Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Will not affect normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

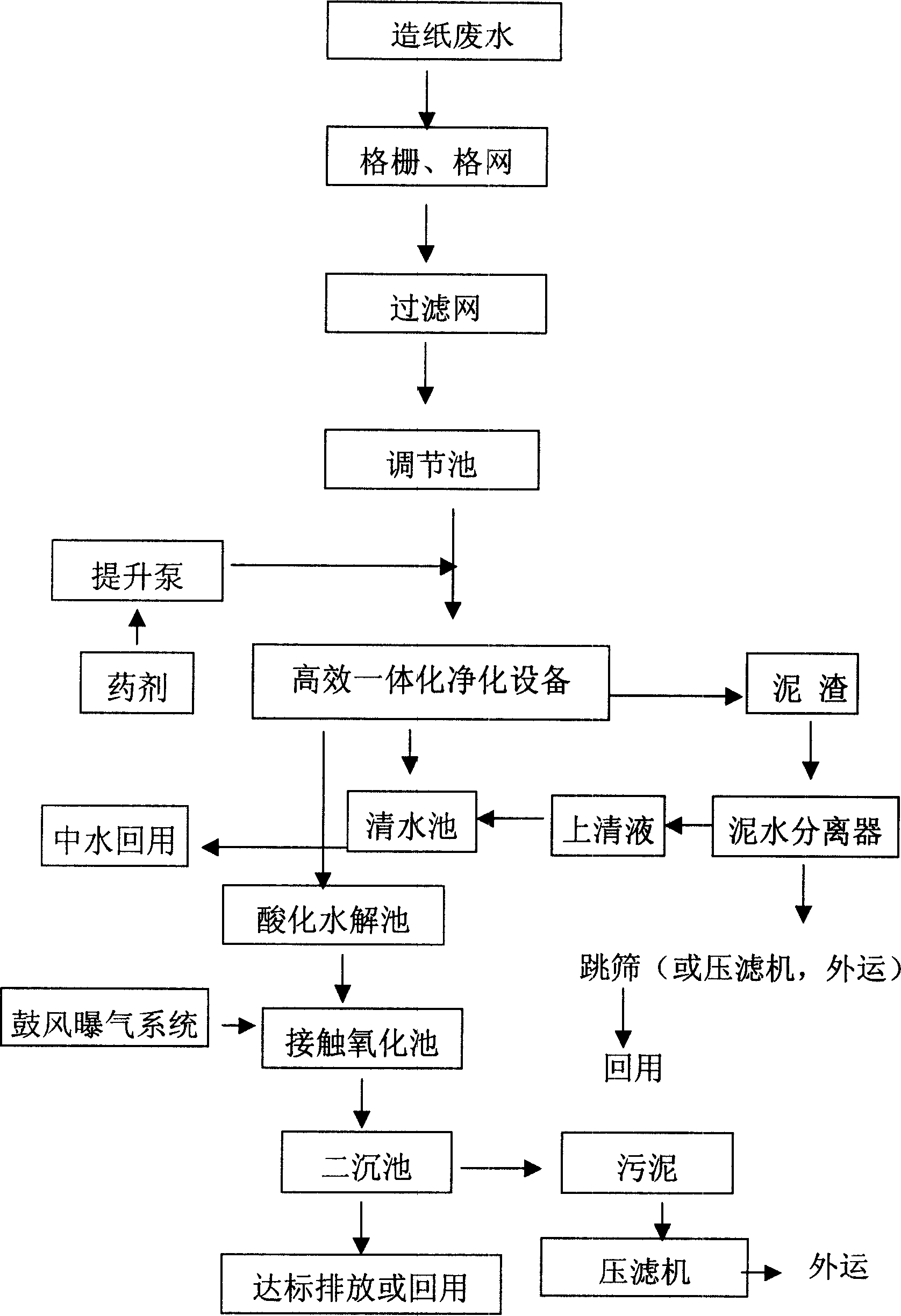

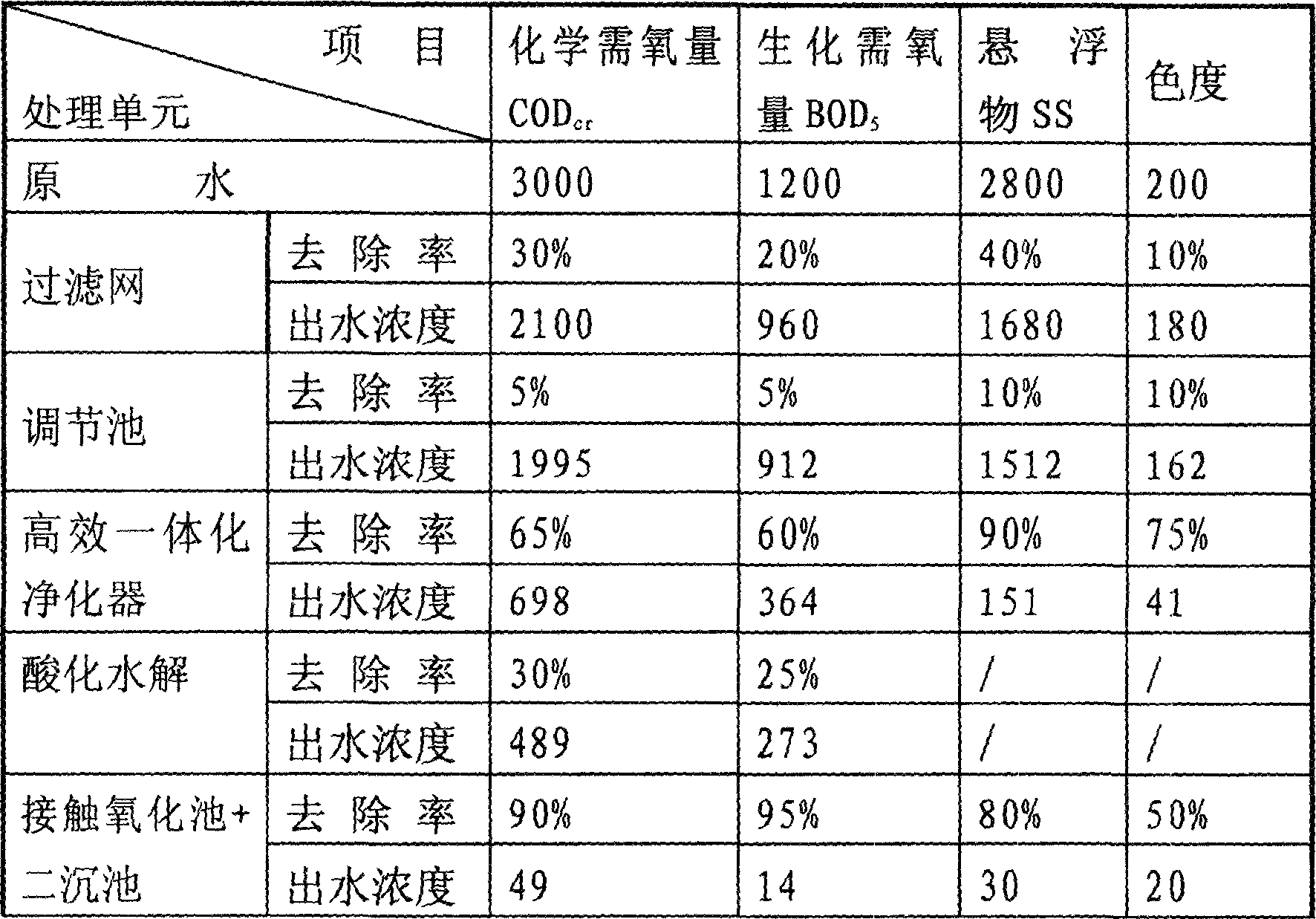

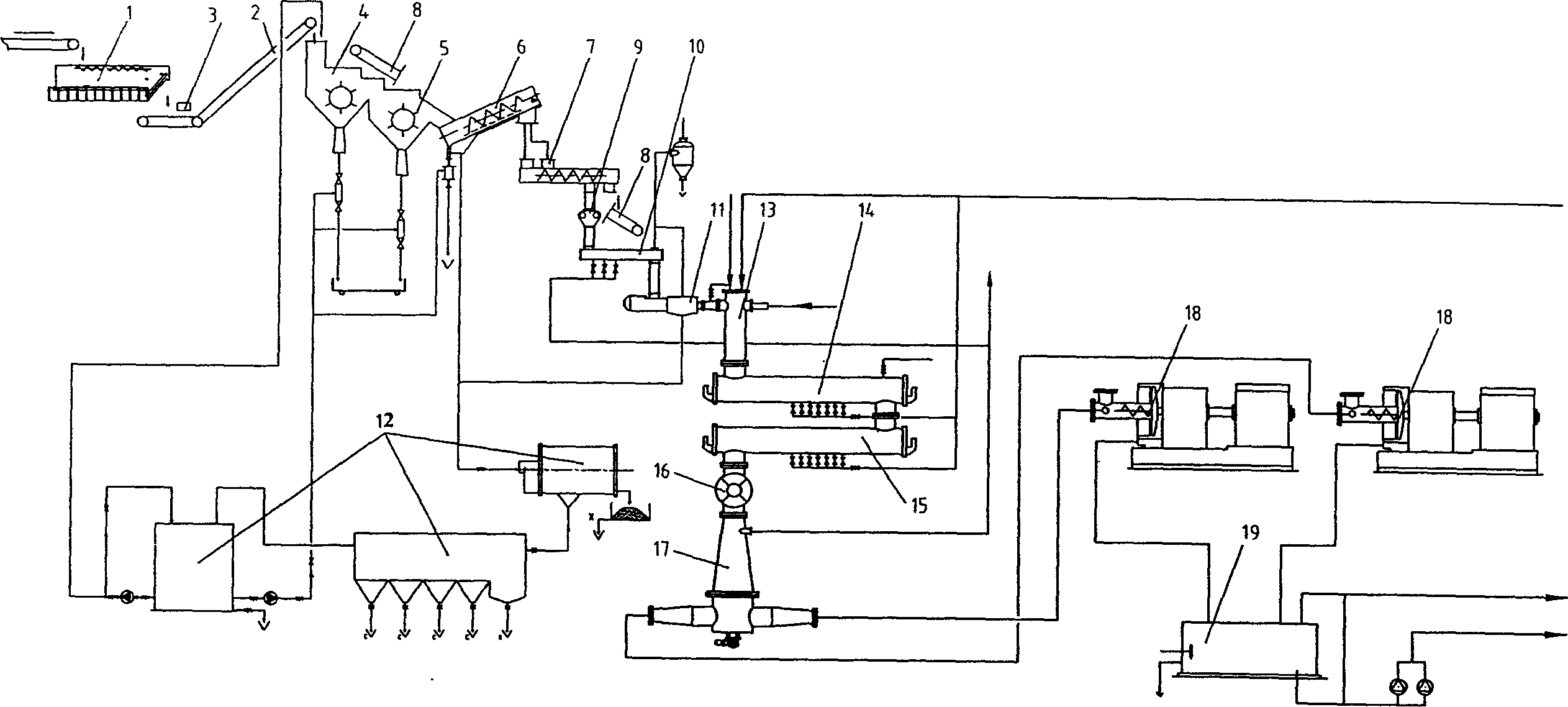

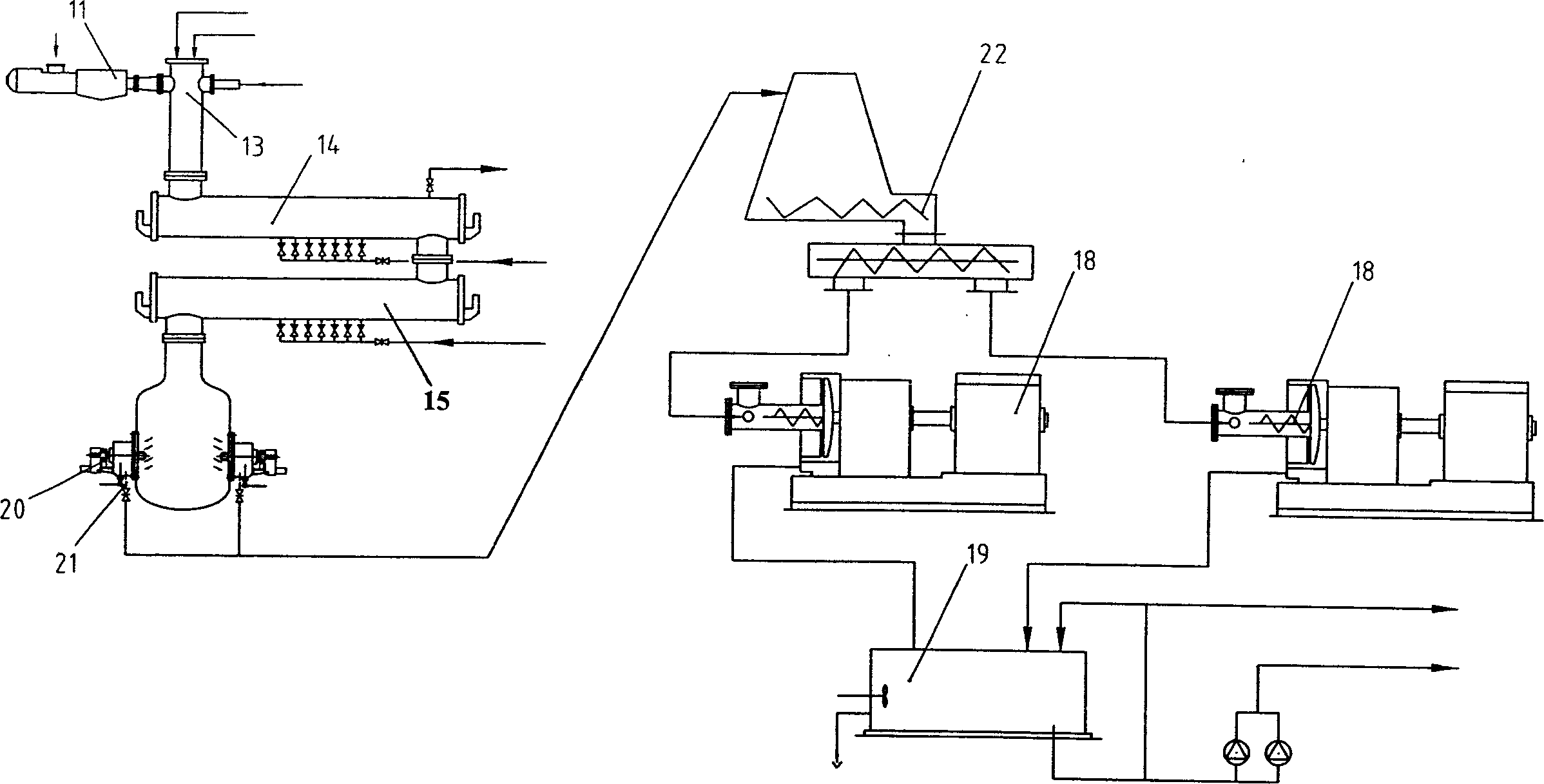

Process for treatnig paper-making waste water of waste paper

InactiveCN1587089ALow running costLow soluble CODSustainable biological treatmentWater/sewage treatment by flocculation/precipitationChemical treatmentAluminium sulfate

The treating process of waste water produced in making paper with waste paper includes the first stage of physical and chemical treatment with the apparatus of patent ZL 97114281.5 with aluminum sulfate added to the inlet as coagulant and acrylamide as coagulant aid; and the second stage of biochemical treatment in hydrolysis acidification-contact oxidation technique and perforation and flow dispersing aeration mode, with the waste water from biochemical treatment flowing into the secondary deposition pond. Of water after the first stage of treatment, 60-80 % is used as intermediate water returned to work shop, while other flows into the second stage of treatment for reuse in production or exhaust. The sludge from the first stage of treatment is treated in jigging sieve before reuse in production. The present invention may realize the closed circular use of paper-making waste water to reduce waste water exhaust.

Owner:SOUTH CHINA UNIV OF TECH

Optimization control system for energy system of drying part of paper machine

ActiveCN101792981AImprove control effectAvoid abnormal situationsDryer sectionTotal factory controlRelational databaseSCADA

The invention discloses an optimization control system for the energy system of the drying part of a paper machine. The optimization control system comprises a newly-added sensor group, an industrial configuration software module, a relation database and a control model library, wherein the newly-added sensor group is connected with the DCS of the drying part in a signaling way, the industrial configuration software module is connected with the DCS of the drying part and the QCS of the paper machine through an SCADA in a signaling way, the relation database is connected with the industrial configuration software module in a signaling way and the control model library is connected with the relation database in a signaling way. The invention can dynamically and accurately control the key variants of the energy system of the drying part of the existing paper machine in real time according to the characteristics of the paper drying process, can minimize the dependence on operator experiences, can improve the paper drying efficiency and can reduce energy consumption of the drying part, thereby realizing the optimum operation of the energy system of the drying part of the paper machine.

