Manufacturing method of curved-surface-shaped sandwich structure and curved-surface-shaped sandwich structure

A technology of a sandwich structure and a manufacturing method, which is applied in the field of a curved sandwich structure, can solve the problem that the expected dimensional accuracy cannot be obtained, and achieve the effect of reducing the forming cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

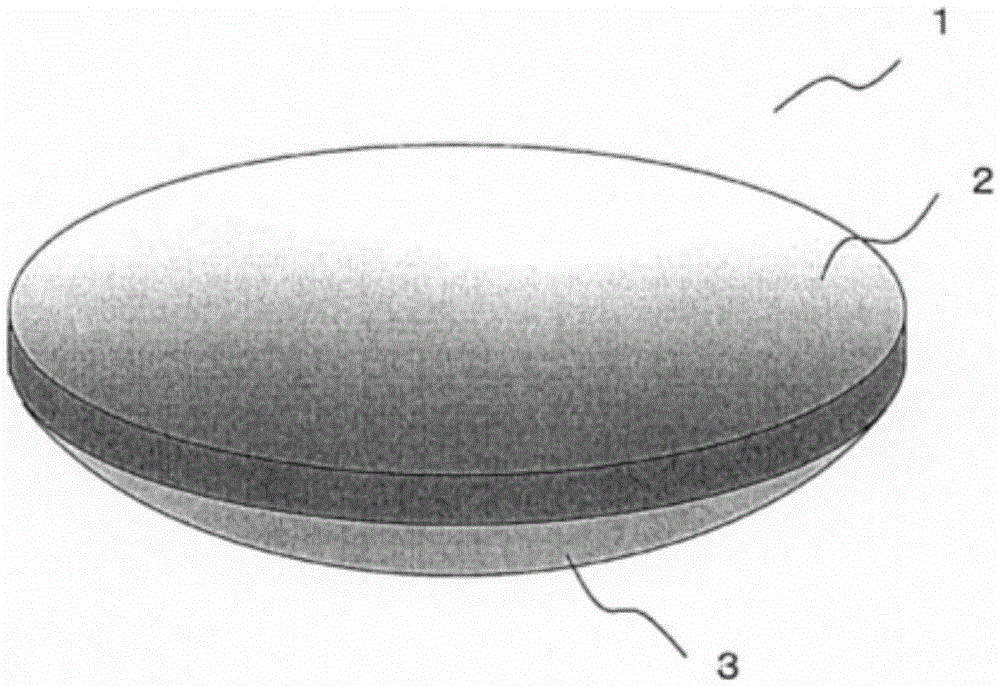

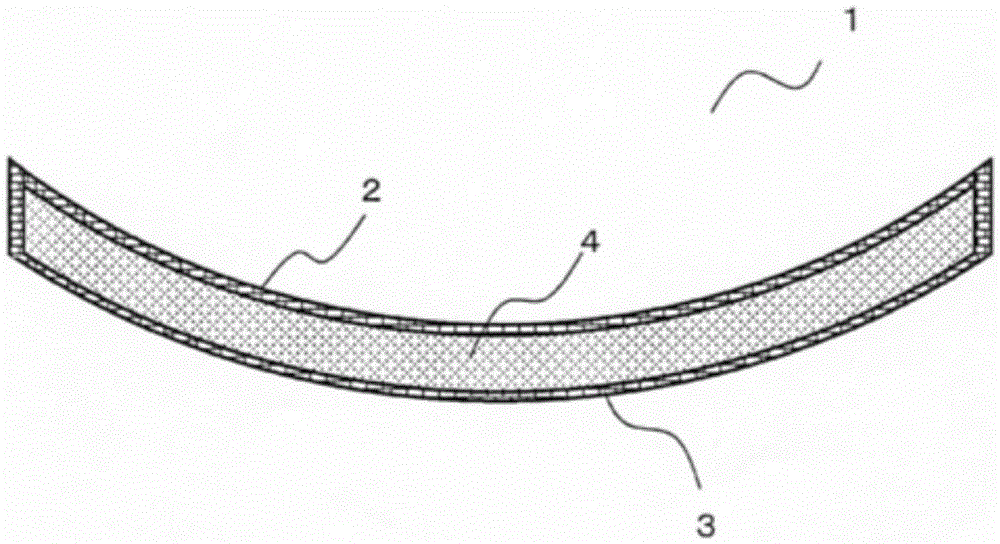

[0059] use figure 1 and figure 2 The curved FRP sandwich structure according to Embodiment 1 of the present invention will be described. figure 1 It is a perspective view showing a curved FRP sandwich structure. and, figure 2 is showing figure 1 Cross-sectional view of a curved FRP sandwich structure.

