Device and method for removing refractory organics and total nitrogen in waste water simultaneously

A technology for refractory organic matter and wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as difficult to achieve removal effect and high COD concentration, and achieve effective cultivation and preservation, Maintain the effect of denitrification reaction and small footprint of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

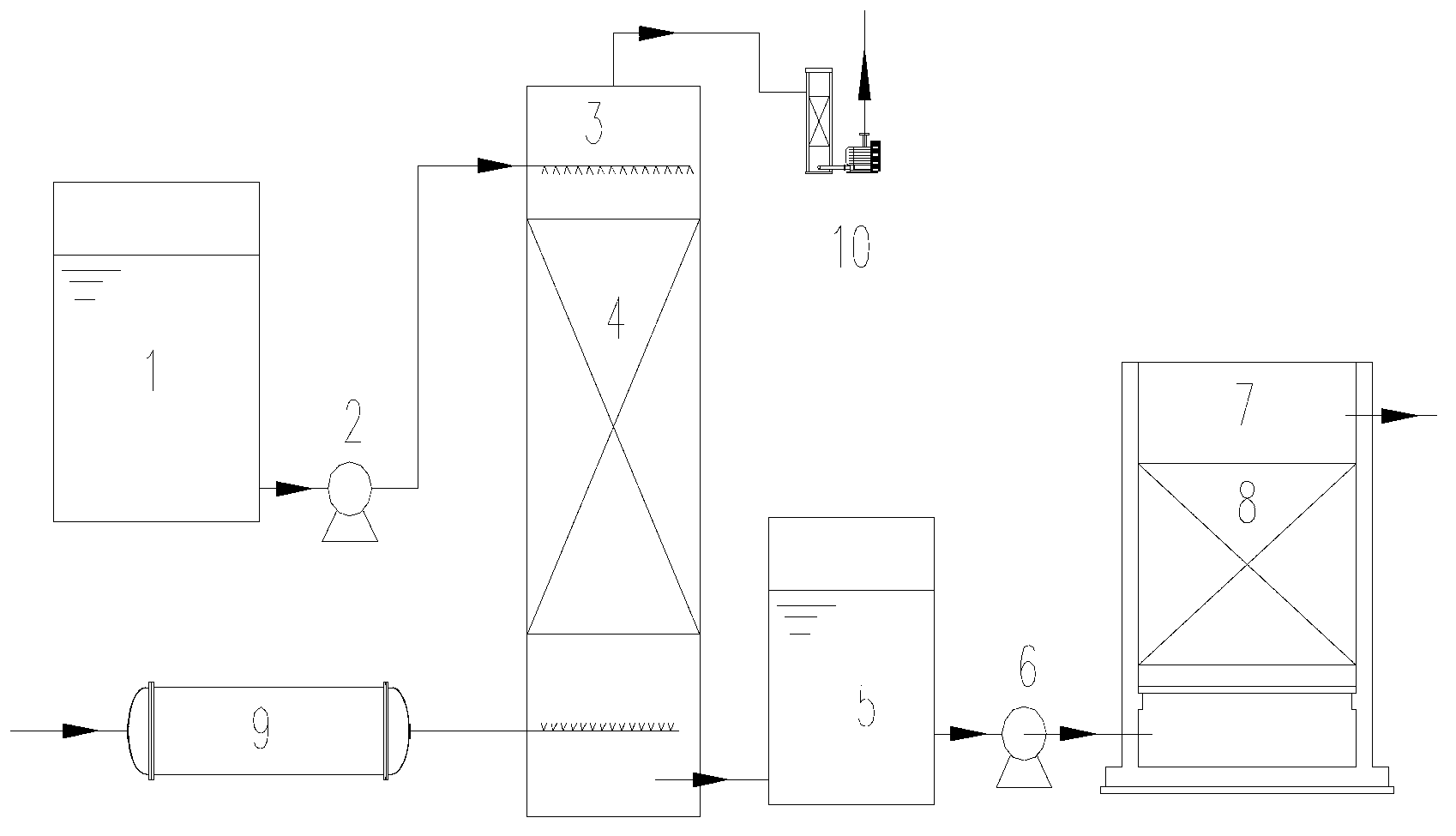

[0035] Wastewater raw water mainly contains ammonia nitrogen and refractory organic pollutants. After primary and secondary biochemical treatment, it mainly contains low concentrations of refractory pollutants and nitrate nitrogen, COD is 150~300mg / L, and nitrate nitrogen is less than 100mg / L. The waste water enters the storage tank 1, and enters the ozone catalytic oxidation tower 3 through the water inlet pump 2. The ozone catalytic oxidation tower 3 is filled with an ozone catalyst, and the lower part is fed with ozone. The ozone catalyst uses activated carbon to immobilize the iron-copper catalyst, and the whole is packaged in a porous regular stainless steel metal mesh Among them, the metal mesh shape cooperates with the ozone catalytic oxidation tower 3 to realize the overall filling. Under the action of ozone, macromolecular refractory organic pollutants (long chain or multi-benzene ring structure) are oxidized to small molecular organic compounds (chain breaking and r...

specific Embodiment 2

[0038] Wastewater raw water mainly contains ammonia nitrogen and refractory organic pollutants. After primary and secondary biochemical treatment, it mainly contains low concentrations of refractory pollutants and nitrate nitrogen, COD is 200~500mg / L, and nitrate nitrogen is less than 100mg / L. The waste water enters the storage tank 1, and enters the ozone catalytic oxidation tower 3 through the water inlet pump 2. The ozone catalytic oxidation tower 3 is filled with an ozone catalyst, and the lower part is fed with ozone. The ozone catalyst adopts a molecular sieve immobilized iron-copper catalyst, and is packaged in a porous regular stainless steel metal mesh as a whole. Among them, the metal mesh shape cooperates with the ozone catalytic oxidation tower 3 to realize the overall filling. Under the action of ozone, macromolecular refractory organic pollutants (long chain or multi-benzene ring structure) are selectively oxidized to small molecular organic compounds (chain bre...

specific Embodiment 3

[0041] Wastewater raw water mainly contains ammonia nitrogen and refractory organic pollutants. After primary and secondary biochemical treatment, it mainly contains low concentrations of refractory pollutants and nitrate nitrogen, COD is 200~500mg / L, and nitrate nitrogen is less than 100mg / L. The waste water enters the storage tank 1, and enters the ozone catalytic oxidation tower 3 through the water inlet pump 2. The ozone catalytic oxidation tower 3 is filled with an ozone catalyst, and the lower part is fed with ozone. The ozone catalyst is made of porous sintered ceramics to immobilize titanium dioxide, and the whole is packaged in a porous regular stainless steel metal mesh Among them, the metal mesh shape cooperates with the ozone catalytic oxidation tower 3 to realize the overall filling. Under the action of ozone, macromolecular refractory organic pollutants (long chain or multi-benzene ring structure) are selectively oxidized to small molecular organic compounds (ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com