Owner:广州博依特智能信息科技有限公司

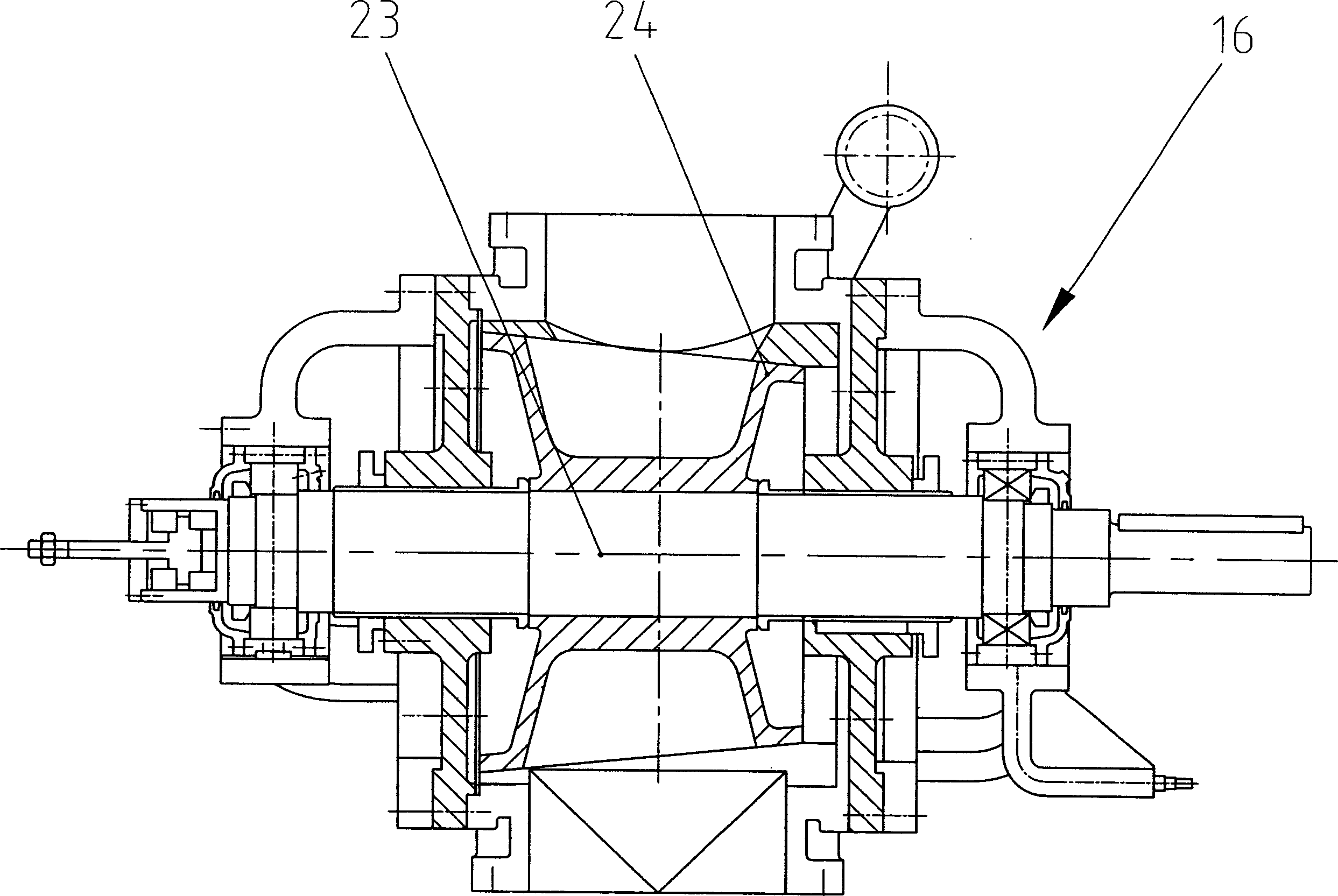

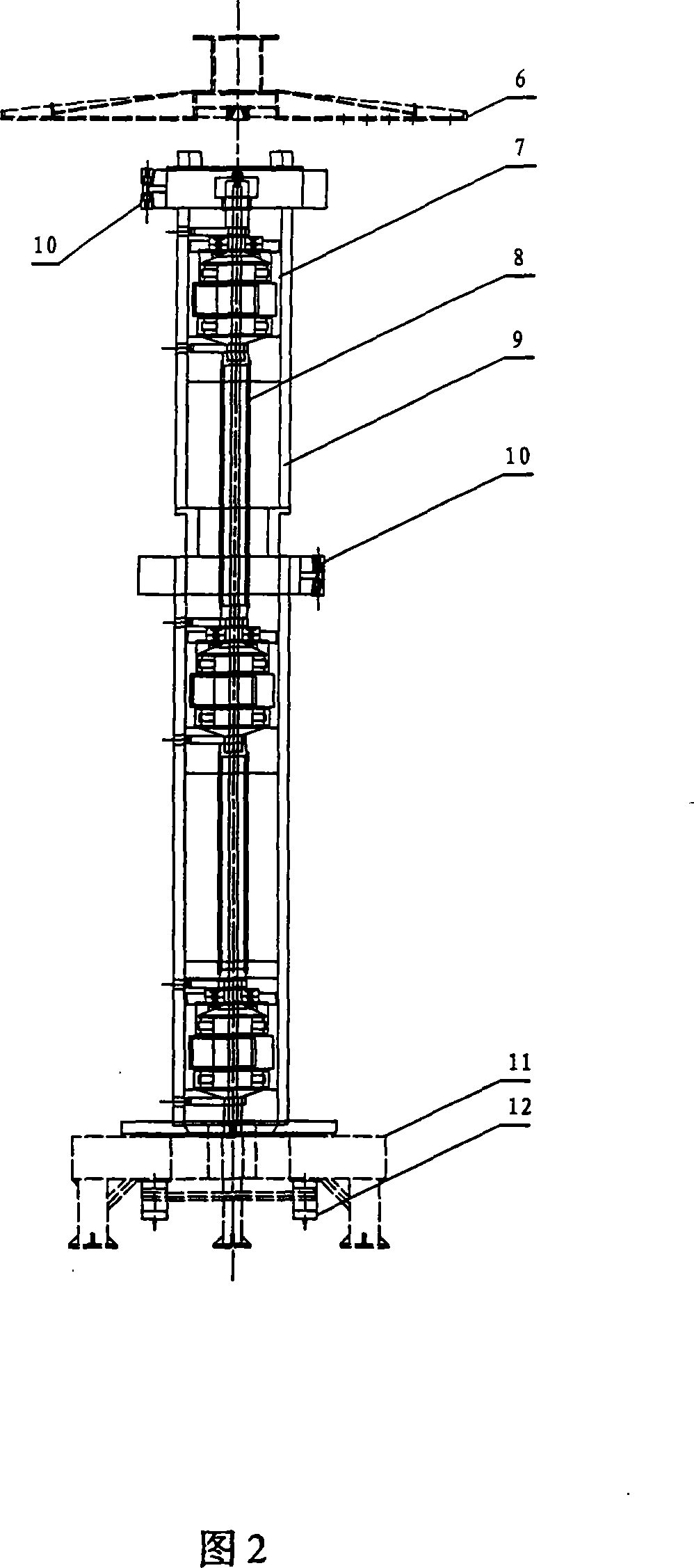

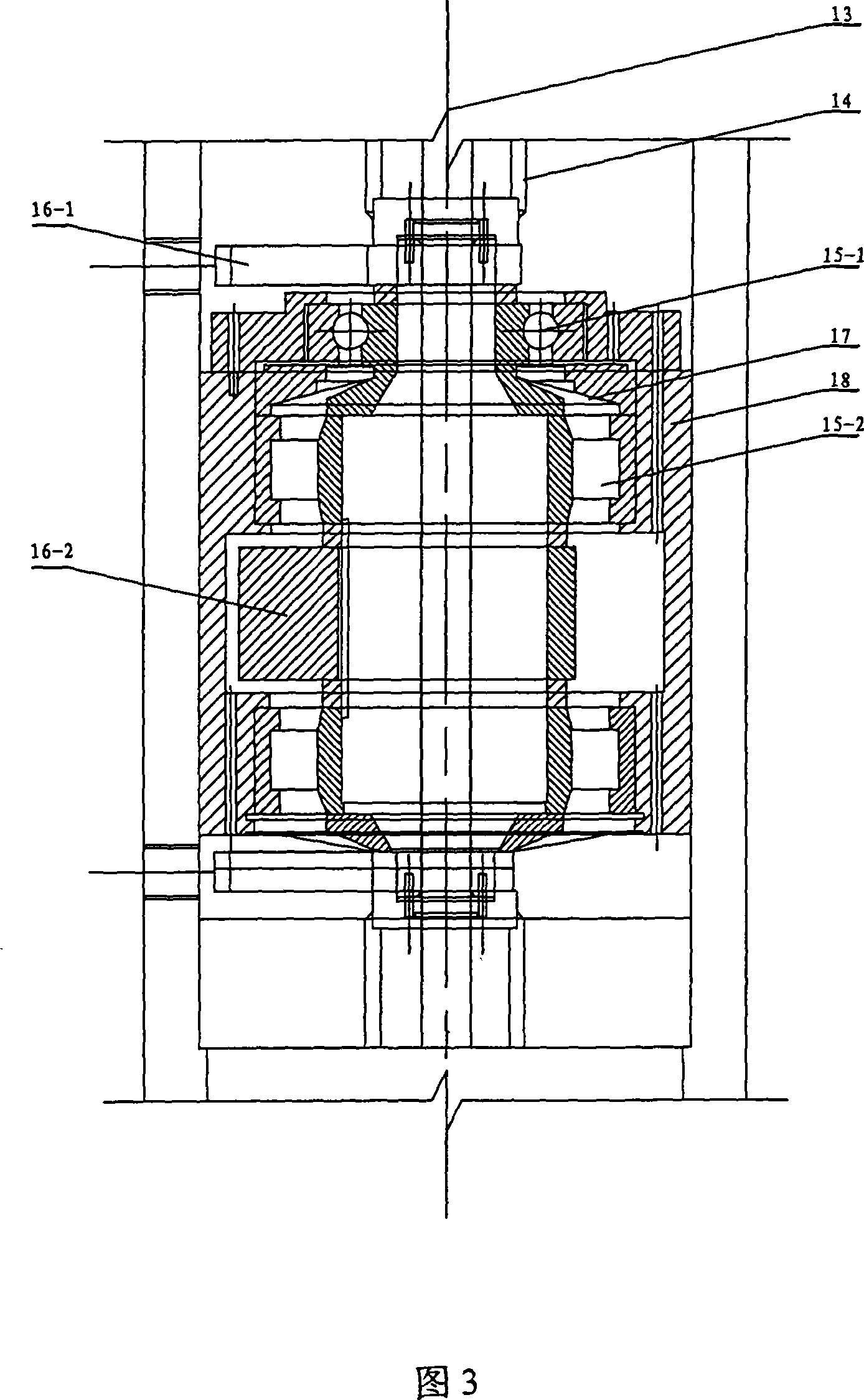

Continuous boiling method and its device for semi chemical mechanical slurry of long bast fiber raw material

InactiveCN1715555AReduce manufacturing costEasy maintenanceCellulosic pulp after-treatmentContinuous pulping processOrifice plateBoiling process

The present invention relates to continuous boiling method and apparatus of semi-chemical mechanical slurry of long bast fiber raw material. During the continuous boiling process, cell bunker rotor valve is used after continuous boiling pipe to exhaust the semi-slurry after being boiled to the distribution bunker in normal pressure, or semi-slurry debonding device is used to debond long bast and large slurry block in the semi-slurry and orifice plate exhaust valve is used to spray the semi-slurry into spraying bunker in normal pressure. Therefore, normal pressure slurry grinding machine may be then used in grinding slurry of the continuously boiled long bast fiber semi-slurry in relatively low cost. In addition, the normal pressure slurry grinding machine may be overhauled easily at normal pressure without need of stopping the whole continuous boiling apparatus.

Owner:天津轻工业机械厂设计研究所 +3

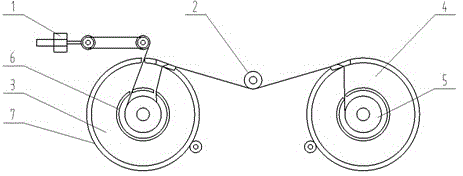

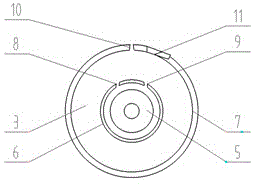

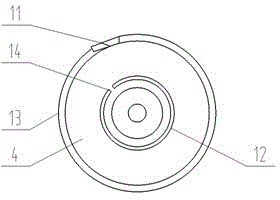

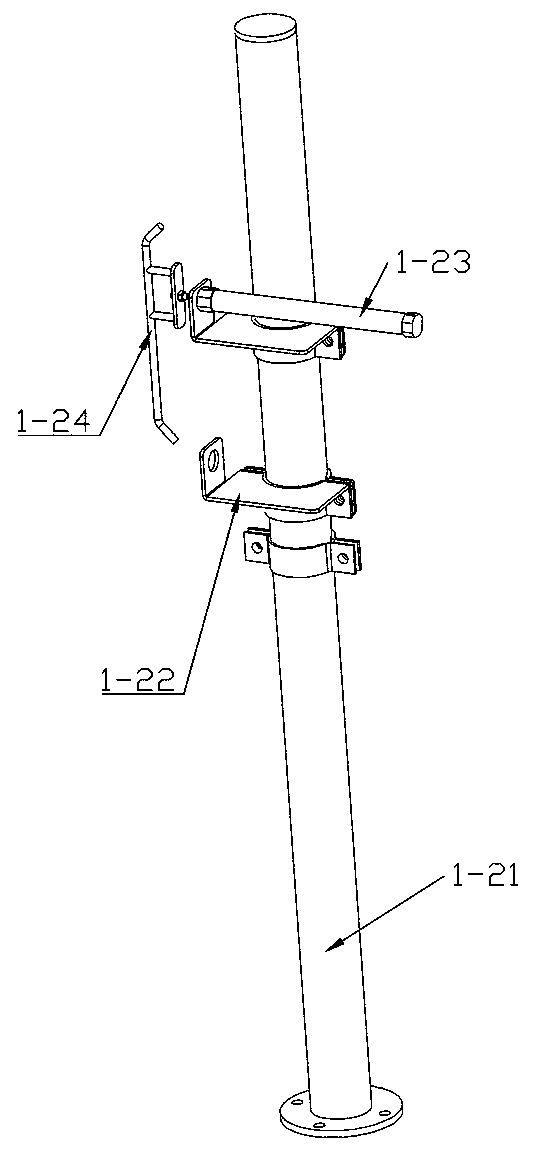

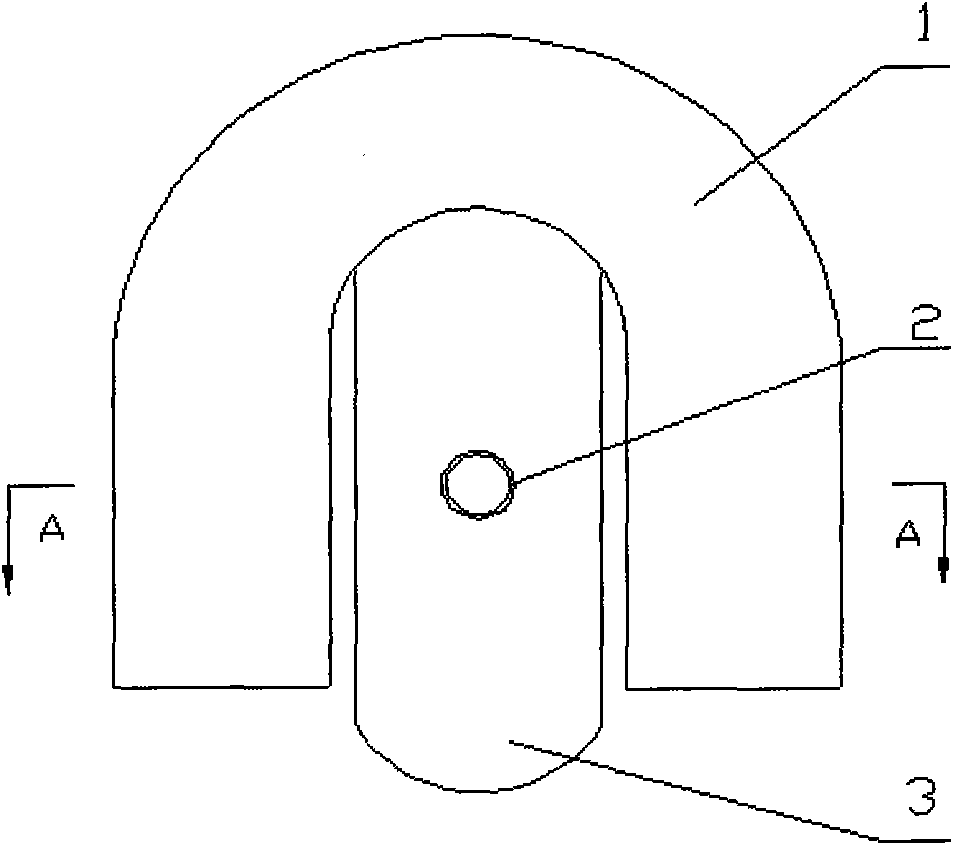

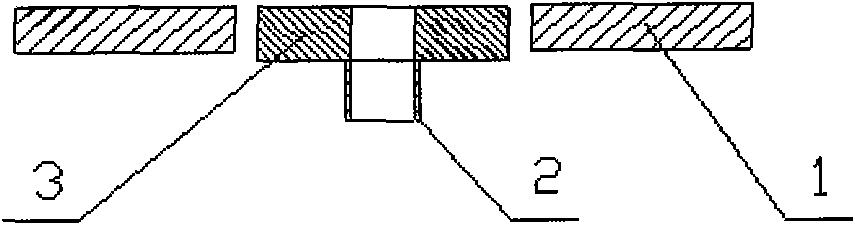

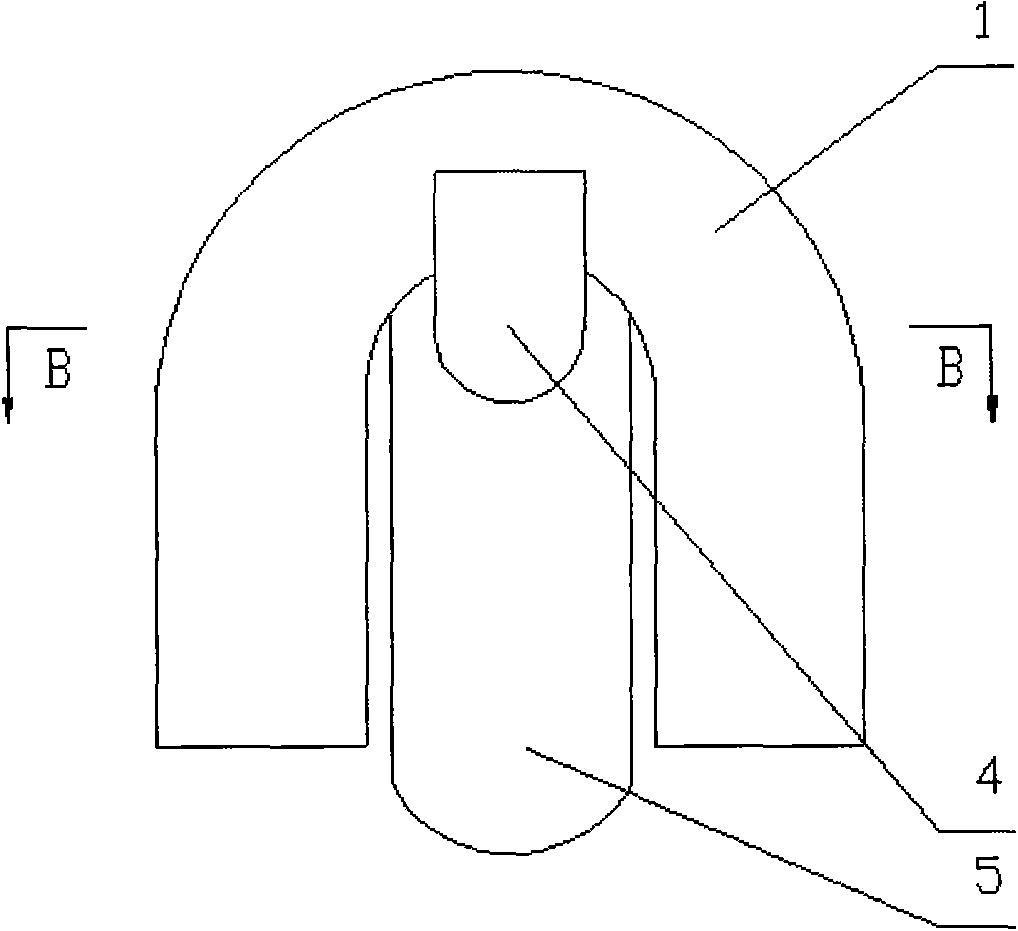

Optical fiber drawing and whipping control device

ActiveCN104355536AWhiplash loweredReduce wasteGlass making apparatusGlass productionEngineeringMirror image

The invention provides an optical fiber drawing and whipping control device comprising a flat cable arm sensor, a compression bar wheel, a whipping ring A and a whipping ring B, wherein the whipping ring A and the whipping ring B are the same in structure and are arranged on the same horizontal straight line by virtue of a mirror image distribution center point; an optical fiber disc is arranged in each of the whipping ring A and the whipping ring B; the flat cable arm sensor is arranged above the whipping ring A; and the compression bar wheel is fixedly arranged between the whipping ring A and the whipping ring B. After switching, optical fibers are swung outside the optical fiber disc, so that whipping cannot be performed on the surface of the optical fiber disc, and thus the optical fiber whipping is effectively reduced. According to the optical fiber drawing whipping control device, the inner diameter of each of an anti-whipping ring washer A and an anti-whipping ring washer B is 2-6mm greater than that of the optical fiber disc, and after switching, the optical fibers are swung outside the optical fiber disc and a protection cover, and the optical fiber disc can be normally operated in the anti-whipping ring washer A and the anti-whipping ring washer B.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

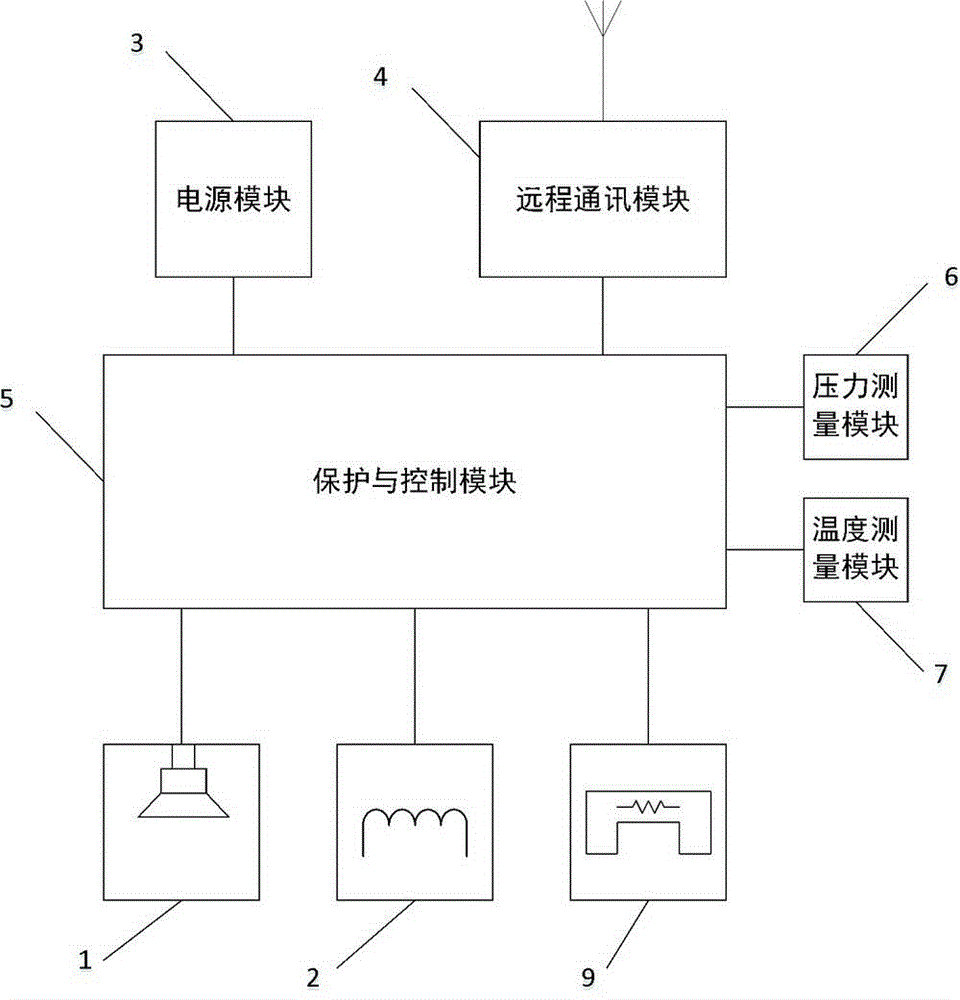

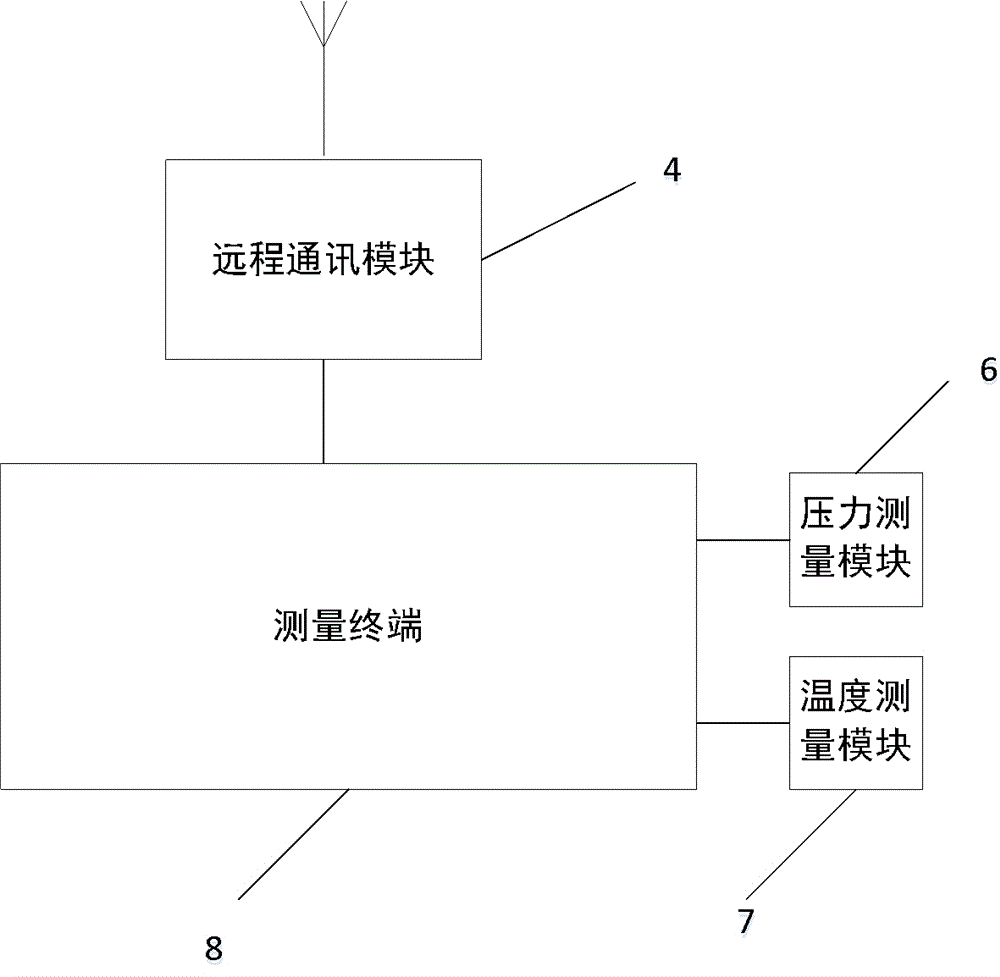

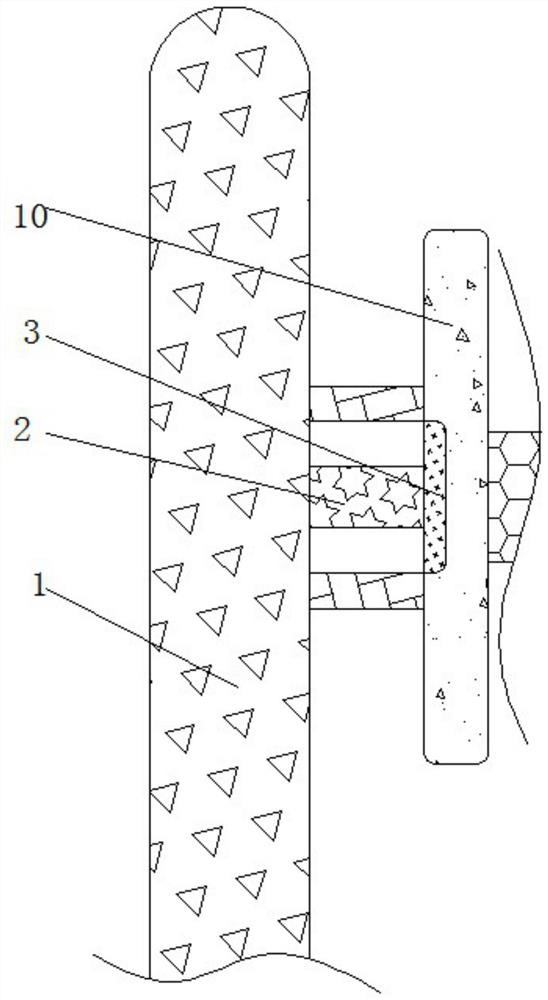

Acoustic-magnetic-thermal combined paraffin-control and plug-removal method and device for oil pipeline

InactiveCN104132215AWill not affect normal productionPower frequency adjustablePipe heating/coolingPipe elementsEngineeringElectromagnetic induction

The invention discloses an acoustic-magnetic-thermal combined paraffin-control and plug-removal method and device for an oil pipeline. According to the method and device, the ultrasonic technology, the electromagnetic induction heating technology and the electromagnetic paraffin-control technology are combined and reinforce one another, and a paraffin-control and plug-removal effect superior to simple superposition can be obtained. The device is composed of an ultrasonic generating module, an electromagnetic induction heating module, a power source module, a remote communication module, a protection and control module, a pressure measuring module, a temperature measuring module, a measuring terminal and an electromagnetic paraffin-control module. By the adoption of the device, precipitation of paraffin is prevented so that scale formation can be avoided and generated paraffin can be removed by means of the high-power ultrasonic cavatition effect and the good paraffin control effect of the alternating magnetic field; the temperature of the oil pipeline is increased by means of the electromagnetic induction heating technology, the temperature of crude oil is kept higher than paraffin precipitation point temperature, and the paraffin precipitation is restrained; meanwhile, the blocking degree of the pipeline can be automatically judged by means of sensors at the head end and tail end of the pipeline, and then corresponding working modes are started. The device is high in universality and operates online completely.

