the upper clamping molds I and II to move downward, and The middle and lower clamping dies and the lower clamping dies Ⅰ and Ⅱ respectively clamp the middle and end of the pipe fittings, together with the sizing sections of the reducing (push) dies Ⅰ and Ⅱ, jointly ensure that the pipe fittings are formed without wrinkling and instability. Said that the left and right reducing (pushing) die components move towards each other to realize the reducing or pushing of the pipe fittings, forming the shaft head with a tapered surface and a vertical shoulder. The invention forms the shaft head on the basis of the hydraulic bulging axle housing body without welding the half shaft casing, truly realizes no weld seam of the axle housing, improves the fatigue strength of the axle housing and reduces the quality, and the shaft head forming mold is formed with the axle housing body in the previous stage Equipment matching greatly saves the forming cost of the shaft head.

Owner:YANSHAN UNIV +1

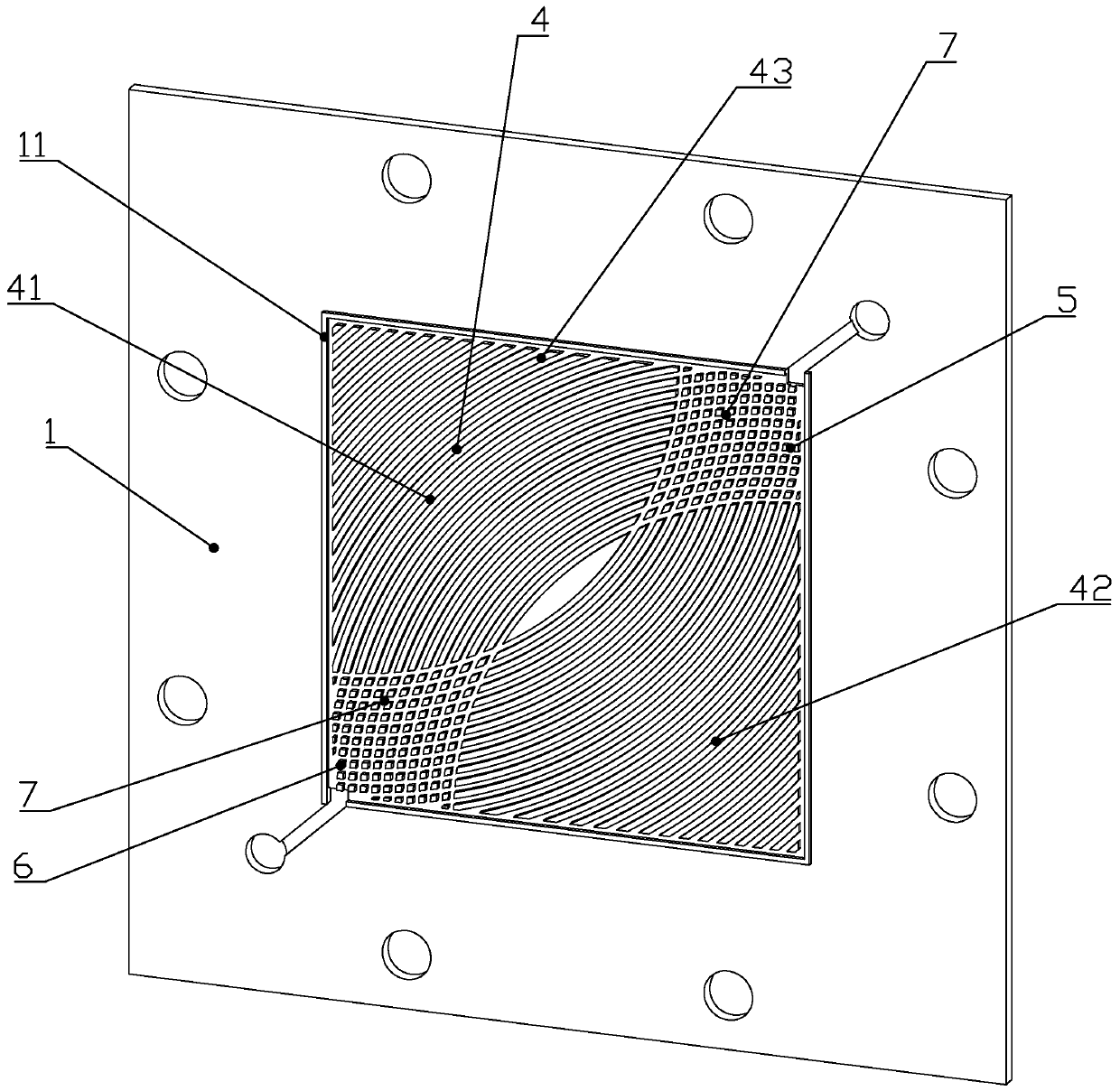

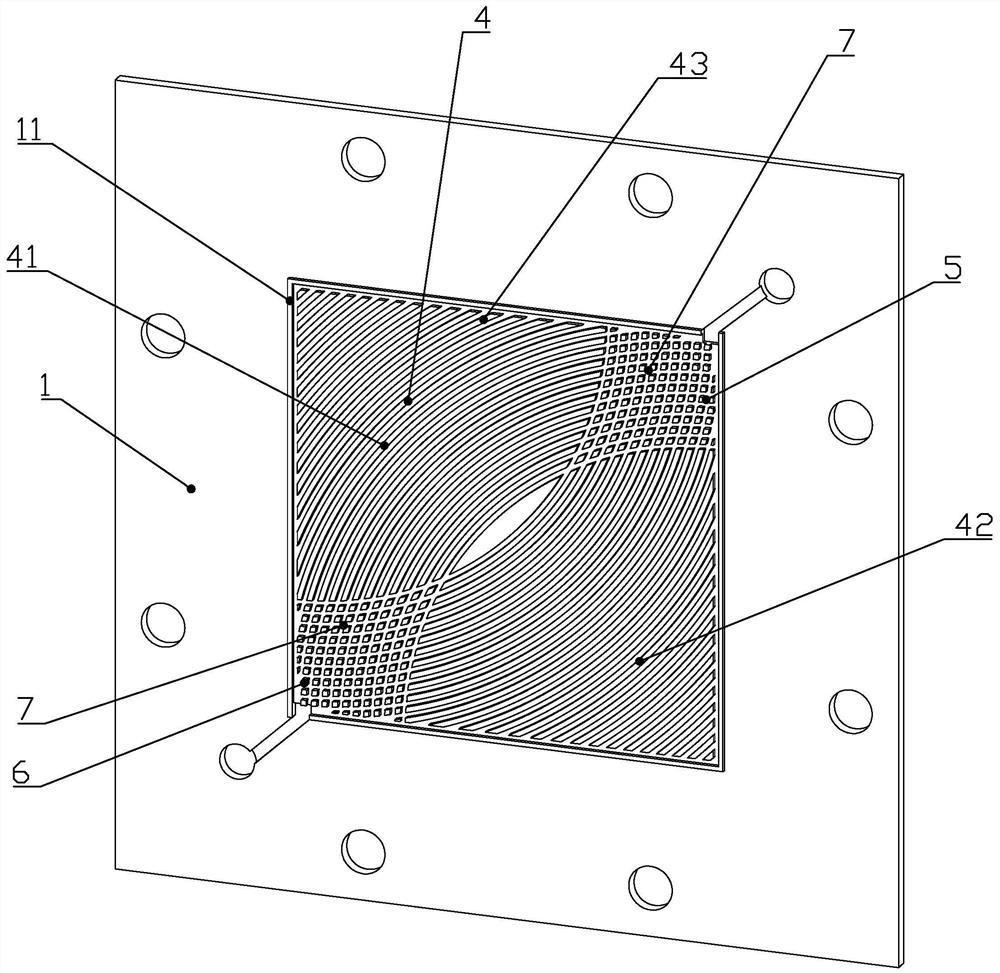

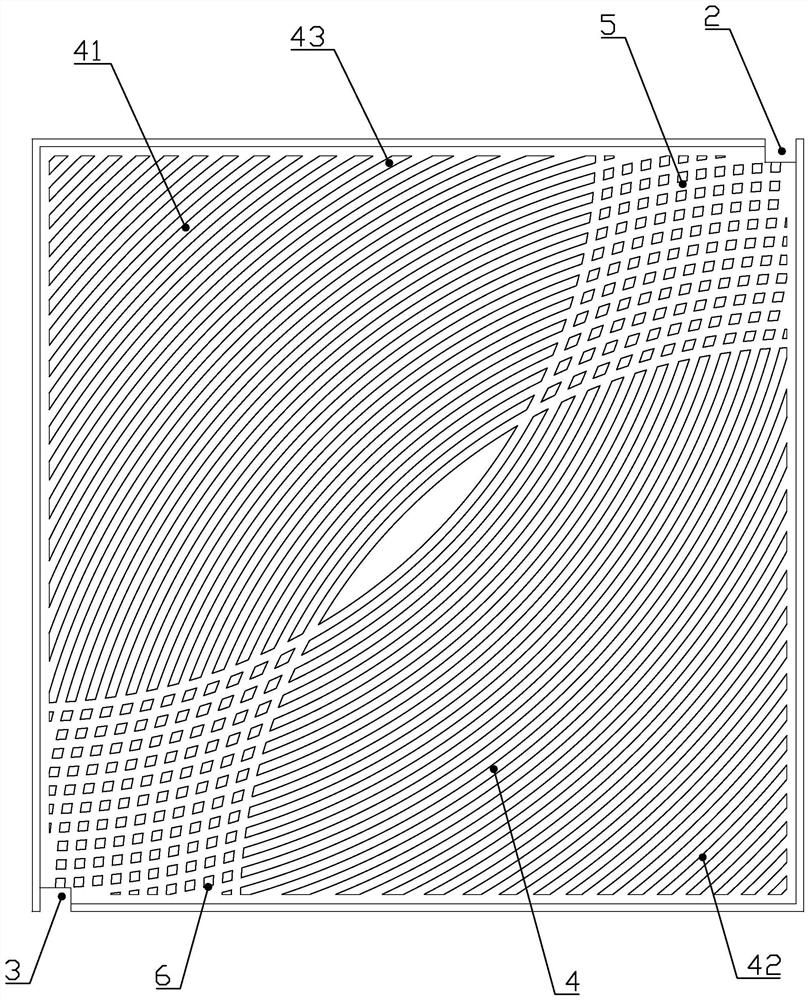

Bipolar plate with high-performance complex bionic structure flow field and preparation method

ActiveCN111261894AReduce transmission resistanceImprove stabilityLaser beam welding apparatusCollectors/separatorsMass transferEngineering