[0060] Such as figure 1 and figure 2 As shown, in the curved FRP sandwich structure 1 , the faces facing each other are arranged at predetermined intervals, one face is concave, and the other face is convex. Therefore, the curved FRP sandwich structure 1 has a curved shape having a desired thickness distribution. The thickness of the curved FRP sandwich structure 1 may not be constant, and the thickness at the end may be 0, that is, the outer peripheral part may not be planar but linear.

[0061] Furthermore, the curved FRP sandwich structure 1 is a sandwich structure in which FRP is used as a skin material. That is, the curved FRP sandwich structure 1 is composed o...

Embodiment approach 2

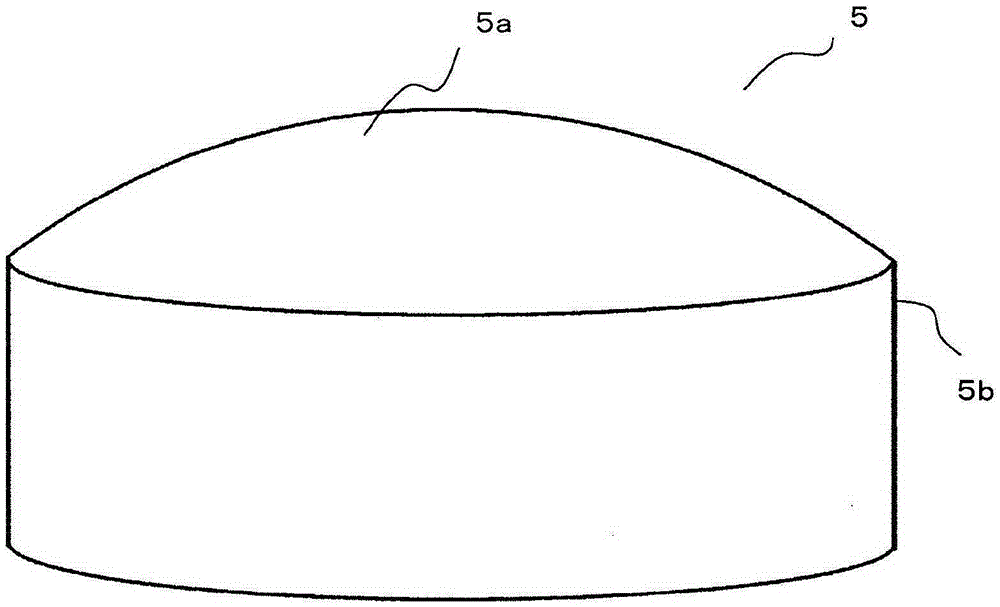

[0128] In Embodiment 1 above, an example in which the shape of the convex curved portion 5 a of the convex molding die 5 is a spherical surface has been described. On the other hand, in Embodiment 2, an example in which the shape of the convex curved portion 5 a is a paraboloid of revolution will be described.

[0129] Figure 22 It is a sectional view at the symmetry plane of the convex molding die 5 used in the second embodiment of the present invention. and, Figure 23 is shown using Figure 22 The perspective view of the curved FRP sandwich structure 1 formed by the convex forming die 5 of . The manufacturing method of the curved FRP sandwich structure 1 is the same as the manufacturing method of the previous first embodiment except that the shape of the convex curved portion 5a is different.

[0130] The paraboloid of revolution forming the shape of the convex curved portion 5a is a curved surface represented by the following formula (1). It should be noted that a in...

Embodiment approach 3

[0141] In Embodiment 1 above, an example in which the shape of the convex curved portion 5 a of the convex molding die 5 is a spherical surface has been described. On the other hand, in Embodiment 3, an example in which the shape of the convex curved portion 5 a is a cylindrical surface will be described.

[0142] Figure 25 It is a cross-sectional view of the male forming die 5 used in Embodiment 3 of the present invention cut along a plane perpendicular to the axial direction. and, Figure 26 It is a perspective view showing a curved FRP sandwich structure 1 molded using the convex molding die 5 shown in the figure. The manufacturing method of the curved FRP sandwich structure 1 according to the third embodiment is the same as the manufacturing method of the previous first embodiment except that the shape of the convex curved portion 5 a is different.

[0143] The cylindrical surface forming the shape of the convex curved portion 5a is a curved surface represented by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com