Active carbon fiber organic gas recovery method and system using nitrogen as desorption medium

A technology of activated carbon fiber and organic waste gas, which is applied in the direction of separation methods, chemical instruments and methods, and purification of combustible gases. It can solve the problems of reduced utilization rate, high operation cost of rectification tower, and influence on adsorption performance, so as to reduce equipment manufacturing cost. , Realize the effect of environmental protection standard emission and reduce operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

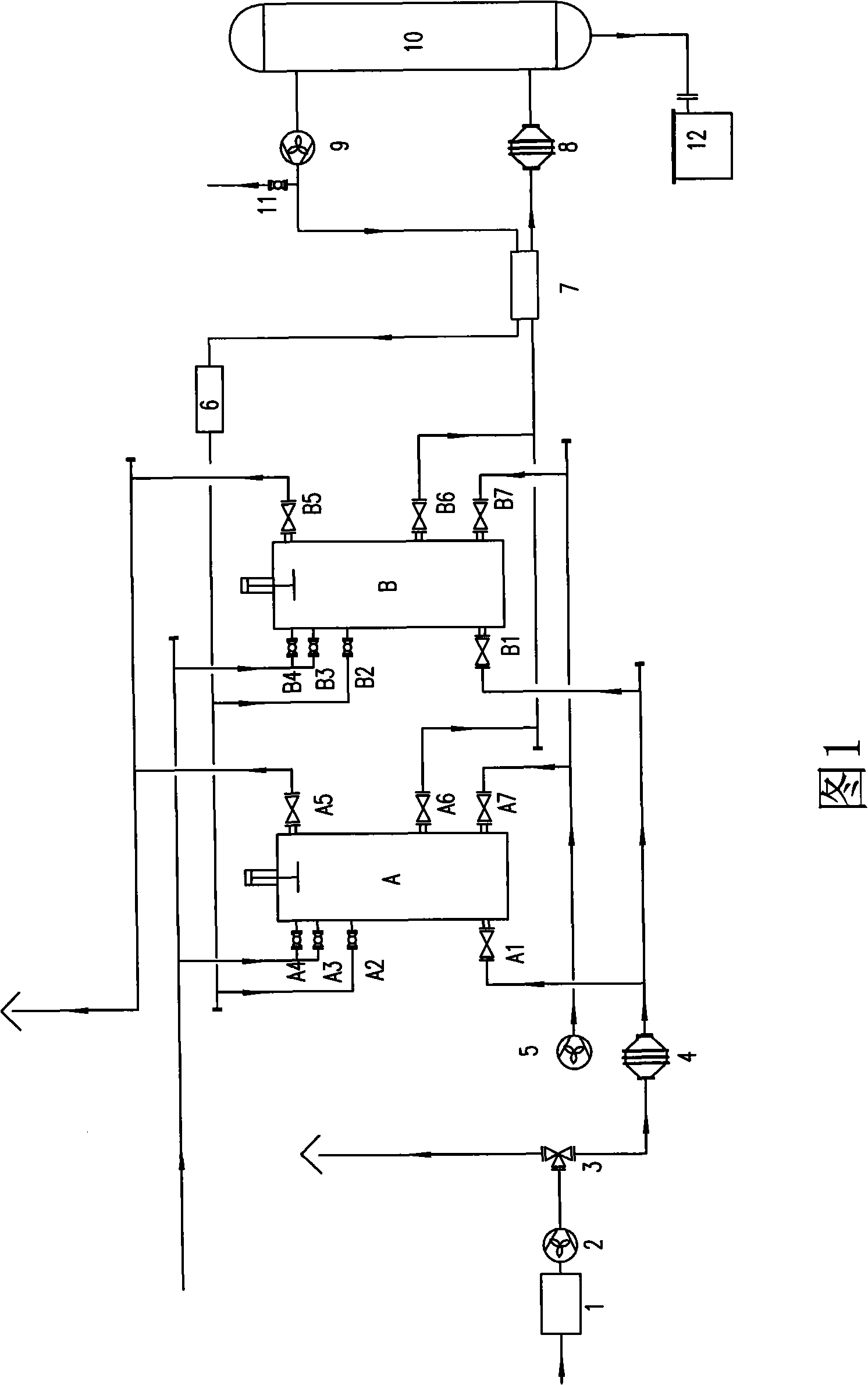

[0032] Fig. 1 is a process flow chart of the method of the present invention. The organic waste gas air collecting system 1 collects the working gas flow to be processed in the process of the present invention. The induced draft fan 2 provides power, and the airflow control three-way valve 3 controls the flow direction. When the system is working, the air inlet is opened to introduce the organic waste gas into the processor for adsorption, and when the system is maintained, the organic waste gas outlet is opened. The filter and pre-cooler pretreatment system 4 can remove most of the suspended solids and particulate impurities in the airflow, and can adjust the temperature and humidity of the exhaust gas to extend the service life of the activated carbon fiber and improve the adsorption effect. The cooling fan 5 can introduce the ambient air into the adsorbers A and B through the cooling air inlet valves A7 and B7 to reduce the temperature of the adsorption layer. The heater 6 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com