A kind of strengthening grinding method of wear-resistant alloy steel workpiece surface

A workpiece surface and grinding method technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of mechanical strengthening of the surface of a single wear-resistant alloy steel workpiece and cannot be chemically modified at the same time, so as to reduce surface tension and prevent Effect of ineffectiveness and inhibition of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

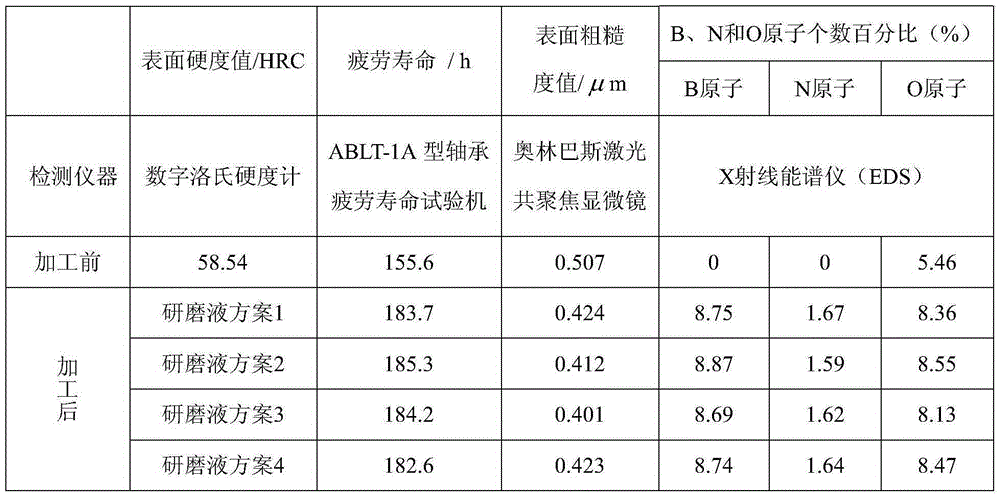

example 1

[0021] Example 1 (refined)

[0022] The wear-resistant alloy steel workpiece is the bearing ring inner ring of GCr15, which is subjected to intensified grinding.

[0023] (1) Preparation of mixture

[0024] ①The modified liquid for enhanced grinding (abbreviated as grinding liquid) is the following 4 preparation schemes:

[0025] Option 1: Add 15% fatty acid imidazoline borate, 2% sodium benzoate, 12% sodium alkyl sulfonate, 5% triethanolamine, 4% fatty alcohol polyoxyethylene ether, borax (chemical name tetraboric acid Sodium) 3%, disodium ethylenediaminetetraacetic acid 0.5%, sodium hydroxide 1%, polyoxypropylene 0.1% and benzotriazole 0.3% are added to 57.1% water and stirred evenly to obtain an enhanced grinding modification solution;

[0026] Scheme 2: According to weight percentage, 16.5% of phosphate amine salt compound, 2.1% of adipic acid, 10% of sodium alkyl sulfate, 4.2% of disodium hydrogen phosphate, 7% of alkylphenol polyoxyethylene ether, aminoacetic acid- Add 2.5% hydr...

example 2

[0038] Example 2 (rough grinding)

[0039] The wear-resistant alloy steel workpiece is 1Cr18Ni9 bearing ring inner ring, which is subjected to intensified grinding.

[0040] (1) Preparation of mixture

[0041] ①Intensified grinding modified liquid is the following 4 preparation schemes:

[0042] Scheme 1: According to weight percentage, fatty acid imidazoline borate 16%, sodium benzoate 2%, sodium alkyl sulfonate 11%, triethanolamine 4%, fatty alcohol polyoxyethylene ether 5%, borax (chemical name tetraboric acid Sodium) 3.5%, disodium ethylenediaminetetraacetic acid 0.4%, sodium hydroxide 1%, polyoxypropylene 0.1% and benzotriazole 0.2% are added to 56.8% water and stirred evenly to obtain an enhanced grinding modification solution;

[0043] Scheme 2: According to weight percentage, 16.5% of phosphate amine salt compound, 3% of adipic acid, 10.5% of sodium alkyl sulfate, 4.4% of disodium hydrogen phosphate, 6% of alkylphenol polyoxyethylene ether, glycine- Add 2% hydrochloric acid, 0...

example 3

[0055] Example 3 (The influence of different jet speeds to strengthen the grinding effect)

[0056] 1. The wear-resistant alloy steel workpiece is the inner ring of 1Cr13 bearing ring, which is subjected to intensified grinding.

[0057] (1) Preparation of mixture

[0058] ①Fatty acid imidazoline borate 18%, sodium benzoate 2.2%, sodium alkyl sulfonate 12.5%, triethanolamine 4.5%, fatty alcohol polyoxyethylene ether 2%, borax (chemical name sodium tetraborate) 2.5%, 0.6% disodium ethylenediaminetetraacetic acid, 1% sodium hydroxide, 0.2% polyoxypropylene and 0.4% benzotriazole were added to 56.1% water and stirred evenly to obtain an enhanced grinding modification solution;

[0059] ②According to the gradation of Φ1mm: Φ2mm: Φ3mm = 2:1:1, the steel balls of the cast steel material with the diameters of Φ1mm, Φ2mm and Φ3mm with Rockwell hardness of 65HRC are mixed together;

[0060] ③Pass the brown fused alumina powder through a 150-mesh sieve and then a 280-mesh sieve to collect the br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com