The invention relates to a bipolar plate with a high-performance complex bionic structure flow field. The bipolar plate comprises a bipolar plate body; a fractal flow field is arranged on the bipolarplate body; the fractal flow field comprises a reaction gas inlet and a gas flow channel; an inlet transition area is arranged between the gas flow channel and the reaction gas inlet; the reaction gasinlet is arranged at the outer end of the inlet transition area; the gas flow channel comprises a first flow channel and a second flow channel; the first flow channel and the second flow channel aresymmetrically arranged by taking the central point of the fractal flow field as a symmetric center. The bipolar plate has the capabilities of enhancing the mass transfer of gas and water and improvingthe management of water, gas and heat. According to the method for preparing the bipolar plate with the high-performance complex bionic structure flow field, the flow channel in any complex shape canbe prepared through the composite preparation of a laser melting technology and a laser polishing technology; the process of the method is simple, and the reliability of the method is high; and the surface smoothness of the flow field flow channel is improved through the laser polishing technology, and therefore, fluidity is improved.

Owner:WENZHOU UNIVERSITY

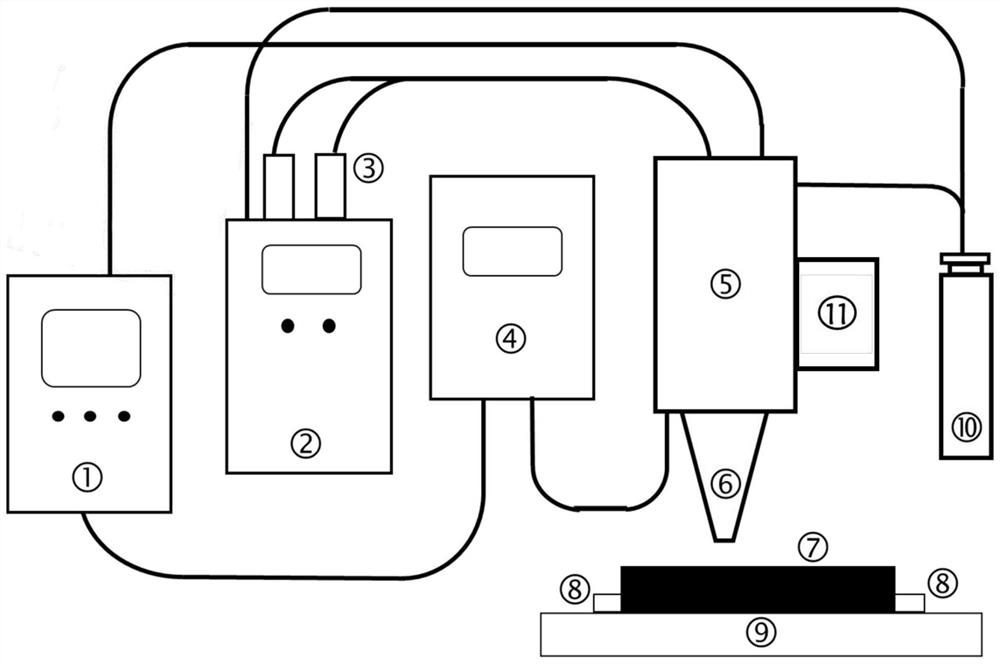

High-frequency pulse laser pressure stress implantation rapid forming system and method

PendingCN112846181AImprove fatigue resistanceImprove forming efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyControl systemMotion system