Owner:HARBIN UNIV OF SCI & TECH +1

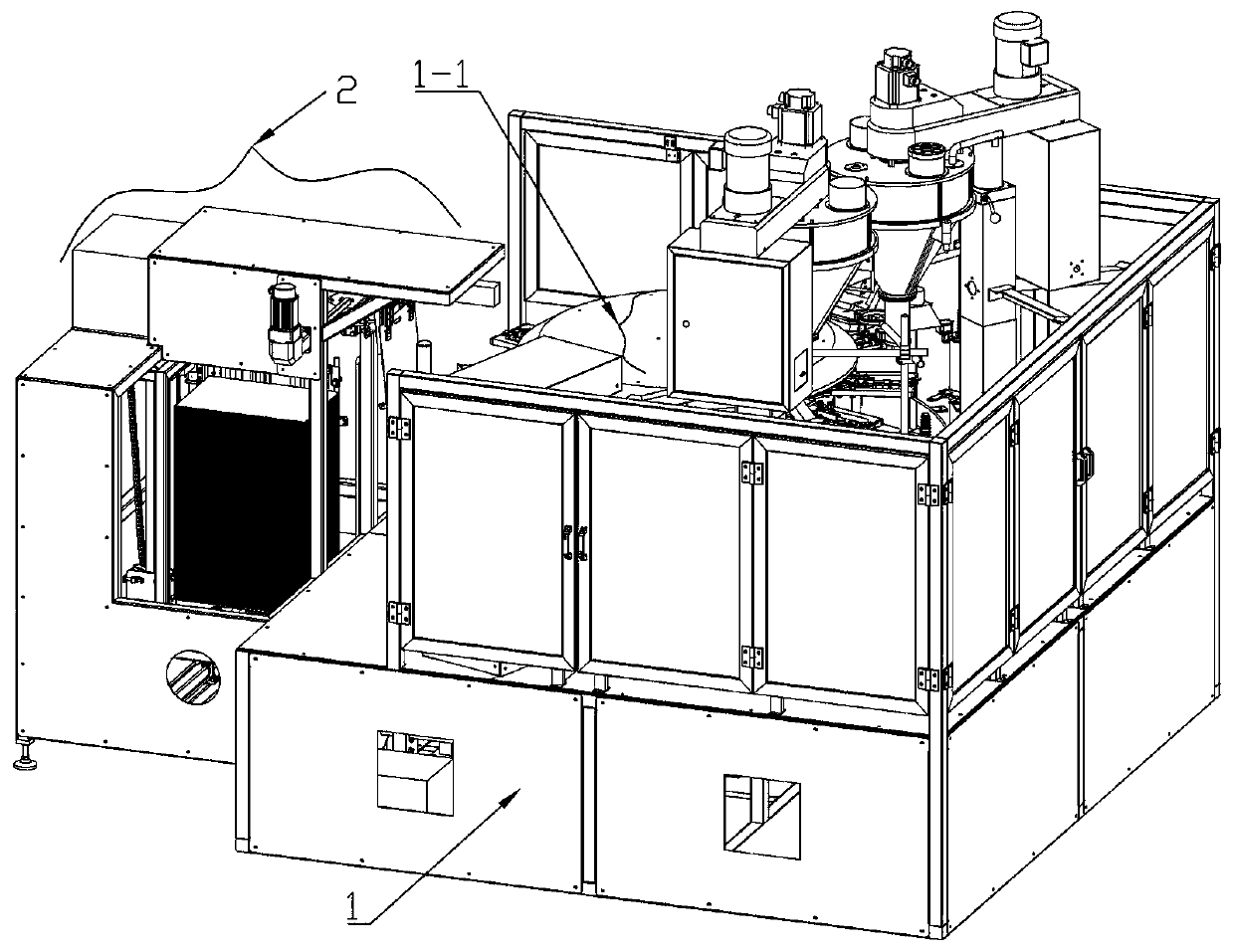

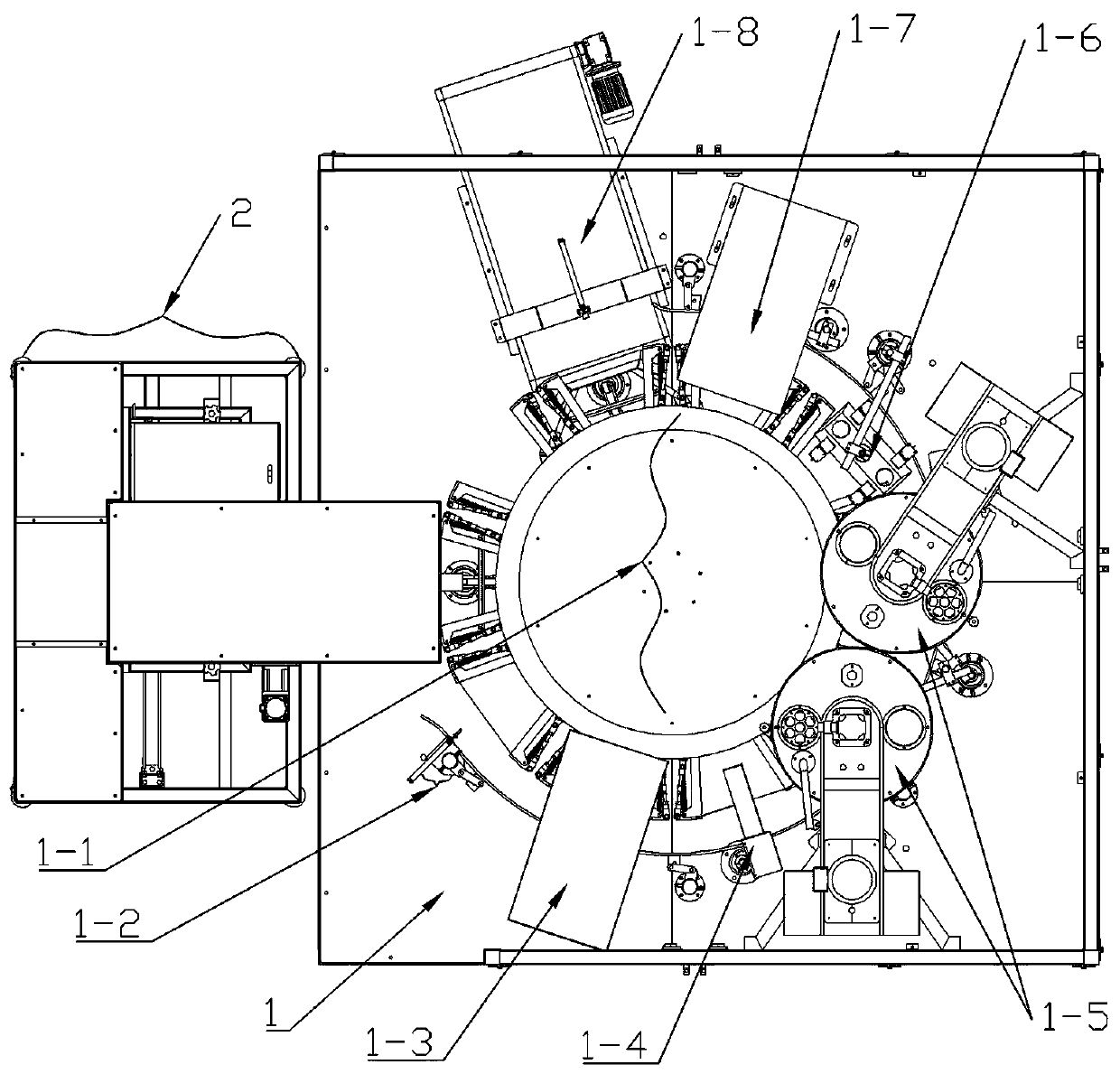

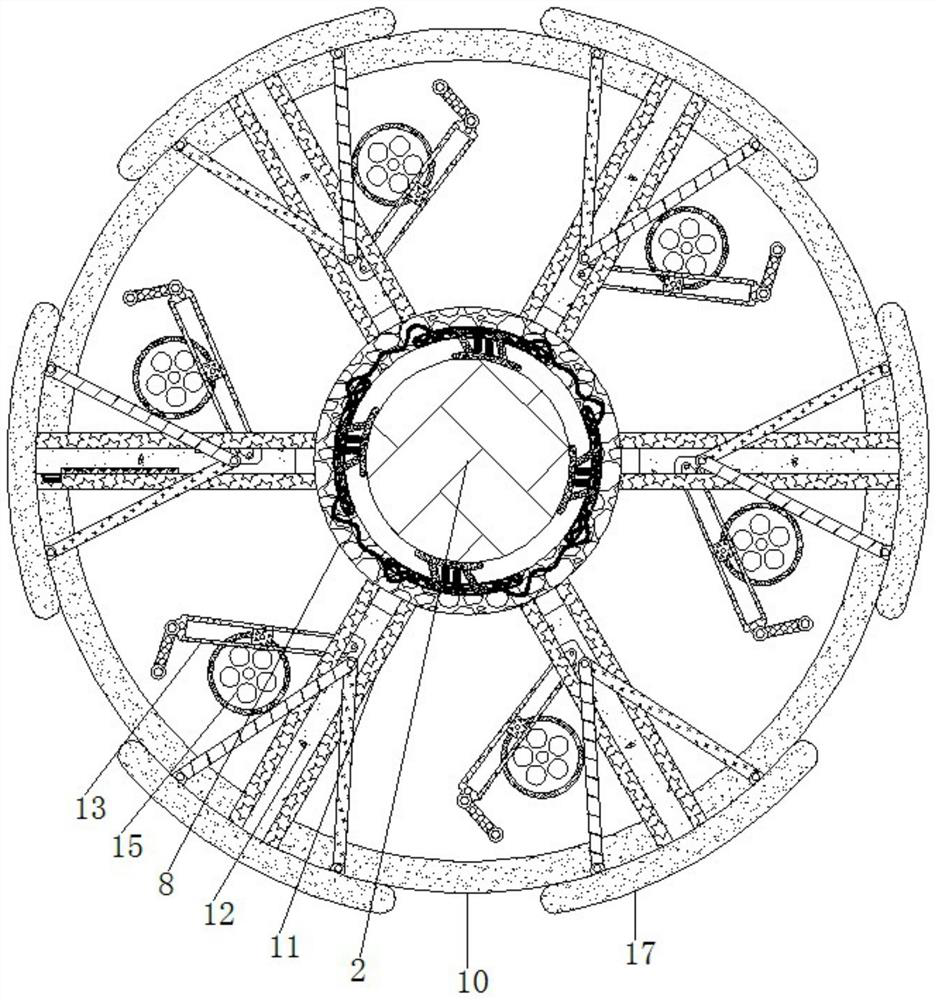

Ten-station flour packing machine

PendingCN110626554ACompact structureSmall footprintPackaging automatic controlEngineeringDust collector

The invention discloses a ten-station flour packing machine which comprises a working platform, a bag supplying mechanism, a packing bag detection mechanism, a bag opening mechanism, an opening detection mechanism, two filling machines, a dust collector, a sealing machine and an output conveyor belt. A center transposition mechanism is arranged at the center of the working platform. The packing bag detection mechanism, the bag opening mechanism, the opening detection mechanism, the filling machines, the dust collector, the sealing machine and the output conveyor belt are mounted on the workingplatform and are successively arranged around the center transposition mechanism. The bag supplying mechanism is located on one side of the working platform and faces a position between the packing bag detection mechanism and the output conveyor belt. A vacancy is reserved between the packing bag detection mechanism and the output conveyor belt. The ten-station flour packing machine is compact instructure and small in occupied space, and can achieve automatic filling. By arranging the two filling machines: one is used and the other is standby. When one of the filling machines fails, the other filling machine can be started immediately to replace the failed filling machine, and the failed filling machine is maintained specially during stop production for maintenance, so that normal production is not affected.

Owner:河南济开电器有限公司 +1

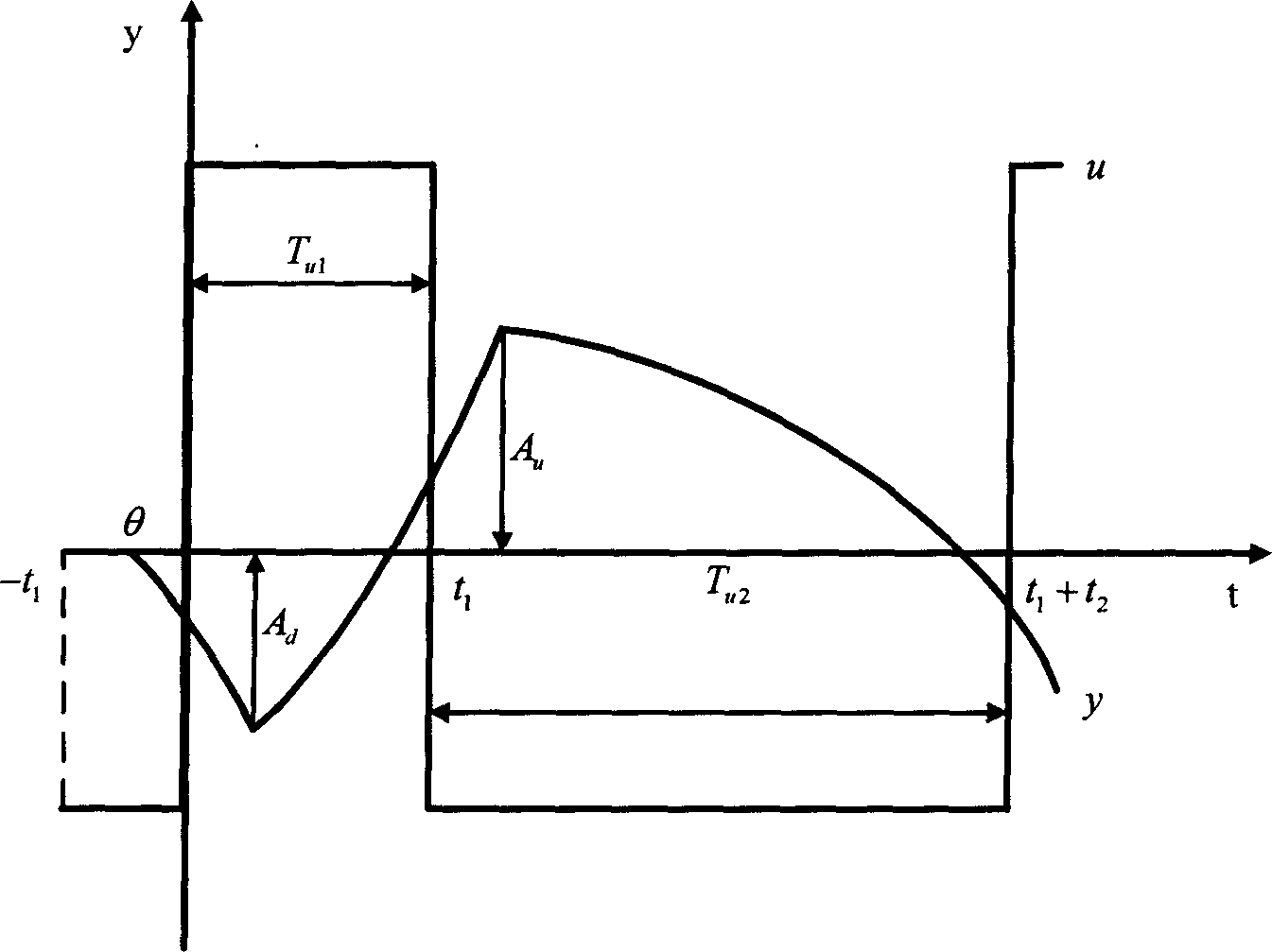

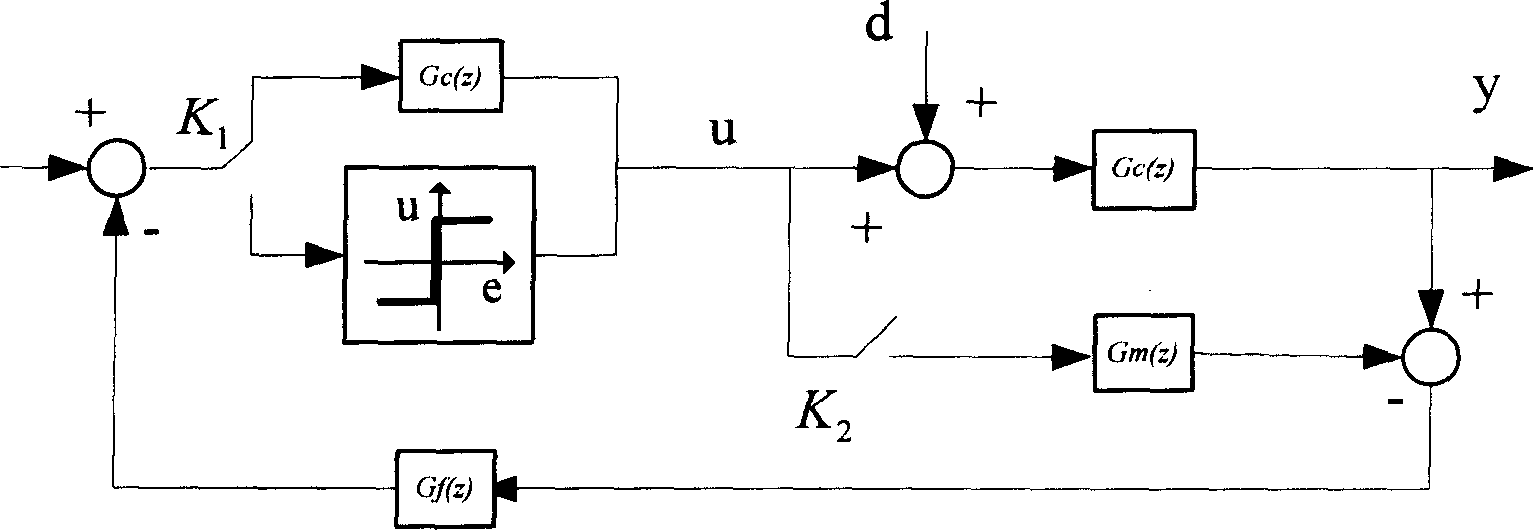

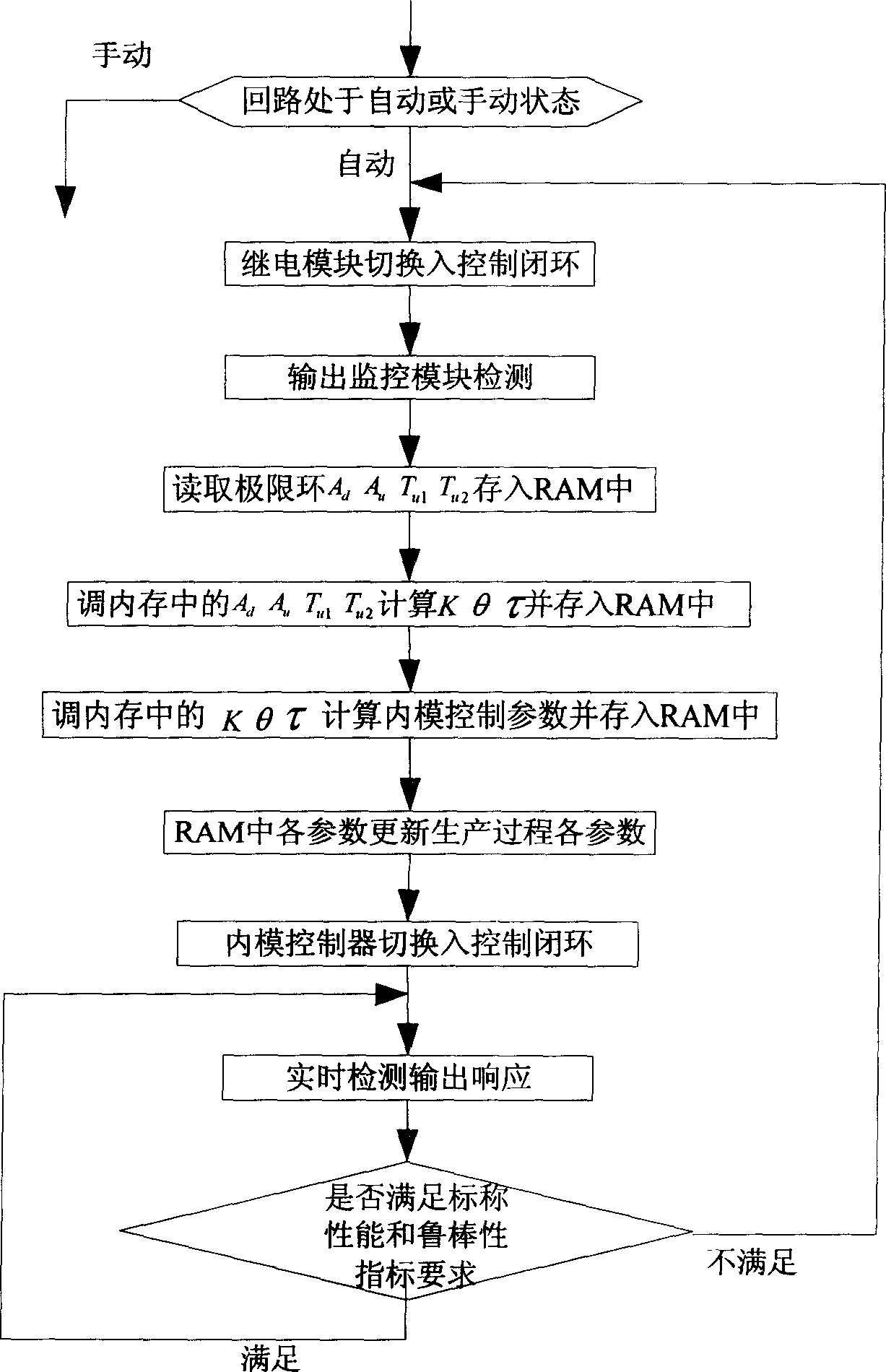

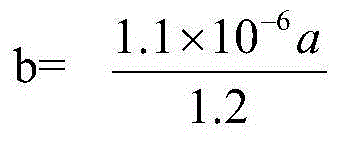

Method for designing inner mould self-setting digital controller

The present invention adopts single-order plus dead-time model; said upper computer controlling output panel control board key to make systems operation on ' identifying stage ', at this point, the relay identifying link switched into closed loop system; under action of relay link, after beginning systems operation, at short notice establishing limit loop; according to real-time measurement to relay output each parameter and biasing relay feed-back identifying formulae to calculate out system identifying three parameters: K, Theta and Pi, and storing in RAM. According to identified model parameter, system calculates each parameter of novel internal mold controller, computational result stored in RAM memory unit, the obtained model and internal mold controller parameter loading in each link in real production process. The present invention realizes the self calibration of digit internal mold controller, reducing hardware cost and raising systematical mobility, reliability and accuracy.

