A mold and method for forming a concave inner ring seal sleeve

The technology of a few-shaped and concave molds is applied to the field of forming molds with a concave "ji"-shaped inner ring and a tight sleeve. , Improve the forming accuracy, the effect of good shape and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

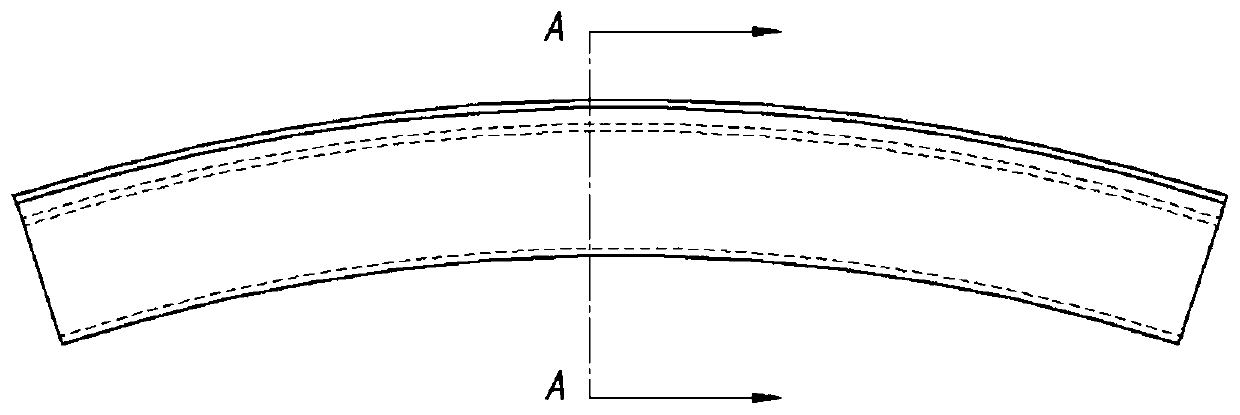

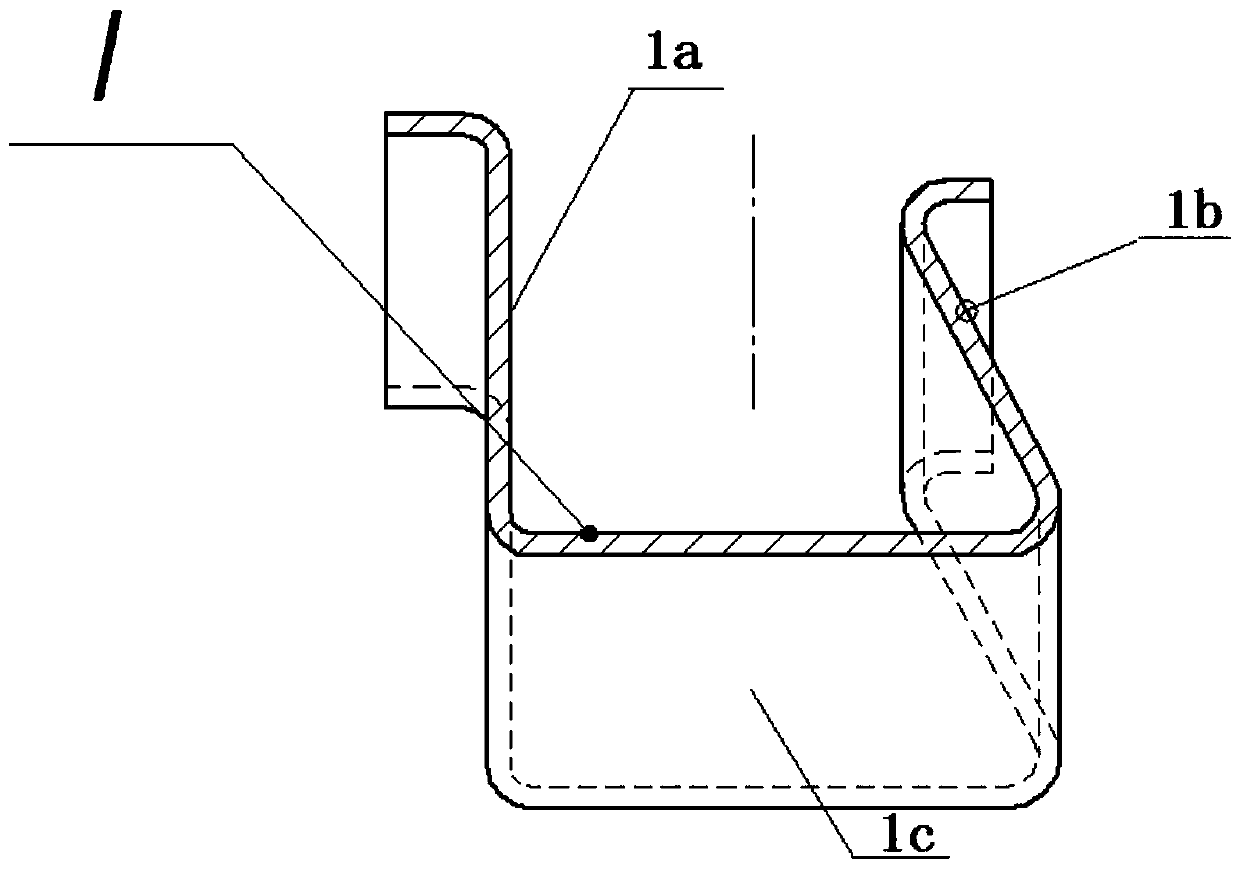

[0028] like figure 1 and figure 2 As shown in the figure, the mold for forming the inner concave "ji"-shaped inner ring seal sleeve of the engine, the formed inner concave "ji"-shaped inner ring seal sleeve is a fan-shaped