The invention relates to a high-frequency pulse laser pressure stress implantation rapid forming system and method. The forming system comprises a laser control system, a high-frequency pulse laser generator, a powder feeder, a motion system, a coaxial powder feeding laser cladding head and an inert gas source, wherein the laser control system is used for obtaining the data of a preformed part and converting the data into a control instruction for controlling the motion mode and the motion path of the motion system; the high-frequency pulse laser generator is connected with the motion system and is used for emitting laser pulses with specified frequency and implanting pressure stress into a cladding point by utilizing the laser pulses; the powder feeder is connected with the motion system and used for providing cladding powder, and an electromagnetic switch is arranged on the powder feeder; the motion system is connected with the coaxial powder feeding laser cladding head and used for controlling the motion state of the coaxial powder feeding laser cladding head; the coaxial powder feeding laser cladding head is used for coaxially conveying the laser pulses and the cladding powder to a metal substrate; and the inert gas source is connected with the powder feeder and the motion system and used for providing inert gas to prevent the cladding powder from being oxidized. simultaneous pressure stress implantation rapid forming is realized in the laser cladding process.

Owner:北京机科国创轻量化科学研究院有限公司烟台分公司

Holding structure of safety belt

InactiveCN102529877AImprove the environmentReduce forming costBelt anchoring devicesEngineeringBelt safety

The present invention provides a holding structure of a safety belt, which has the following functions: reducing forming cost, improving appearance quality and improving environment in the carriage. An inner decoration component (2) has a vertical two-part structure which is composed of an upper inner decoration component (10) and a lower inner decoration component (20). An appearance surface (20M) side of the inner decoration component is provided with a safety belt holding member (30) which is used for snapping and holding the safety belt (3). The safety belt holding member is integrally formed at a random one selected from a lower end of the upper inner decoration component in mutual connection, and furthermore projects from a sub-molding-surface of the random one. The safety belt holding member furthermore opposes a holding surface (17) of the appearance surface side of the other member in the lower end of the upper inner decoration component and the upper end of the lower inner decoration component. The safety belt is inserted between the safety belt holding member and the holding surface and is jointed with the safety belt holding component.

Owner:SUZUKI MOTOR CORP

Device and method for bending pipe with sealed end by using tension rope or plug

The invention discloses a device and a method for bending a pipe with a sealed end by using a tension rope or plug, which relate to a pipe bending device and a pipe bending method. The invention solves the problems of unreliable sealing and low forming efficiency in a pipe internal pressure bending forming process. In the device, plugs are arranged at the two ends of a pipe, the plugs and the pipes are sealed by the annular grooves with slant walls on the inner sides of the plugs, a tension rope sealing ring is arranged in a counter bore, the outer end face of the tension rope sealing ring is provided with a pressure plate, one end of the tension rope is connected with the inner end face of the first plug, the other end of the tension rope passes through a tension rope central hole, the tension rope sealing ring and the pressure plate to be connected with a tensioning wrench, and the tensioning wrench is arranged on the pressure plate through a rotating shaft. The method comprises: assembling the bending device, and tensioning the rope by using the tensioning wrench; filling high-pressure medium under the pressure of 0.5 to 100MPa into the pipe by using a pressurizing cylinder, and bending the pipe; and discharging the high-pressure medium, taking the tensioning rope and plugs, and accomplishing the bending forming of the pipe. The device and the method are used for bending forming of pipes.