Owner:SHANGHAI JIAO TONG UNIV

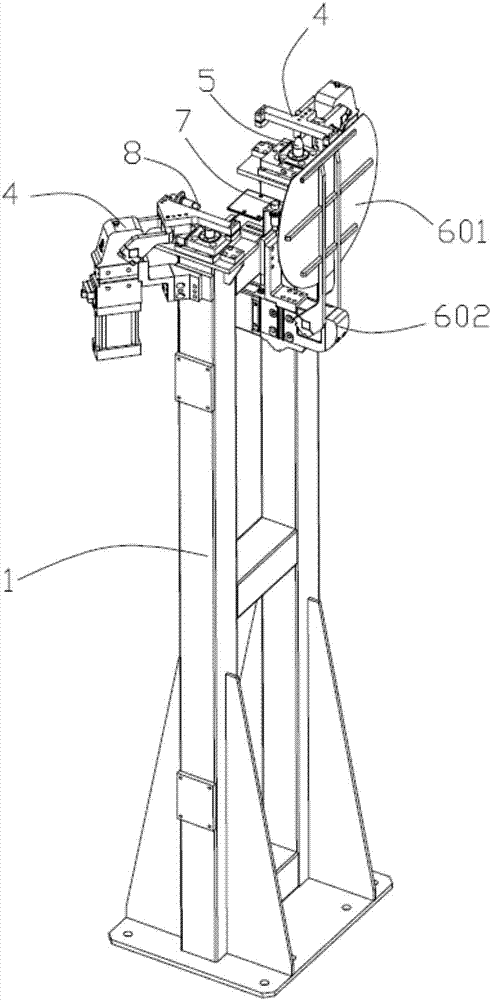

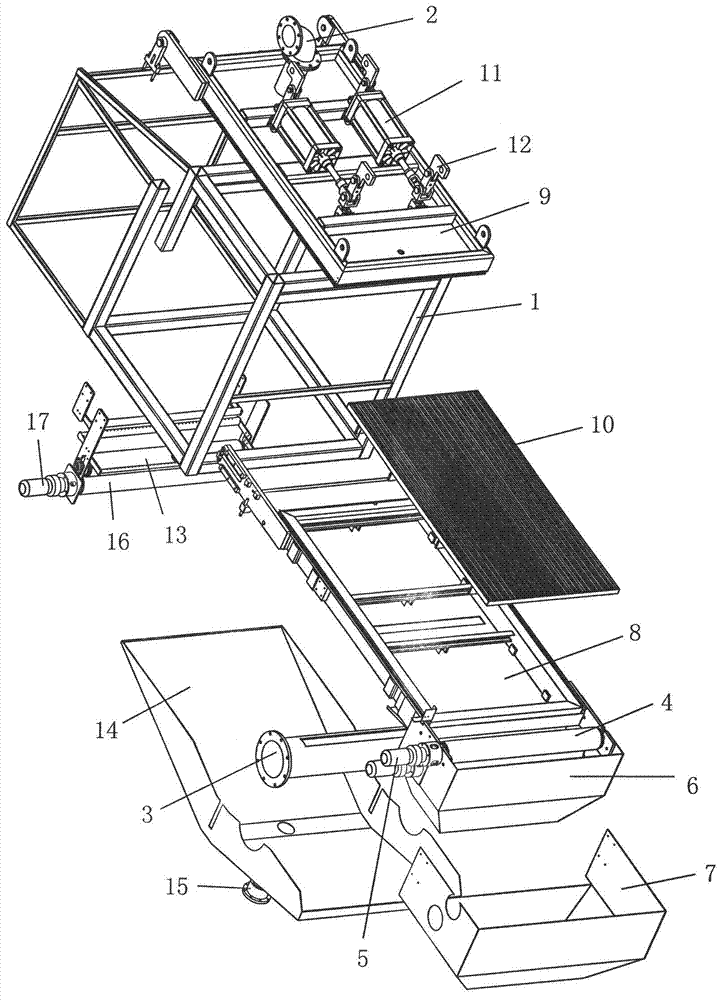

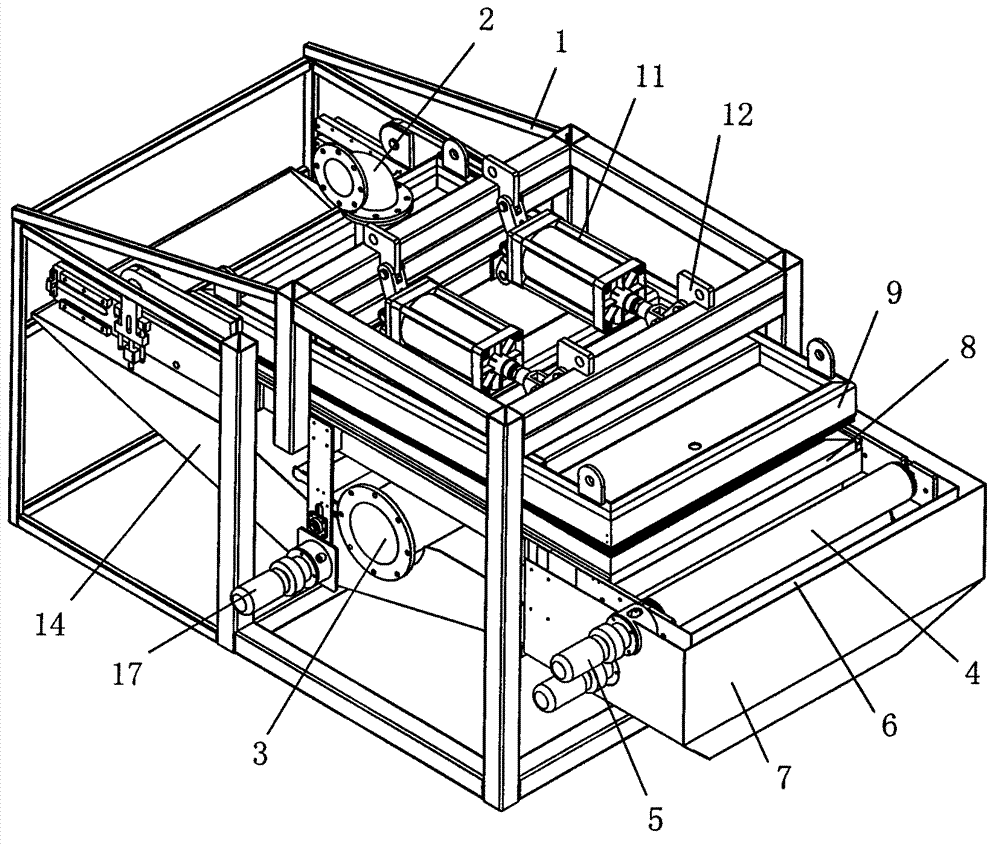

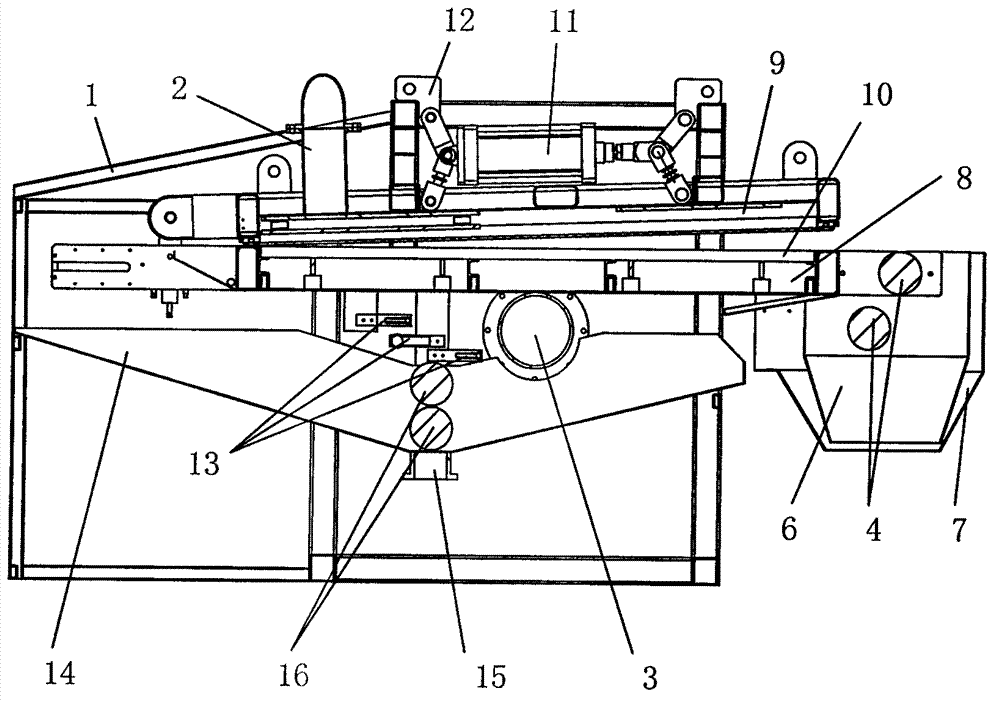

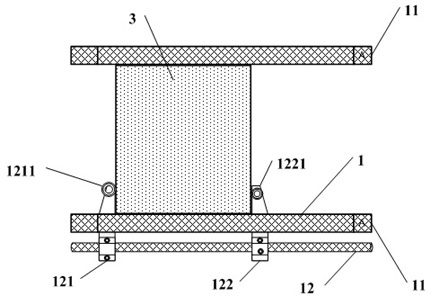

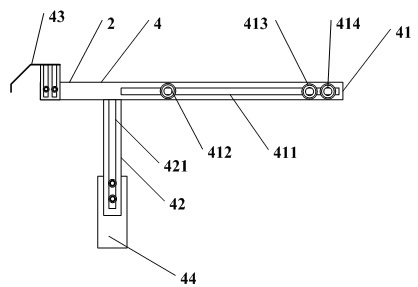

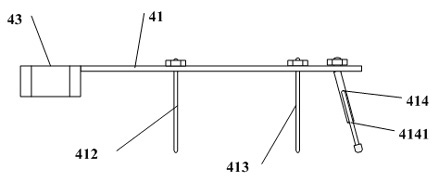

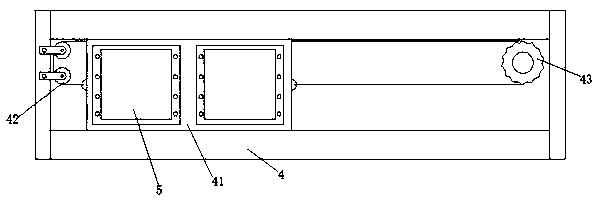

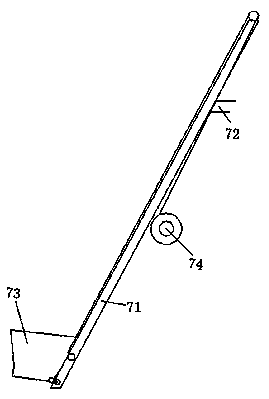

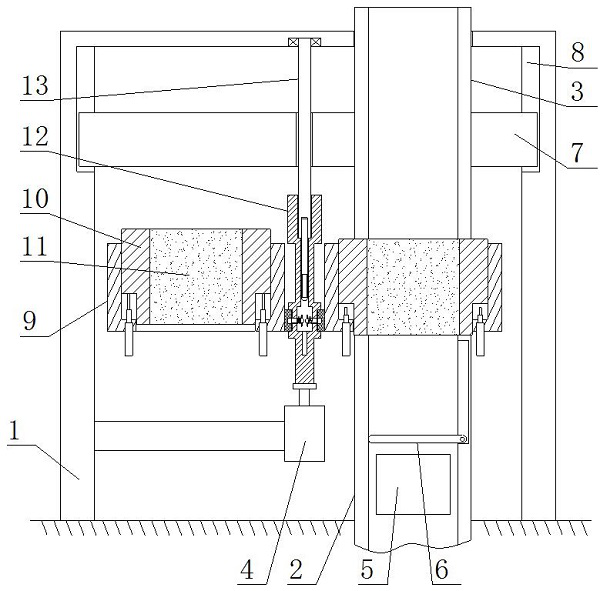

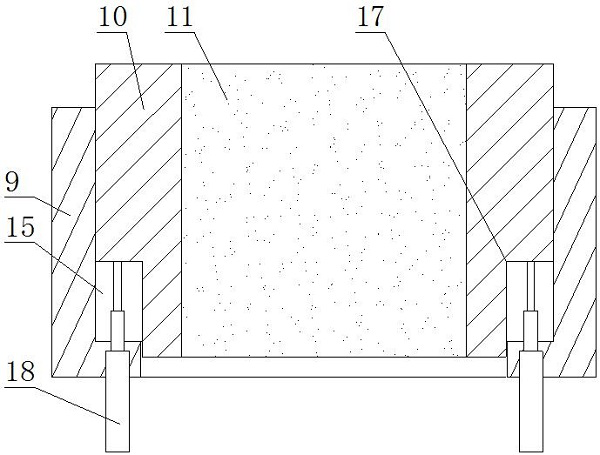

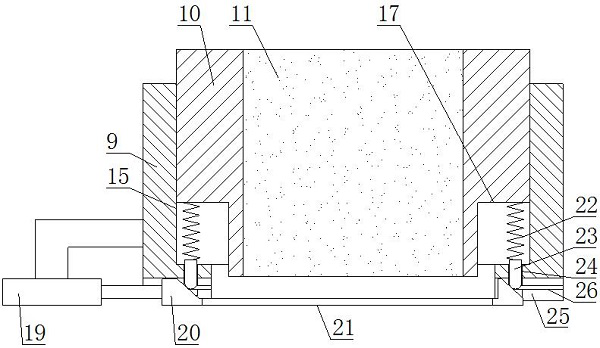

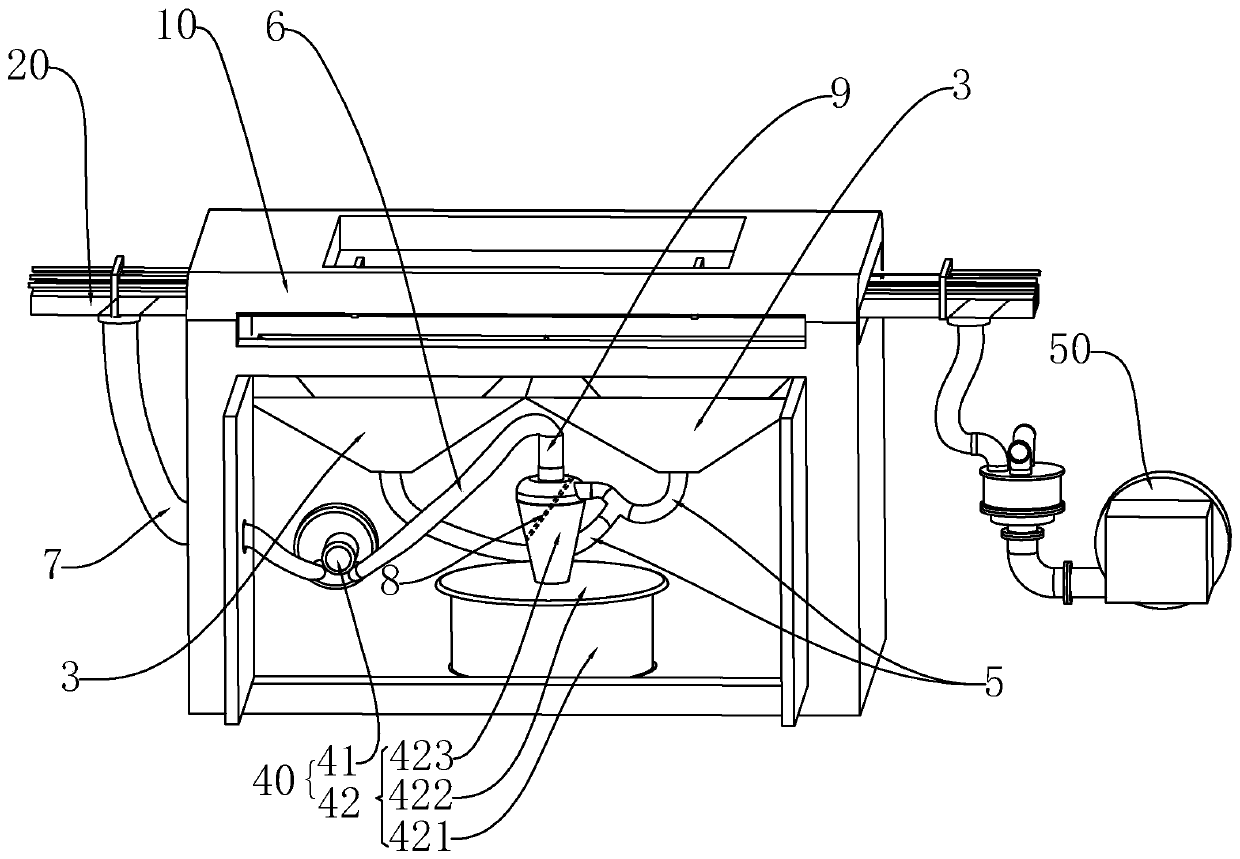

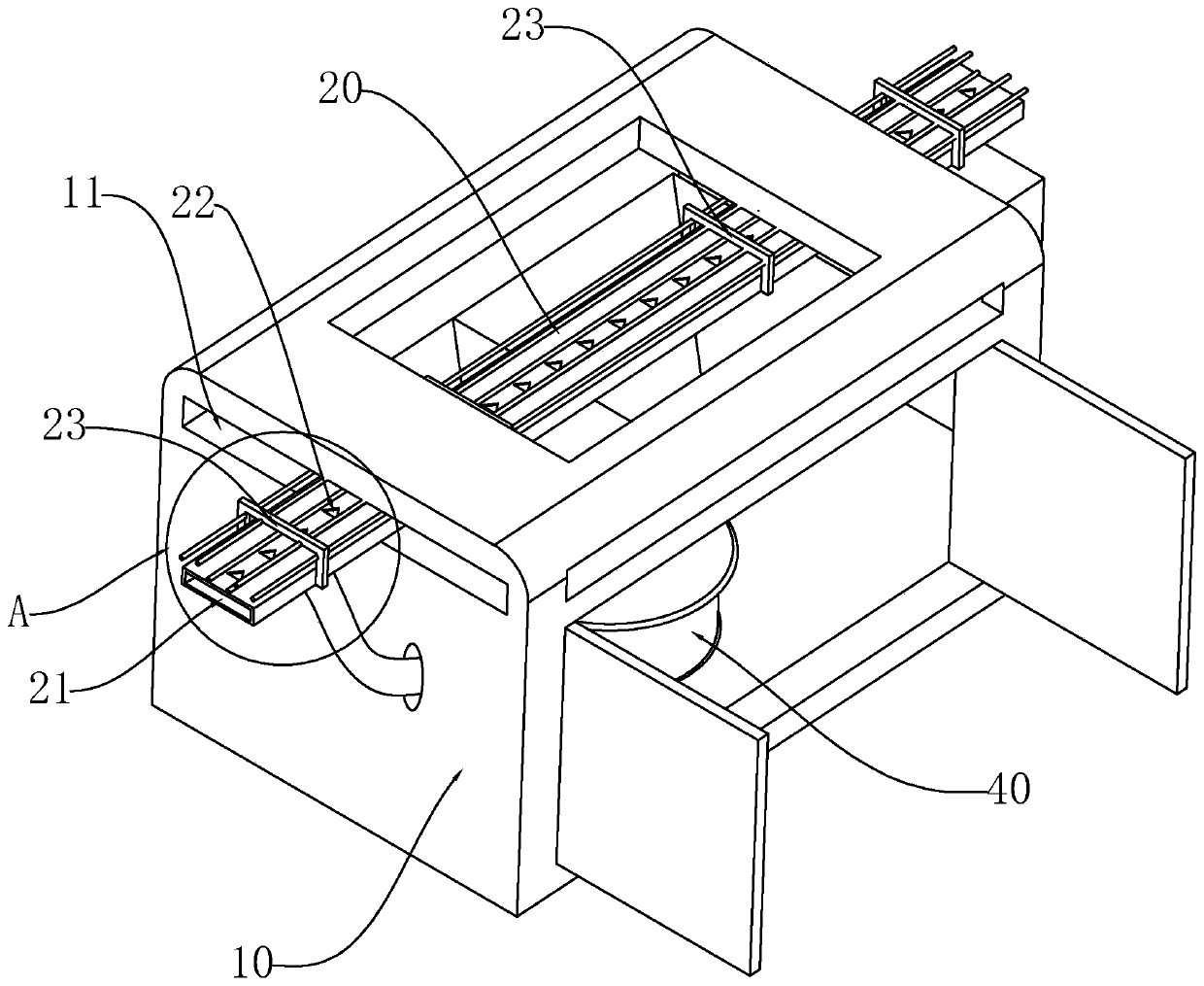

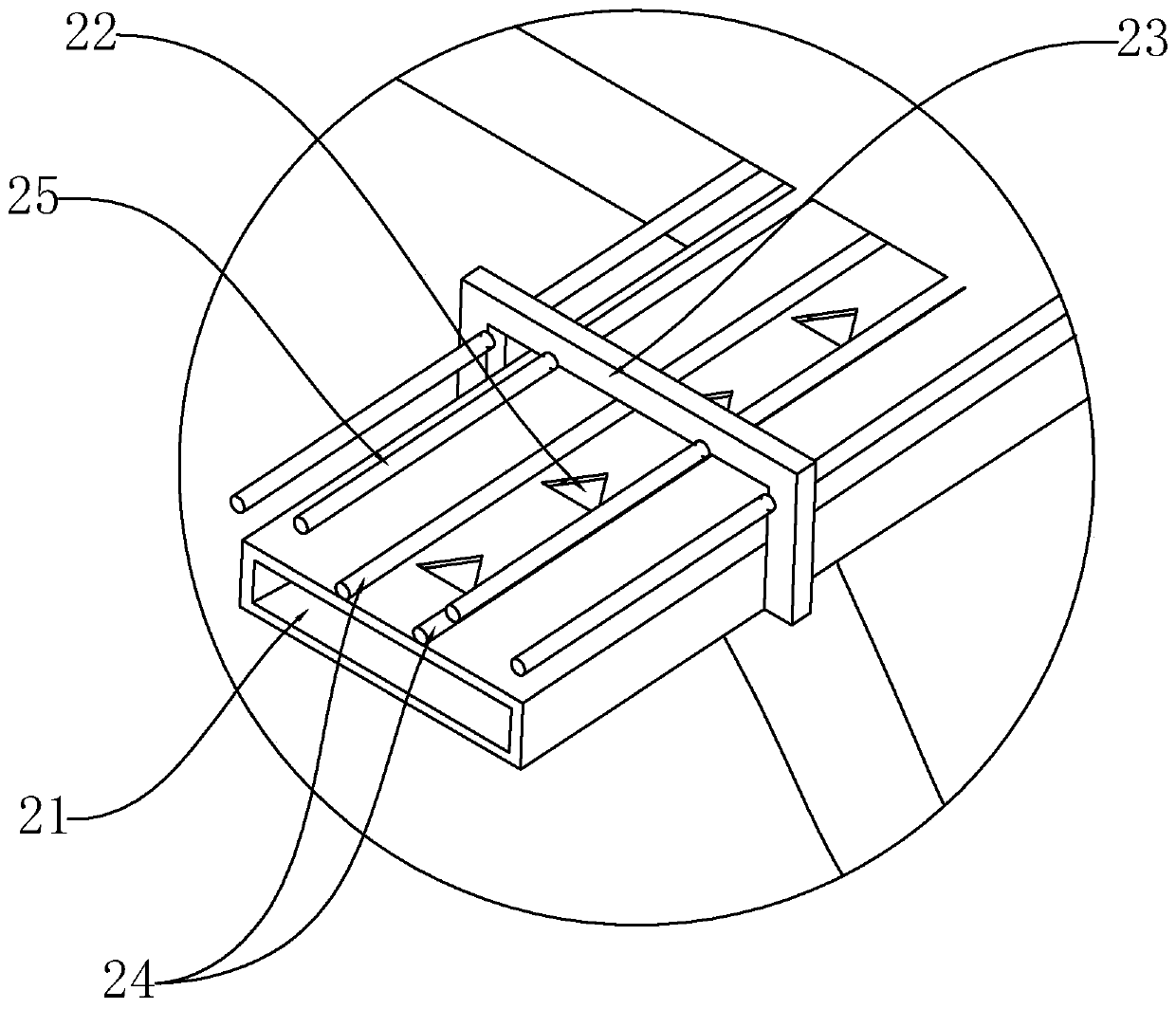

Thickness detecting experimental platform

ActiveCN108020164AWill not affect normal productionDebugging is inconvenientProgramme controlCaliper-like sensorsProduction lineComputer module

