Method for low-temperature oxidative degradation of organic gas

An organic gas, oxidative degradation technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of short lifespan of catalyst active components, poor catalyst activity and stability, and high reaction temperature, and achieve high reaction temperature. , long active life, the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

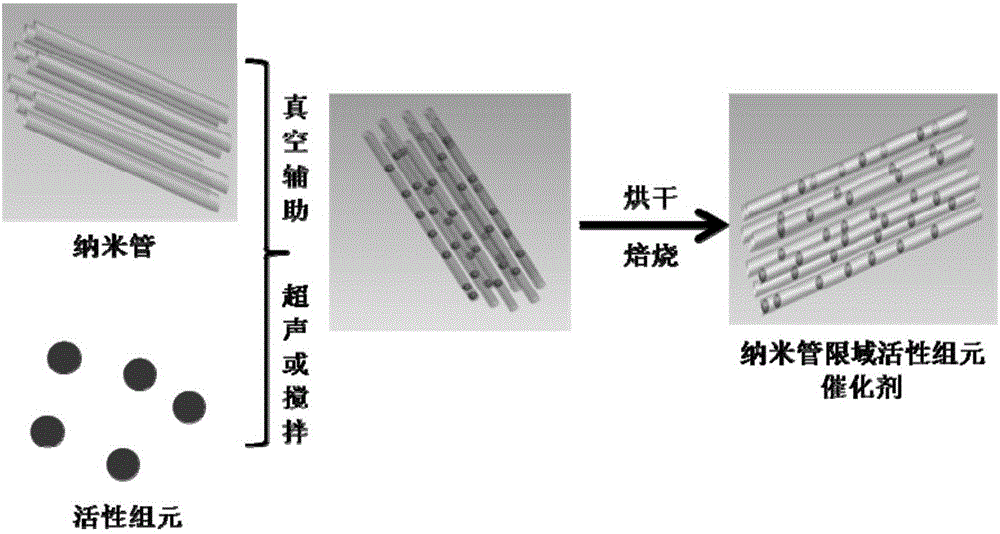

[0022] Preparation process see figure 1 , mix a palladium chloride solution with a concentration of 2wt% in mass fraction percentage with titanium dioxide nanotubes, stir for 30 minutes, and at -0.1MPa, under normal temperature conditions, use ultrasonic assist to embed noble metal Pd into titanium dioxide nanotubes, then wash and filter And put it in an oven and dry it at 60°C for 12 hours, transfer it to a muffle furnace and bake it at 400°C for 2 hours to obtain a titanium dioxide nanotube-confined Pd catalyst, and its transmission electron microscope picture is as follows figure 2 shown. Put the obtained titanium dioxide nanotube-confined Pd catalyst into the reactor, the concentration of ethylene is 0.5ppm-1000ppm, the molar ratio of ethylene and oxidant is 1:300-100000; the oxidant is air or oxygen; the catalyst space velocity is 5000h -1 , stable at 55°C for 2 hours, the instantaneous removal rate of organic gas ethylene is as high as 95%.

Embodiment 2

[0029] Mix the manganese nitrate solution with a mass fraction percentage concentration of 50wt% and the silicon oxide / titanium oxide composite nanotube, after stirring for 30 minutes, under the condition of -0.08MPa and normal temperature, the transition metal oxide MnO 2 Embedded in the composite nanotubes, then washed, filtered and dried in an oven at 60°C for 12 hours, transferred to a muffle furnace and baked at 400°C for 2 hours to obtain a silica / titania composite nano-confined MnO 2 catalyst. The resulting silica / titanium oxide composite nanoconfined MnO 2 The catalyst is placed in the reactor, the concentration of butane is 0.5ppm-1000ppm, the molar ratio of butane to oxidant is 1:300-100000; the oxidant is air or oxygen; the catalyst space velocity is 2500h -1 , stable at 160°C for 2 hours, the instantaneous removal rate of organic gas butane is as high as 70%.

Embodiment 3

[0035] Mix the chloroplatinic acid solution and the 1wt% chloroauric acid solution with the mass fraction percentage concentration of 2wt% respectively with the titanium dioxide nanotubes, and after stirring for 30min, at -0.1MPa, under normal temperature conditions, the noble metal Pt and Au ions are mixed with stirring assistance. Embedding in nanotubes, then washing, filtering and drying in an oven at 60°C for 12 hours, transferred to a muffle furnace and calcined at 400°C for 2 hours to obtain a titanium dioxide nanotube-confined Pt-Au catalyst. Put the obtained titanium dioxide nanotube confinement Pt-Au catalyst into the reactor, the mixed concentration of toluene and xylene is 0.5ppm~1000ppm, the molar ratio of the mixed gas of toluene and xylene to the oxidant is 1:300~100000; the oxidant is Air or oxygen; the catalyst space velocity is 1000h -1 , stable at 180°C for 2 hours, the instantaneous removal rate of the mixed gas of organic gas toluene and xylene is as high a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com