Owner:HARBIN INST OF TECH

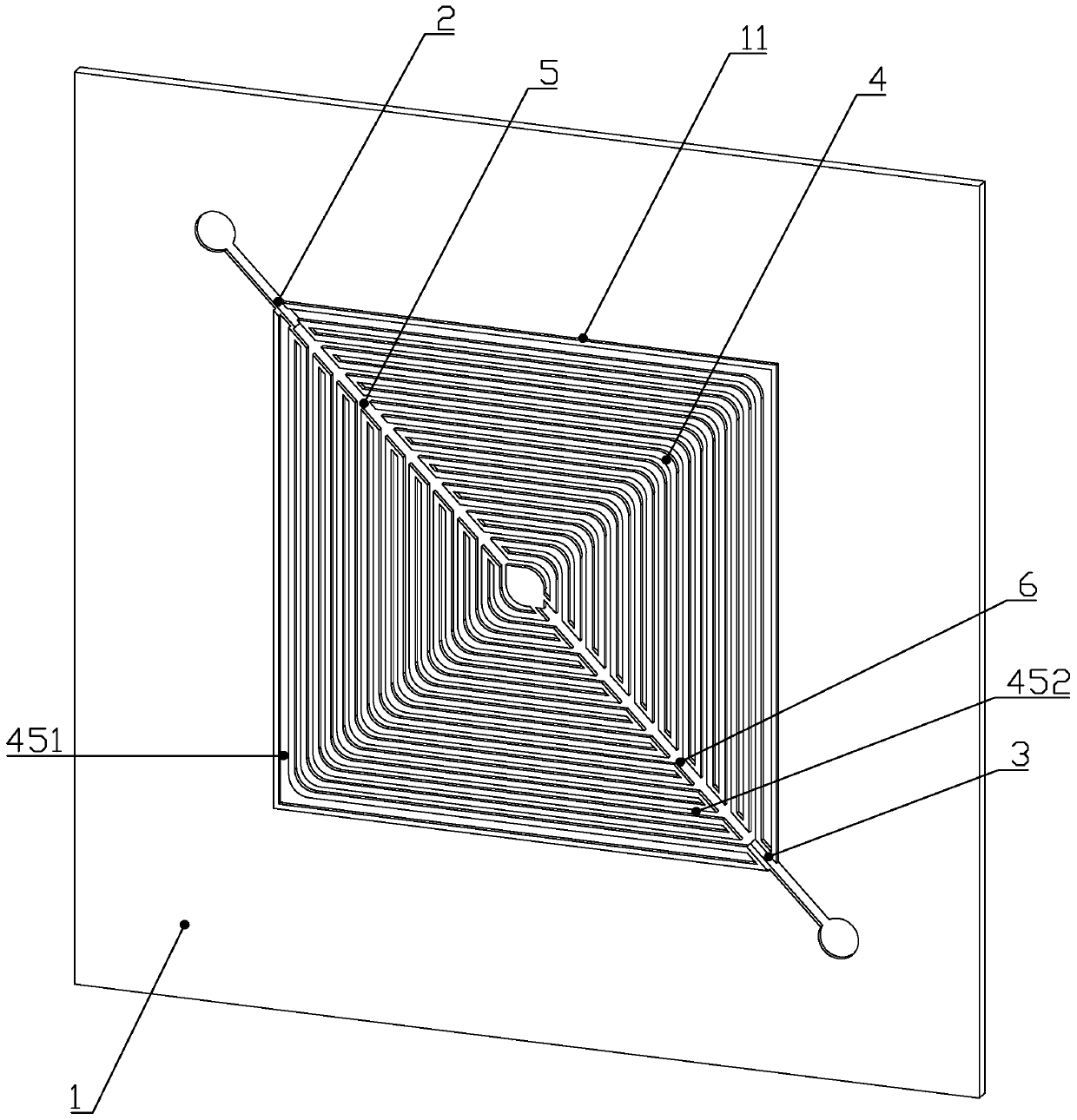

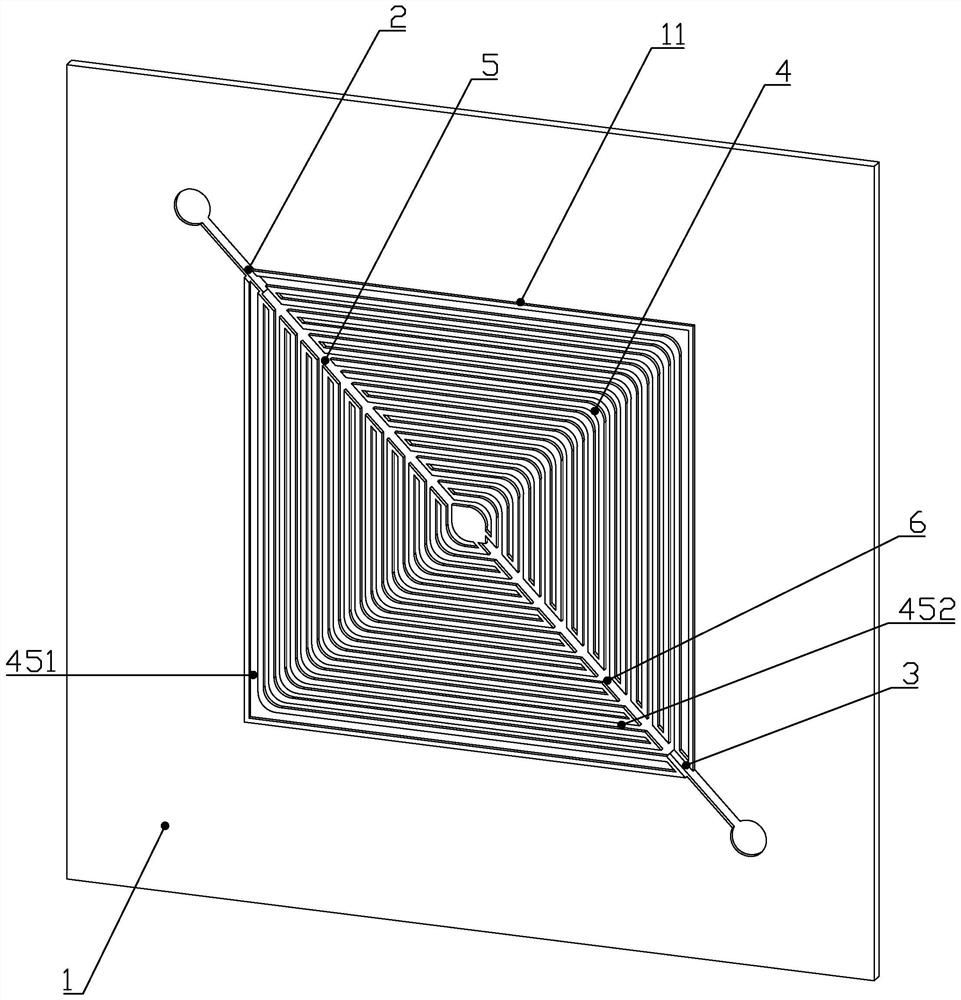

Electromagnetic forming device and forming method based on conductive channel

ActiveCN113333561BImprove forming qualityReduce forming costIncreasing energy efficiencyElectrical resistance and conductanceEngineering

The invention provides an electromagnetic forming device and forming method based on a conductive channel, comprising: the conductive channel is placed on one side of the mold; the mold includes a left area, a right area and a central concave area; the conductive channel includes a first And the third sub-conductive channel; the first and second sub-conductive channels are respectively placed on one side of the left area of the mold and one side of the right area of the mold, and the third sub-conductive channel connects the first and second sub-conductive channels to form A circular conductive channel with a notch, and the direction of the notch faces the middle concave area of the mold; the metal workpiece is placed at the gap inside the conductive channel; the metal workpiece and the conductive channel form a conductive loop; the uniform pressure drive coil is placed inside the conductive channel , and placed above the metal workpiece; pass a pulse current to the uniform pressure drive coil, and drive the metal workpiece to deform toward the middle concave area of the mold. The invention reduces the contact resistance formed by poor contact between the metal workpiece and the conductive channel, and improves the forming quality of the workpiece.

Owner:HUAZHONG UNIV OF SCI & TECH

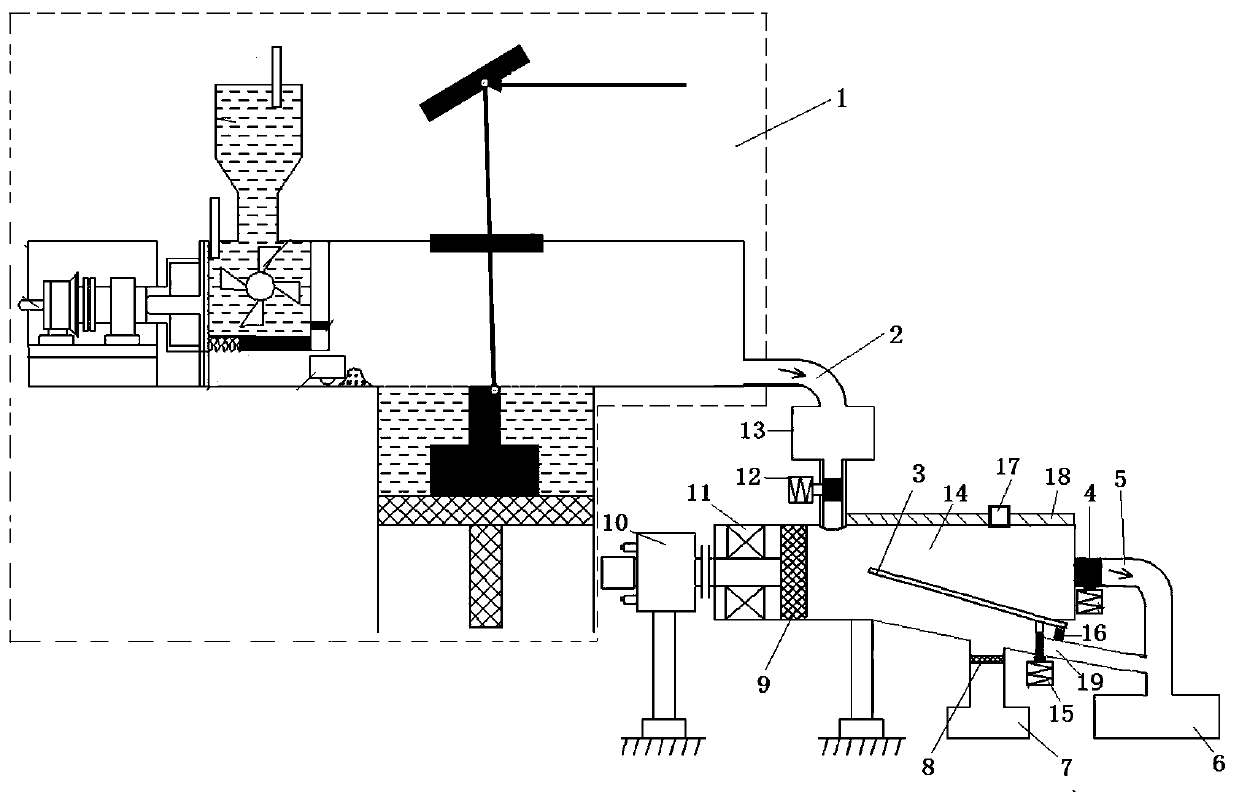

A Slurry Recovery System for Selective Laser Melting Forming

ActiveCN108057889BSolve difficult to recycleReduce forming costAdditive manufacturing apparatusIncreasing energy efficiencyHydraulic cylinderSelective laser melting