The invention discloses a thickness detecting experimental platform. The platform comprises a motion simulation module and a thickness detection module, the motion simulation module drives a to-be-detected product to execute predetermined simulation motions which are used to simulate different motions of the production in a practical production line, and the thickness detection module is used to detect the thickness of the to-be-detected product driven by the motion simulation module. According to the platform, the motion simulation module drives the to-be-detected product to simulate the different motions in the practical production line, the condition of the product in the practical production line can be reproduced in a lab, and thus, thickness detection equipment can be debugged offline in the lab, online debugging is not needed, normal production of the production line is not influenced, and debugging is convenient.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +2

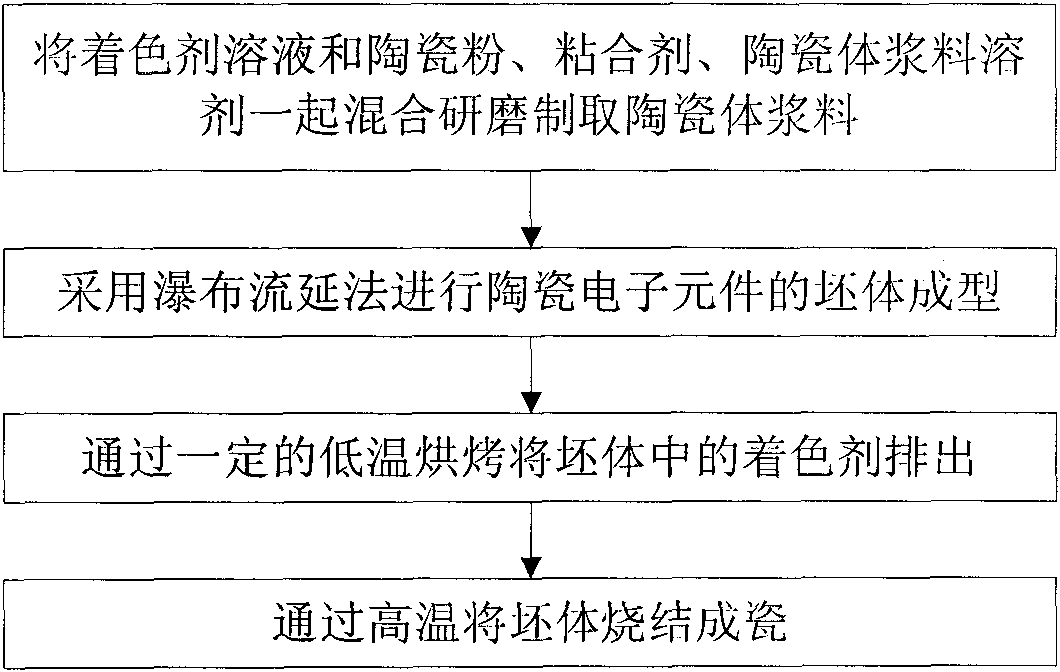

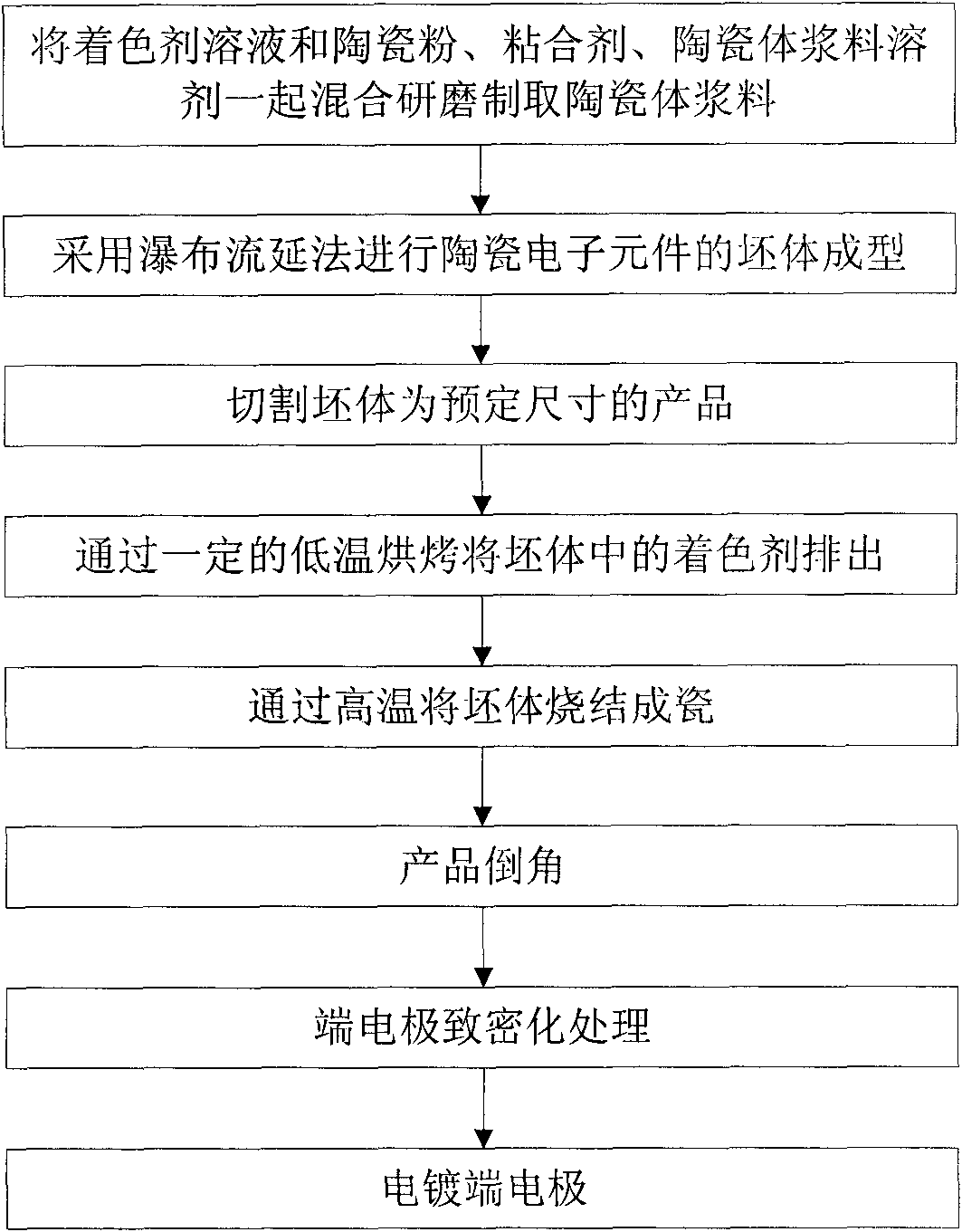

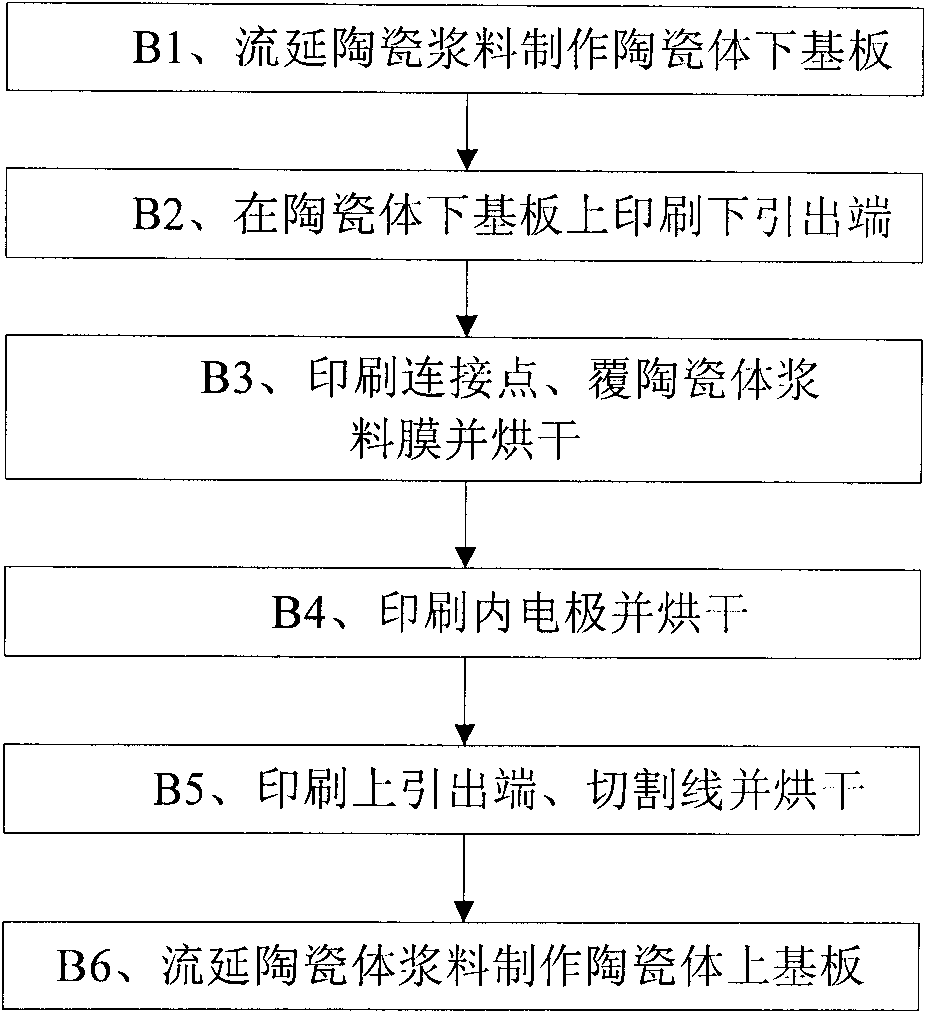

Manufacturing method of ceramic electronic component

InactiveCN101798224AEasy to identifyAccurate identificationInductances/transformers/magnets manufactureInsulating bodiesMetallurgySlurry

The invention relates to a manufacturing method of a ceramic electronic component, which comprises the following steps: A, mixing and grinding a colorant solution with ceramic powder, a binder and a ceramic body slurry solvent together to prepare ceramic body slurry; B, printing an inner electrode and connection points, and forming a green body of the ceramic electronic component; C, discharging the colorant in the green body of the ceramic electronic component through certain low-temperature baking; and D, sintering the green body at high temperature to form the ceramic electronic component.The technical scheme of the invention can solve the problems in the prior art that the inner electrode can not be positioned easily in the printing process, the printing effect of the connection points can not be recognized easily, and products can not be accurately positioned in the cutting process, thereby improving the printing effect, the reliability of product connection and the accuracy of product cutting.

