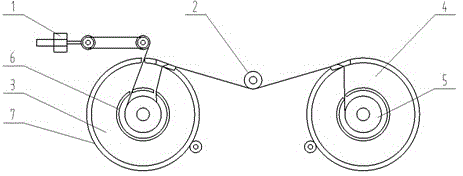

Optical fiber drawing and whipping control device

A control device and wire drawing technology, which is applied in manufacturing tools, glass manufacturing equipment, glass production, etc., can solve problems such as fiber damage, fiber breakage, and fiber waste, and achieve the effects of reducing whiplash, prolonging service life, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

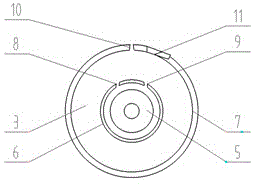

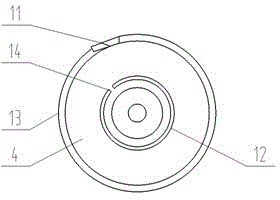

[0022] In the operation of the traditional wire drawing take-up machine, the optical fiber will be pressed by the pressure rod and drawn into the cutting groove. After the switching is successful, due to the high speed, the broken end of the optical fiber will be whipped on the surface of the optical fiber, causing the optical fiber to be damaged when the optical fiber is rewound. Fiber will be broken, resulting in waste of optical fiber. In order to better solve this problem, an optical fiber drawing whip control device as described in the present invention is designed. It is mainly to provide an automatic control system and control method for reducing whiplash in the process of wire drawing switching. It is an automatic control system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com