The present invention proposes a selective laser melting forming slurry recovery system. The transfer bin of the system is connected to the forming system through the receiving port, and the solid-liquid separation cavity is connected to the lower part of the transfer bin through a pressure-sensing electromagnetic valve. A pressure plate is installed in the cavity, which is controlled by a hydraulic cylinder to move up and down in the cavity. The first discharge port and the second discharge port are set on the solid-liquid separation cavity and connected to the powder collector at the same time, and an electric switch is installed on the first discharge port. , Install a pressure valve on the second discharge port, install a separation liquid collector at the bottom of the solid-liquid separation chamber, and install a filter screen at the connection. The slurry recovery system of the present invention solves the problem that the organic solvent slurry SLM is difficult to recover after forming, realizes the reuse of metal powder and reinforcement materials in the slurry, and reduces the cost of SLM forming.

Owner:ZHONGBEI UNIV

Vacuum electric scanning supersonic spray deposition laser additive manufacturing device

ActiveCN112776324ASimplify the sintering processPrevent splashIncreasing energy efficiencyManufacturing environment conditioningParticle beamLaser additive manufacturing

The invention discloses a vacuum electric scanning supersonic spray deposition laser additive manufacturing device. The vacuum electric scanning supersonic spray deposition laser additive manufacturing device comprises a forming workbench and a laser spray additive device installed above the workbench, the laser spray additive device comprises a cold spray head, a laser generator and a laser beam control device, the spraying direction of the cold spray head can be adjusted so that sprayed powder particle beams can be scanned on the workbench based on the shape of a part, the laser beam control device is installed at an emitting opening of the laser generator and used for controlling the emitting direction of laser beams, the laser beams and the powder particle beams sprayed by the cold spray head are converged at one point, and the surface of the base body and the powder particles are heated to be in a molten state. According to the device, the part is formed by directionally spraying powder and heating and sintering in real time, layer-by-layer powder laying and sintering are not needed, the forming efficiency is greatly improved, the powder cannot be wasted, the forming cost is reduced, the forming quality consistency is good, the forming quality is improved, the part sintering procedure is simplified, and the sintering efficiency is improved.

Owner:AIR FORCE UNIV PLA +2

Internal Spinning Forming Method of Bellows

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

A bipolar plate with high-performance complex bionic structure flow field and preparation method

ActiveCN111261894BSimple engineering processImprove reliabilityLaser beam welding apparatusCollectors/separatorsBiomimeticsEngineering

The invention relates to a bipolar plate with a high-performance complex bionic structure flow field, comprising a bipolar plate body, a fractal flow field is arranged on the bipolar plate body, and the fractal flow field includes a reaction gas inlet and a gas flow An inlet transition area is provided between the gas flow channel and the reaction gas inlet, the reaction gas inlet is arranged at the outer end of the inlet transition area, and the gas flow channel includes a first flow channel and a second flow channel , taking the central point of the fractal flow field as the center of symmetry, the first flow channel and the second flow channel are arranged symmetrically, the bipolar plate can enhance the mass transmission of gas and water, and improve the management ability of water, gas and heat. The method for preparing this type of bipolar plate with high-performance and complex bionic structure flow field is prepared by composite preparation of laser melting technology and laser polishing technology, and can prepare flow channels of arbitrary complex shapes. The process is simple and the reliability is high. At the same time, the laser Polishing technology improves the surface finish of the flow field flow channel, thereby improving fluidity.

