Laser continuous cutting device and cutting method for cutting saw band

A cutting device and cutting saw technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low cutting efficiency, large proportion of tooling auxiliary time, and inability to realize continuous sawtooth cutting and forming, etc. Achieve good cutting quality, improve laser cutting efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

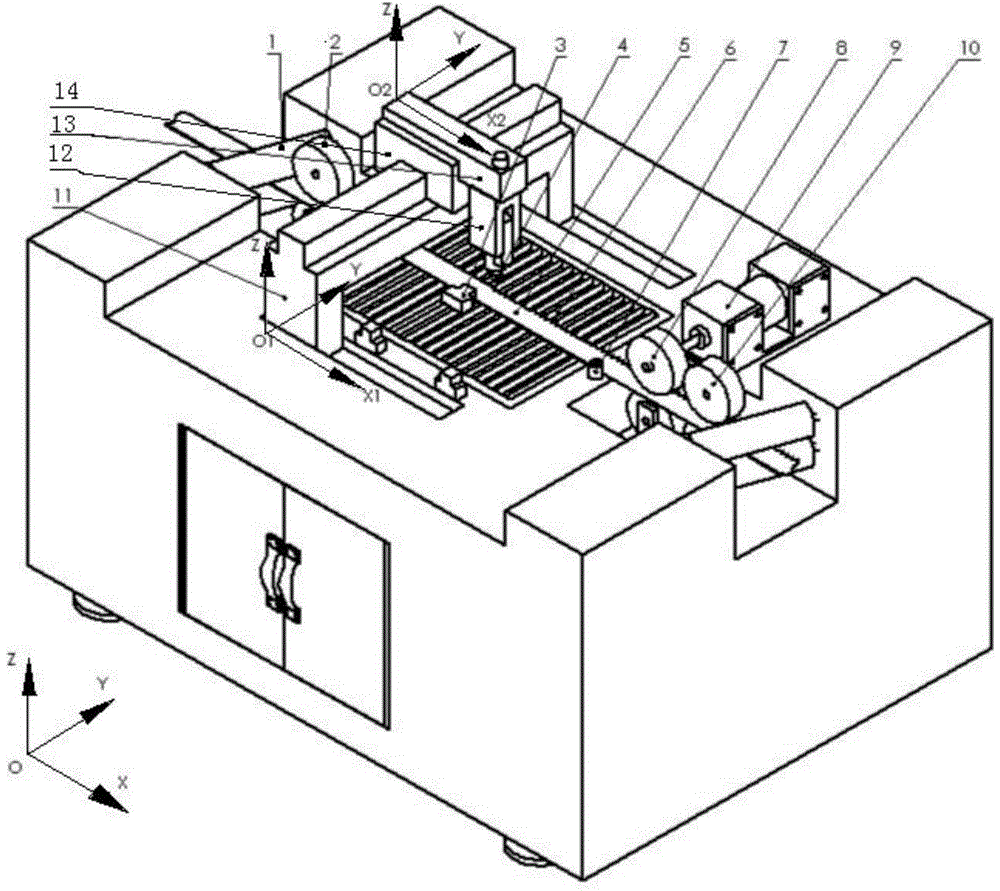

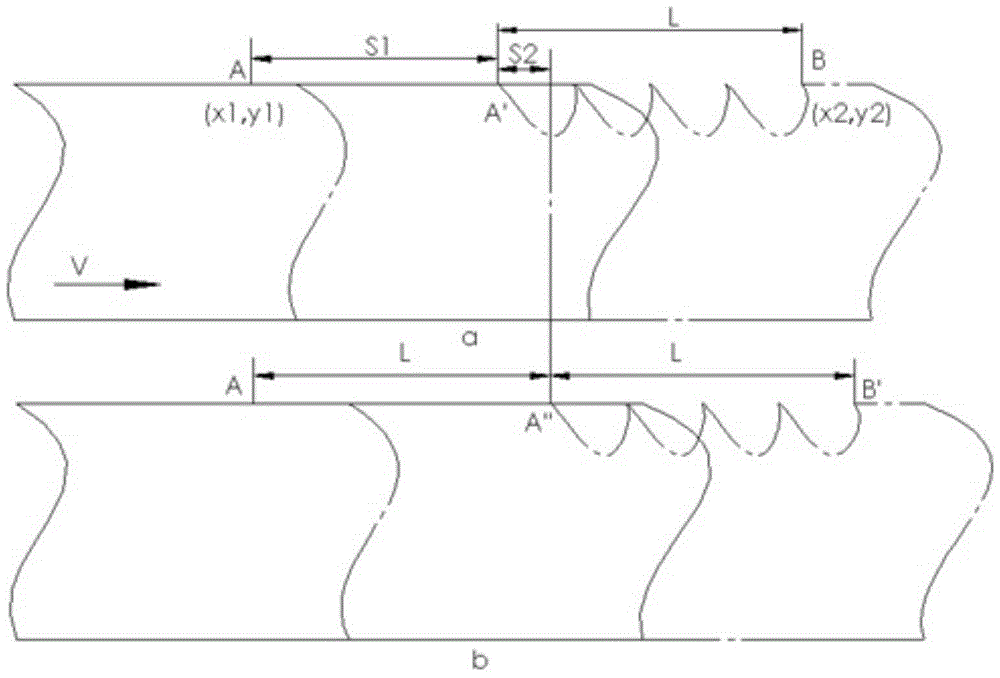

[0027] A laser continuous cutting device and cutting method, based on numerical control motion synthesis, can realize high-precision laser sawtooth continuous cutting, such as figure 1 and 3 As shown, the specific cutting process is as follows:

[0028] 1) During the whole working process, the bimetal strip feeds in one direction at a constant speed;

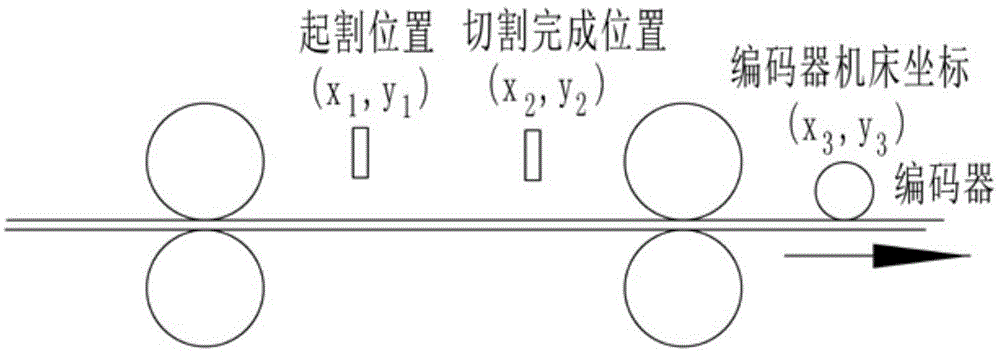

[0029] 2), the code detector is fixed as a machine tool coordinate ( x 3 ,y 3 ), used to detect the feed length of the saw band, the starting cutting position of the laser head is A ( x 1 ,y 1 ), the position of the laser head after each cutting is B ( x 2 ,y 2 );

[0030] 3) The position where laser cutting is completed is the tooth tip position. After cutting a group of teeth (or groups of teeth), the laser head quickly returns to the starting point A(x1, y1);

[0031] 4) After the laser head returns to the cutting start point A(x1, y1), prepare for a new round of cutting;

[0032] 5) At this time, the displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com