Owner:SHENZHEN SUNLORD ELECTRONICS

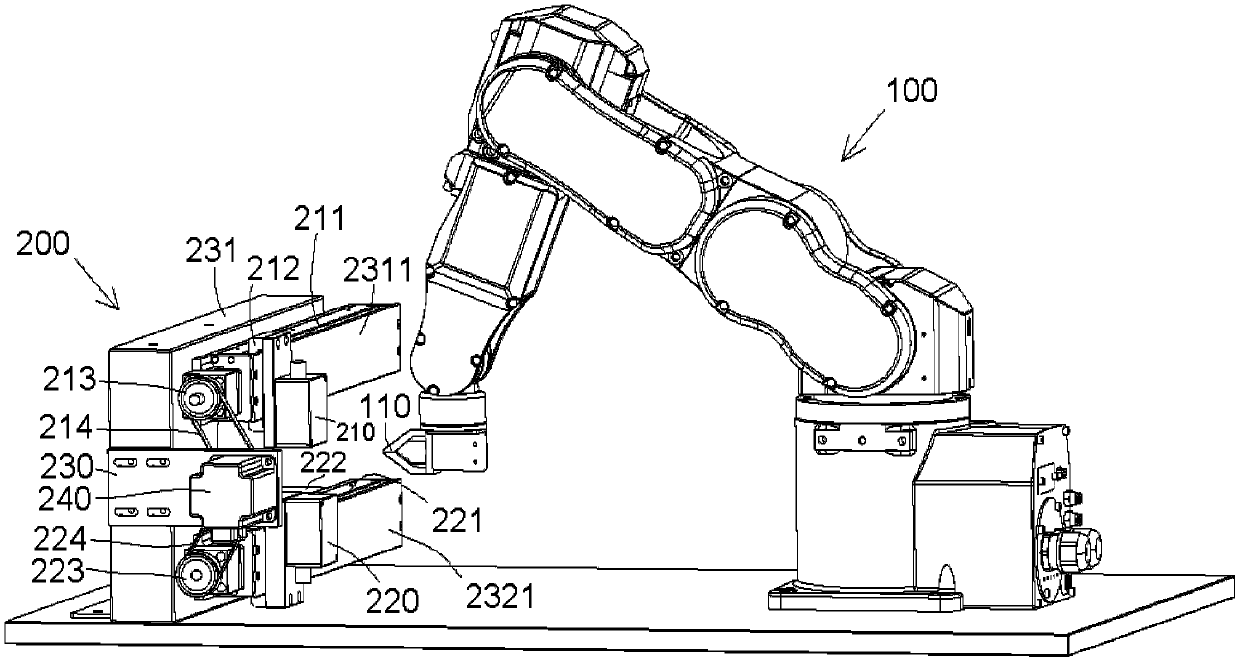

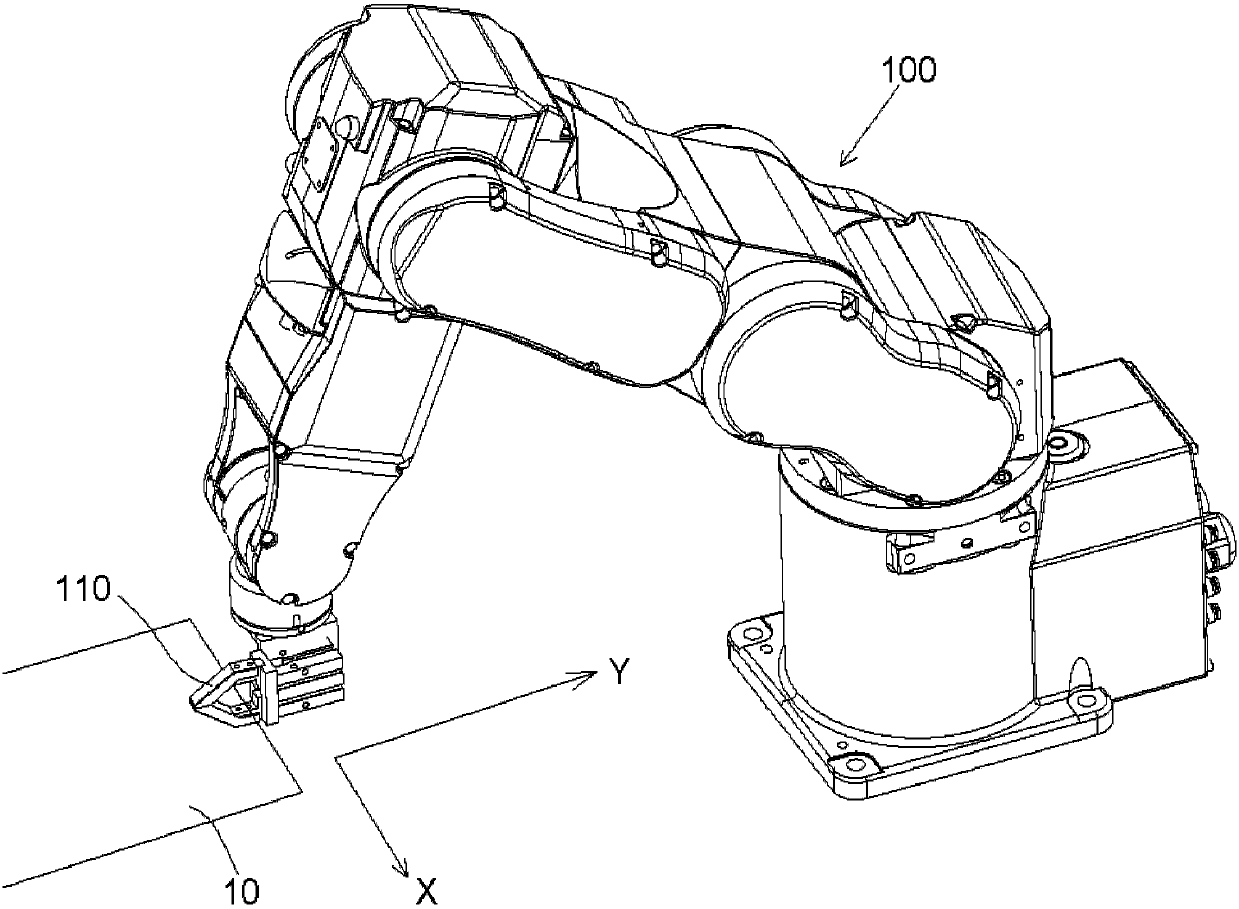

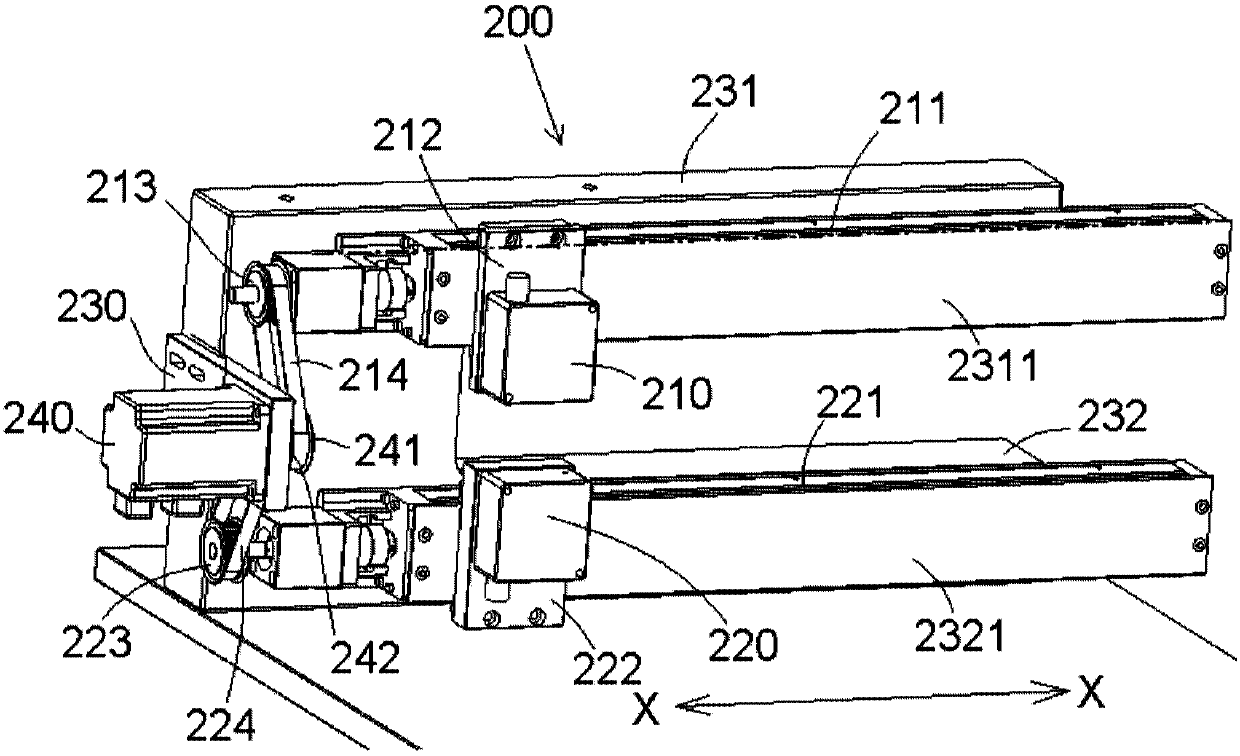

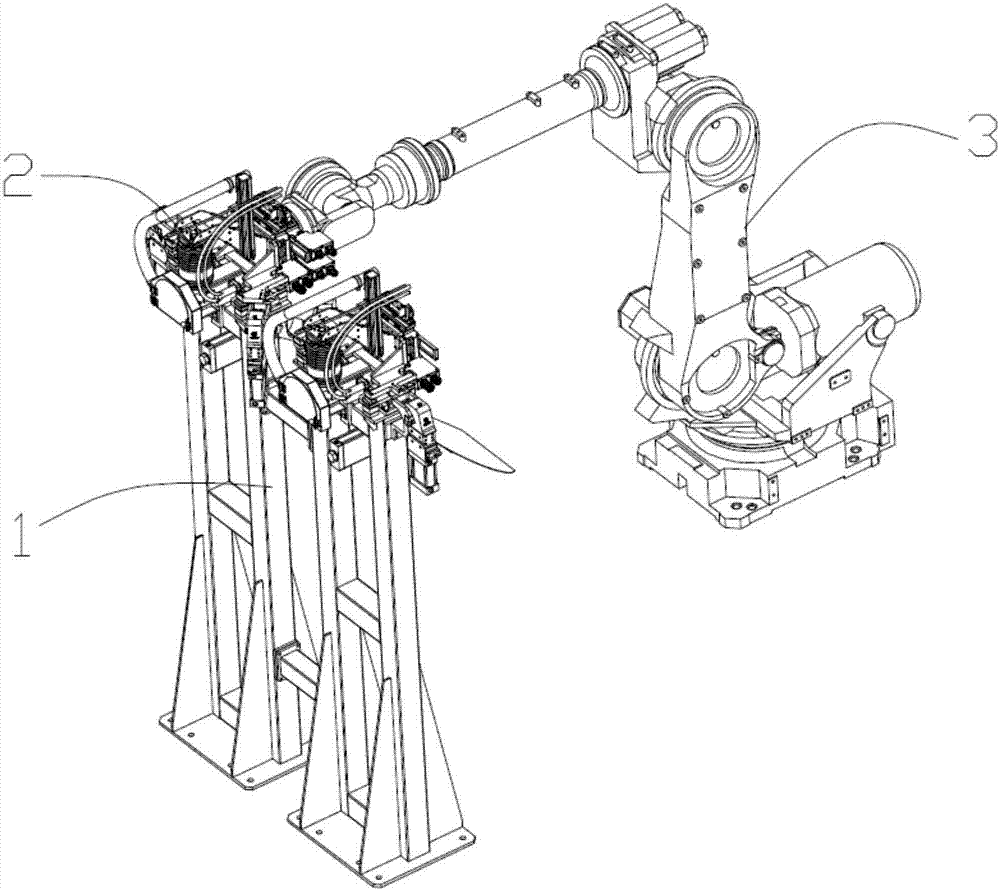

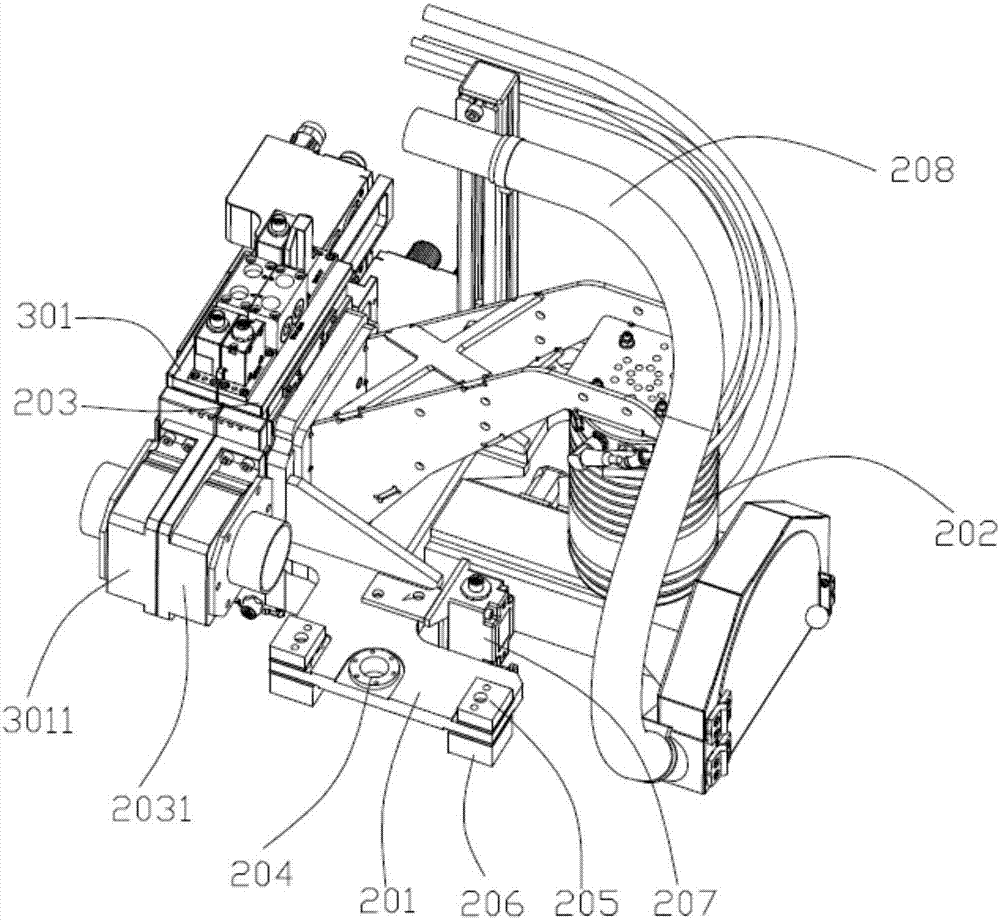

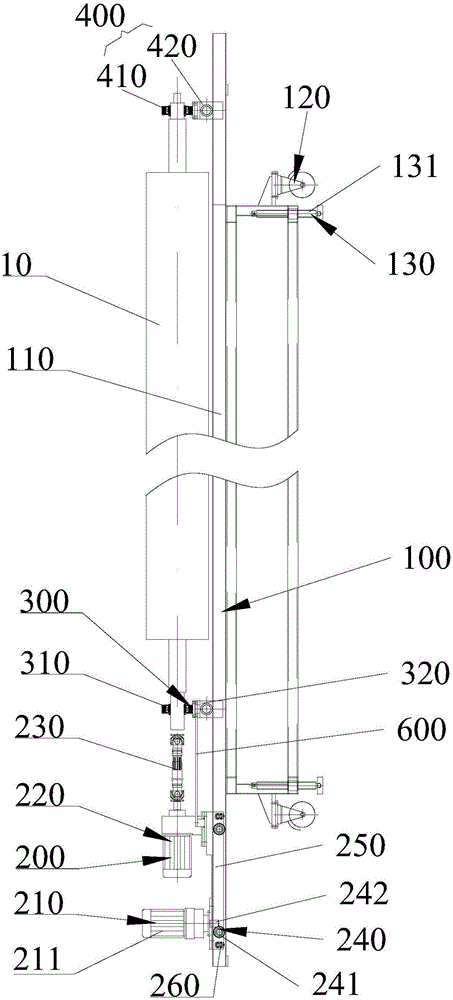

Grinding head replacing system and robot grinding system

PendingCN107984389AWill not affect normal productionAvoid waiting in lineGrinding wheel securing apparatusGrinding/polishing safety devicesEconomic benefitsAssembly line

The invention relates to a grinding head replacing system and a robot grinding system equipped with the grinding head replacing system. The grinding head replacing system comprises a parking table which is arranged beside a grinding robot in an off-line mode, and the parking table is provided with two grinding head parking positions, wherein one of the grinding head parking positions is used for bearing a to-be-offline grinding head, and the other grinding head parking position is provided with a to-be-online grinding head. The two grinding head parking positions are provided with mounting mechanisms for fixing and mounting the grinding heads correspondingly. Each grinding head comprises a grinding machine, a grinding head support used for being mounted on the corresponding grinding head parking position, and a quickly-replacing female disc matched with a quickly-replacing male disc on the grinding robot. The grinding machines and the quickly-replacing female discs are both mounted onthe grinding head supports. According to the grinding head replacing system and the robot grinding system, the switching work of the to-be-offline grinding head and the to-be-online grinding head canbe achieved, the situation that normal production cannot be influenced by replacing operation of grinding wheels is ensured, the situation that due to grinding wheel replacing, an assembly line stopsto wait is avoided, and the production efficiency and economic benefits can be improved.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

A fully automatic packaging equipment

ActiveCN107264878BLow professional skills requiredAvoid adjustmentWrapper twisting/gatheringSolid materialModularityModular design

The invention discloses full-automatic packaging equipment. The full-automatic packaging equipment comprises an automatic bag feeding machine, an automatic rationed packing scale, an automatic bag putting machine and an automatic bag sewing machine. The packaging equipment adapts to functions of different packaging specifications and can be switched by pressing a key so as to adapt to the packaging specifications of different sizes, so that a large amount of adjustment is avoided, foolproof operation is realized, the requirement of workshop operators on professional skills is reduced, and the performance of a multifunctional full-automatic packaging machine is realized. The full-automatic packaging equipment adopts a modular design concept and can be compatible with two kinds of line-shaped packaging bags, so that the labor cost is reduced, and the efficiency is improved. In addition, a manual operation station is reserved on the full-automatic packaging equipment, a manual bag feeding mode and an automatic bag feeding mode can be switched at any time, and in a physical production process, a manual bag putting mode can be switched when the automatic bag feeding machine fails, so that normal production of users cannot be influenced.

Owner:ZHANGZHOU KEHONG ELECTRON

Online cleaning agent composition for heat conduction oil and cleaning method

InactiveCN107118851AImprove solubilityDoes not affect heat transferOrganic detergent compounding agentsSurface-active detergent compositionsClearing AgentCleansing Agents

The invention relates to the technical field of cleaning agents, particularly provides an online cleaning agent composition for heat conduction oil and a cleaning method, and aims at solving the problem that heat conduction oil cannot be cleaned in an online way. The cleaning agent composition comprises the following raw materials in parts by weight: 20 to 30 parts of base oil, 2 to 12 parts of an ashless dispersant, 18 to 28 parts of a clearing agent, 2 to 12 parts of a surfactant, and 30 to 45 parts of washing agent. According to the online cleaning method, online cleaning is performed on heat conduction oil through the cleaning agent composition, cooling is not required under the condition that a heat conduction oil system is normally operated, the cleaning agent composition is added into the heat conduction oil system, coked oil dirt on pipe walls is cleaned according to a compatibility principle, the online cleaning of the heat conduction oil is realized, the normal operation of the system is not affected, the phenomenon that pipes are blocked by dirt does not occur, the cleaning efficiency is higher than 98 percent, heat conduction can be improved, and energy consumption can be reduced.

Owner:SHANDONG ENKLI CHEM

Method for maintaining blast furnace taphole

ActiveCN101892337AIntegrity guaranteedImprove blockageBlast furnace componentsBlast furnace detailsEngineeringTherapeutic effect

The invention relates to a method for maintaining a blast furnace taphole. The technical scheme is that the method comprises the following steps of: cleaning iron runners on two sides of the taphole, a mud sleeve and a taphole frame 1, welding a blind plate 3 to the taphole frame, grouting a grouting nozzle stub on the blind plate 3 by adopting a thermoplastic phenolic resin bonded hard press-in material, standing for 1 to 1.2 hours, detaching the blind plate 3, and cleaning up the grouting material in the taphole; welding a baffle plate 5 to the taphole frame, and pouring an iron runner castable; and respectively opening a grouting hole on a left cross joint, a right cross joint and a vertical joint on the taphole cooling wall, and grouting each grouting hole until the pressure is 4.5 to 5MPa. The method has the characteristics of good treatment effect, reduction of gas leakage in a blast furnace taphole area and guarantee of normal production of the blast furnace.

Owner:WUHAN WINNING TECH +1

Roller changing carriage with function of online transitional roller changing

ActiveCN106746576AEvenly heatedPrevent radial deformationGlass transportation apparatusPulp and paper industryGlass manufacture

The invention belongs to the technical field of glass manufacture, and aims to provide a roller changing carriage with a function of online transitional roller changing. The roller changing carriage comprises a carriage main body, a movable trolley device, a driving end supporting mechanism and a driven end supporting mechanism, wherein a plurality of universal wheels are fixedly arranged at the bottom of a supporting platform of the carriage main body, so that the roller changing carriage can move freely; the movable trolley device is arranged on the supporting platform, and is driven to move along the supporting platform by virtue of a roller in-out moving mechanism in the movable trolley device, when a transitional roller is fixedly connected to the roller changing carriage under assistance of the driving end supporting mechanism and the driven end supporting mechanism, the transitional roller can move along the supporting platform under driving of the roller in-out moving mechanism to enter and exit a slag box, and can also automatically rotate under driving of a roller rotation mechanism, so that the translational roller can be changed online, and normal production cannot be influenced.

Owner:XINYI GLASS WUHU

Filter for processing grinding fluid

The invention discloses a filter for processing grinding fluid. The filter comprises a rack and a box body arranged on the rack, wherein a water inlet which is connected with a water inlet tube and a water outlet which is connected with a water outlet tube are arranged in the box body; a control valve is arranged on the water inlet tube; a piece of screen cloth is arranged inside the box body in a penetrating manner; the two ends of the screen cloth extend out of the box body, then are encircled, and are driven by a rotary mechanism to rotate; the water inlet and the water outlet are respectively arranged in the two sides of the screen cloth; the rack body is provided with at least one rolling rod brush on the outer side of the box body and on one side of the mesh cloth forward direction; the rolling rod brush is driven by a rolling brush drive mechanism to rotate; and the rack body is provided with a slag-out material receiving hopper below the rolling rod brush. By adopting the structure, grinding mud in the grinding fluid can be well filtered without blocking a pipeline, so that the grinding fluid can be recycled, a pond does not need to be cleaned, labor force is saved, and normal production is not affected.

Owner:宁波江宸智能装备股份有限公司

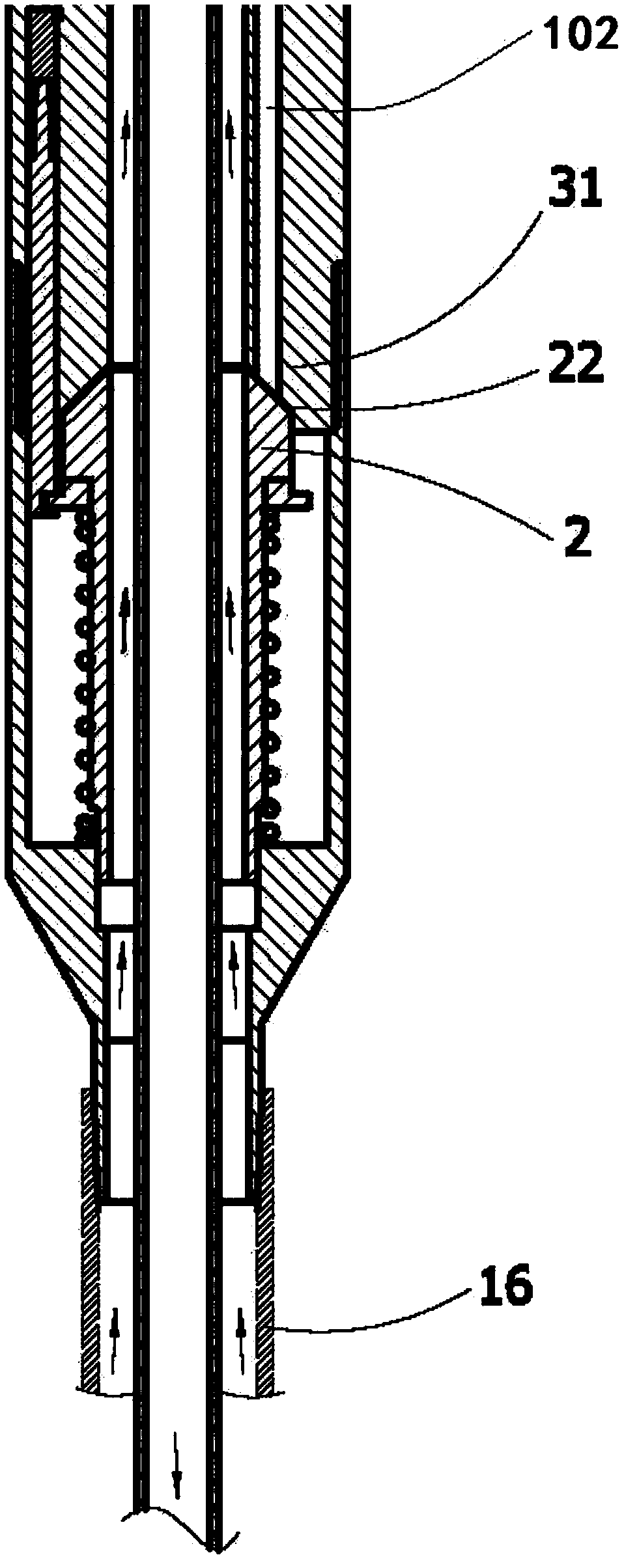

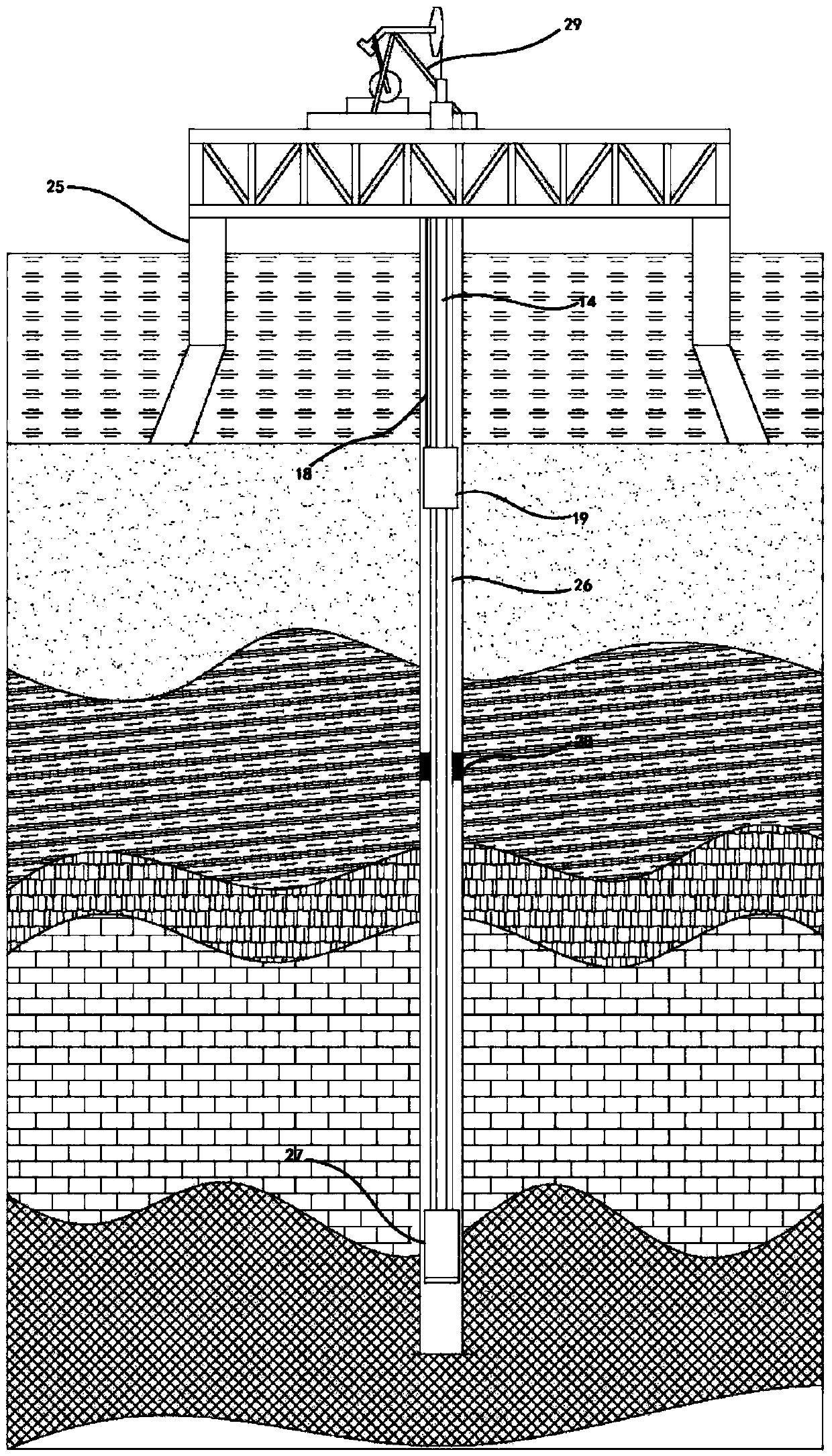

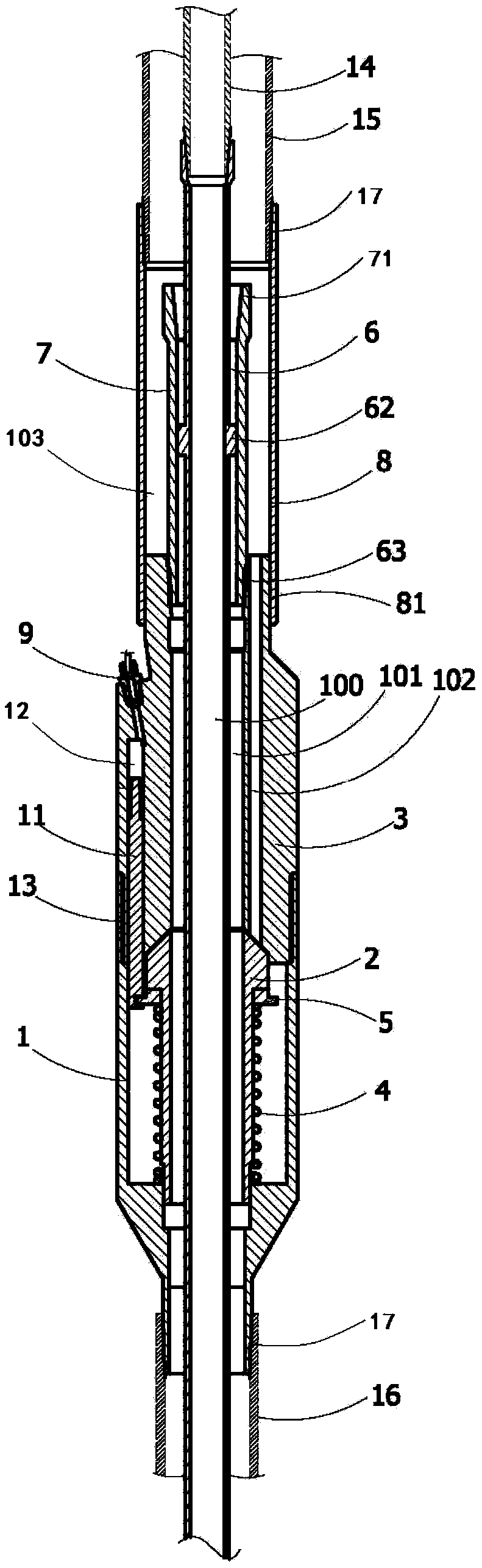

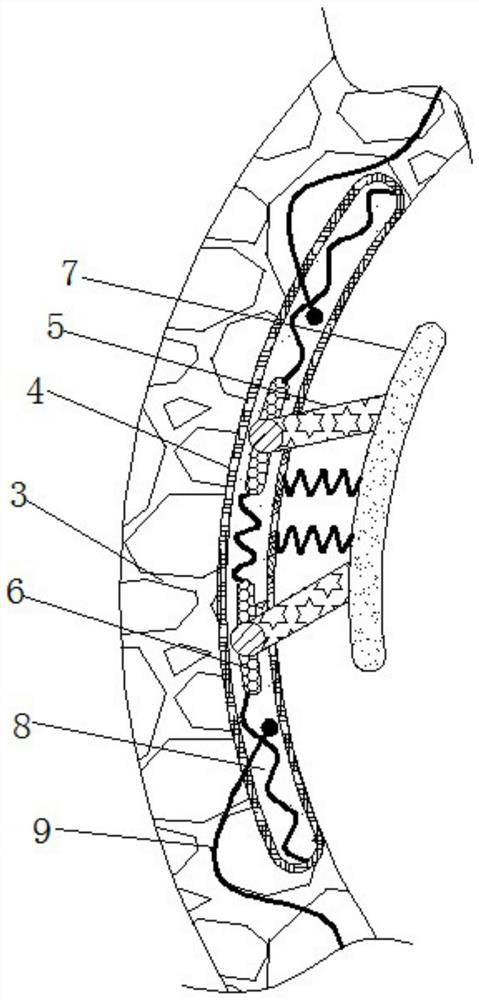

Annular valve plate type downhole safety device

ActiveCN107829710AWill not affect normal productionPrevent returnDrilling rodsFluid removalEngineeringMechanical engineering

The invention discloses an annular valve plate type downhole safety device. The device comprises a main body, an upper cover located at the upper portion of the main body and a lower cover located atthe lower portion of the main body; the main body is provided with a hollow channel and an inner sealing insertion pipe penetrating through the hollow channel, the top of the inner sealing insertion pipe is used for being communicated with an oil pumping pipe, and the bottom of the inner sealing insertion pipe is used for being communicated with a pump cylinder at the bottom of a pipe column of anoil pipe; an inner hole formed in the inner sealing insertion pipe forms an independent conveying channel between the pump cylinder and the oil pumping pipe. The device relates to but is not limitedto offshore oil extraction technologies; by means of the device, the defects existing in the prior art can be effectively overcome, and downhole fluid can still be controlled to return when an oil pumping rod or a small oil pipe is placed in the oil pipe.

