Rotating electric-discharging low temperature plasma organic waste gases purifying device

A low-temperature plasma and organic waste gas technology, applied in the field of environmental technology and waste gas treatment, can solve the problems of low organic waste gas treatment capacity, insufficient mixing, and small discharge plasma area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

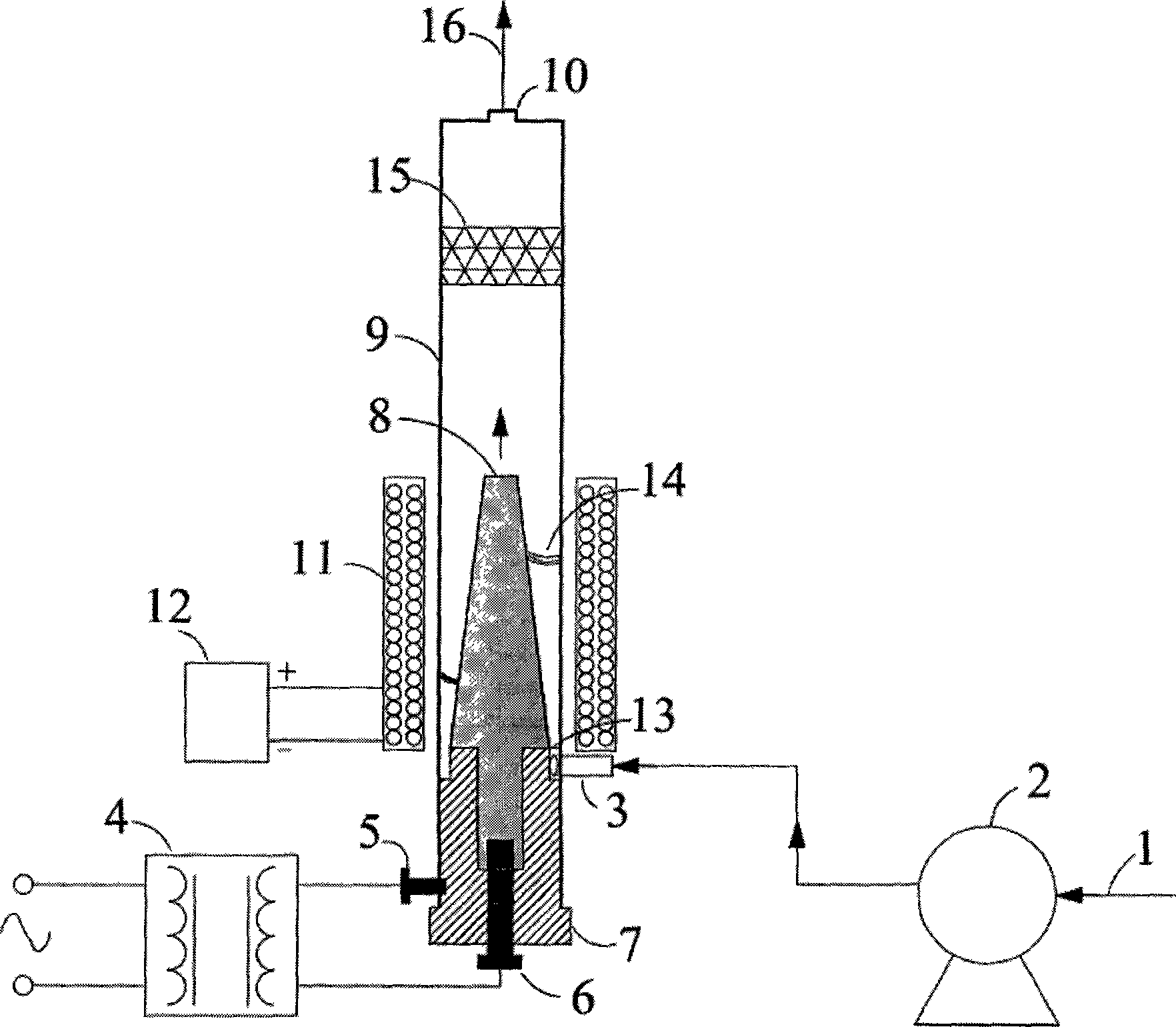

[0017] Referring to the accompanying drawings, the materials used for the center electrode 8 and the outer electrode 9 are brass and red copper respectively; the length of the center electrode is 120mm; the outer diameter of the outer electrode is 60mm, the thickness is 4mm, and the length is 400mm; the minimum distance between the two electrodes is 4mm; the magnetic field strength is 0.011 T; organic waste gas 1 is waste gas containing toluene, the concentration is 2000mg / m 3 , flow 10.8m 3 / h; the output voltage of the AC high-voltage power supply 4 is controlled at 10kV; during the experiment, the concentration of toluene is determined by activated carbon adsorption and carbon disulfide desorption gas chromatography. No attached TiO is placed downstream of the center electrode 2 When the catalyst carrier is 15, the removal rate of toluene is 56.4%; 2 When the honeycomb ceramic carrier is 15, the removal rate of toluene is 81.3%.

Embodiment 2

[0019] Referring to the accompanying drawings, the materials used for the center electrode 8 and the outer electrode 9 are brass and red copper respectively; the length of the center electrode is 120mm; the outer diameter of the outer electrode is 60mm, the thickness is 4mm, and the length is 400mm; the minimum distance between the two electrodes is 4mm; the magnetic field strength is 0.011 T; organic waste gas 1 is waste gas containing carbon tetrachloride, concentration 5500mg / m 3 , flow 10.8m 3 / h; the output voltage of the AC high-voltage power supply 4 is controlled at 10kV. No attached TiO is placed downstream of the center electrode 2 When the catalyst carrier is 15, the removal rate of toluene is 66.4%; 2 When the honeycomb ceramic carrier is 15, the removal rate of toluene is 88.4%.

Embodiment 3

[0021] Referring to the accompanying drawings, the material used for the central electrode 8 and the external electrode 9 is copper; the central electrode is 180mm long; the external electrode has an outer diameter of 102mm, a thickness of 4mm, and a length of 500mm; the minimum distance between the two electrodes is 5mm; the magnetic field strength is 0.03T; Waste gas 1 is waste gas containing xylene, concentration 3000mg / m 3 , flow 60m 3 / h; the output voltage of the AC high-voltage power supply 4 is controlled at 10kV; during the experiment, the concentration of toluene is determined by activated carbon adsorption and carbon disulfide desorption gas chromatography. No attached TiO is placed downstream of the center electrode 2 When the catalyst carrier is 15, the removal rate of toluene is 50.1%; 2 When the honeycomb ceramic carrier is 15, the removal rate of toluene is 74.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com