Purification method of hydrophobic polypeptide raw material

A purification method and hydrophobic technology, applied in the field of peptides, can solve the problems of low recovery rate and difficulty in dissolving hydrophobic peptides, and achieve the advantages of reducing solvent consumption, shortening operation time and operability, reducing energy consumption and production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

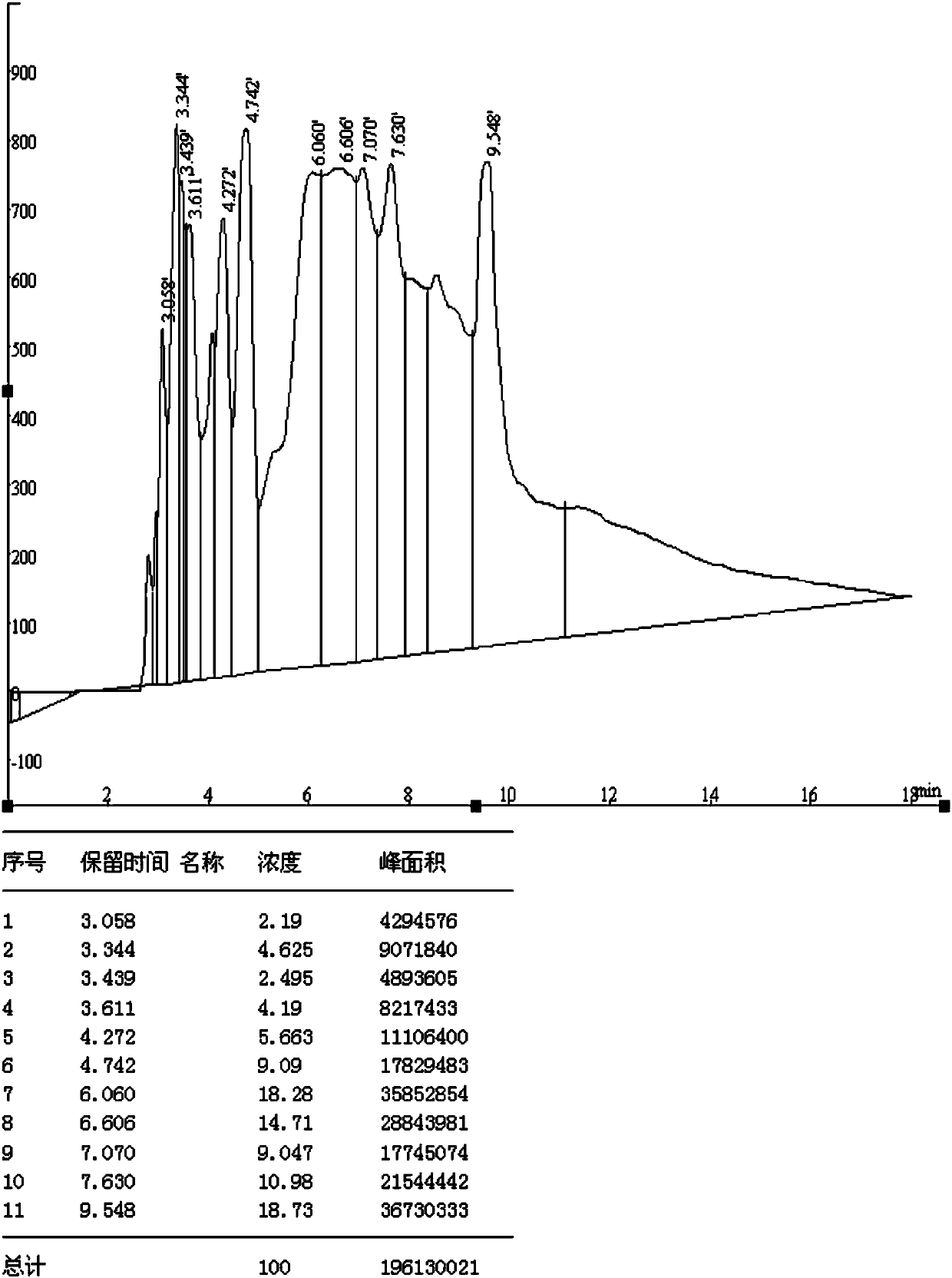

[0073] Dissolve 1 mg of Fmoc-cys(pal)-OH in 1 mL of a mixed solution of n-hexane and isopropanol (v:v=1:9), filter, and use a nitrile column Haobo CN 5 μm 20*250 mm for gradient detection analysis. The normal phase analysis conditions are: mobile phase A liquid is n-hexane, B liquid is isopropanol; time: 0-20min; flow rate: 1.00mL / min; A:B ratio: 99:1 to 5:95; wavelength: 220nm . Analysis results such as figure 1 As shown, it shows that the mobile phase is suitable for the analysis of Fmoc-cys(pal)-OH, and the peaks in the crude product can be well separated.

[0074] Dissolution and treatment of Fmoc-cys(pal)-OH crude product: 200mg of Fmoc-cys(pal)-OH crude product is ultrasonically dissolved with 20mL n-hexane-isopropanol mixed solution (v:v=1:9), after the dissolution is complete, centrifuge , and waited for sample preparation after filtration with a 0.45 μm organic phase filter membrane.

[0075] The preparative chromatographic column was LC3000I high performance liqui...

example 2

[0080] 1 mg of Fmoc-cys(pal)-OH was dissolved in 1 mL of n-hexane-isopropanol mixed solution (v:v=1:9), filtered, and gradient detection analysis was carried out using a nitrile column Haobo CN 5 μm 20*250 mm. The normal phase analysis conditions are: mobile phase A liquid is n-hexane, B liquid is isopropanol; time: 0-20min; flow rate: 1.00mL / min; A:B: 95:5 to 5:95; wavelength: 220nm . Analysis results such as Figure 5 As shown, it shows that the mobile phase is suitable for the analysis of Fmoc-cys(pal)-OH, and the peaks in the crude product can be well separated.

[0081] Dissolution and treatment of Fmoc-cys(pal)-OH crude product: 400mg Fmoc-cys(pal)-OH crude product was ultrasonically dissolved with 30mL n-hexane and isopropanol mixed solution (v:v=1:9), after the dissolution was complete, Centrifuge, and filter with a 0.45 μm organic phase filter and wait for sample preparation.

[0082] The preparative chromatographic column was LC3000I high performance liquid chroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com