Owner:WENZHOU UNIV

Superalloy fluid medium ultra-high pressure forming method and device

Owner:BEIHANG UNIV

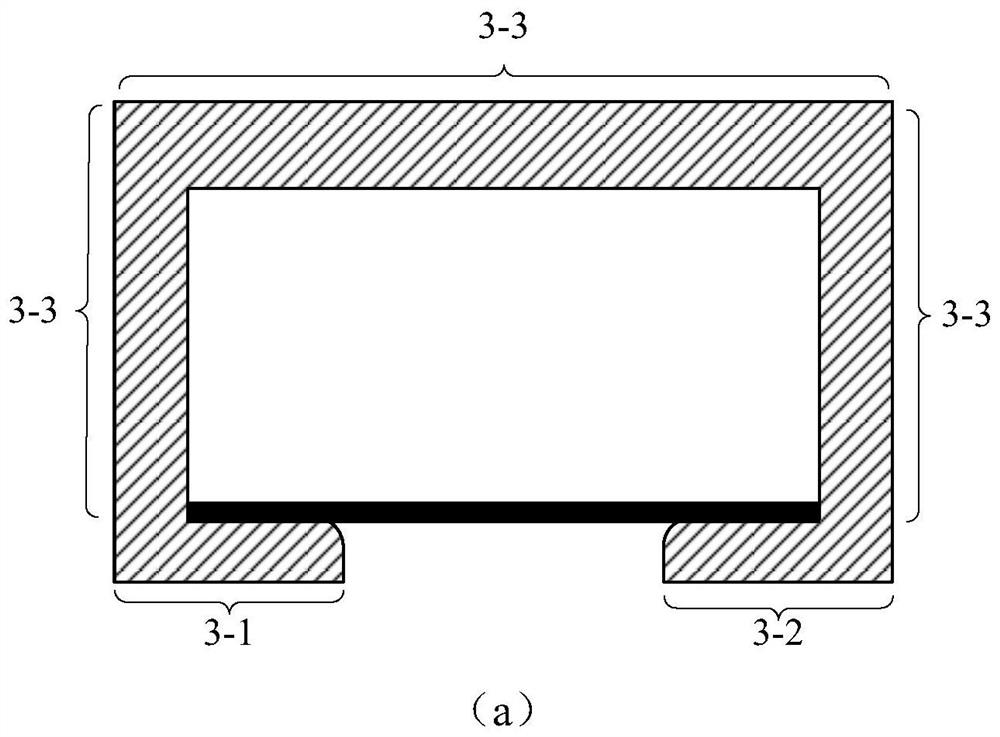

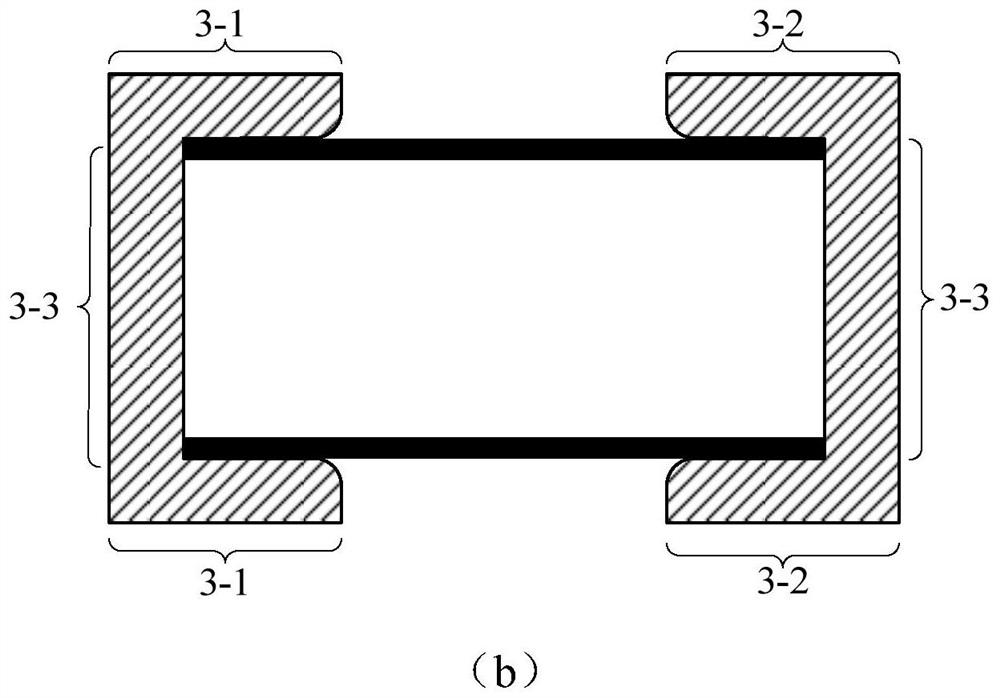

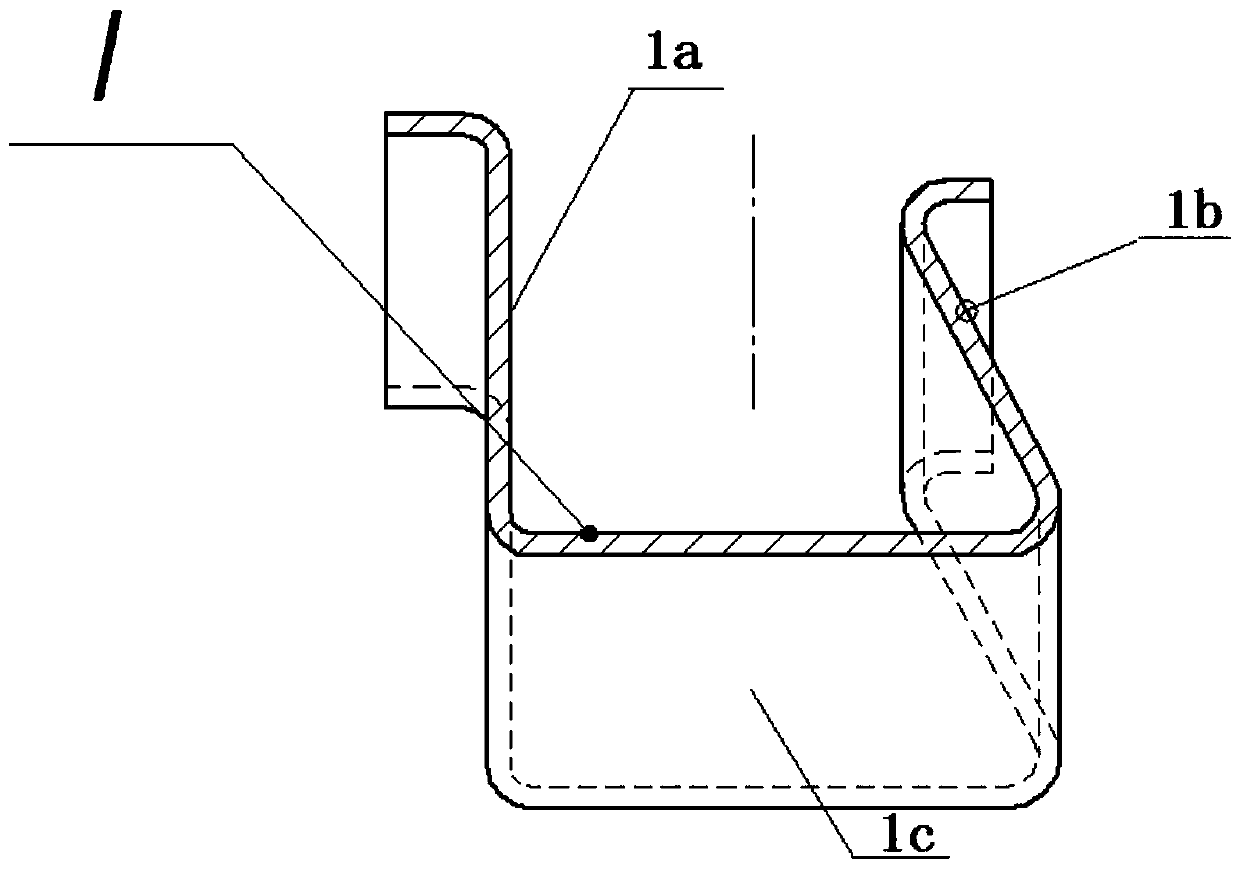

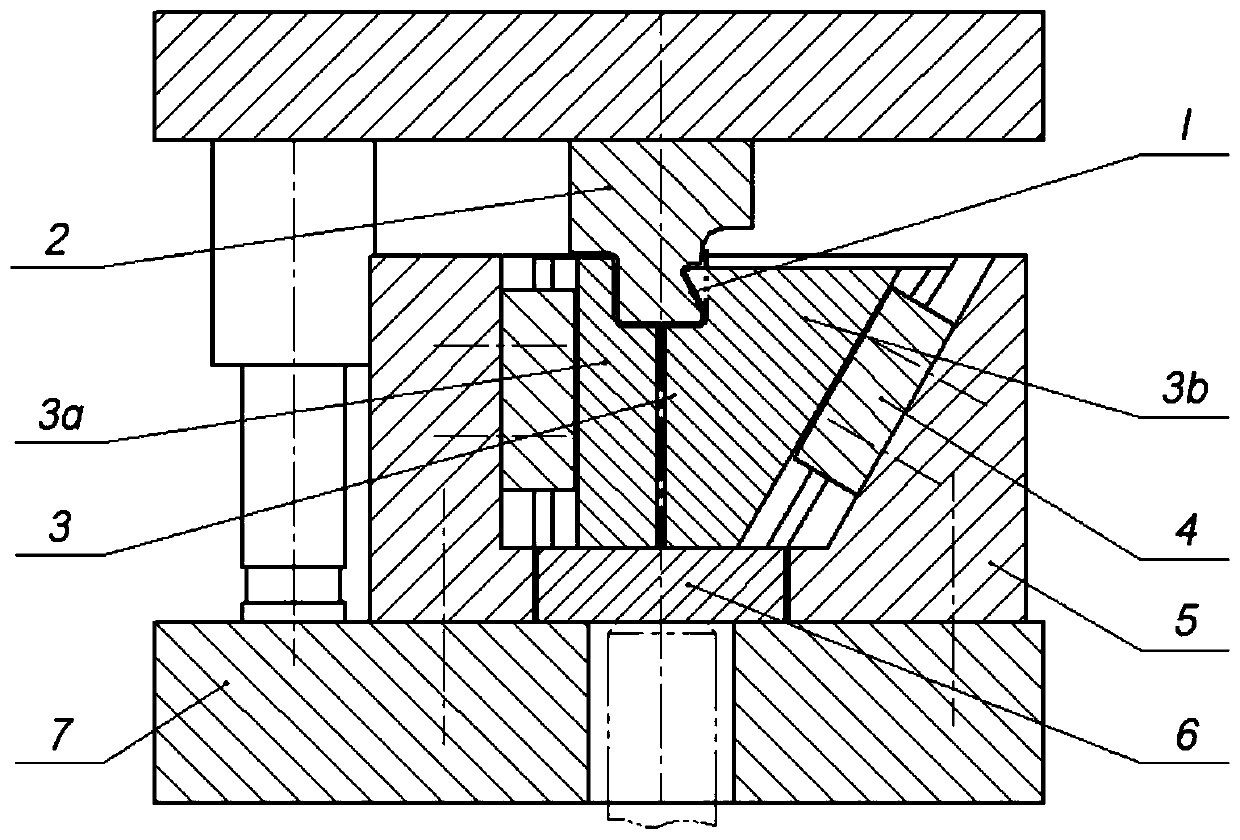

A mold and method for forming a concave inner ring seal sleeve

ActiveCN110227745BMeet the needs of developmentReduce in quantityShaping toolsStructural engineeringOblique angle

The invention discloses an inwards-concave n-shaped inner ring sealing sleeve forming die and method. The forming device comprises a male die (2), a female die (3), a guide plate (4), a female die frame (5), a top plate (6) and a rear guide column die frame (7); during molding, the inner ring sealing sleeve (1) is divided into two parts of a straight waist-shaped surface and an inclined waist-shaped surface by adopting a fan-shaped curved surface along the chord length direction of the inner ring sealing sleeve (1) fan-shaped groove and perpendicular to the bottom ring surface (1c) of the n-shaped cross section, then a right-angle concave mold is used (3a) and an oblique-angle female die (3b) are used for simultaneously punching and forming the two parts. According to the forming die and method, the forming of the part is completed at one time, the part is convenient to assemble and disassemble, and the quality of the shape surface is good.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

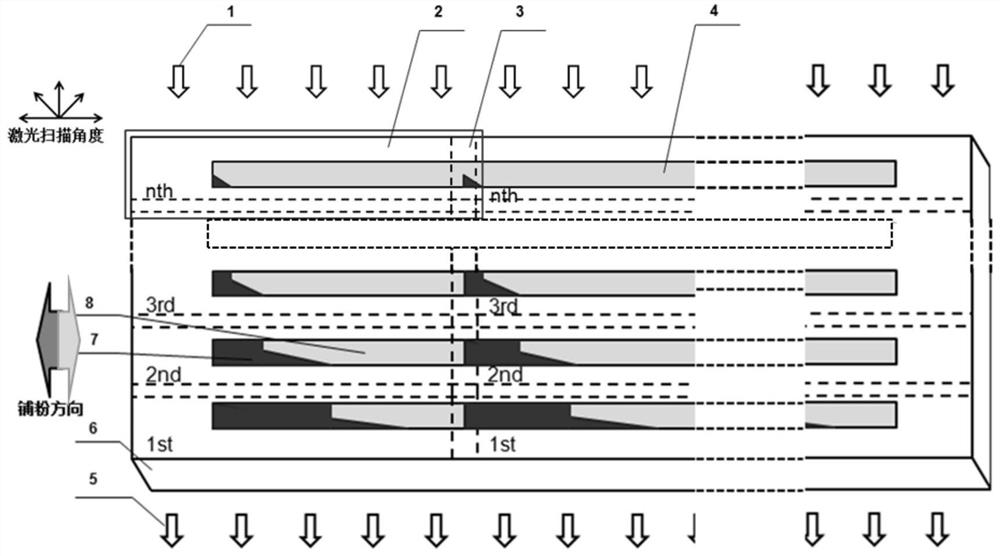

Arrangement and scanning strategy for multiple same-cabin parts of selective laser melting strip-shaped structure

PendingCN114535608AImprove forming efficiencyReduce forming costAdditive manufacturing apparatusIncreasing energy efficiencyErbium lasersManufacturing efficiency

The invention provides an arrangement and scanning strategy for multiple same-cabin parts of a selective laser melting strip-shaped structure. The arrangement and scanning strategy comprises a multi-laser arrangement strategy, a part placement strategy and a laser cooperative scanning strategy of selective melting additive manufacturing equipment involved in the method. When the number of the cabins is not less than four, the utilization rate of equipment space is improved through