Exhuast gas desulfurization, recycle and treatment method and apparatus

A treatment method, exhaust gas desulfurization technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of unstable treatment effect, inconvenient transportation, low degree of intensification, etc., and achieve easy movement and transportation, reducing human operations, and high degree of intensification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

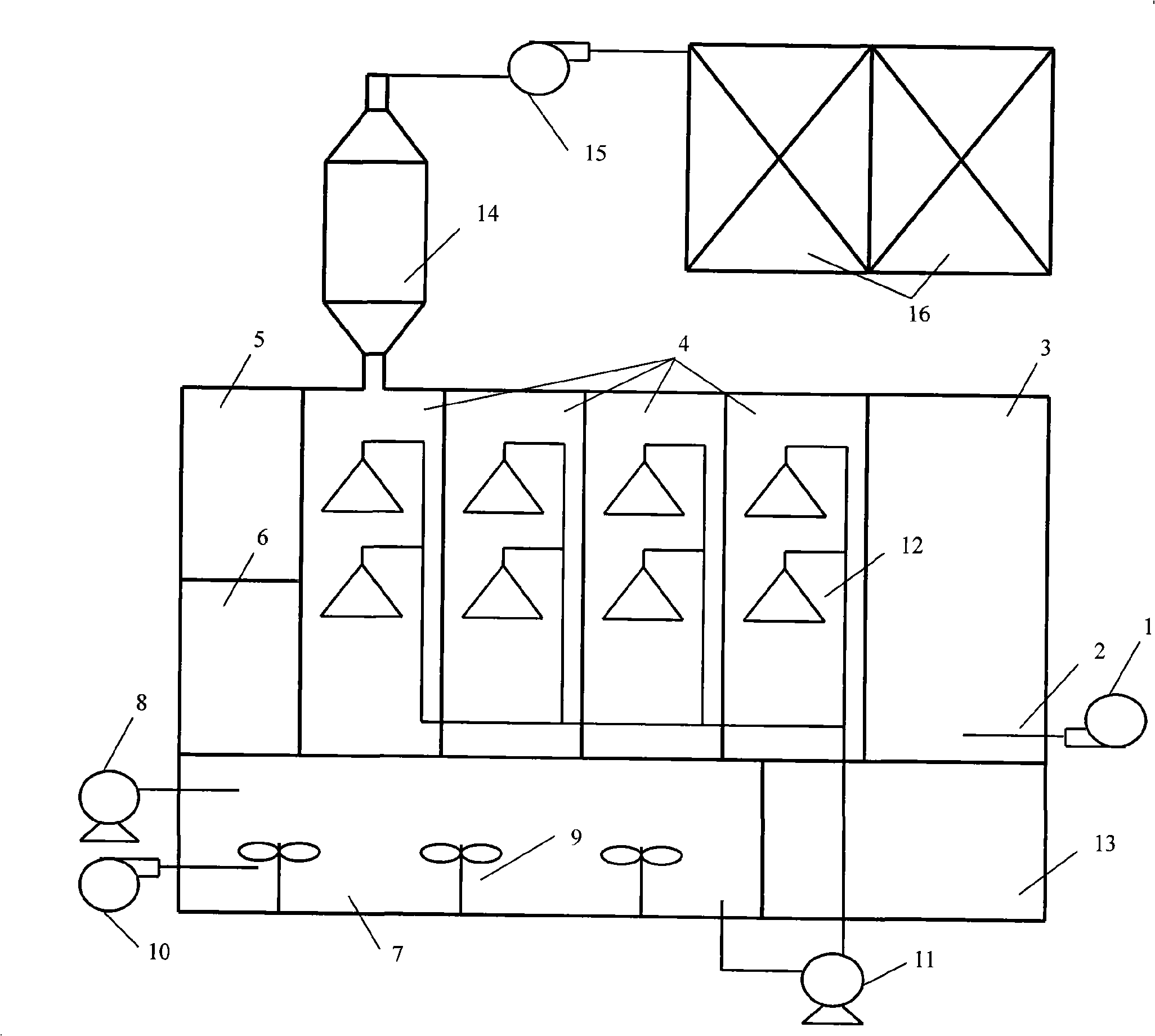

[0043] See attached figure 1 , the exhaust gas is sent to the dust removal device 3 by the exhaust gas inlet pipe 2 of the exhaust gas inlet fan 1 for processing, and the gas after dust removal enters the desulfurization absorption tower 4; the limestone is first sent to the crushing device 5, and then enters the feeding device 6 after being crushed, and then oxidized with the cycle The process water in the device 7 is mixed to form a slurry and collected in the bottom circulation oxidation tank. The process water inlet pump 8 is used to send water to the circulation oxidation device 7, and the agitator 9 is used to mix the limestone slurry for stirring; the limestone slurry is pumped into the desulfurization by the slurry circulation pump 11 In the system 4, the spray device 12 contacts and reacts with the exhaust gas after dedusting, and the generated CaSO 3 Collected in the tank of the bottom circulation oxidation device; the aeration fan 10 is used for the CaSO in the circ...

Embodiment 2

[0055] A pharmaceutical factory uses concentrated sulfuric acid as an oxidant in the production process, and a high concentration of acid gas will be produced during the reaction process. The source of pollution is shown in Table 2.

[0056] Table 2 Pollutant source intensity

[0057] Flue gas emission (Nm 3 / h)

8000

Sulfur dioxide emission concentration (mg / Nm 3 )

76580

Sulfur dioxide emission rate (kg / h)

76.6

Main components of exhaust gas

8.6%SO 2 , 0.7%SO 3 , 4.1% CO 2 , 86.6% air

[0058] The technological process of utilizing the process and equipment of the present invention to carry out flue gas desulfurization and dust removal treatment is as follows:

[0059] (1) Pharmaceutical acid gas first enters the dust removal system and is treated with a bag filter. The dust removal efficiency is about 98%, and the particle concentration is changed from the initial 3000mg / m 3 down to 60mg / m 3 the following....

Embodiment 3

[0066] The installed capacity of a boiler room in a thermal power plant is about 70MW. Coal combustion produces a large amount of sulfur-containing flue gas. The pollution source intensity is shown in Table 3.

[0067] Table 3 Pollutant Source Intensity

[0068] Flue gas emission (Nm 3 / h)

220000

Sulfur dioxide emission concentration (mg / Nm 3 )

1600

Sulfur dioxide emission rate (kg / h)

352

Main components of exhaust gas

1.1%SO 2 , 8.2%CO 2 , 89.5% air, 1.2% other

[0069] The technological process of utilizing the process and equipment of the present invention to carry out flue gas desulfurization and dust removal treatment is as follows:

[0070] (1) The flue gas from the coal-fired boiler enters the dust removal system first, and is processed by an electrostatic precipitator and a bag filter in series. The dust removal efficiency is about 99.5%, and the particle concentration is changed from the initial 16000m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com