Method for multistage adsorption and recovery of organic gases through active carbon fiber

A technology of activated carbon fiber and organic gas, which is applied in the field of adsorption, purification and recovery of organic matter in organic waste gas with high concentration and large air volume. High grade and investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

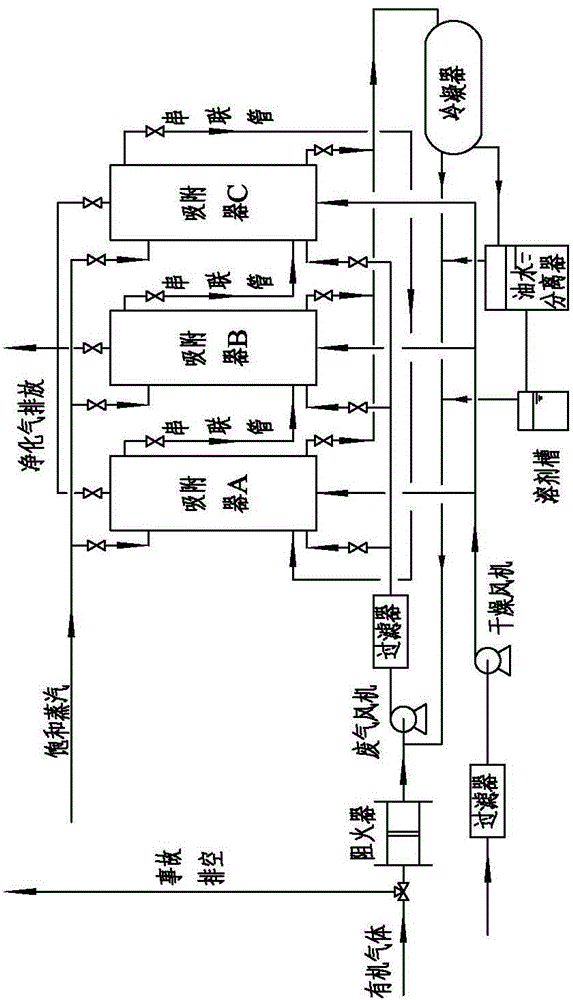

[0022] The present invention will be further described below in conjunction with the accompanying drawings, and the embodiments are not intended as a restrictive description of the present invention documents.

[0023] A chemical company discharges organic gas containing toluene during the product refining and drying process, with an exhaust volume of 4000m 3 / h, the concentration of organic matter in the gas is 6000mg / m 3 about. After the organic gas is collected by the pretreatment system, it is sent to the activated carbon fiber adsorption system through the waste gas fan. First, it enters the adsorber A and is absorbed. After stage adsorption, the purified air is discharged from the main discharge port.

[0024] As the adsorption progresses, the adsorber A gradually becomes saturated. When the adsorber A reaches saturation or the adsorption time is set, the adsorption process of the adsorber A ends, the air inlet of the adsorber A is closed, and the series pipe between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com