the strategy that the same cabins are arranged at equal intervals; the number of the lasers is determined according to the number of the parts, the number of the lasers is 2-4 times that of the parts, the number of effective lap joint areas is minimum, the debugging time is shortened, and the additive forming efficiency is improved; in order to solve the problem of splashing interference of printing of multiple pieces in the same cabin, the invention provides a full headwind, multi-laser same-direction and asynchronous scanning strategy, the problem of mutual connection of splashing of the multiple pieces in the same cabin is solved, and the forming quality is ensured. By means of the method, manufacturing of more than four strip-shaped products in the same cabin and the same strategy can be achieved while the product quality is guaranteed, the manufacturing efficiency is improved to 400% or above, and the additive forming cost is reduced by 60%.

Owner:NANJING CHENGUANG GRP +1

Laser continuous cutting device and cutting method for cutting saw band

ActiveCN104014938BNo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusDrive wheelMilling cutter

Owner:湖南泰嘉智能科技有限公司

Seat belt retaining structure

InactiveCN102529877BReduce forming costImprove appearance qualityBelt anchoring devicesEngineeringDivided structure

PROBLEM TO BE SOLVED: To provide a retaining structure of a seat belt capable of reducing forming cost, improving appearance quality, and improving the environment in the interior of a vehicle. SOLUTION: A seat belt holder 30, which is engaged with and retains the seat belt 3, is provided on a side of a design surface 20M of an interior part 2 having an upper / lower two-divided structure composed of an upper interior part 10 and a lower interior part 20. The seat belt holder 30 is integrally formed with either one of a lower end part of the upper interior part 10 and an upper end part of the lower interior part 20, which are mutually coupled, projects from a break line portion of either one of them, and faces a retaining surface 17 on the design surface side, of the another one. The seat belt 3 is inserted between the seat belt holder 30 and the retaining surface 17 so as to be engaged with the seat belt holder 30.

