Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

A porous and separator technology, applied in secondary batteries, battery components, secondary battery repair/maintenance, etc., can solve the problems of battery chemical performance attenuation, impact on battery performance, safety performance degradation, etc., to achieve low coating Layer water absorption, reduce the risk of short circuit, reduce the effect of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Inorganic / Organic Composite Functionalized Porous Separator Membrane

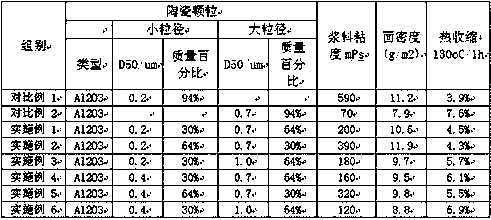

[0036] The coating slurry formulation is based on the weight percentage of the dry material. The coating slurry consists of three parts: 5 wt% water-based polymer binder, 1 wt% sodium carboxymethyl cellulose, and 94 wt% inorganic ceramic particles. Among them, the inorganic ceramic particles are selected from Al 2 o 3 , wherein, the D50 of the small-sized particle is 0.2um, and the mass percentage that it occupies is 30%, and the D50 of its large-sized particle is 0.7um, and the mass percentage that it occupies is 64%; In the present invention, Al 2 o 3 represented by other inorganic materials such as SiO 2 , γ-AlOOH, BaSO 4 , CaO, TiO 2 , ZnO 2 , MgO, ZrO 2 , SnO 2 Also applicable to the present invention, the ratio of its particle size to Al 2 o 3 Same. The water-based polymer binder is selected from styrene / acrylate copolymer emulsion, and its dry glue water drop contact ...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is the composition of coating slurry:

[0057] The coating slurry formulation is based on the weight percentage of the dry material. The coating slurry consists of three parts: 5 wt% water-based polymer binder, 1 wt% sodium carboxymethyl cellulose, and 94 wt% inorganic ceramic particles. Among them, the inorganic ceramic particles are selected from Al 2 o 3 , the D50 of the small-sized particles is 0.2um, and its mass percentage is 64%, the D50 of its large-sized particles is 0.7um, and its mass percentage is 30%. The water-based polymer binder is styrene / acrylic acid Ester copolymer emulsion, the dry glue water drop contact angle is 140 o . During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for about 50 wt% of the total weight of the slurry.

[0058] The rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0060] The difference between embodiment 3 and embodiment 1 is the composition of coating slurry:

[0061] The coating slurry formulation is based on the weight percentage of the dry material. The coating slurry consists of three parts: 5 wt% water-based polymer binder, 1 wt% sodium carboxymethyl cellulose, and 94 wt% inorganic ceramic particles. Among them, the inorganic ceramic particles are selected from Al 2 o 3 , the D50 of the small-sized particles is 0.2um, and its mass percentage is 30%, the D50 of its large-sized particles is 1.0um, and its mass percentage is 64%. The water-based polymer binder is styrene / acrylic acid Ester copolymer emulsion, the dry glue water drop contact angle is 140 o . During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for about 50 wt% of the total weight of the slurry.

[0062] The rest are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com