Owner:CHINA NAT OFFSHORE OIL CORP +1

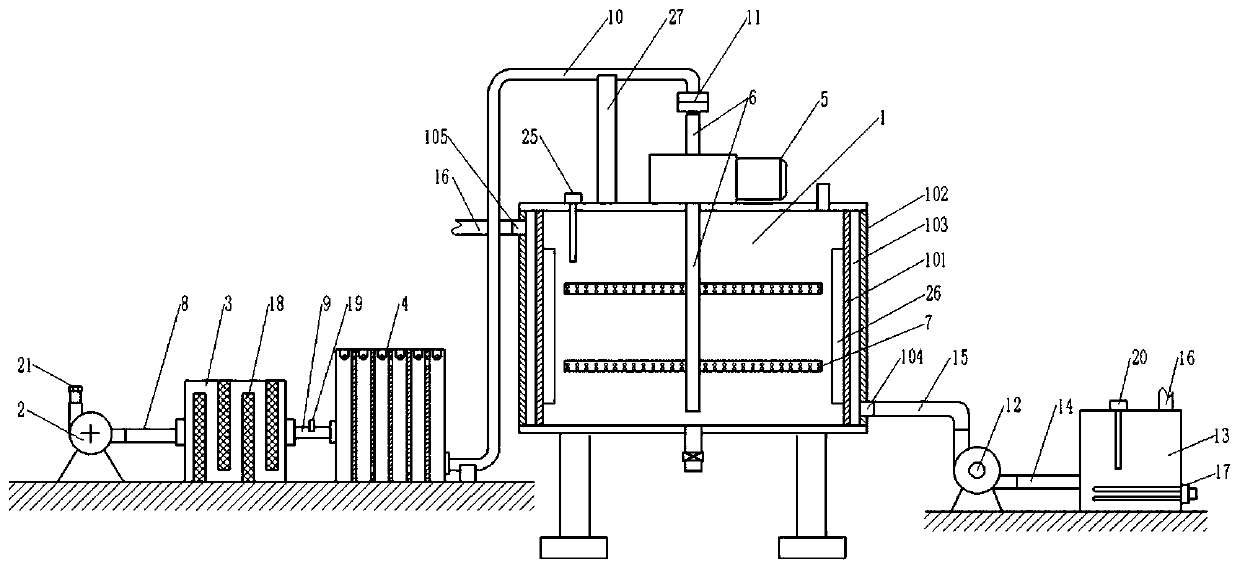

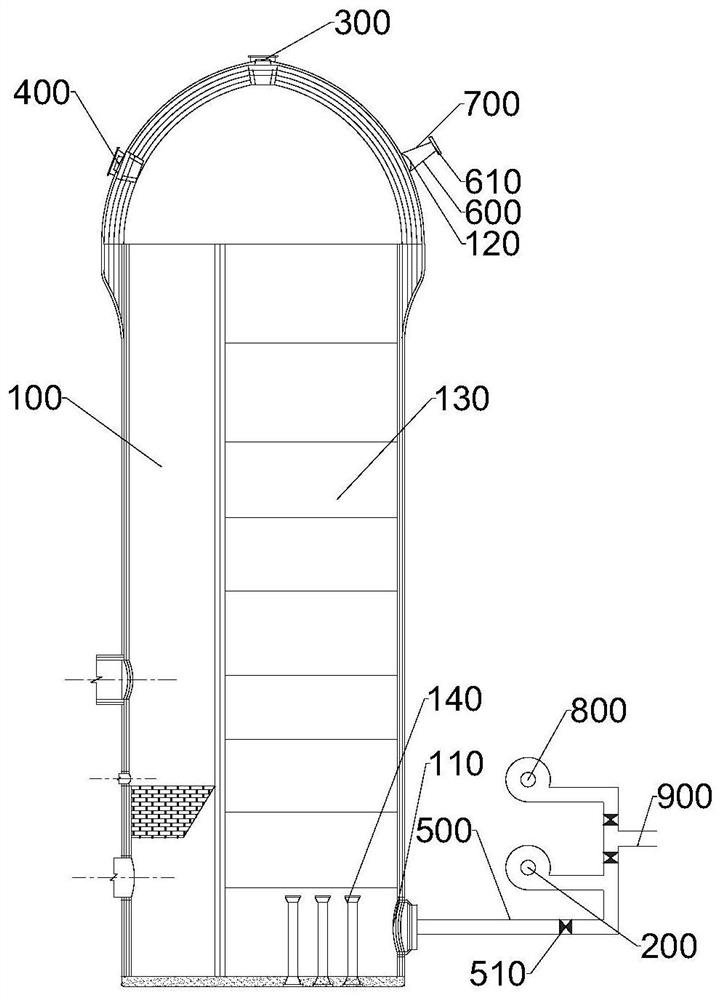

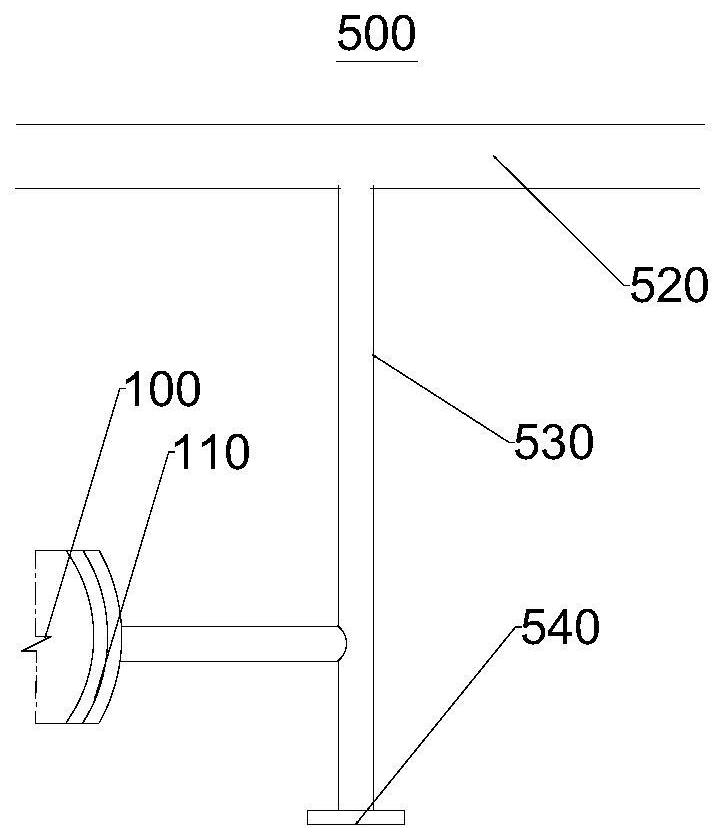

Mixing and stirring apparatus for producing polypeptide nutrient solution

InactiveCN109954438AHeating fastWill not affect normal productionFeeding-stuffRotary stirring mixersWater tanksAir heating

The invention discloses a mixing and stirring apparatus for producing a polypeptide nutrient solution. The apparatus comprises a stirring tank, a fan, a heating box, a sterilizing box, a water pump and a water tank, the sidewall of the stirring tank is a double-layer wall structure, a hollow layer is formed between the inner wall and the outer wall, the upper wall of the stirring tank is providedwith a driving device, a hollow rotating shaft is vertically arranged in the stirring tank, the shaft body, located in the stirring tank, of the hollow rotating shaft is horizontally connected with ahollow stirring shaft, the hollow stirring shaft is communicated with the hollow portion of the hollow rotating shaft, and the sidewall of the hollow stirring shaft is provided with micro-pores communicated with the hollow structure. The apparatus can heat the polypeptide nutrient solution in two ways of water bath heating and hot air heating, so heating in one heating manner is carried out when aheating device adopting another heating manner fails to make normal production not affected, thereby the probability of production affection caused by faults of the heating devices is greatly reducedand the two heating modes can be simultaneously used to realize the rapid heating of the polypeptide nutrient solution.

Owner:DONGSHAN TENGXIN FOOD CO LTD

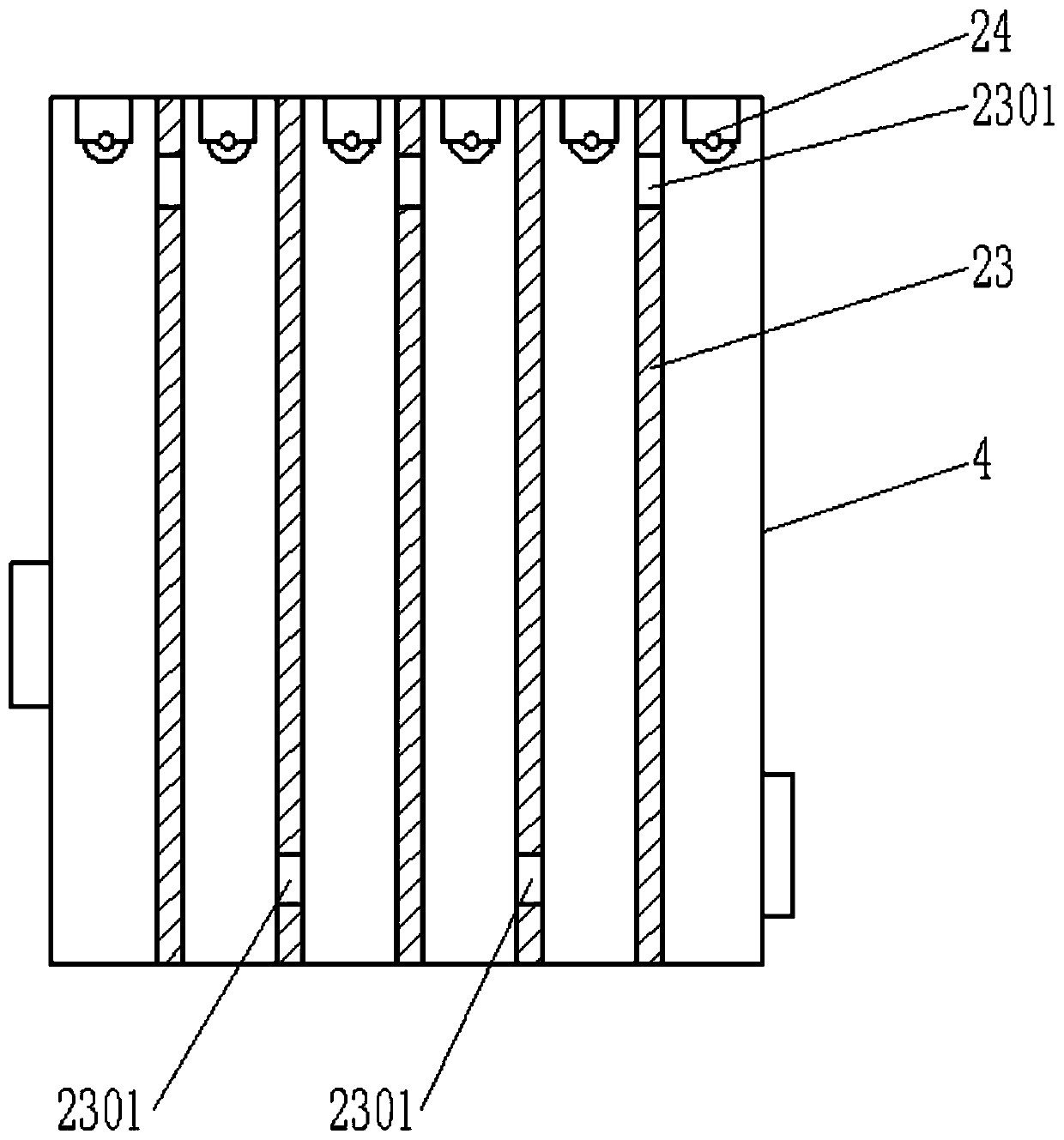

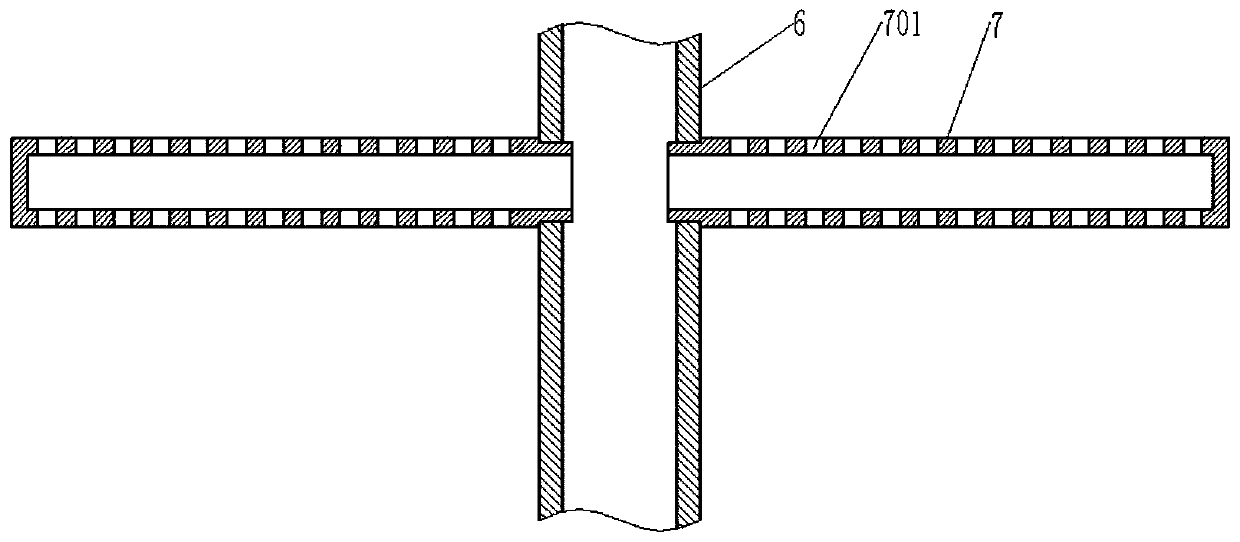

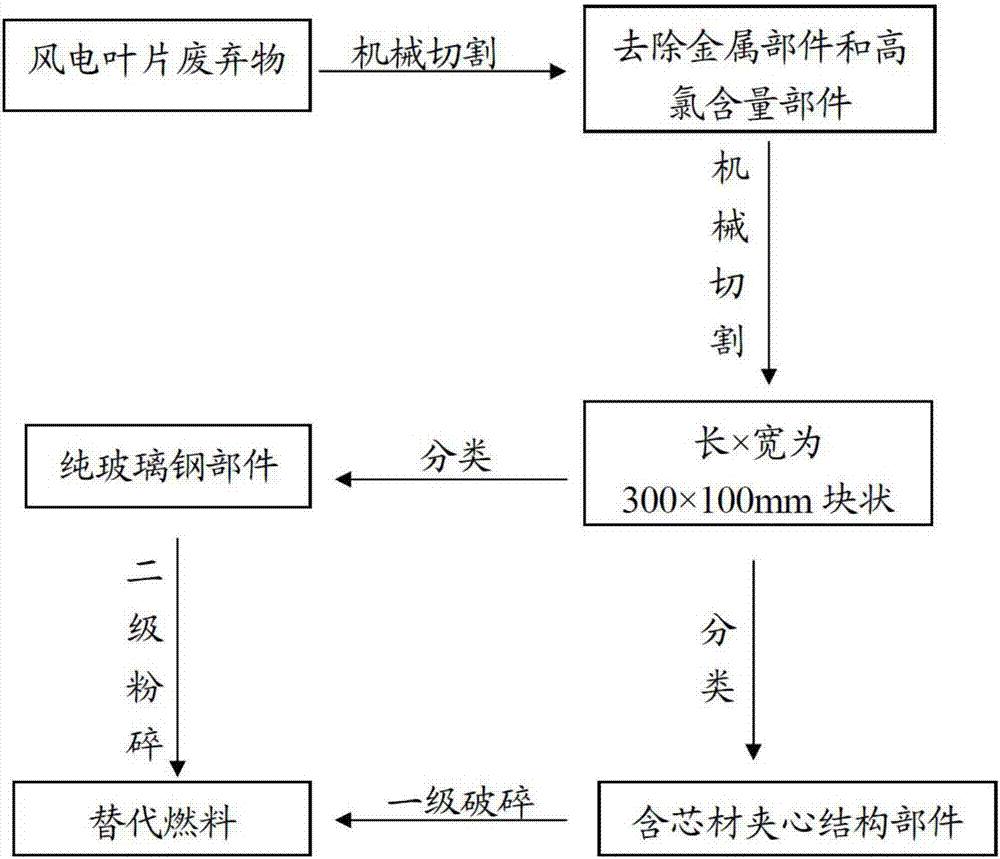

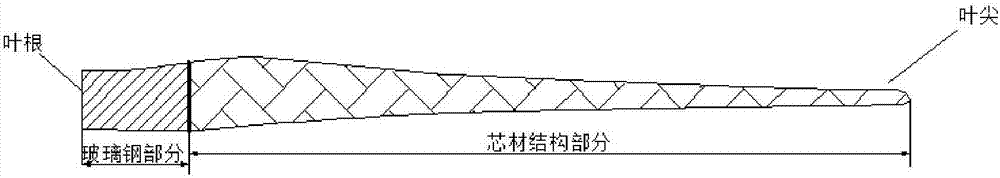

Method for absorbing wind turbine blade wastes in cement kiln

InactiveCN107305010AConsumptionReduce wearIncinerator apparatusCombined combustion mitigationAlternative fuelsHigh energy

The invention provides a method for absorbing wind turbine blade wastes in a cement kiln. The method comprises the following steps: separating metal parts and high-chlorine content parts in the wind turbine blade wastes, and segmenting the remaining wind turbine blade wastes as massive wastes; grinding the massive wastes into particles so as to obtain ground materials; and taking the ground materials as alternative fuel of the cement kiln, and combusting the fuel in a cement kiln decomposing furnace. The method disclosed by the invention is simple, practical, less in initial investment and subsequent maintenance cost, environment-friendly and harmless, belongs to a circular economy manner, accords with the treatment policy of 'reduction, recycling and harmlessness' of municipal wastes, can thoroughly implement and carry out the national policy of cooperatively treating non-medical wastes and industrial wastes in the cement kiln, solves the thermosetting material waste disposal difficulty problem troubling the society for a long time, provides alternative fuel and raw materials for the high-energy-consumption cement industry and has wide application prospects.

Owner:SINOMATECH WIND POWER BLADE

Automatic component inserter for PCB

InactiveCN102076177AWill not affect normal productionIncrease productivityPrinted circuit assemblingElectrical componentsEngineeringElectronic component

The invention discloses an automatic component inserter for a printed circuit board (PCB), and aims to provide the automatic component inserter for the PCB, which can automatically insert components for the PCB lacking positioning holes. The automatic component inserter comprises a coordinate positioning mechanism for positioning the PCB for inserting and a board feeding mechanism for feeding a board to the coordinate positioning mechanism, wherein the board feeding mechanism comprises a board feeder; the coordinate positioning mechanism comprises a positioning pin rotating shaft; the board feeder comprises a push-pull rod and a connecting rod connected with the push-pull rod; the push-pull rod is provided with a first positioning board catching pin and a second positioning board catching pin mutually matched for clamping the PCB; and the positioning pin rotating shaft is provided with a main positioning pin and a secondary positioning pin matched for clamping the PCB. The automatic component inserter for the PCB can be used for automatically inserting electronic components for the PCB.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

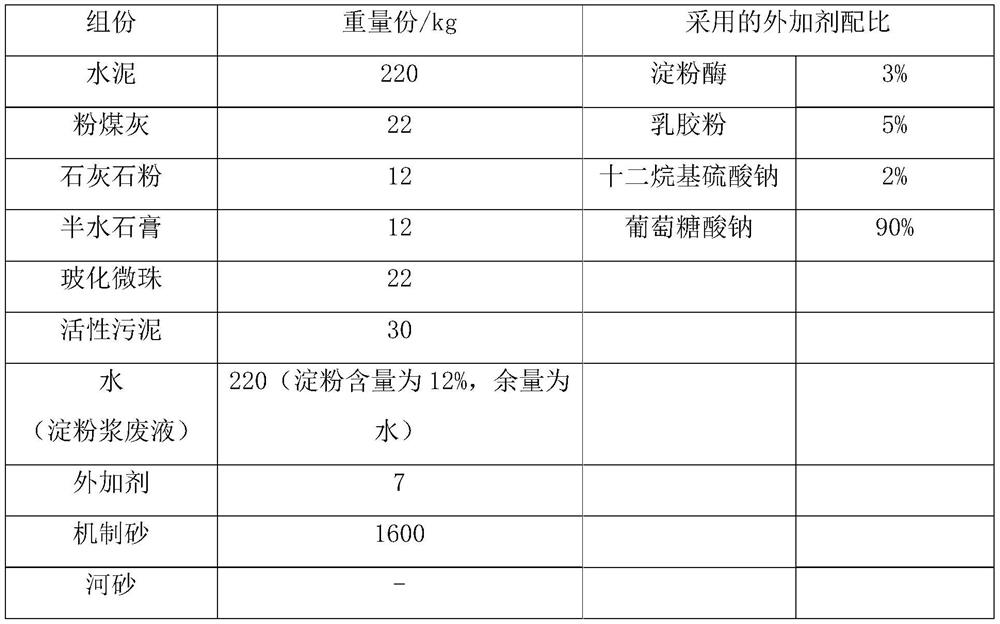

Full-machine-made sand wet-mixed mortar and processing method thereof

The invention provides full-machine-made sand wet-mixed mortar, which comprises the following components in parts by weight: 180-200 parts of cement, 18-22 parts of fly ash, 8-12 parts of limestone powder, 8-12 parts of semi-hydrated gypsum, 18-22 parts of vitrified micro beads, 180-220 parts of water, 3-7 parts of an additive, 20-30 parts of activated sludge and 1200-1600 parts of machine-made sand, wherein the water is from starch slurry waste liquid with the starch content of 8-12%, and the additive comprises 3% of amylase, 5% of latex powder, 2% of lauryl sodium sulfate and 90% of sodium gluconate. The invention further provides a processing method of the wet-mixed mortar, wherein starch production wastewater and activated sludge generated in urban life are utilized, so that secondarypollution of the starch industry and the activated sludge to the environment is avoided, and a large amount of waste materials can be consumed while the production cost is reduced. According to the invention, additives used in the production process are simple in component, can be purchased in the market, do not affect normal production of enterprises and can be popularized in wet-mixed mortar enterprises; and a full-machine-made sand formula is used, so that river ecology is not damaged.

Owner:重庆富普新材料有限公司 +1

Automatic cable winding device for computer data communication

InactiveCN112919235AThere will be no size errorWill not affect normal productionFilament handlingControl theoryElectric cables

The invention relates to the technical field of data cables, and discloses an automatic cable winding device for computer data communication. The automatic cable winding device comprises a support, a rotating shaft is movably connected to the exterior of the support, a shell is movably connected to the exterior of the rotating shaft, a shell body is fixedly connected to the inner side of the shell, a supporting rod is movably connected to the interior of the shell body, a connecting plate is fixedly connected to the exterior of the supporting rod, a friction block is fixedly connected to the exterior of the supporting rod, an electrorheological body is arranged in the shell body, and an electric wire is fixedly connected to the interior of the shell. Through the interaction of the rotating shaft, the friction block, the supporting rod, the connecting plate, the shell body, the electrorheological body, the shell and the electric wire, winding is not affected by the structure during normal winding, when the rotating shaft stops rotating, the rotating shaft can be limited to not rotate, and therefore it is guaranteed that no size error exists in the wound cable, the labor amount of workers is reduced, and the normal production of the cable is not influenced.

Owner:涂志坚

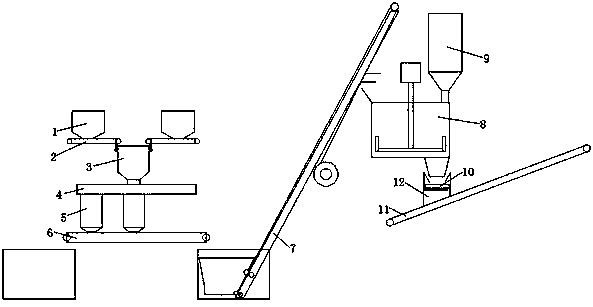

Concrete prefabricate mixing device

PendingCN109664409AReduce the number of runsShorten the timeMixing operation control apparatusSold ingredients supply apparatusReciprocating motionSmall footprint

The invention particularly relates to a concrete prefabricate mixing device. The device comprises a plurality of first storage hoppers, a first conveyor belt capable of conveying materials in the first storage hoppers is arranged below the first storage hoppers, the discharge end of the first conveyor belt 1 is provided with a first measuring hopper, a second storage hopper is arranged below the first measuring hopper, a second conveyor belt capable of doing reciprocating motion is arranged below the second storage hopper, hoists are arranged below the two ends of the second conveyor belt, a mixer is arranged at the discharge ends of the hoists, a water tank for water storage and a second measuring hopper for measuring cement are arranged over the mixer, a third conveyor belt capable of doing reciprocating motion is arranged in a discharge outlet of the mixer, one end of the third conveyor belt stretches into one workshop, a fourth conveyor belt is arranged below the other end of the third conveyor belt, and the discharge end of the fourth conveyor belt stretches into the other workshop. By means of the device, production requirements of various products can be simultaneously met,the occupied area is small, the mixing efficiency is high, and equipment is sufficiently utilized.

