Process for treatnig paper-making waste water of waste paper

A treatment method and papermaking technology from waste paper, which are applied in biological water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., which can solve the problem of heavy equipment maintenance, high operating cost and large investment. and other problems, to achieve the effect of reducing operating costs, saving operating costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

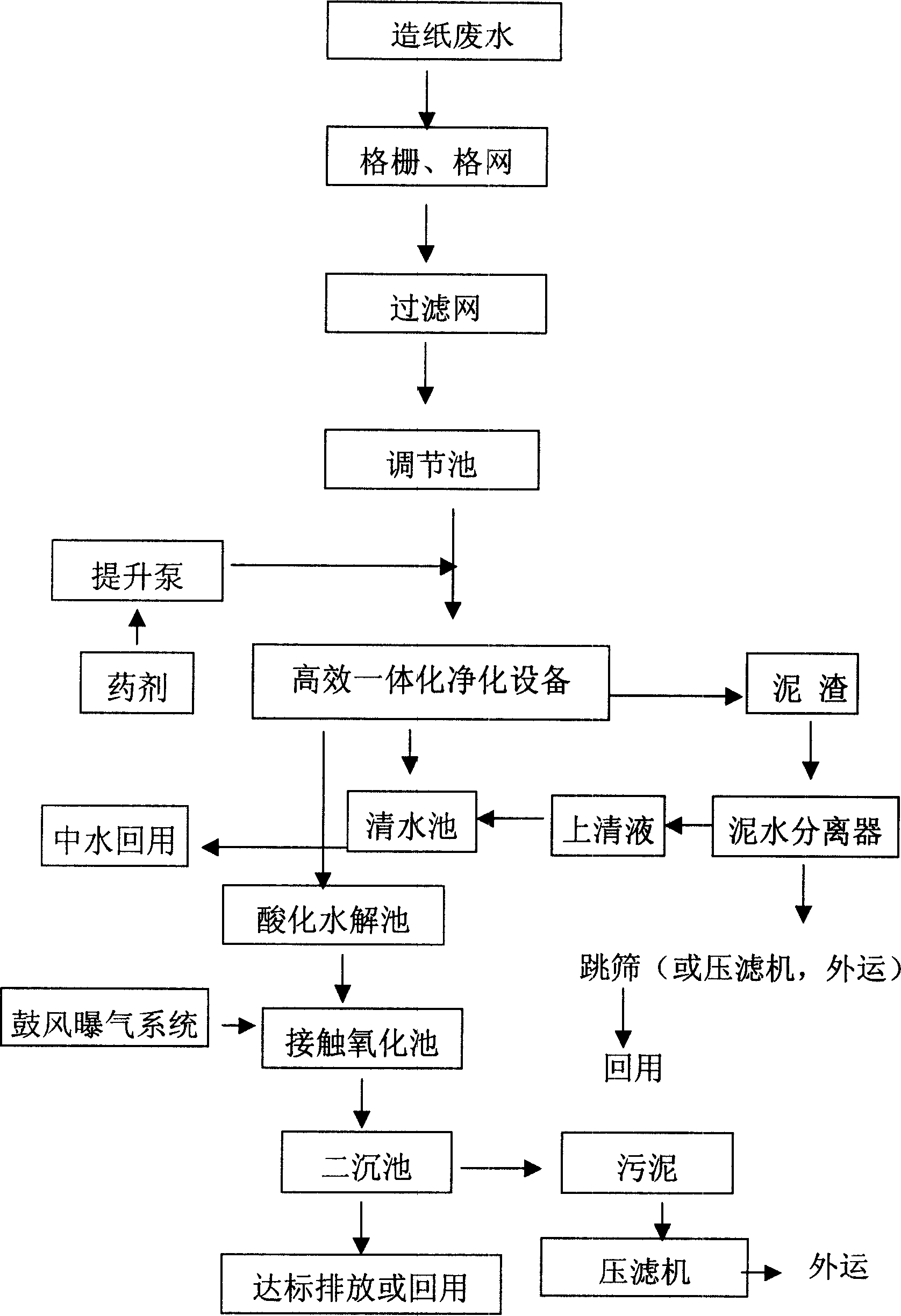

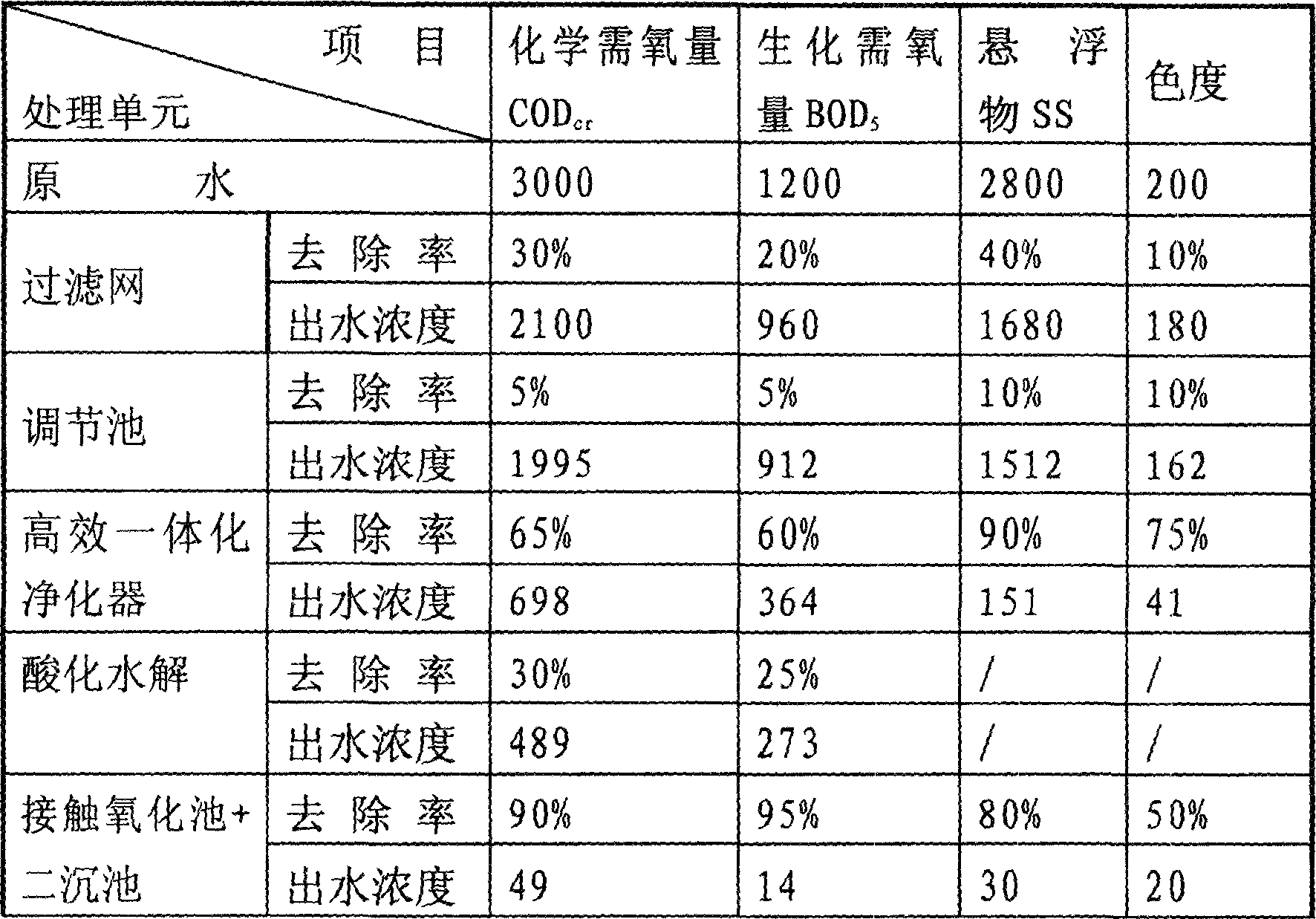

[0018] Such as figure 1 As shown, the entire treatment process of the present invention is as follows: Waste paper and papermaking wastewater enters the regulating pool after removing some impurities through grilles, grids and filters. After the wastewater is balanced in water quality and quantity in the regulating tank, it is pumped to the high-efficiency integrated purifier by the lifting pump, and a certain chemical agent is added. The wastewater and the agent are mixed and reacted in the device, and most of the treated clean water overflows from the upper part of the purifier. It flows to the clear water tank, and a small part enters the biochemical treatment tank (including hydrolytic acidification and contact oxidation), and then it is discharged after secondary sedimentation in the secondary sedimentation tank. The suspended matter that sinks from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com