groove-shaped thin wall with an inverted "ji"-shaped cross section. For sheet metal parts, the outer ring surface of the inner ring sealing sleeve 1 is at right angles to the bottom ring surface 1c, forming the right-angled surface 1a of the inner ring sealing sleeve 1, and the other side (inner ring surface) faces inward due to the inner ring sealing sleeve 1 It forms an acute angle with the bottom ring surface 1c, forming the acute angle surface 1b of the inner ring sealing sleeve 1;

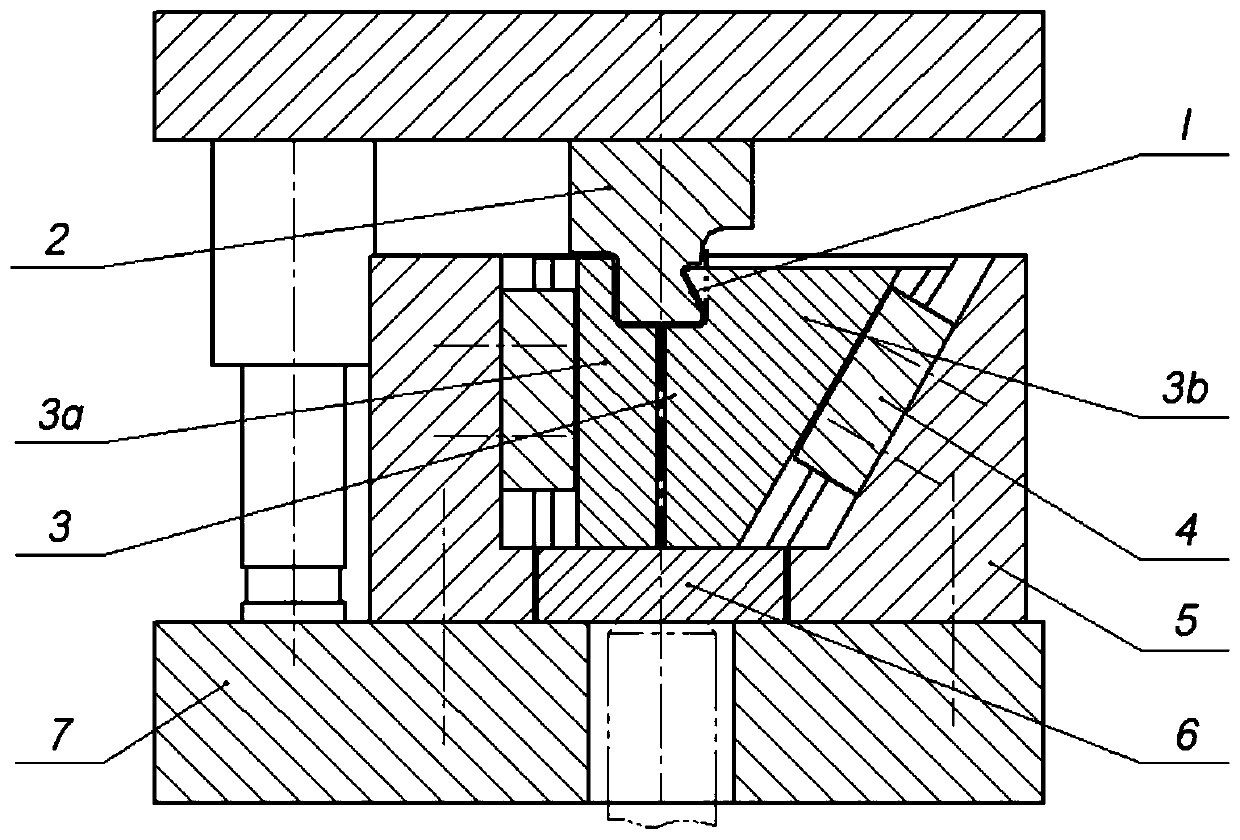

[0029] like image 3 , the forming mold used for the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com