Simulation test device for recovering volatile organic gases

A volatile organic and gas recovery technology, applied in the direction of vapor condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenience, trouble, no simple and compact structure of volatile organic gas, etc., and achieve easy installation, construction and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

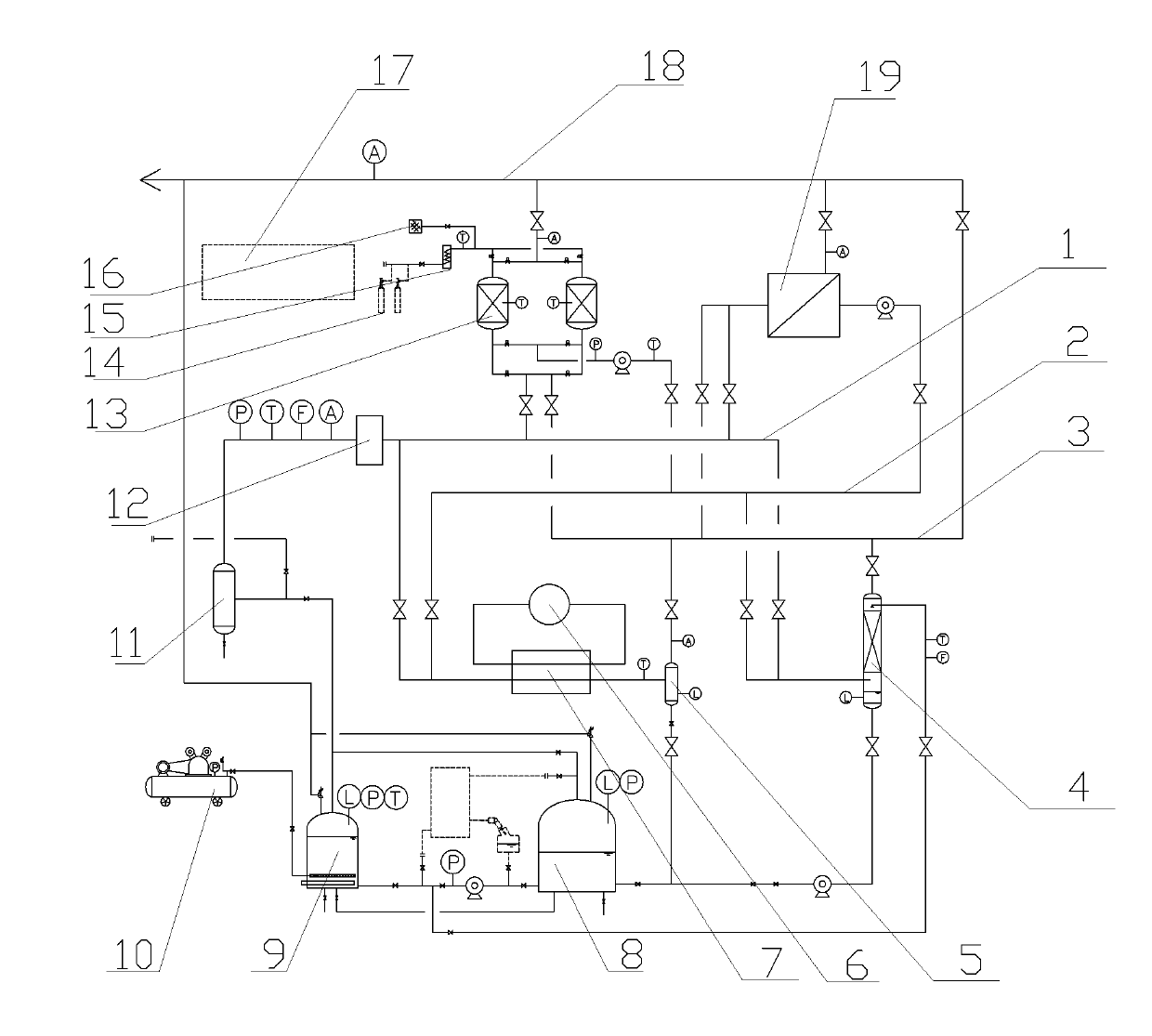

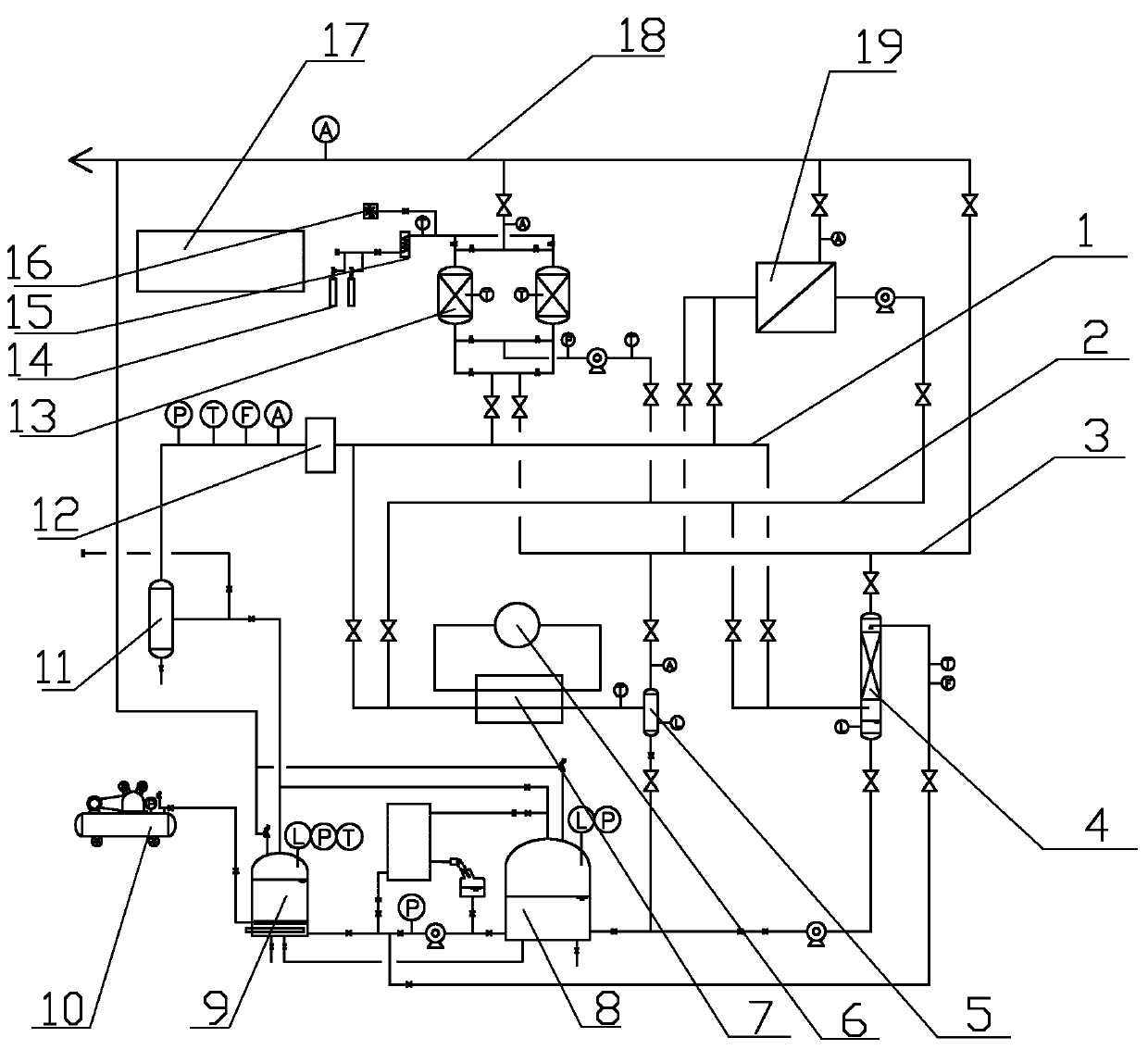

[0019] The specific implementation of the volatile organic gas recovery simulation test device of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the volatile organic gas recovery simulation test device includes an oil and gas generating unit, an oil and gas processing unit, a pipeline and a control system 17, the pipeline is provided with a valve, and the oil and gas processing unit includes an adsorption unit, a membrane separation unit, a condensation units and absorption units. Described adsorption unit comprises two adsorption tanks 13 and the nitrogen bottle 14 that is communicated with described two adsorption tanks 13, is provided with heater 15 and filter on the pipeline between described nitrogen bottle 14 and described two adsorption tanks 13. device 16. The oil-gas generating unit includes an oil-gas generator 9, an oil tank 8 and an air compressor 10 respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com