Rb-doped concentration gradient ternary cathode material and preparation method thereof

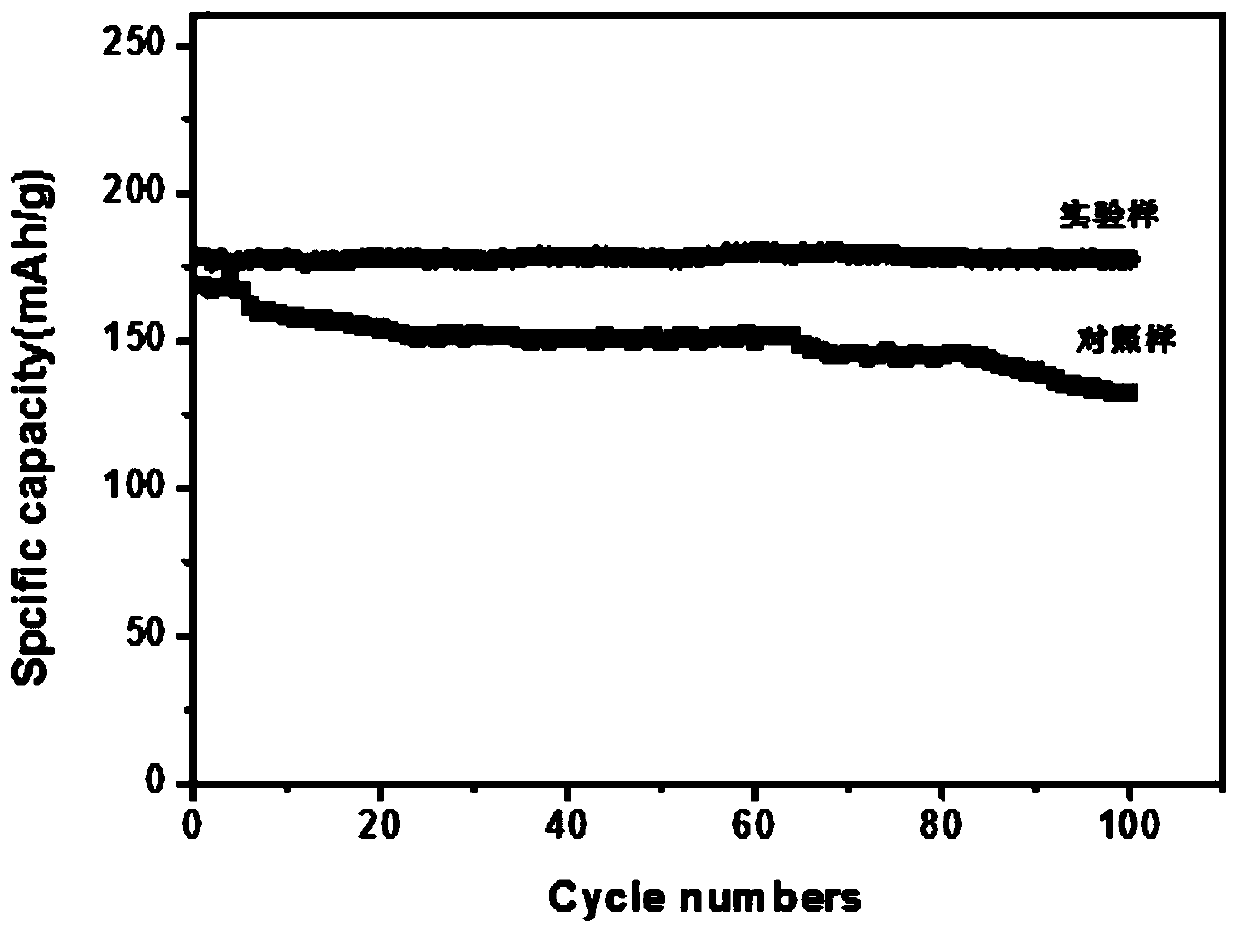

A cathode material and doping concentration technology, which is applied in the field of rubidium doped concentration gradient ternary cathode material and its preparation, can solve the problems of poor high-power discharge and charge performance, difficulty in meeting the development needs of new energy vehicles, and low capacity. Achieve the effects of high tap density, high yield and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A rubidium-doped concentration gradient ternary cathode material whose chemical expression is Li 1-x Rb x Ni 1-a-b co a mn b o 2 , where x is 0.05, 0.1≤a≤0.2, 0.1≤b≤0.3, 0.5≤1-a-b≤0.8.

[0031] The preparation method of the above rubidium-doped concentration gradient ternary cathode material, the specific steps are as follows:

[0032] (1) Synthesize the precursor of nickel-cobalt-manganese ternary cathode material with concentration gradient;

[0033] ① Weigh a certain mass of Ni (NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2, dissolved in deionized water so that the total metal concentration is 5mol / L, the former is recorded as high nickel content nickel cobalt manganese solution, the latter is recorded as low nickel content nickel cobalt manganese solution, low nickel content nickel cobalt manganese solution and high nickel content The volume ratio of the nickel-cobalt-manganese solution and the bottom solution is 1:5:3; a sodium hydroxide solution with a concentr...

Embodiment 2

[0045] A method for preparing a rubidium-doped concentration gradient ternary cathode material, the specific steps are as follows:

[0046] (1) Synthesize the precursor of nickel-cobalt-manganese ternary cathode material with concentration gradient;

[0047] ①Weigh a certain mass of NiCl according to the molar ratio of Ni:Co:Mn=8:1:1 and 5:2:3 2 , CoCl 2 , MnCl 2 , dissolved in deionized water so that the total metal concentration is 1mol / L, the former is recorded as high nickel content nickel cobalt manganese solution, the latter is recorded as low nickel content nickel cobalt manganese solution, low nickel content nickel cobalt manganese solution and high nickel The volume ratio of the nickel-cobalt-manganese solution and the bottom solution is 1:1:1; a sodium hydroxide solution with a concentration of 0.15mol / L is also prepared;

[0048] ②Use a peristaltic pump to inject the low-nickel-content nickel-cobalt-manganese solution into the high-nickel-content nickel-cobalt-ma...

Embodiment 3

[0055] A method for preparing a rubidium-doped concentration gradient ternary cathode material, the specific steps are as follows:

[0056] (1) Synthesize the precursor of nickel-cobalt-manganese ternary cathode material with concentration gradient;

[0057] ① Weigh a certain mass of Ni(CH 3 COO) 2 , Co(CH 3 COO) 2 , Mn(CH 3 COO) 2 , dissolved in deionized water, so that the total metal concentration is 10mol / L, the former is recorded as high nickel content nickel cobalt manganese solution, the latter is recorded as low nickel content nickel cobalt manganese solution, low nickel content nickel cobalt manganese solution and high nickel content The volume ratio of the nickel content nickel cobalt manganese solution and the bottom solution is 1:9:5; another sodium hydroxide solution with a concentration of 0.5mol / L is prepared;

[0058] ②Use a peristaltic pump to inject the low-nickel-content nickel-cobalt-manganese solution into the high-nickel-content nickel-cobalt-mangan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com