Owner:SUZUKI MOTOR CORP

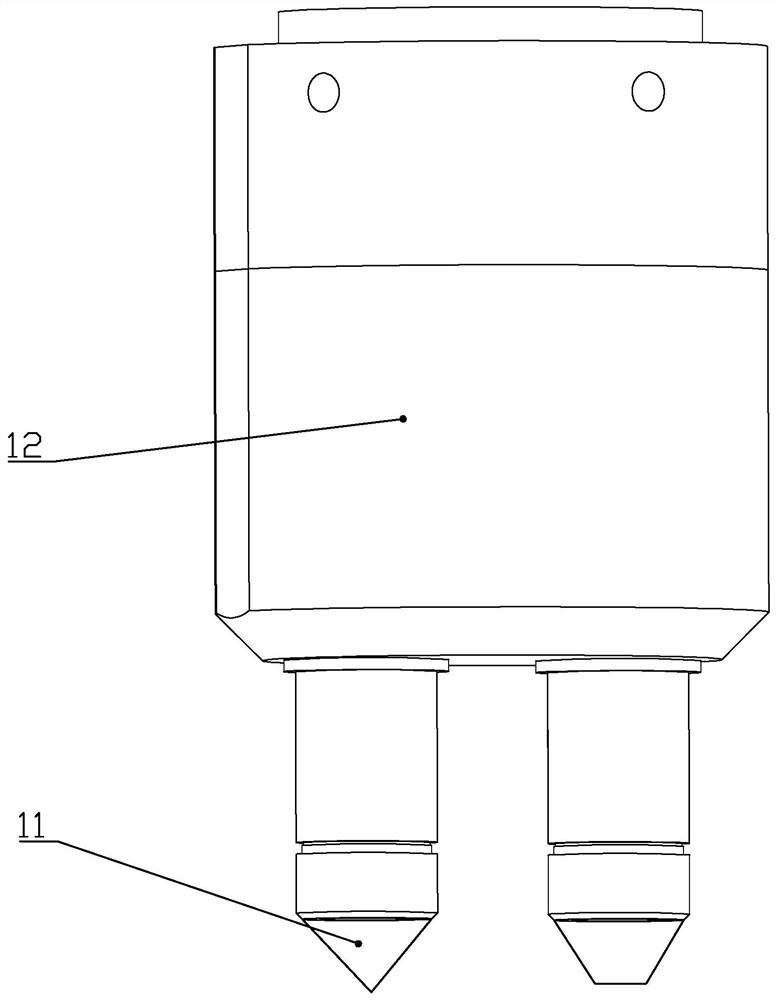

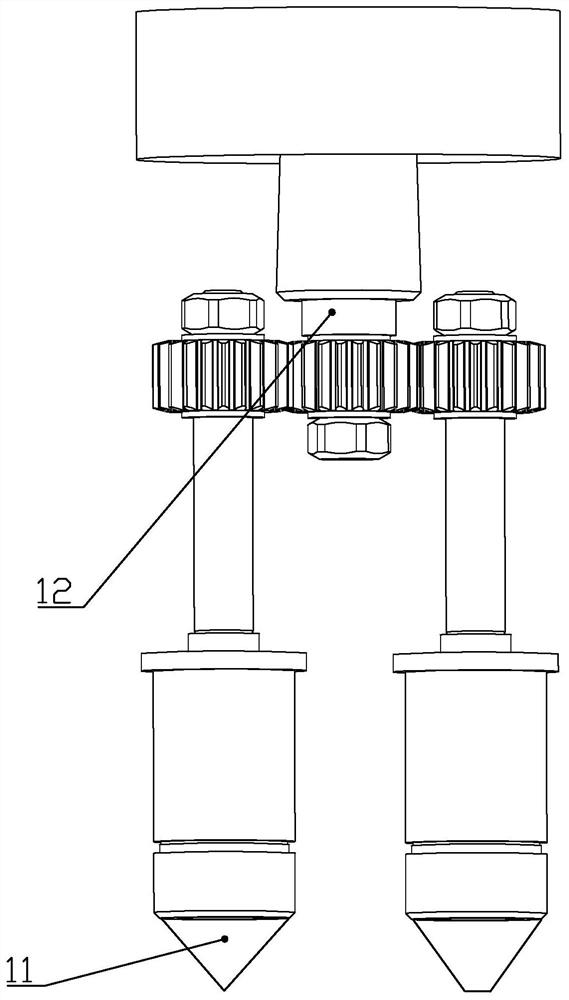

A kind of production method and forming equipment of brake shoe

The invention discloses a production method of a brake rubber block as well as a forming device. The production method comprises the following steps: uniformly mixing and stirring the following materials: 13-15 parts of rock wool, 4-6 parts of barite powder, 5-7 parts of resin powder, 1-2 parts of vermiculite powder, 1-2 parts of feldspar powder, 1-2 parts of tyre powder, 0.2-0.3 part of zinc stearate and 0.8-1.2 parts of frictional powder; arranging a brake framework, and brushing glue on a concave arc surface which is required to be covered with the brake rubber block; pushing the arranged brake framework below a discharge mold groove, weighing 30-40g of mixed material and pouring the material into the discharge mold groove so as to enable the mixed material to be contained in the concave arc surface of the brake rubber block; and pushing the discharge mold groove and the brake framework together into a mold press and performing extrusion forming for 3-5 minutes at the pressure of 18-22PA under the condition that the temperature of a pressing die compartment is controlled to be 170-190 degrees. The production method of the brake rubber block as well as the forming device have the following advantages that the forming efficiency is high, and the forming cost is reduced; less mixed material is used compared with that of the prior art; on the aspect of the finished product quality, the brake rubber block and the brake framework which are produced by the technology provided by the invention are more firm.

Owner:莆田市金田摩配有限公司

A processing device and processing method for a bipolar plate with a complex flow field and a special-shaped cross-section

ActiveCN111230315BReduce processing stepsAvoid inclusionsFuel cellsMetal working apparatusEngineeringErbium lasers

The invention relates to a processing device and a composite processing technology for a bipolar plate with a complex cross-section and a complex flow field. The processing device includes a laser, a rotating mechanism, a sealed cabin, and a fixed platform mechanism for fixing the bipolar plate. The composite processing technology Including the use of laser precision etching technology and laser polishing technology on the processing device to process and post-process the bipolar plate. By adopting the above technical solution, the processing of flow fields with arbitrary complex structures can be solved. The processing device changes the laser and bipolar plate. The angle between the plates, and then use laser precision etching technology to realize the processing of flow channels with special-shaped cross-section shapes, and use laser polishing technology as a post-processing process to solve the removal of oxides and inclusions in the flow channels after etching and improve the flow field Surface finish, which in turn improves bipolar plate performance.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com