Owner:HUBEI XINGBAO TECH CO LTD

Off-line stove cooling method for hot-blast stove

ActiveCN111664713ARealization of offline cooling furnaceWill not affect normal productionLinings repairFurnace coolingTemperature controlHot air oven

The invention provides an off-line stove cooling method for a hot-blast stove, and relates to the technical field of hot-blast stove maintenance. The off-line stove cooling method for the hot-blast stove comprises the steps: a K-type thermocouple is arranged on the arch apex side of the hot-blast stove, and a first pipeline is laid between a first manhole and a standby combustion fan; a gas inlet,an oxidant gas inlet and a waste gas discharge outlet of the hot-blast stove are closed, and a combustor of the hot-blast stove is stopped; cool air is blown to the hot-blast stove through the firstpipeline, and after the cool air is subjected to heat exchanging in the hot-blast stove, generated hot air is discharged from a second manhole; and taking the temperature of the K-type thermocouple asthe main basis and the temperature of a B-type thermocouple as the reference, by adjusting the air inlet speed of the cool air and the discharging speed of the hot air, the cooling speed of the hot-blast stove is controlled to be 1-8 DEG C / h. According to the stove cooling method, the hot-blast stove to be subjected to first-aid repair can be independent from a hot-blast stove system, the coolingspeed of the hot-blast stove can be strictly controlled, the temperature control requirement of stove cooling is met, and inclement accidents such as refractory brick breaking or collapsing of partssuch as the arch apex of the hot-blast stove are prevented.

Owner:SGIS SONGSHAN CO LTD

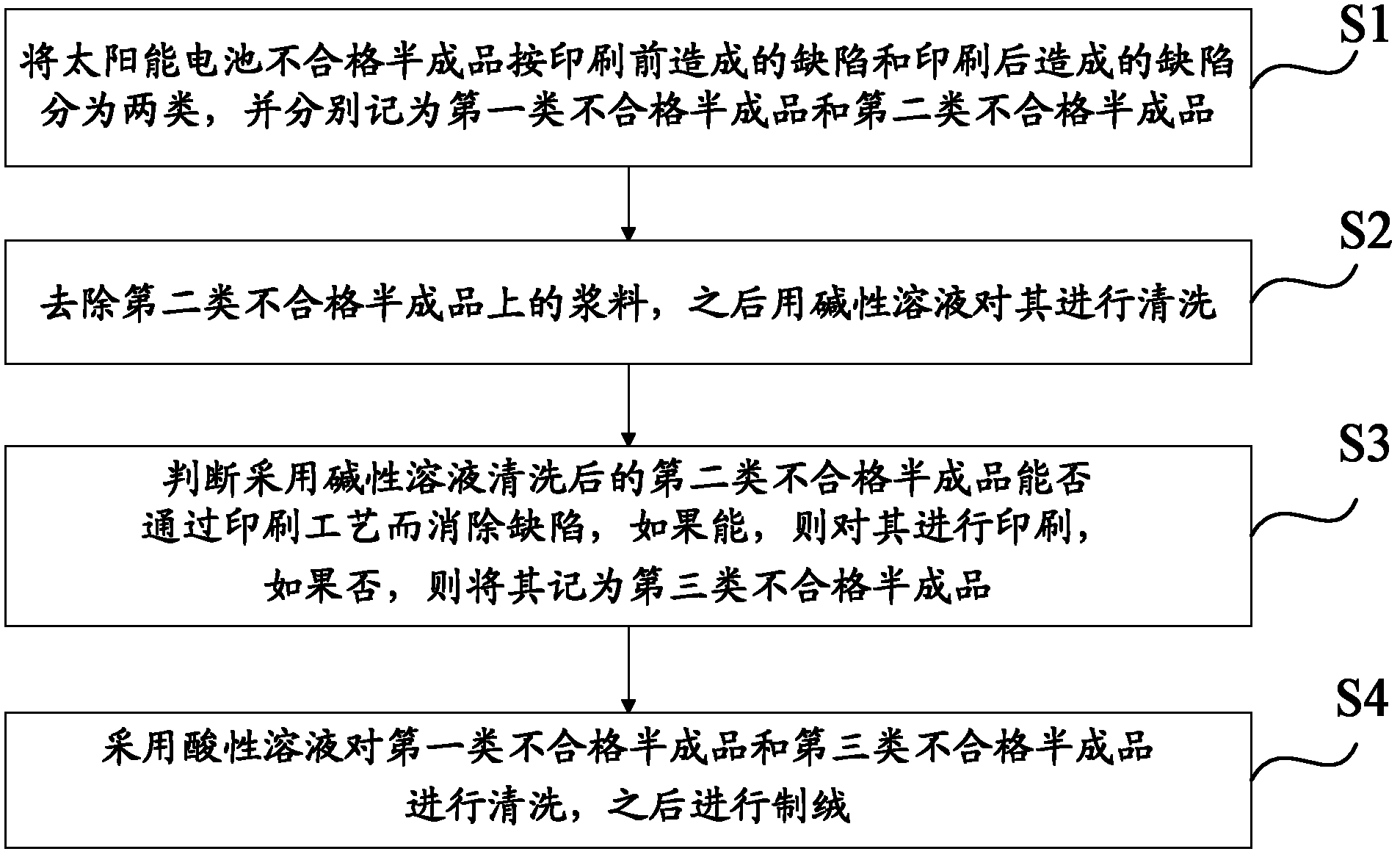

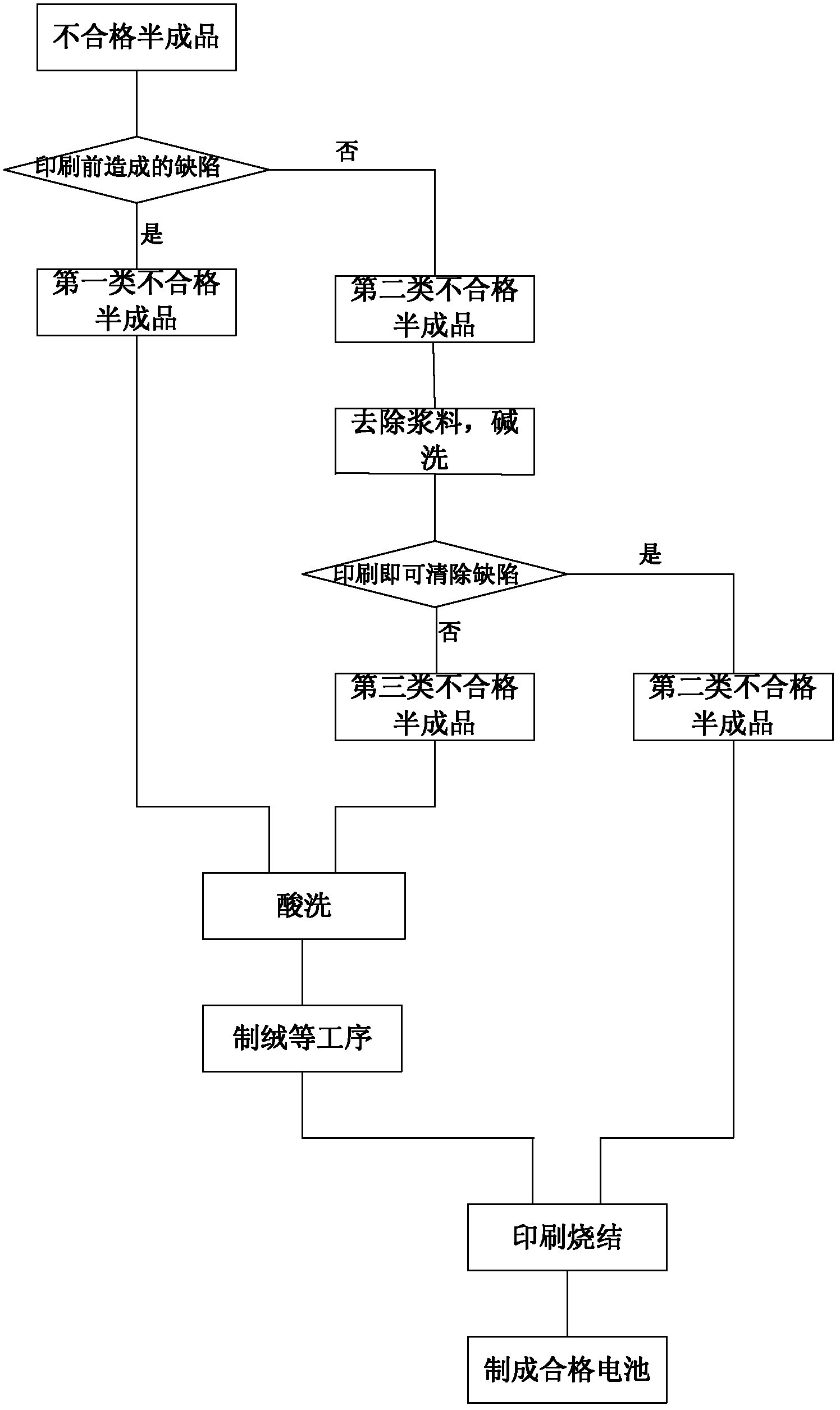

Treatment method for unqualified semi-finished products of solar cells

ActiveCN102496662AImprove pass rateDecrease stockFinal product manufactureSemiconductor devicesSlurryEngineering

The embodiment of the invention discloses a treatment method for unqualified semi-finished products of solar cells. The method comprises the following steps of: classifying the unqualified semi-finished products of the solar cells into two classes according to defects caused before printing and defects caused after the printing, and marking the unqualified semi-finished products of the solar cells as first-class unqualified semi-finished products and second-class unqualified semi-finished products respectively; removing slurry from the second-class unqualified semi-finished products, and cleaning the second-class unqualified semi-finished products by using an alkaline solution; judging whether the defects of the second-class unqualified semi-finished products cleaned by the alkaline solution can by eliminated by a printing process, if so, printing the second-class unqualified semi-finished products cleaned by the alkaline solution, otherwise marking the second-class unqualified semi-finished products cleaned by the alkaline solution as third-class unqualified semi-finished products; and cleaning the first-class and third-class unqualified semi-finished products by using an acidic solution, and texturing the first-class and third-class unqualified semi-finished products cleaned by the acidic solution. By the treatment method for the unqualified semi-finished products of the solar cells, the inventory of the unqualified semi-finished products of the solar cells can be decreased, the qualified rate of finished products of the solar cells can be increased, and influence on normal production can be avoided.

Owner:BAODING TIANWEI YINGLI NEW ENERGY RESOURCES

Treatment method and tool for rotary kiln flame high-temperature belt formed ring

ActiveCN103256807ASimple structureWill not affect normal productionRotary drum furnacesIncrustation removal devicesEngineeringRotary kiln

The invention discloses a treatment method and tool for a rotary kiln flame high-temperature belt formed ring. The treatment method includes the steps that (1) a plurality of through holes in multiple rows and multiple lines are formed in a rotary kiln barrel of a flame high-temperature belt zone; (2) a castable precast block is constructed, and a horn-shaped center hole is formed in the center of the castable precast block; (3) the castable precast block is constructed in heat insulation cotton of the flame high-temperature belt zone, and the through holes and the center hole form intercommunicating holes; (4) production is stopped after the ring is formed, and an air pick extends into the intercommunicating holes to knock the formed ring out; (5) after the formed ring is knocked out, the tool is used, quick-drying refactory castables are filled inside and outside pipe holes of the tool, the intercommunicating holes are plugged, and then reproduction can be carried out. The treatment method is quick and convenient to realize, the tool is simple in structure, convenient to use and practical, the formed ring in a rotary kiln can be knocked out under the condition that a furnace body is not cooled, production can be carried out instantly, long-time kiln halt is not needed, maintenance cost is reduced, and continuity of production can be guaranteed.

Owner:焦作诺尔曼炉业有限公司

Waste gas exhausting device for polyimide production

ActiveCN114177710AQuick changeWill not affect normal productionDispersed particle filtrationTransportation and packagingPolyimideEngineering

The invention relates to the technical field of waste gas treatment, in particular to a polyimide production waste gas exhaust device which comprises a top cabinet and a lower exhaust pipe. A pipe hole is formed in the top of the top cabinet, and the upper exhaust pipe is in sliding connection with the pipe hole; the side blocks are arranged on the two sides of the rotating plate, and filter holes are formed in the side blocks; the inner cylinder is in sliding connection with the filter holes; the filter element is mounted in the inner cylinder; the driving part is arranged in the side block; the first motor is fixed in the top cabinet, an output shaft of the first motor is connected with the bottom end of the rotating rod, a limiting ring groove is formed in the side surface of the rotating rod, a rotating hole is formed in the center of the rotating plate, and the limiting ring groove is rotationally connected with the rotating hole; the top plate is fixed to the upper exhaust pipe, an end face hole is formed in the top end face of the rotating rod, the screw is rotationally connected with the end face hole, a threaded hole is formed in the top plate, and the screw is in threaded connection with the threaded hole; and the switching part is arranged in the rotating rod. By means of the device, the filter element saturated in adsorption can be rapidly replaced, and production is greatly facilitated.

Owner:河北彩客新材料科技股份有限公司

Bottle cap dedusting conveying device

PendingCN111301959ASimple structureSmall footprintCleaning using gasesMechanical conveyorsParticulatesDust control

The invention discloses a bottle cap dedusting conveying device. The bottle cap dedusting conveying device comprises a box body, a conveying rail and one or more hoppers; a containing cavity is formedin the box body, and a rail channel penetrating through the left side and the right side of the box body is formed in the box body; the conveying rail penetrates through the rail channel and is usedfor conveying bottle caps in the length direction; and the one or more hoppers are arranged in the containing cavity, openings of the hoppers are located in the lower part of the conveying rail, the lower ends of the hoppers communicate with a dust sucking mechanism, and the dust sucking mechanism is used for sucking particulate matter attached to the bottle caps. According to the bottle cap dedusting conveying device of the structure, the conveying rail penetrates through the box body, the hoppers located on the lower part of the conveying rail and the dust sucking mechanism connected with the hoppers are arranged in the box body, through cooperation of the dust sucking mechanism and the hoppers, the particulate matter such as dust or plastic debris on the conveying rail is sucked, thus the dedusting device is simple in structure and small in occupied area, and meanwhile normal production of products is not affected.

Owner:ZHONGSHAN HUIWEI PLASTIC METAL IND

Regeneration cycle method of acidic etching solution

InactiveCN109972139AReduce addLow costPhotography auxillary processesProcess efficiency improvementCopperOxidizing agent

The invention discloses a regeneration cycle method of an acidic etching solution. The regeneration cycle method comprises the following steps that S1, an acidic etching waste solution generated on anacidic etching line of a PCB is collected into an etching waste solution tank; S2, the waste solution in the etching waste solution tank is conveyed into an electrolytic cell, and copper ions in thewaste solution is precipitated to form electrolytic copper sheets through electrolysis action in a cathode region; S3, waste solution in an anode area of the electrolytic cell is conveyed to an acid mist absorption cylinder; S4, chlorine gas is conveyed into the waste liquid in the acid mist absorption cylinder, and an regenerated etching solution is prepared through the reaction with the chlorinegas; and S5, the regenerated etching solution in the acid mist absorption cylinder is conveyed to the acidic etching line (developing-etching-stripping (DES)) for being used in an etching process torealize the regeneration cycle of the acidic etching solution. According to the regeneration cycle method, the reuse rate of the regenerated etching solution can be enabled to reach to 100%, the addition of hydrochloric acid and an oxidant is reduced by about 80%, and the material cost is greatly reduced.

Owner:GUANGZHOU JICHI ENVIRONMENTAL TECH CO LTD

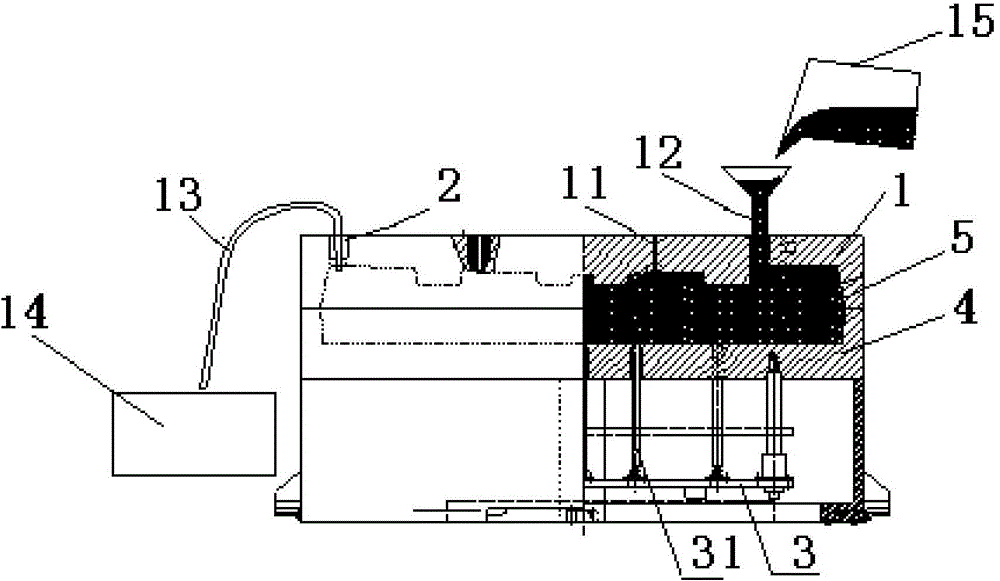

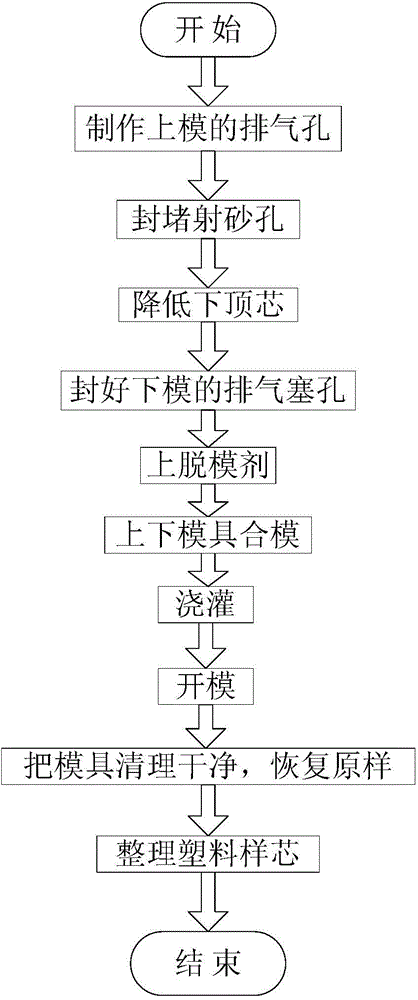

Manufacturing process for core box mould plastic sample core

The invention discloses a manufacturing process for a core box mould plastic sample core. The manufacturing process comprises the following steps: (1), forming exhaust holes in an upper mould; (2), blocking off sand shooting holes; (3) lowering a lower mandrel; (4) sealing venting plug hole of a lower mould; (5) charging a mould releasing agent; (6) assembling the upper mould and the lower mould; (7) irrigating; (8) disassembling the upper mould and the lower mould; (9) cleaning and restoring the upper mould and the lower mould; and (10) clearing up the plastic sample core. According to the manufacturing process for the core box mould plastic sample core, a light plastic sample core can be manufactured so as to replace a sand core to perform core assembly verification of a sand type casting mould; the plastic sample core does not need to be manufactured in a production line, does not influence the regular production of the production line and can be used for reducing the manufacturing cost of the sand type casting mould.

Owner:GUANGXI YUCHAI MASCH CO LTD

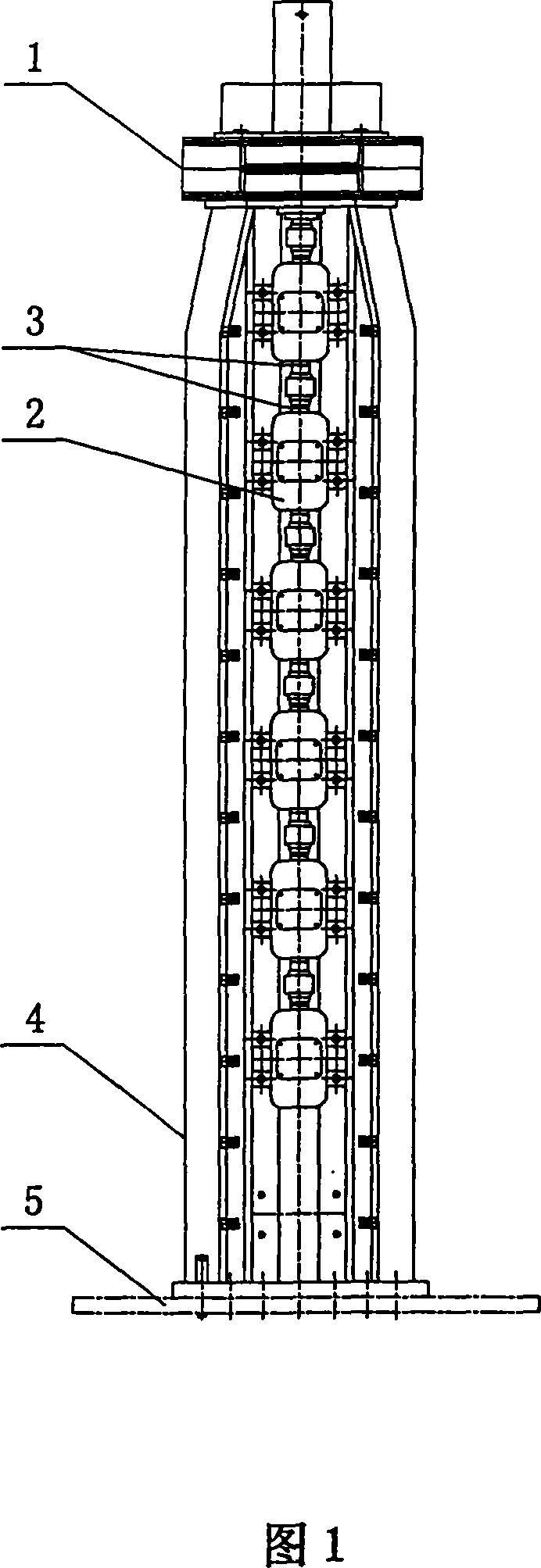

Core mould vibrating bar for core mould vibrating machine

InactiveCN101053977AImprove working conditionsExtended service lifeCeramic shaping apparatusElectric machineryEngineering

The present invention relates to a mandrel vibrating rod for mandrel vibrating machine, which comprises a pressure head cap, an eccentric block device, a central shaft, a sleeve, a locking shoe, a frame and a motor. At least two eccentric block devices pass through the central shaft and are connected inside of the sleeve, the sleeves are connected with each other by the locking shoes, the pressure head cap is arranged at the upper end of the sleeve, the sleeve is arranged vertically on the frame, the bottom of the frame is provided with at least one motor which is connected with the central shaft. The present invention has the advantages of prolonged service life, reduced accident rate, simple maintenance for motor, reduced maintenance costs, shorter time for exchanging fittings, simple disassembly, and reduced maintenance difficulty.

Owner:上海闵马水泥制管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com